Patents

Literature

35 results about "Growth kinetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

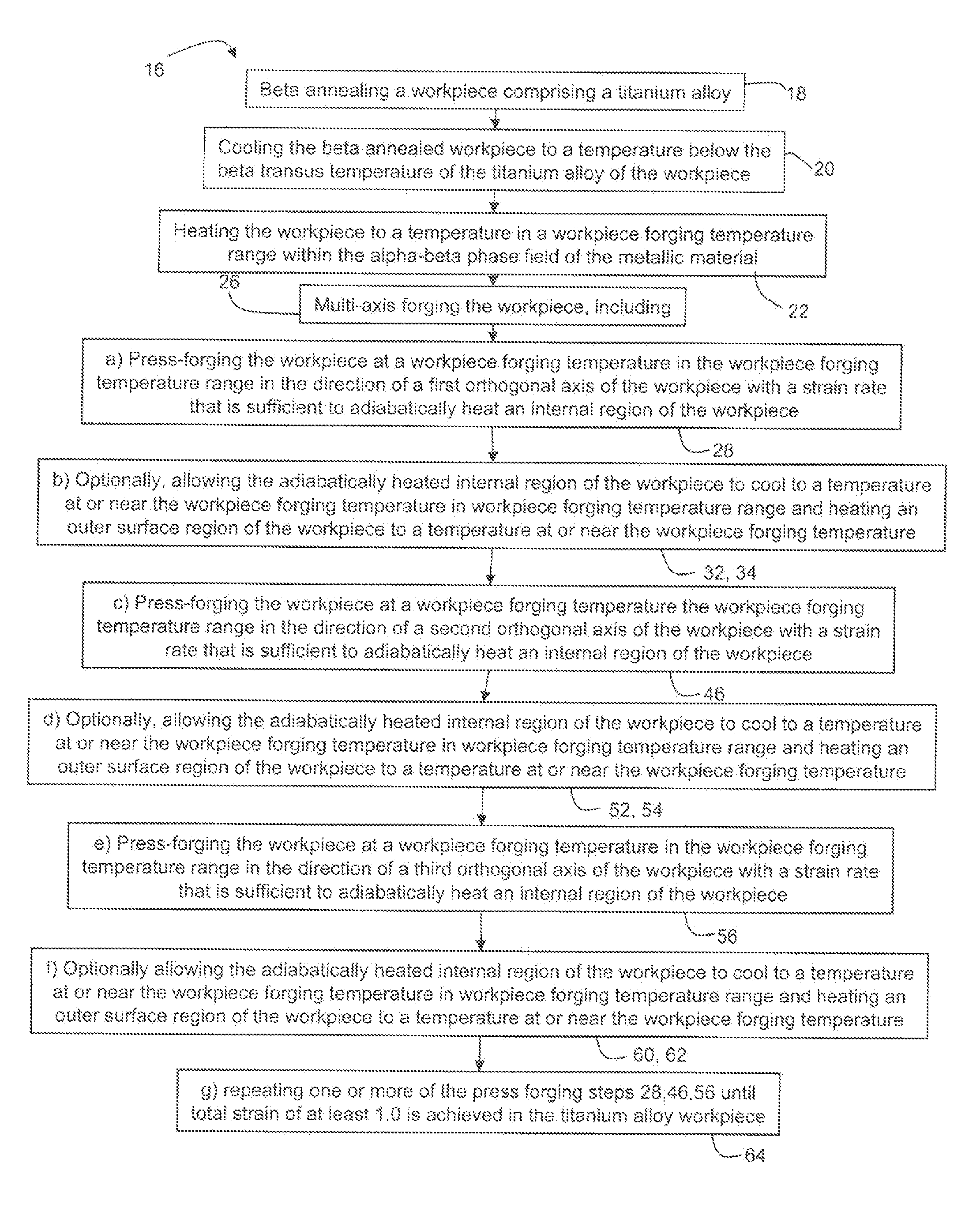

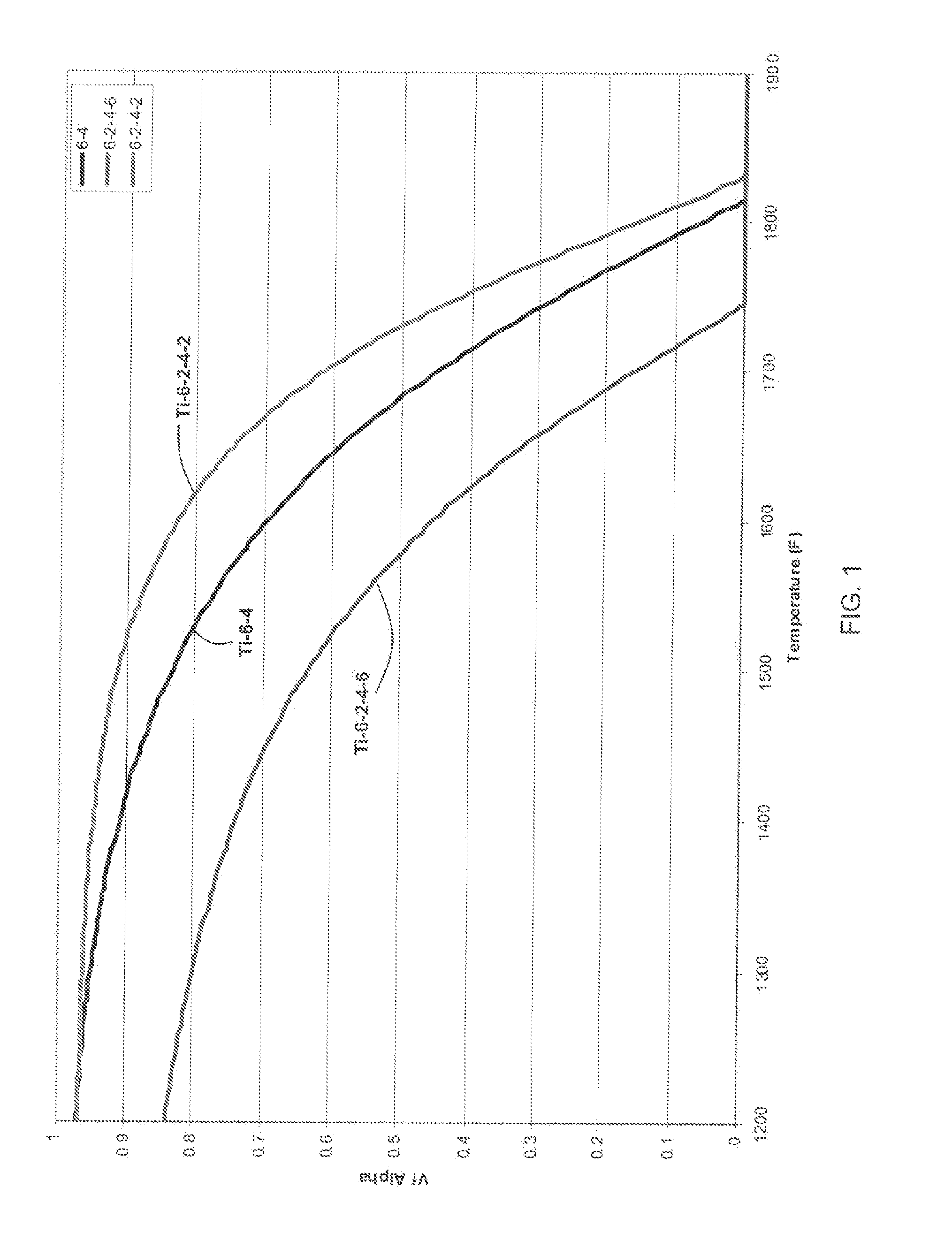

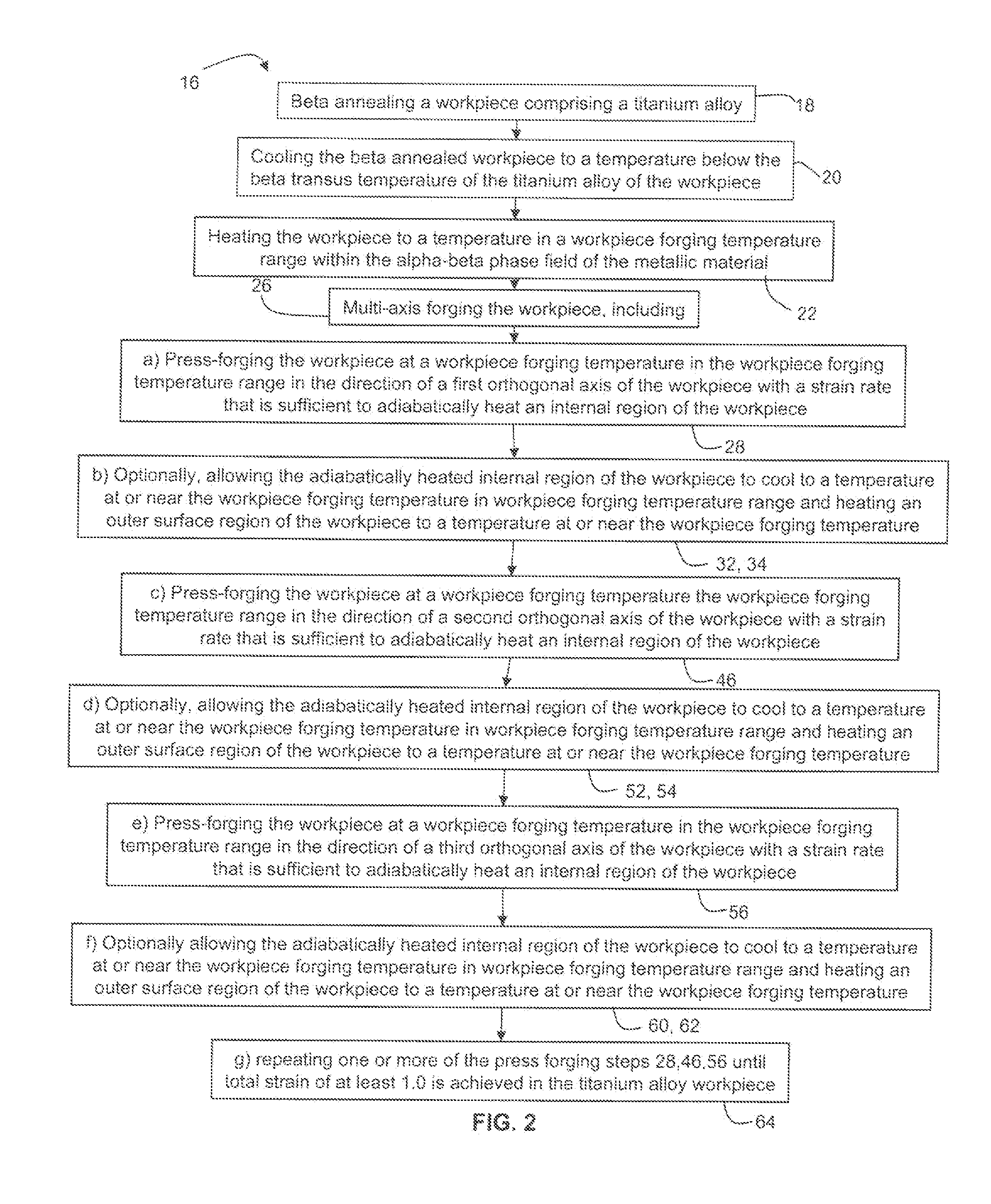

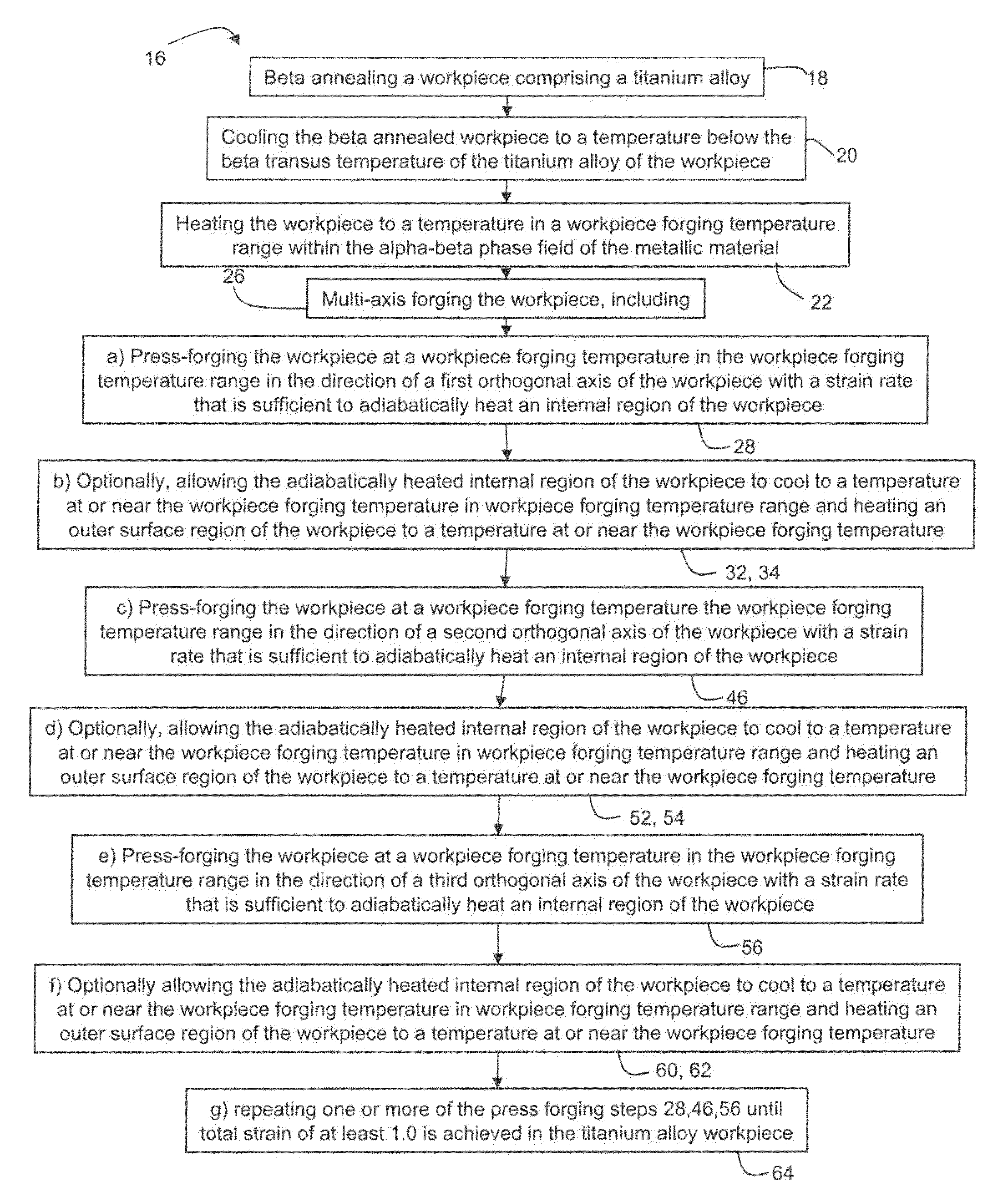

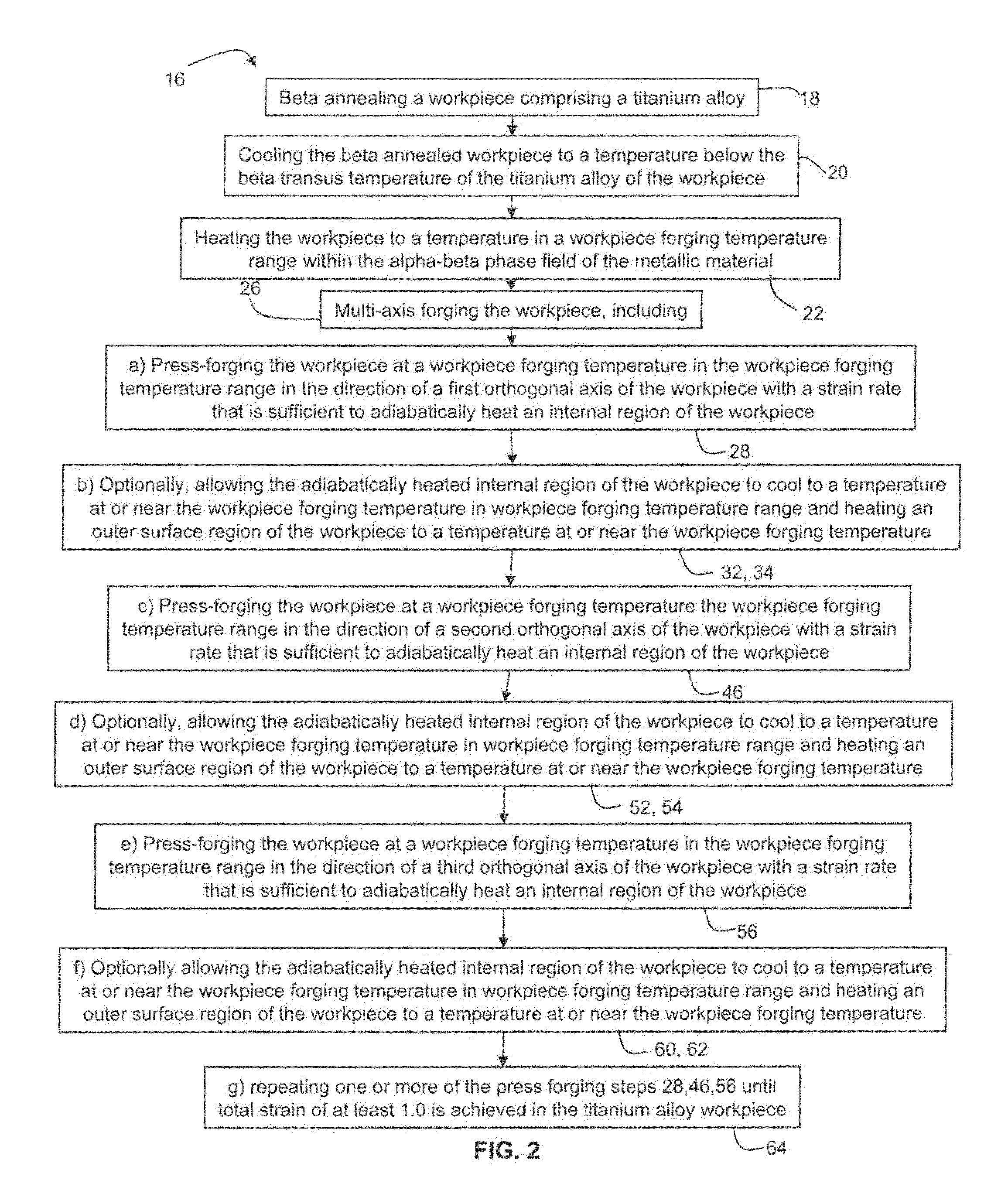

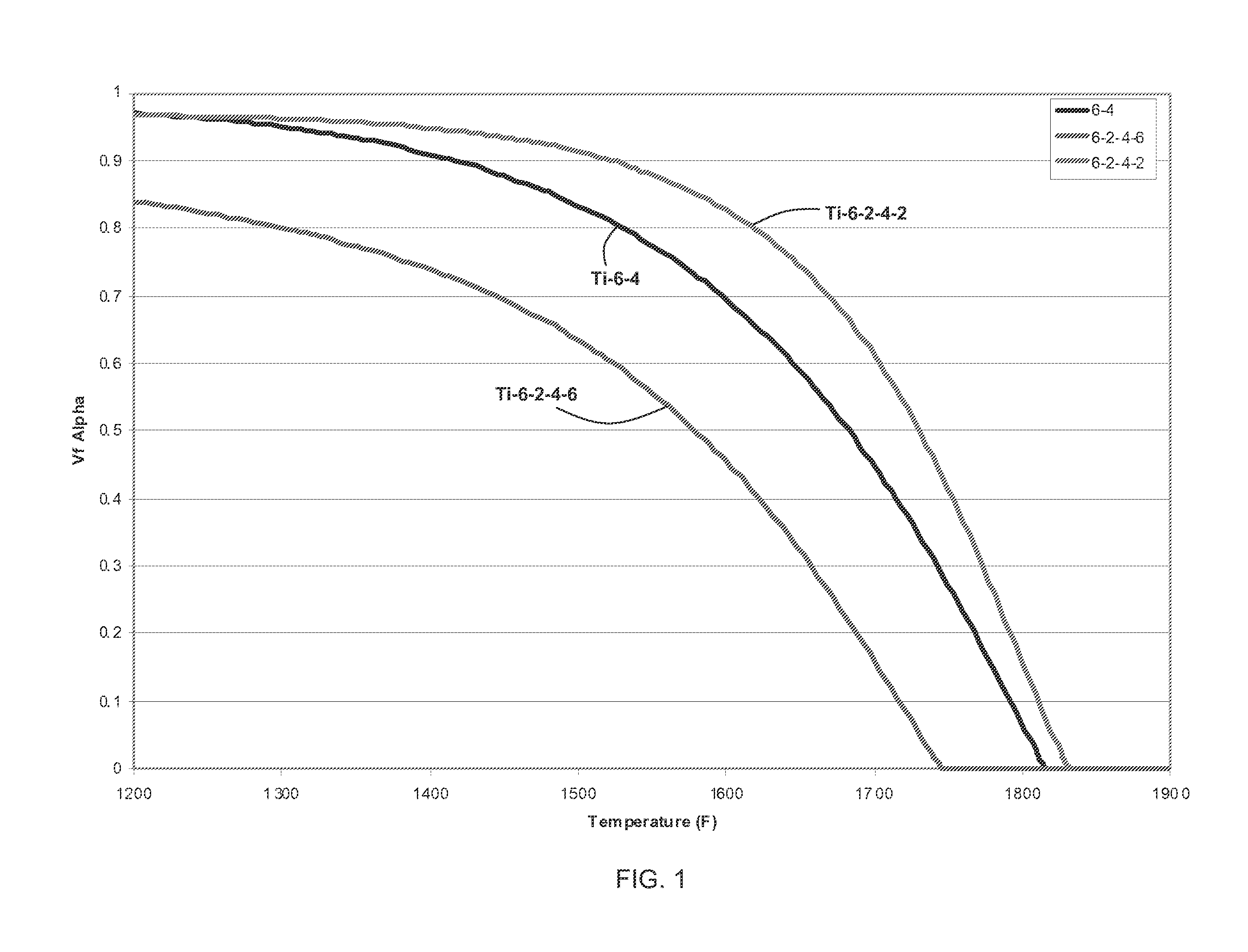

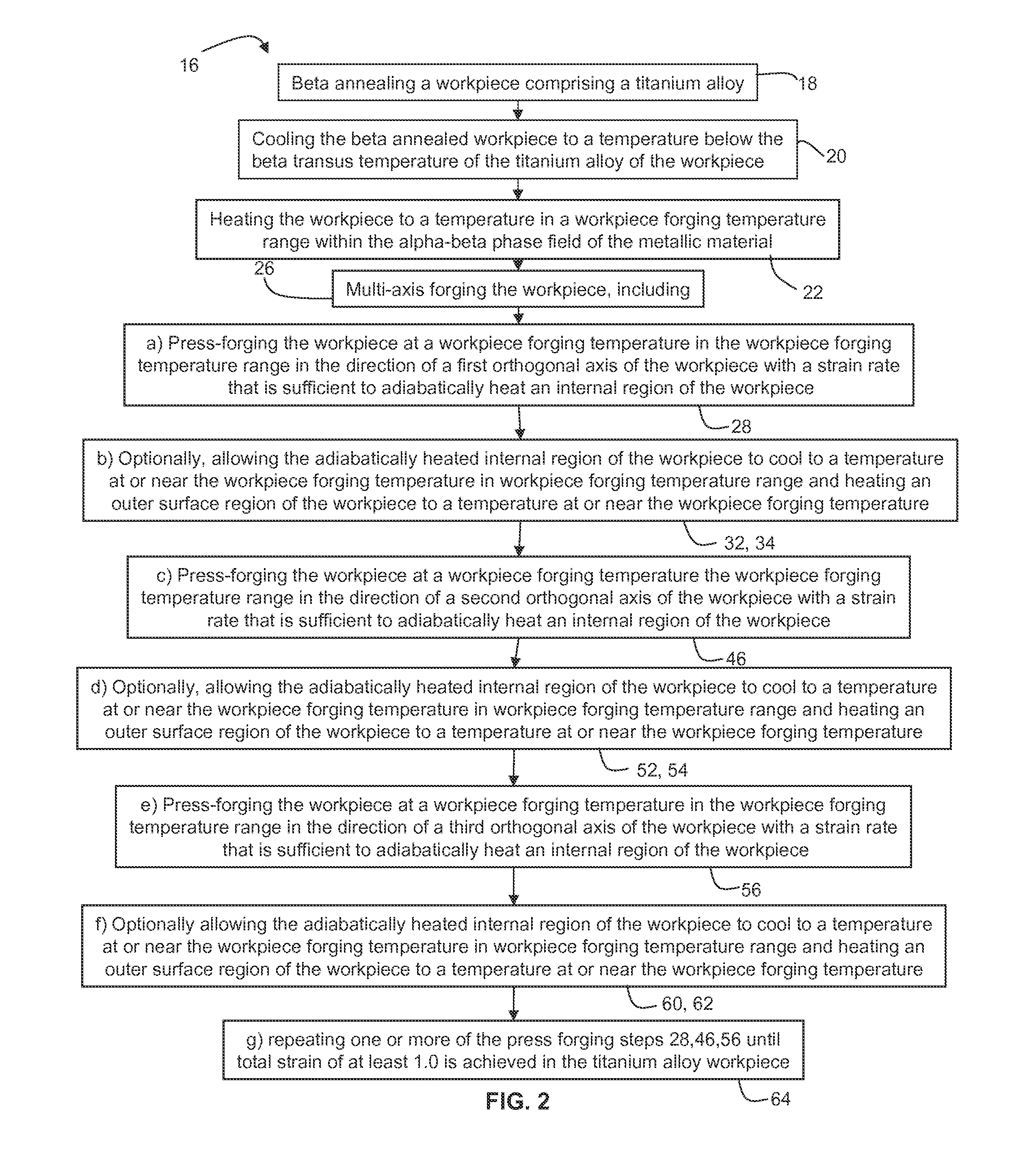

Methods for processing titanium alloys

Methods of refining the grain size of a titanium alloy workpiece include beta annealing the workpiece, cooling the beta annealed workpiece to a temperature below the beta transus temperature of the titanium alloy, and high strain rate multi-axis forging the workpiece. High strain rate multi-axis forging is employed until a total strain of at least 1 is achieved in the titanium alloy workpiece, or until a total strain of at least 1 and up to 3.5 is achieved in the titanium alloy workpiece. The titanium alloy of the workpiece may comprise at least one of grain pinning alloying additions and beta stabilizing content effective to decrease alpha phase precipitation and growth kinetics.

Owner:ATI PROPERTIES LLC

Methods for processing titanium alloys

Methods of refining the grain size of a titanium alloy workpiece include beta annealing the workpiece, cooling the beta annealed workpiece to a temperature below the beta transus temperature of the titanium alloy, and high strain rate multi-axis forging the workpiece. High strain rate multi-axis forging is employed until a total strain of at least 1 is achieved in the titanium alloy workpiece, or until a total strain of at least 1 and up to 3.5 is achieved in the titanium alloy workpiece. The titanium alloy of the workpiece may comprise at least one of grain pinning alloying additions and beta stabilizing content effective to decrease alpha phase precipitation and growth kinetics.

Owner:ATI PROPERTIES LLC

Methods for processing titanium alloys

Methods of refining the grain size of a titanium alloy workpiece include beta annealing the workpiece, cooling the beta annealed workpiece to a temperature below the beta transus temperature of the titanium alloy, and high strain rate multi-axis forging the workpiece. High strain rate multi-axis forging is employed until a total strain of at least 1 is achieved in the titanium alloy workpiece, or until a total strain of at least 1 and up to 3.5 is achieved in the titanium alloy workpiece. The titanium alloy of the workpiece may comprise at least one of grain pinning alloying additions and beta stabilizing content effective to decrease alpha phase precipitation and growth kinetics.

Owner:ATI PROPERTIES LLC

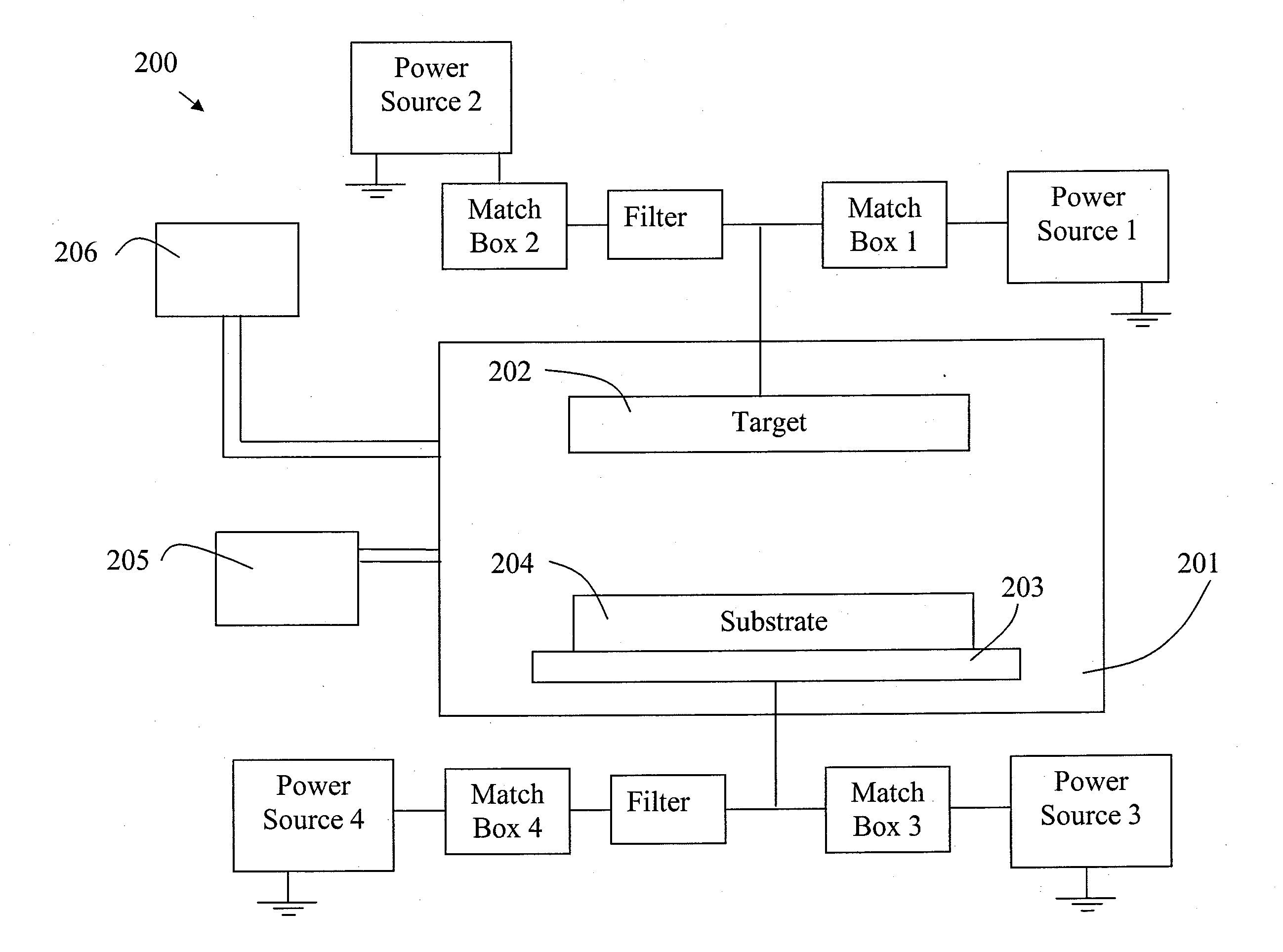

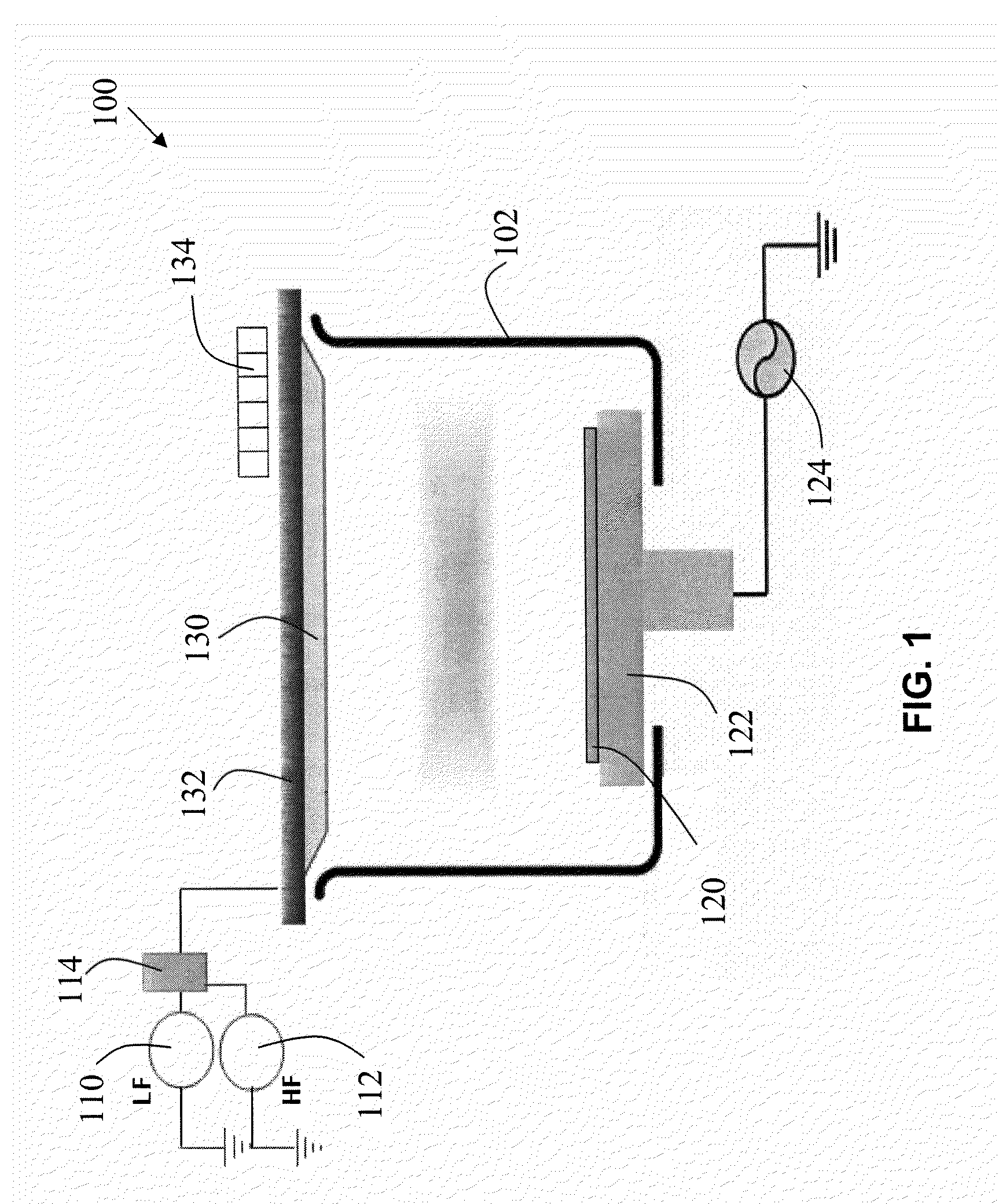

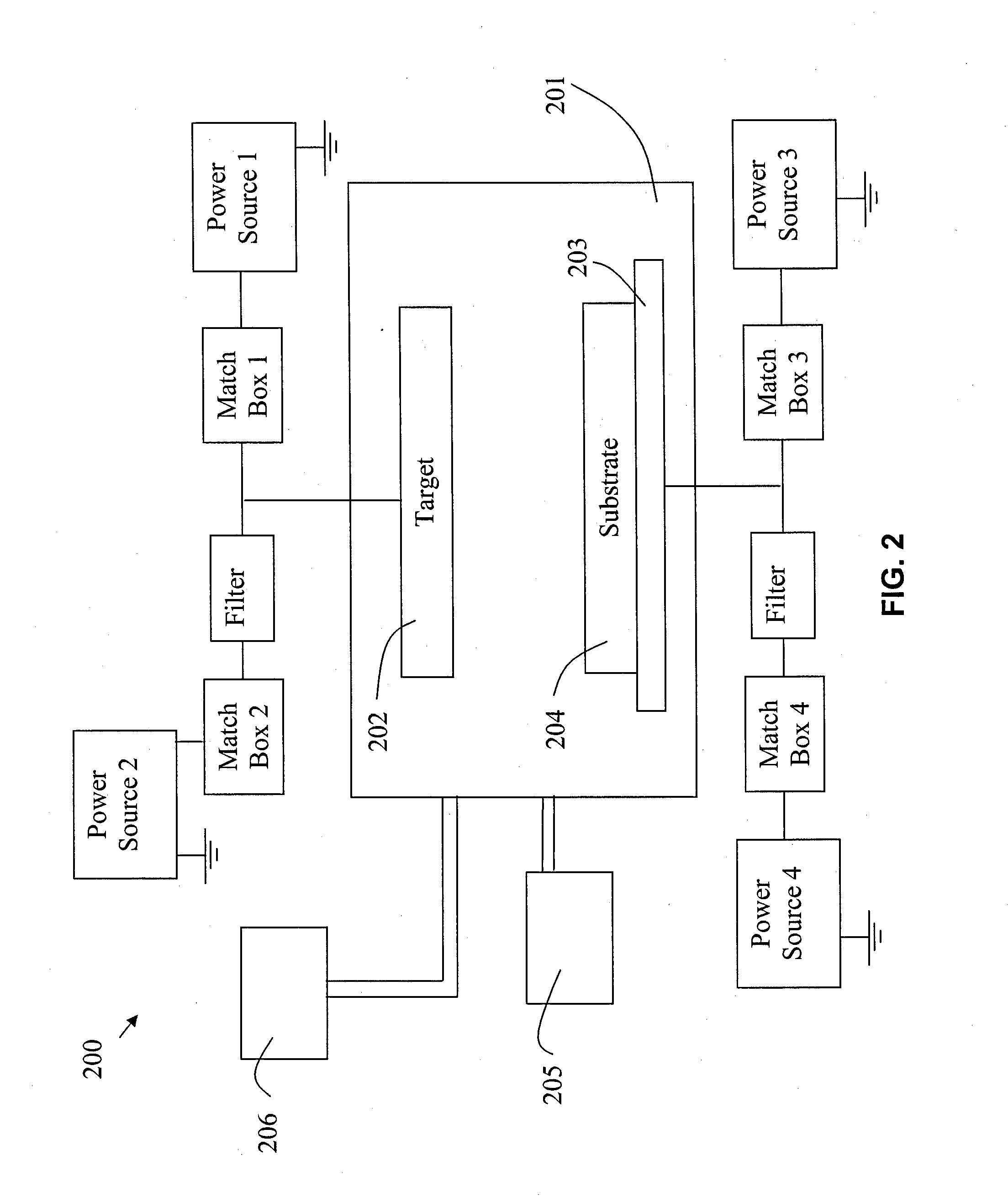

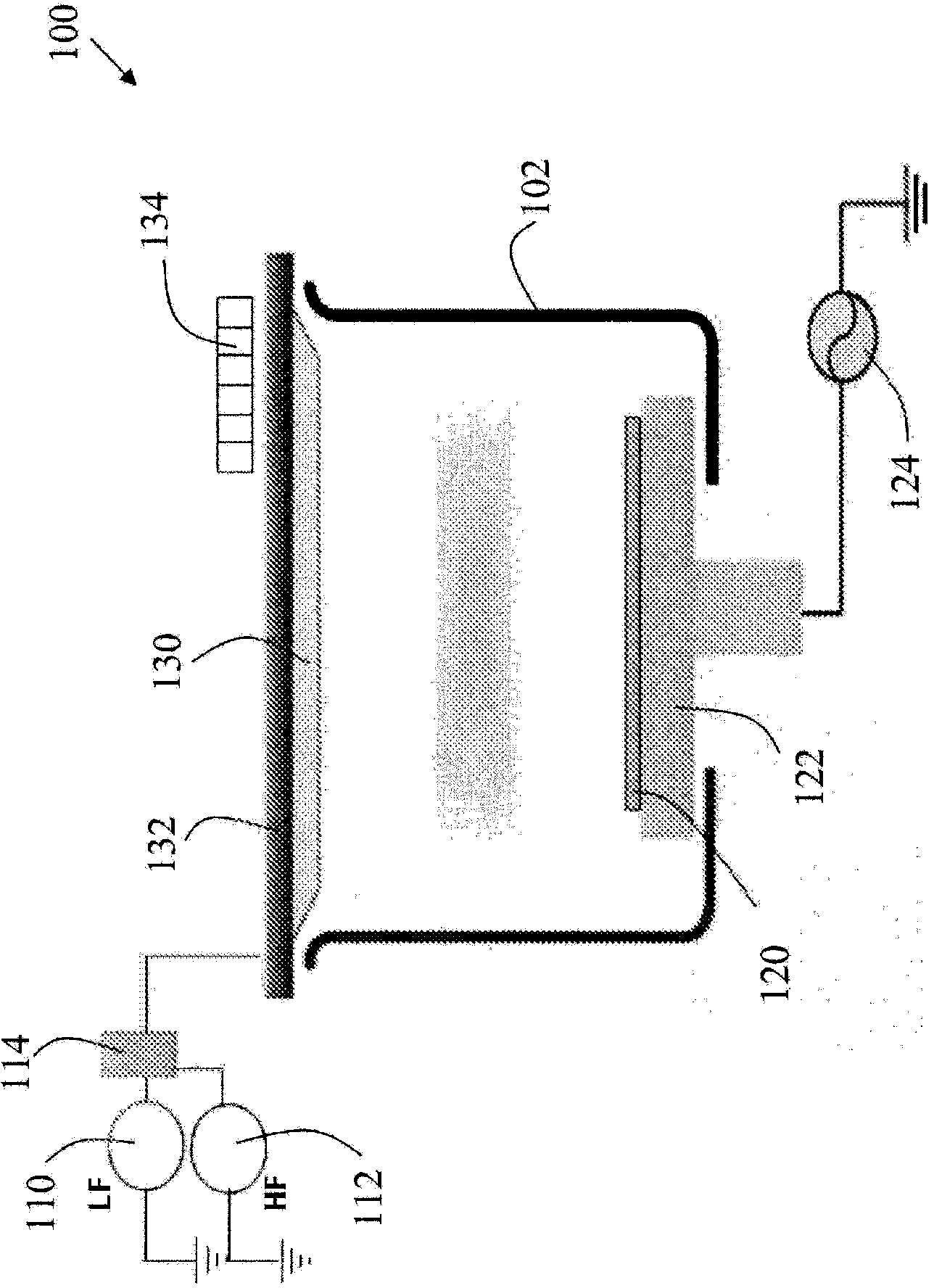

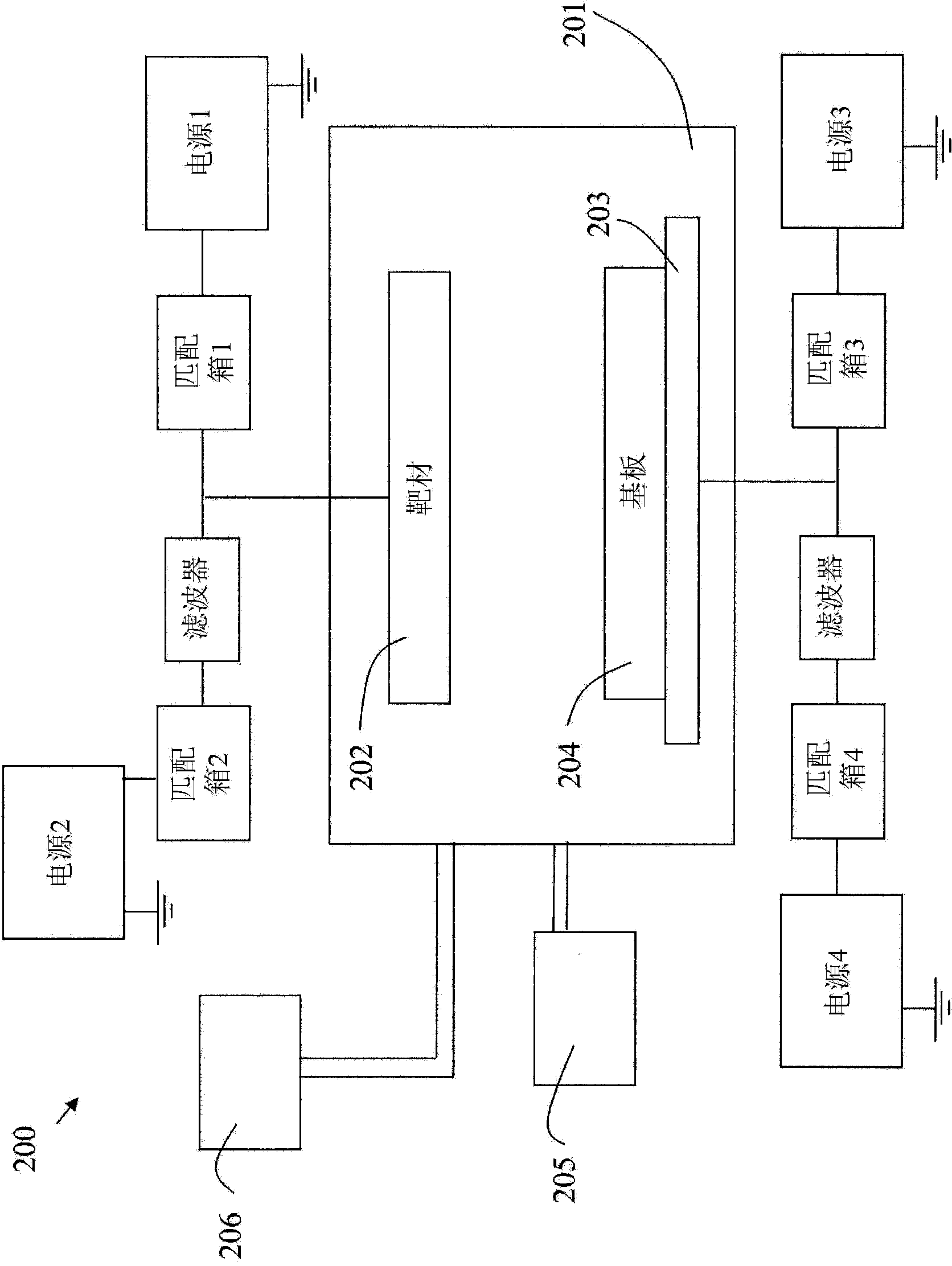

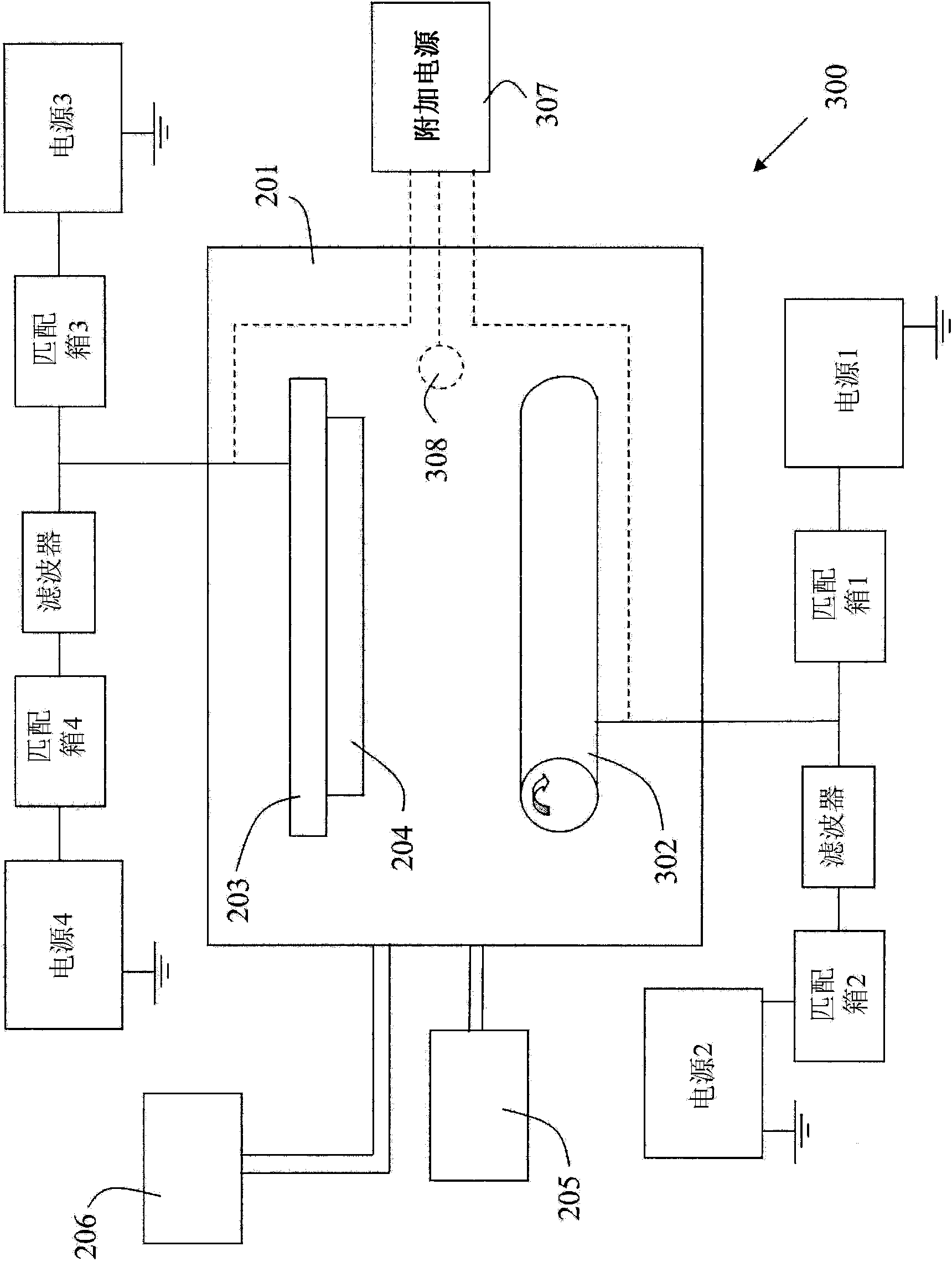

Multiple Frequency Sputtering for Enhancement in Deposition Rate and Growth Kinetics of Dielectric Materials

InactiveUS20130248352A1Increase sputtering rateReduce thermal stressCellsElectric discharge tubesCapacitanceIon density

A method of sputter depositing dielectric thin films may comprise: providing a substrate on a substrate pedestal in a process chamber, the substrate being positioned facing a sputter target; simultaneously applying a first RF frequency from a first power supply and a second RF frequency from a second power supply to the sputter target; and forming a plasma in the process chamber between the substrate and the sputter target, for sputtering the target; wherein the first RF frequency is less than the second RF frequency, the first RF frequency is chosen to control the ion energy of the plasma and the second RF frequency is chosen to control the ion density of the plasma. The self-bias of surfaces within said process chamber may be selected; this is enabled by connecting a blocking capacitor between the substrate pedestal and ground.

Owner:APPLIED MATERIALS INC

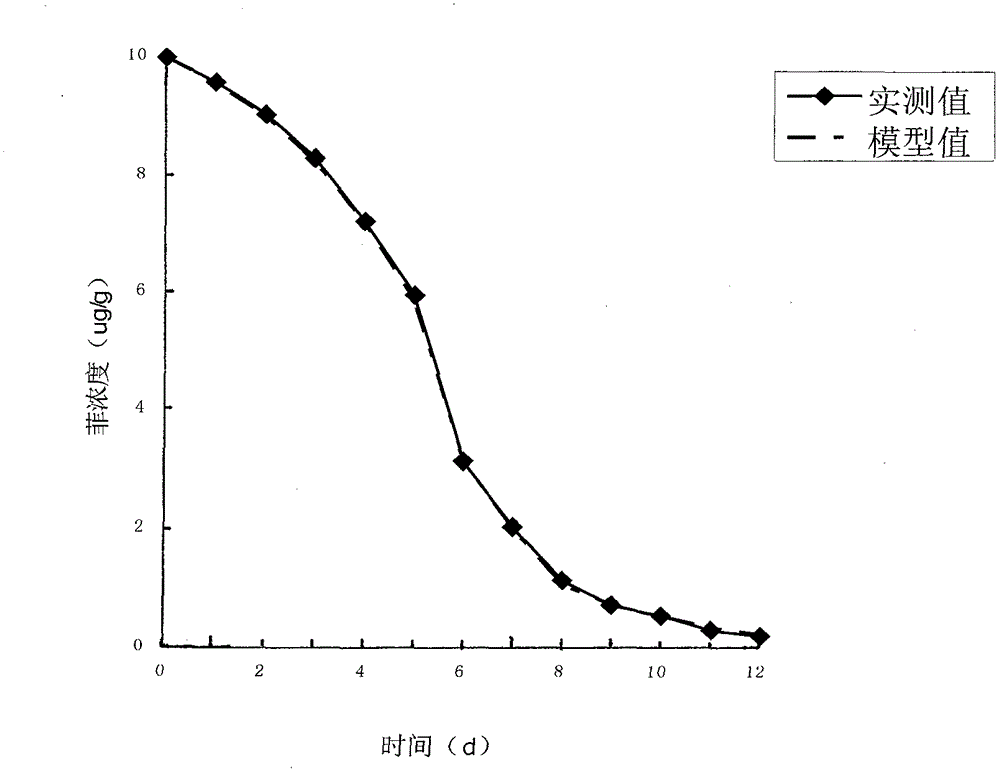

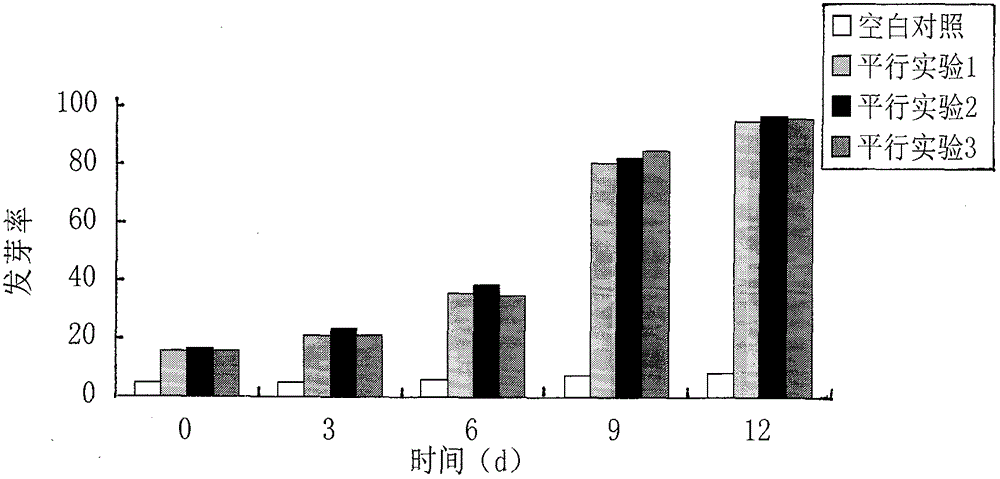

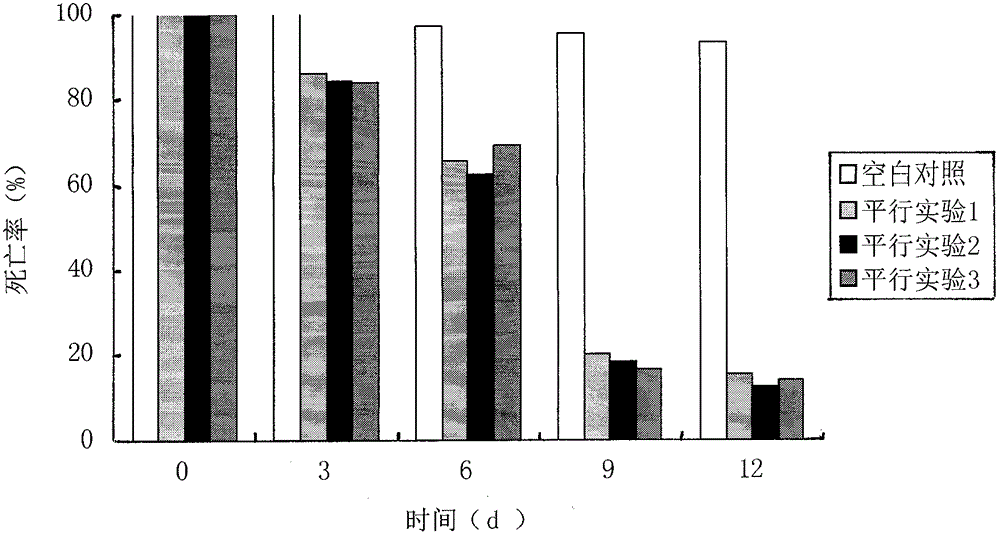

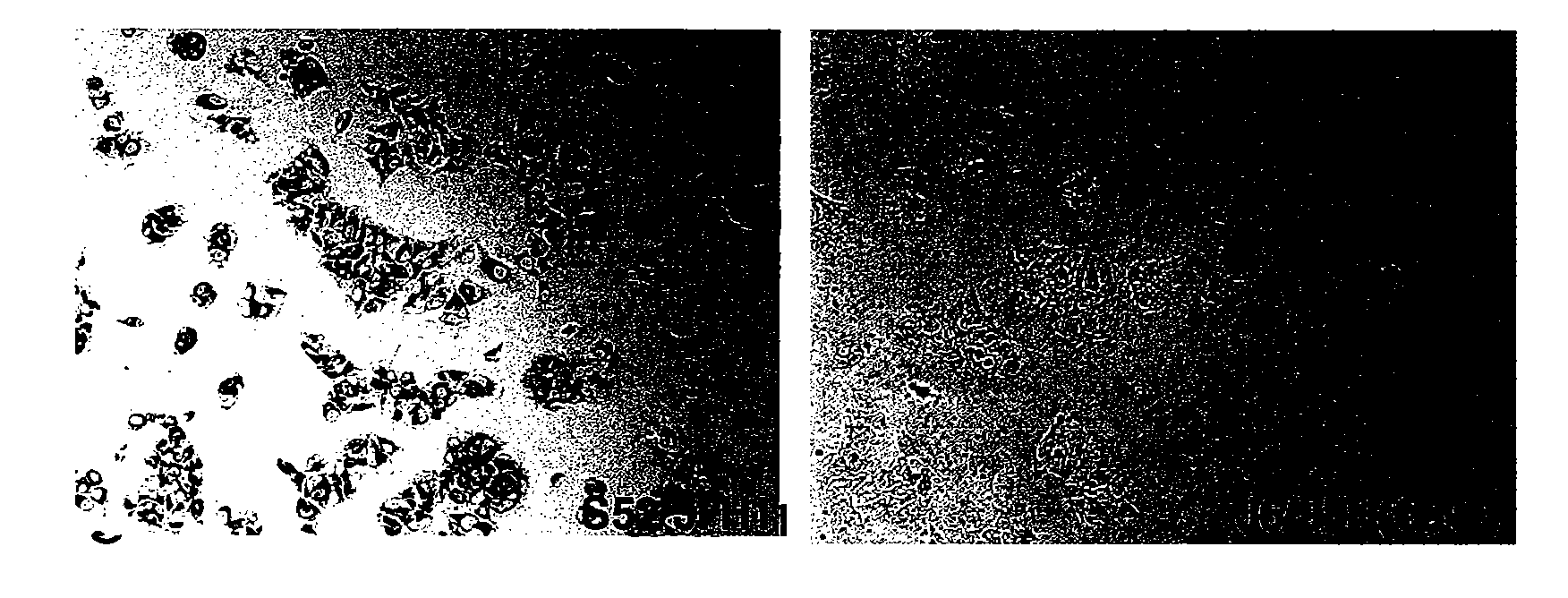

Assessment method of restoration effect of phenanthrene-polluted soil

InactiveCN103056159AScientifically reflect the law of growthIntuitively reflect the repair effectContaminated soil reclamationPhenanthrenePollution soil

The invention discloses an assessment method of a restoration effect of phenanthrene-polluted soil. The assessment method is characterized in that a growth kinetics model of phenanthrene-polluted soil degrading bacteria is established by utilizing a Matlab software, and the established model is simple and can scientifically reflect the growth rule of microbes; and the degradation ratio of phenanthrene in the soil is forecasted in real time and corn sprouting rate and angleworm mortality rate are selected as monitoring indexes, so that the restoration effect of the degrading bacteria to the phenanthrene-polluted soil can be visually reflected, the accuracy of the model can be simultaneously verified in real time, and the monitoring indexes are two living body indexes capable of being detected at any time. The assessment method of the restoration effect of the phenanthrene-polluted soil is established, and has practicability and actual value.

Owner:XINJIANG UNIVERSITY

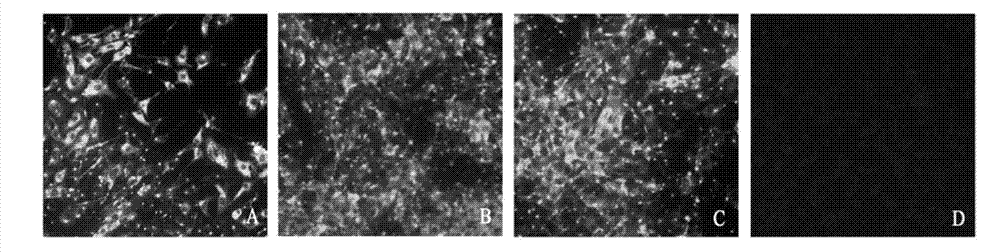

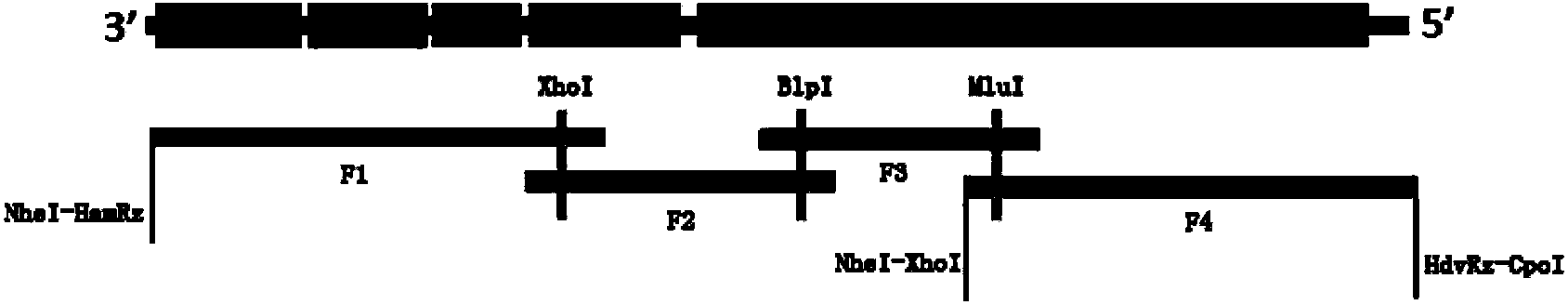

Cell culture system of a hepatitis c genotype 3a and 2a chimera

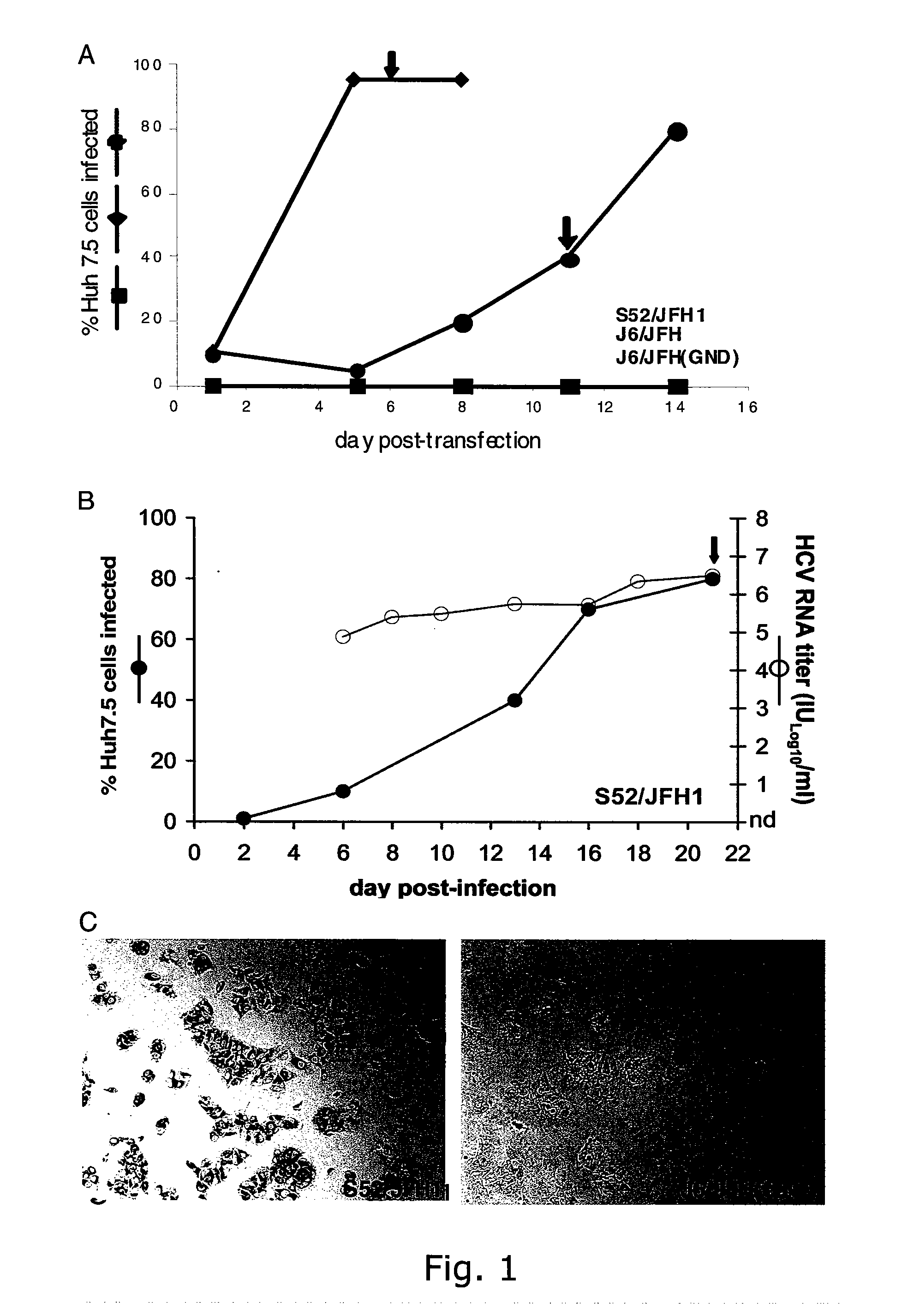

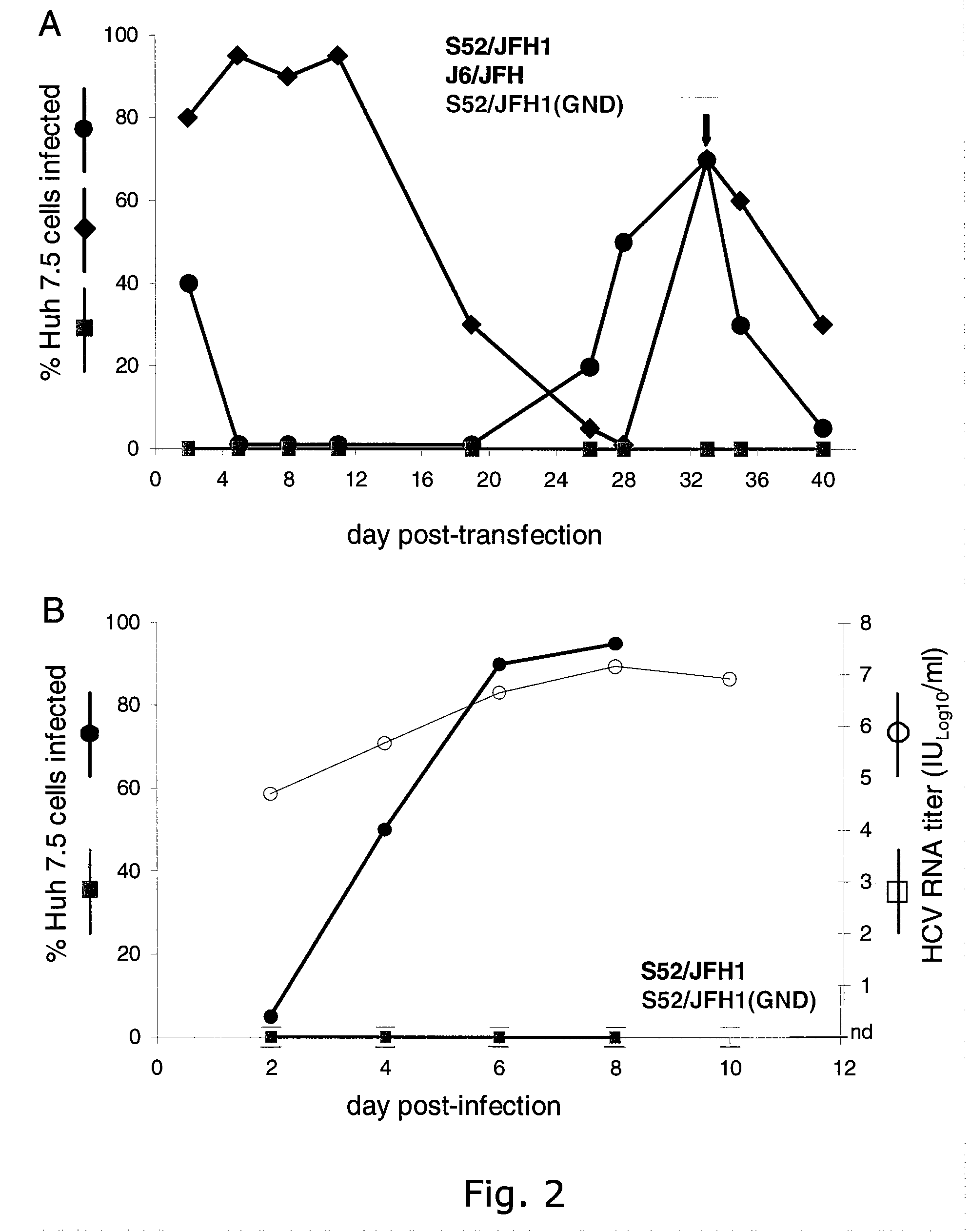

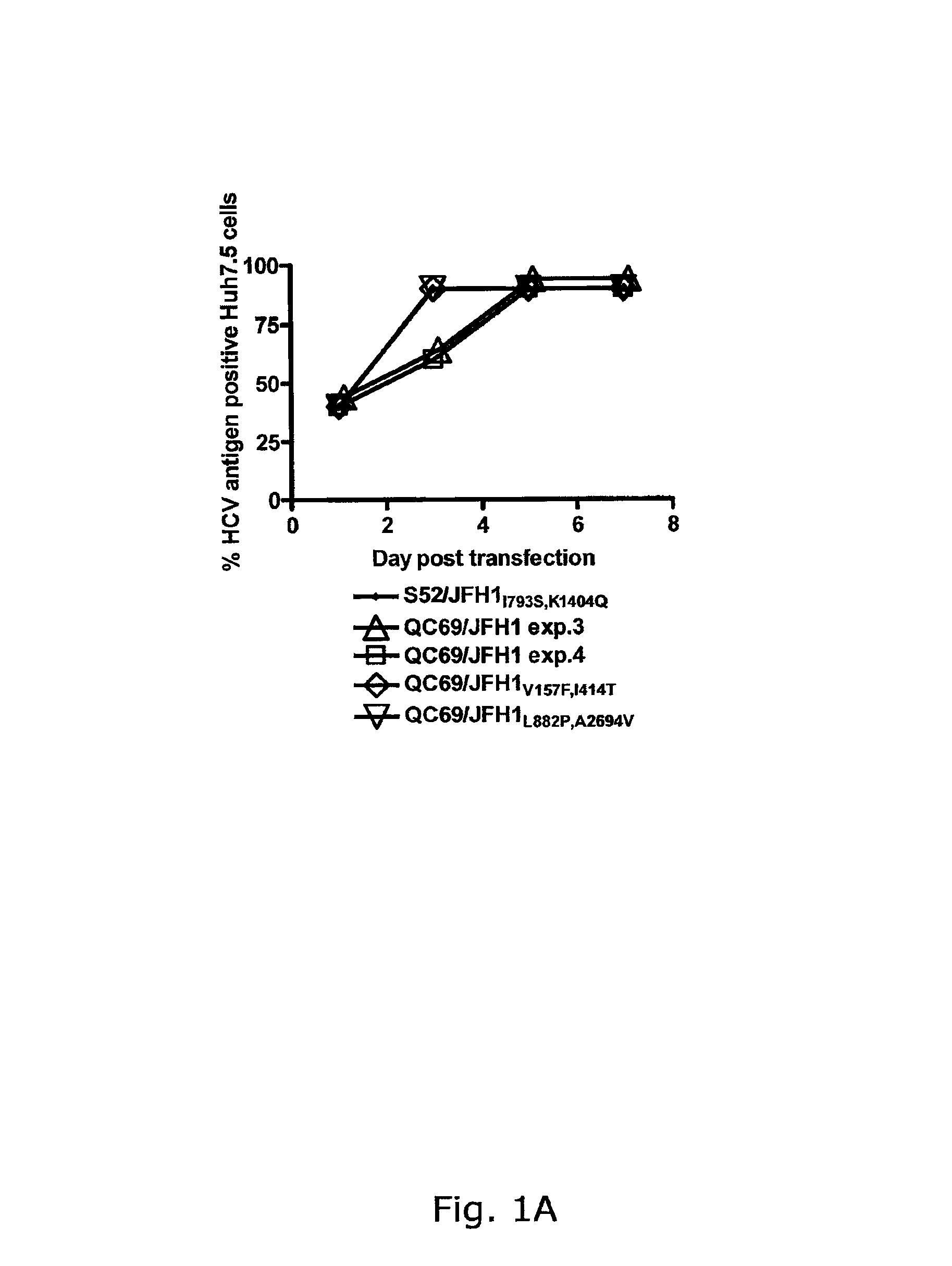

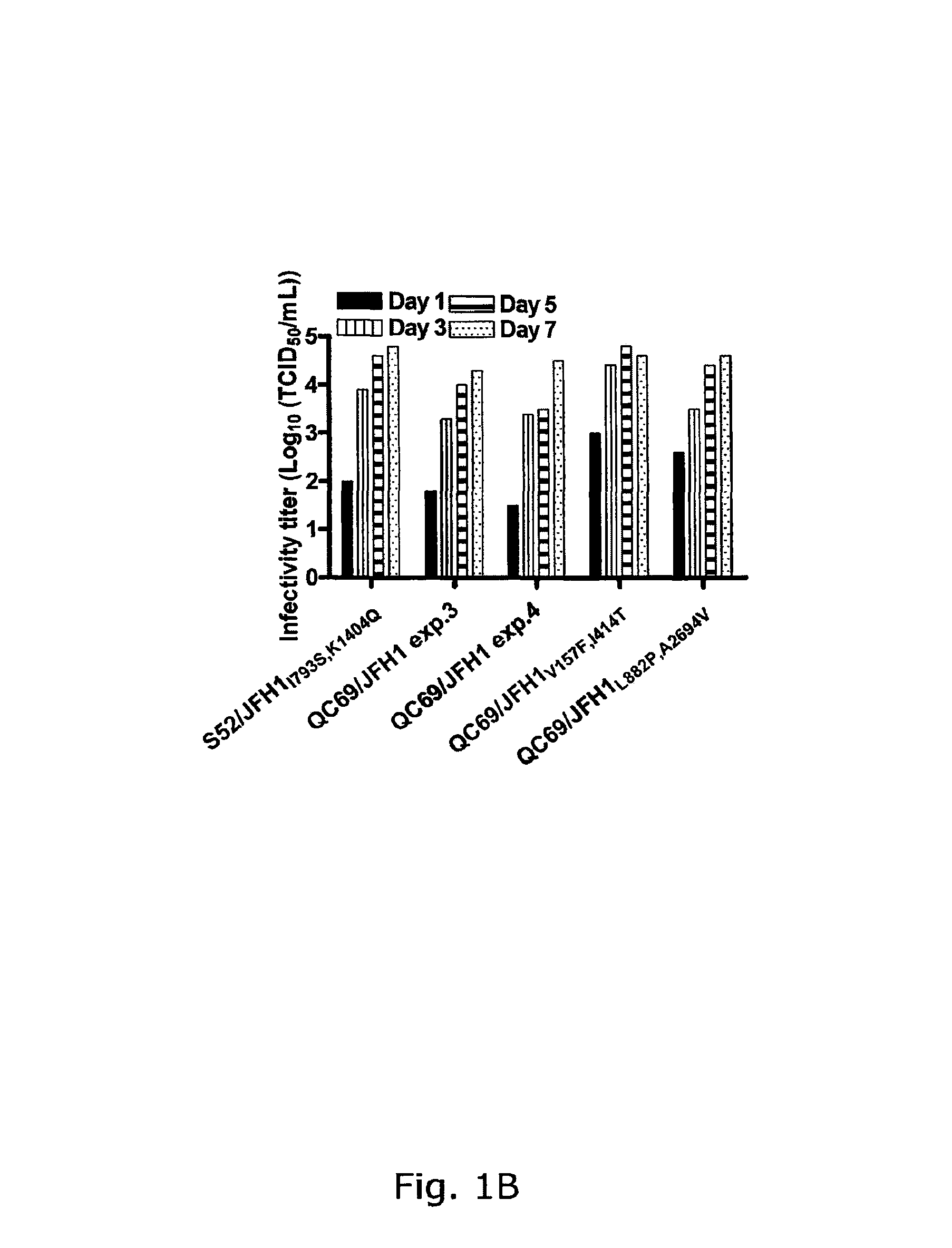

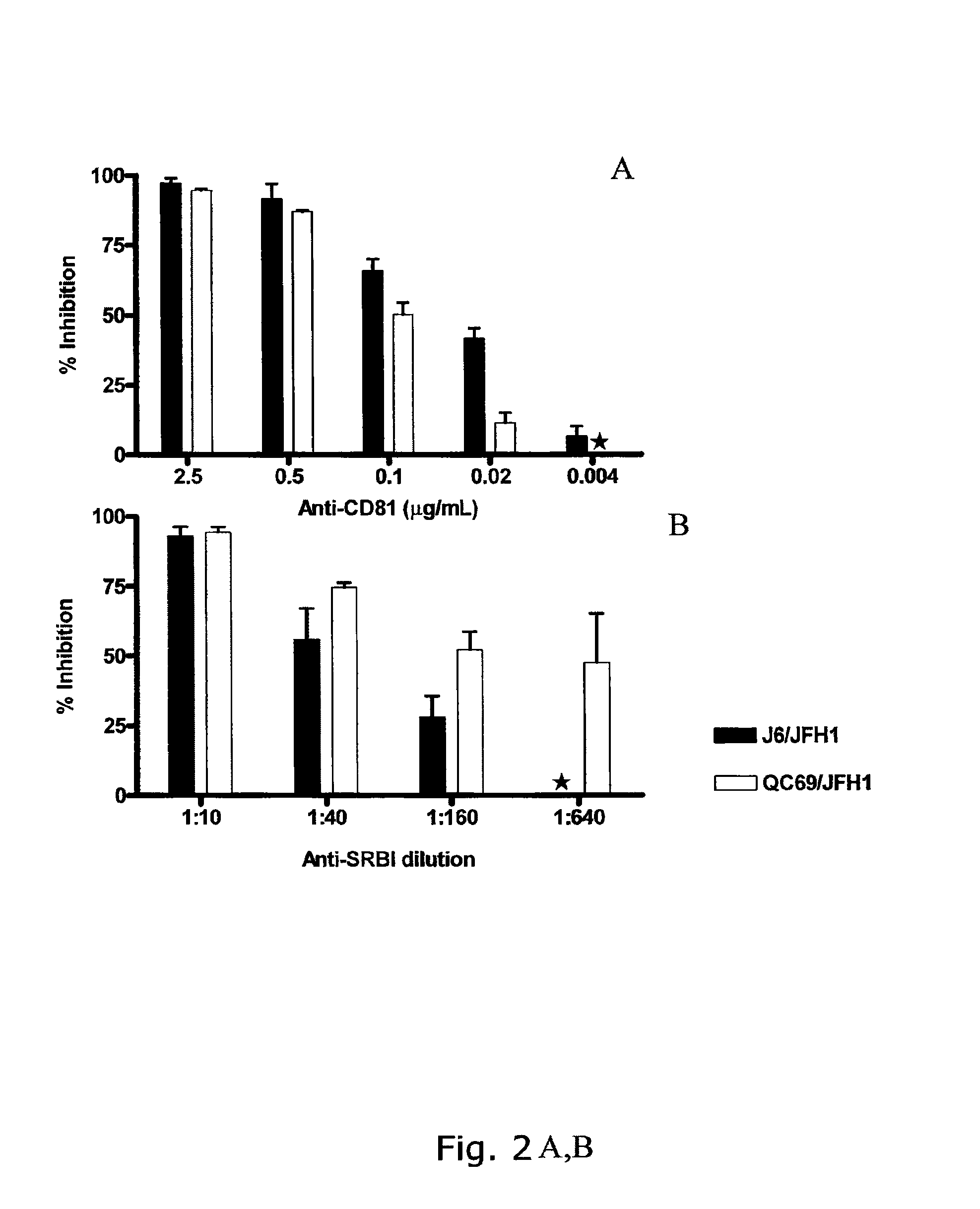

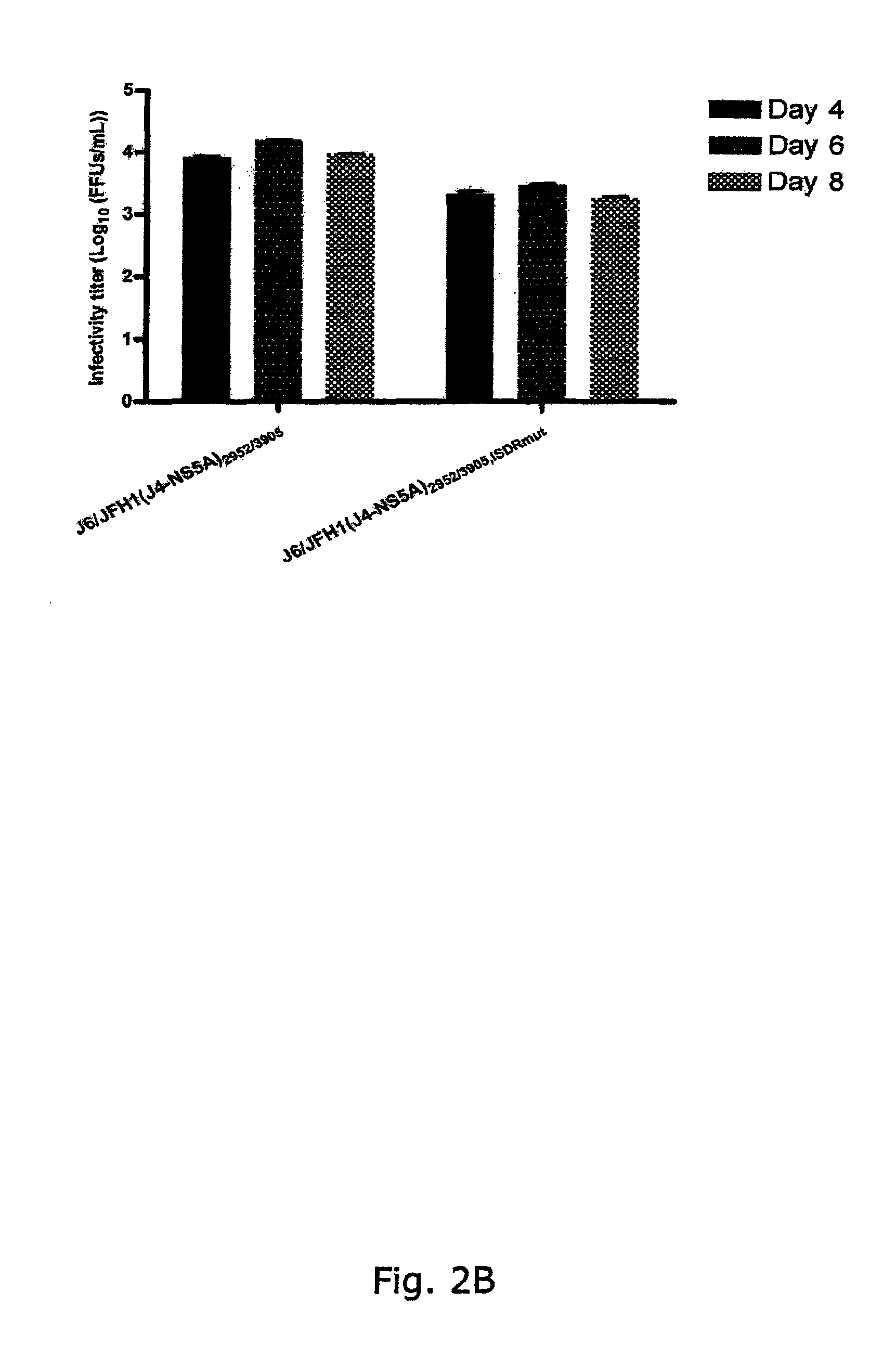

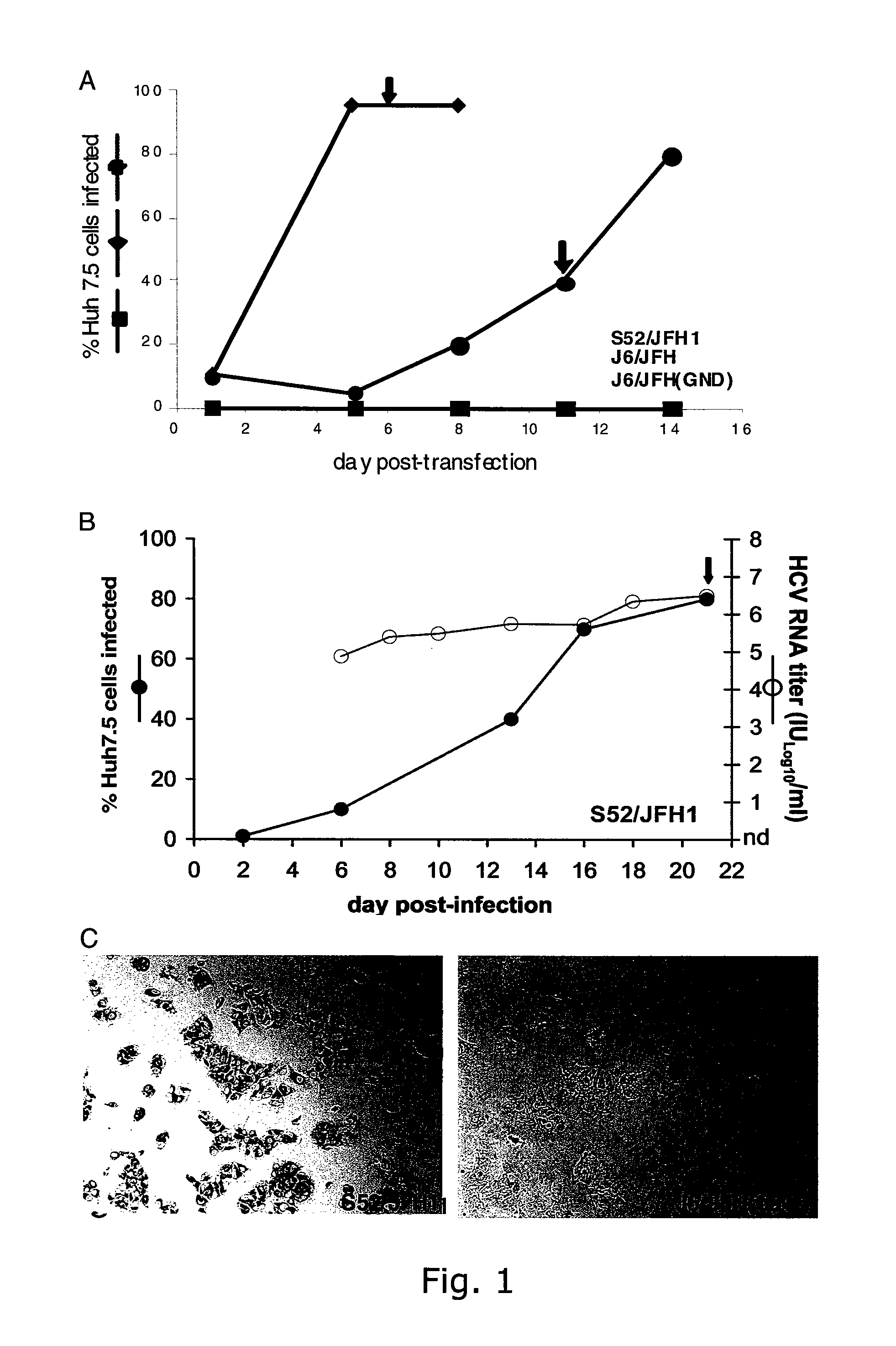

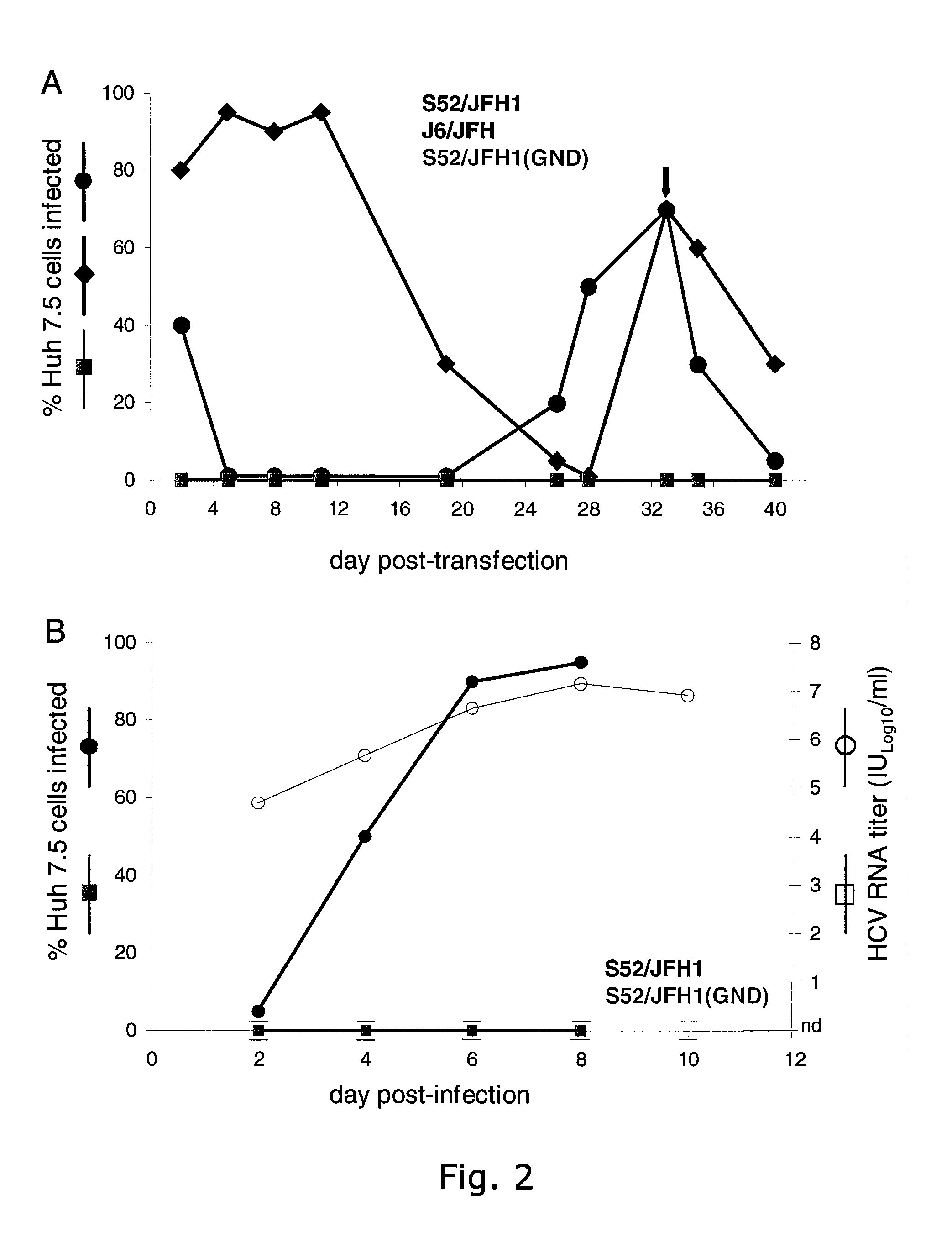

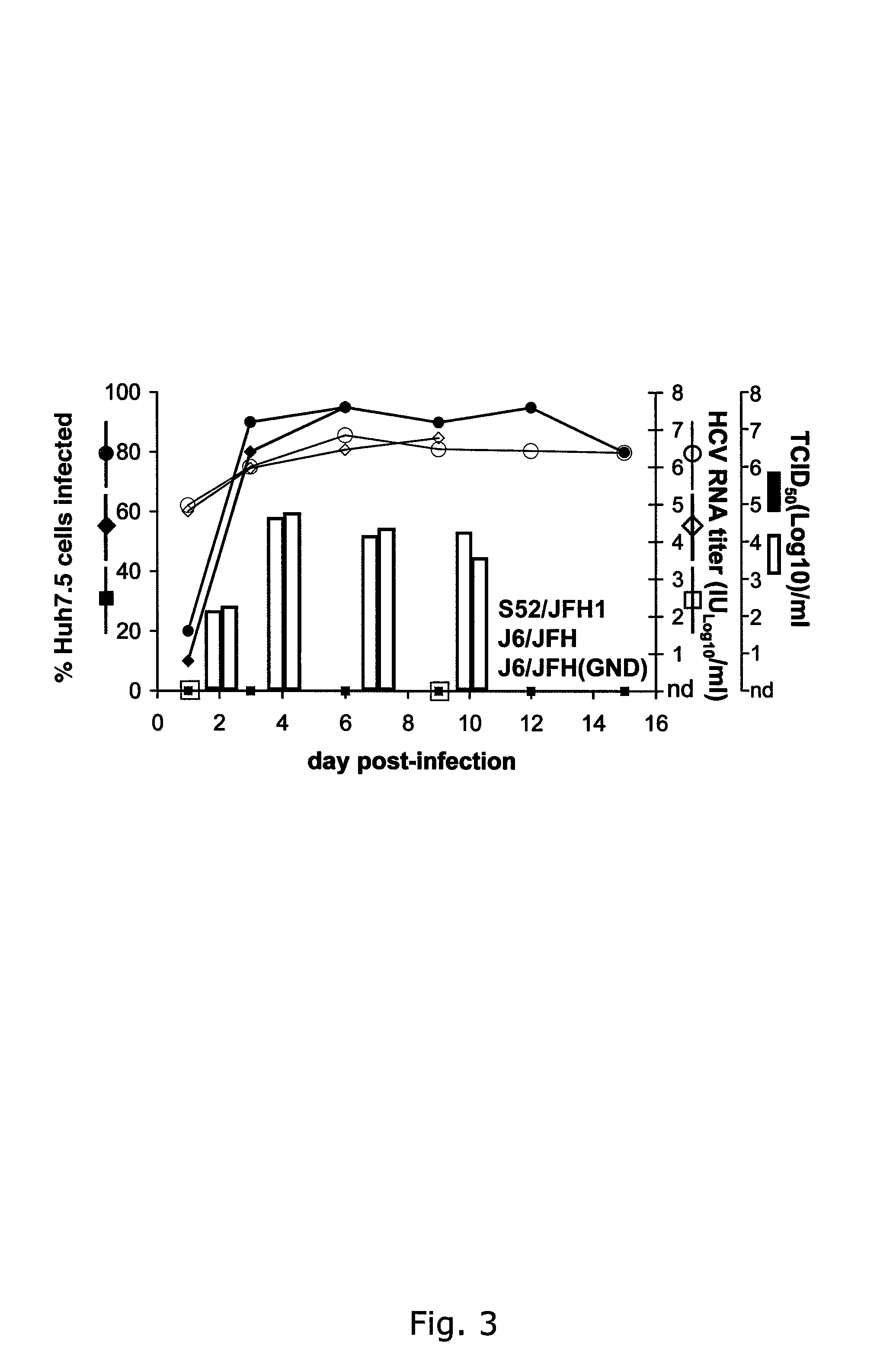

InactiveUS20100093841A1Efficient and sustainable growthDifferential efficiencyOrganic active ingredientsSsRNA viruses positive-senseGenomic sequencingNS5A

The present inventors have developed a culture system for genotype 3a, which has a high prevalence worldwide. Since intergenotypic recombinant genomes exploiting the replication characteristics of JFH1 will be a valuable tool for the genotype specific study of the replaced genes and related therapeutics, the present inventors constructed a genotype 3a / 2a (S52 / JFH1) recombinant containing the structural genes (Core, E1, E2), p7 and NS2 of strain S52 and characterized it in Huh7.5 cells. S52 / JFH1 and J6 / JFH viruses passaged in cell culture had comparable growth kinetics and yielded similar peak HCV RNA titers and infectivity titers. Direct genome sequencing of cell culture derived S52 / JFH1 viruses identified putative adaptive mutations in Core, E2, p7, NS3 and NS5A; clonal analysis revealed, that all genomes analyzed exhibited different combinations of these mutations. Finally, viruses resulting from transfection with RNA transcripts of five S52 / JFH1 recombinant containing these combinations of putative adaptive mutations performed as efficiently as J6 / JFH viruses in Huh7.5 15 cells and were all genetically stable after viral passage. In conclusion, the present inventors have developed a robust and genetically stable cell culture system for HCV genotype 3a.

Owner:HVIDOVRE HOSPITAL

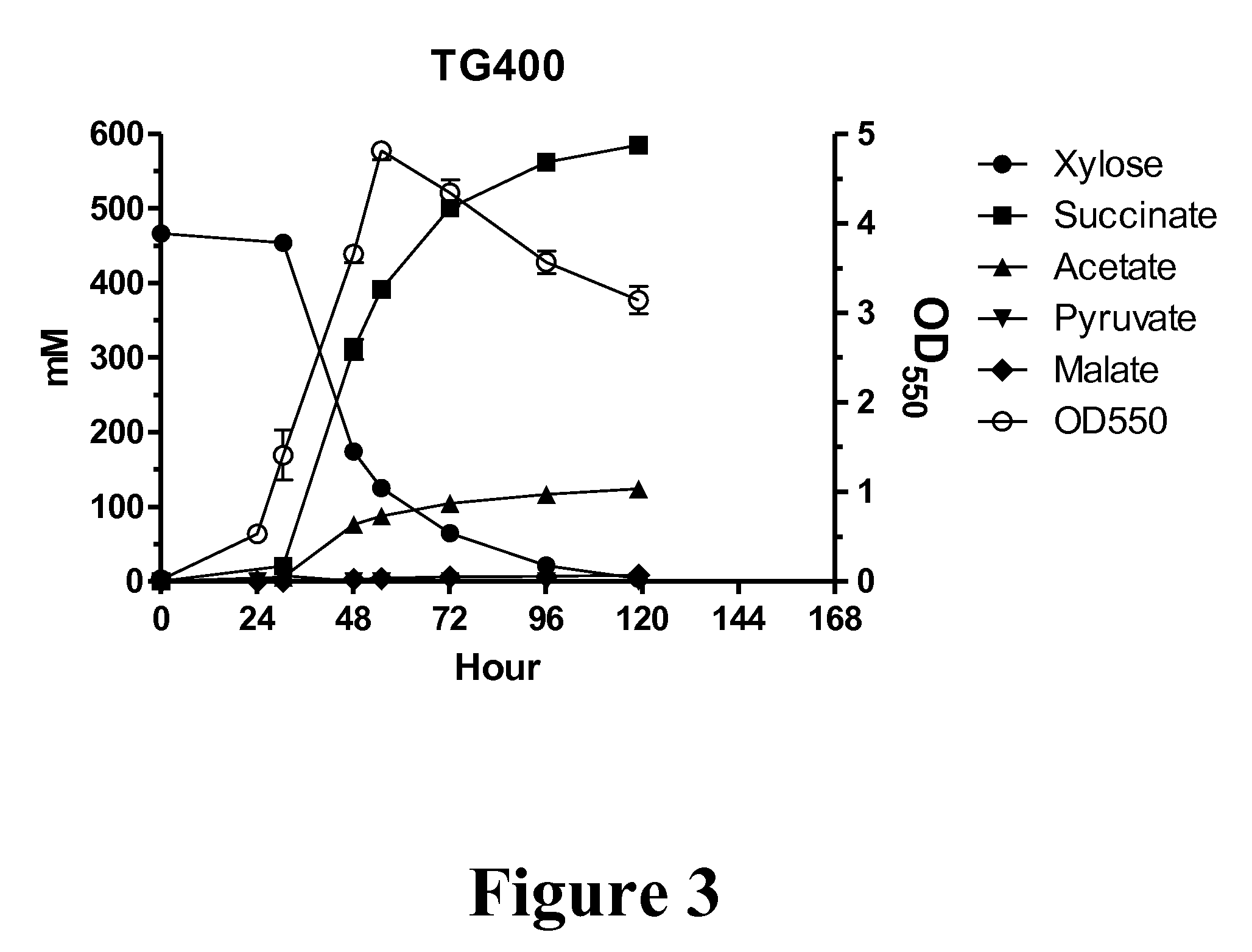

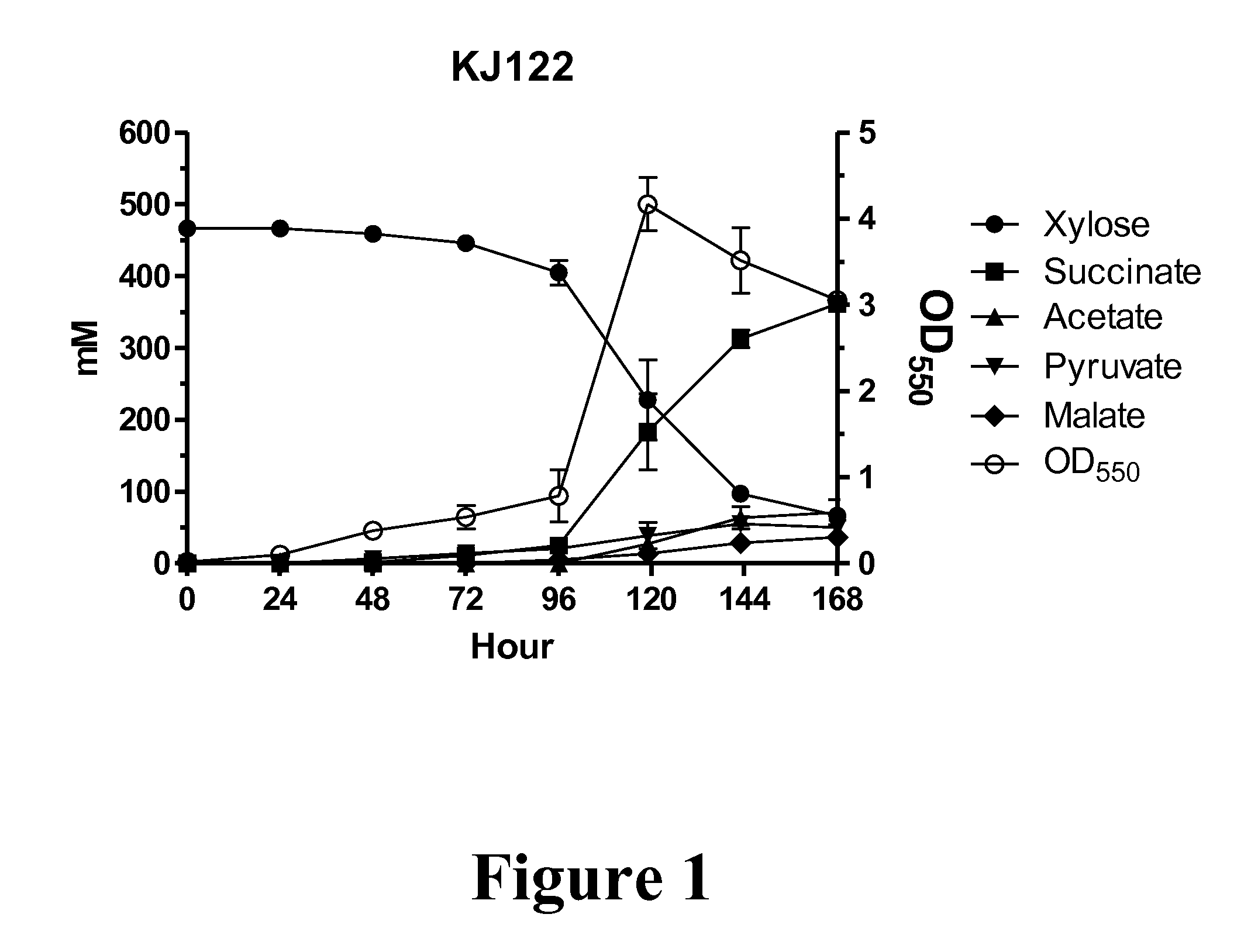

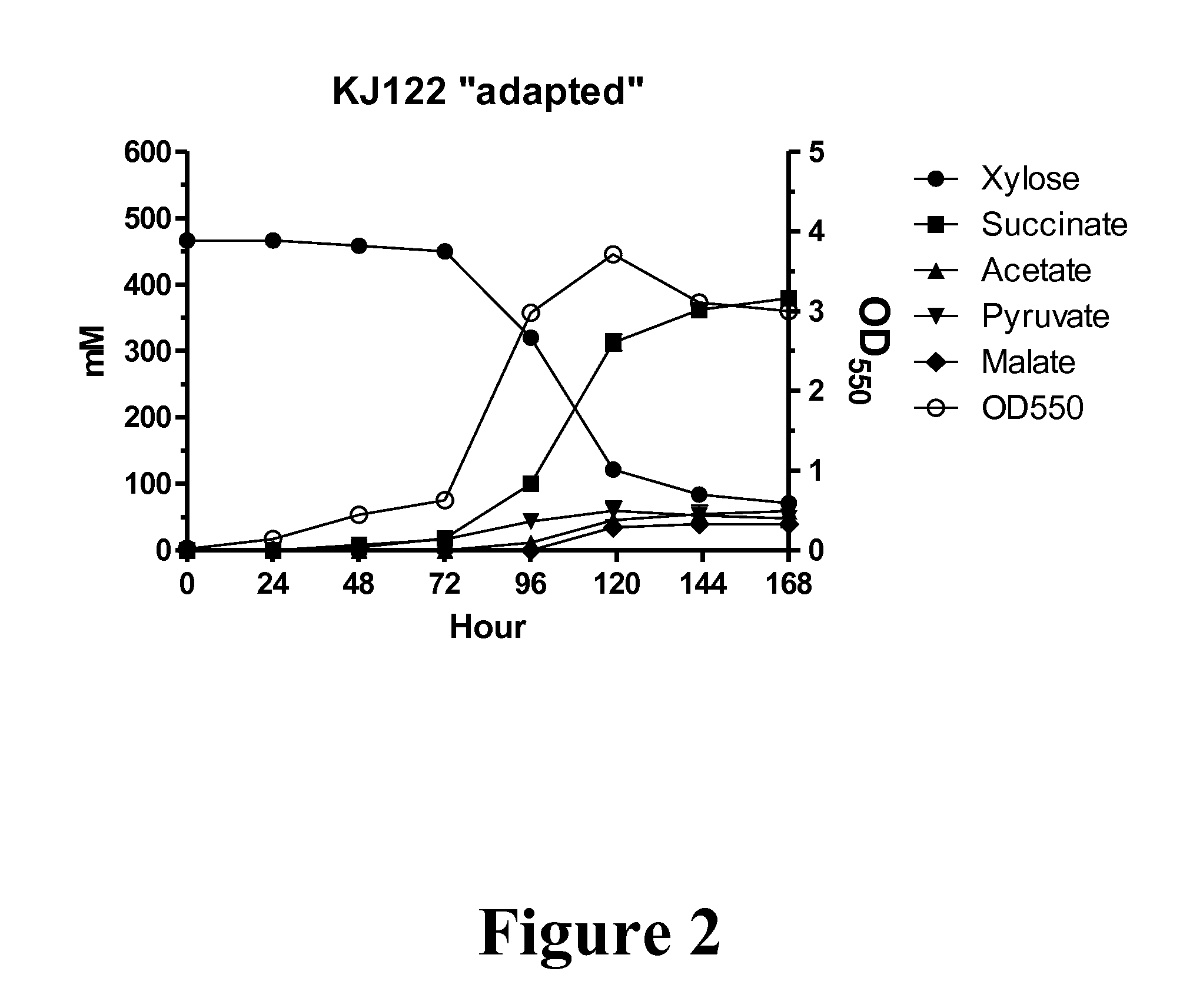

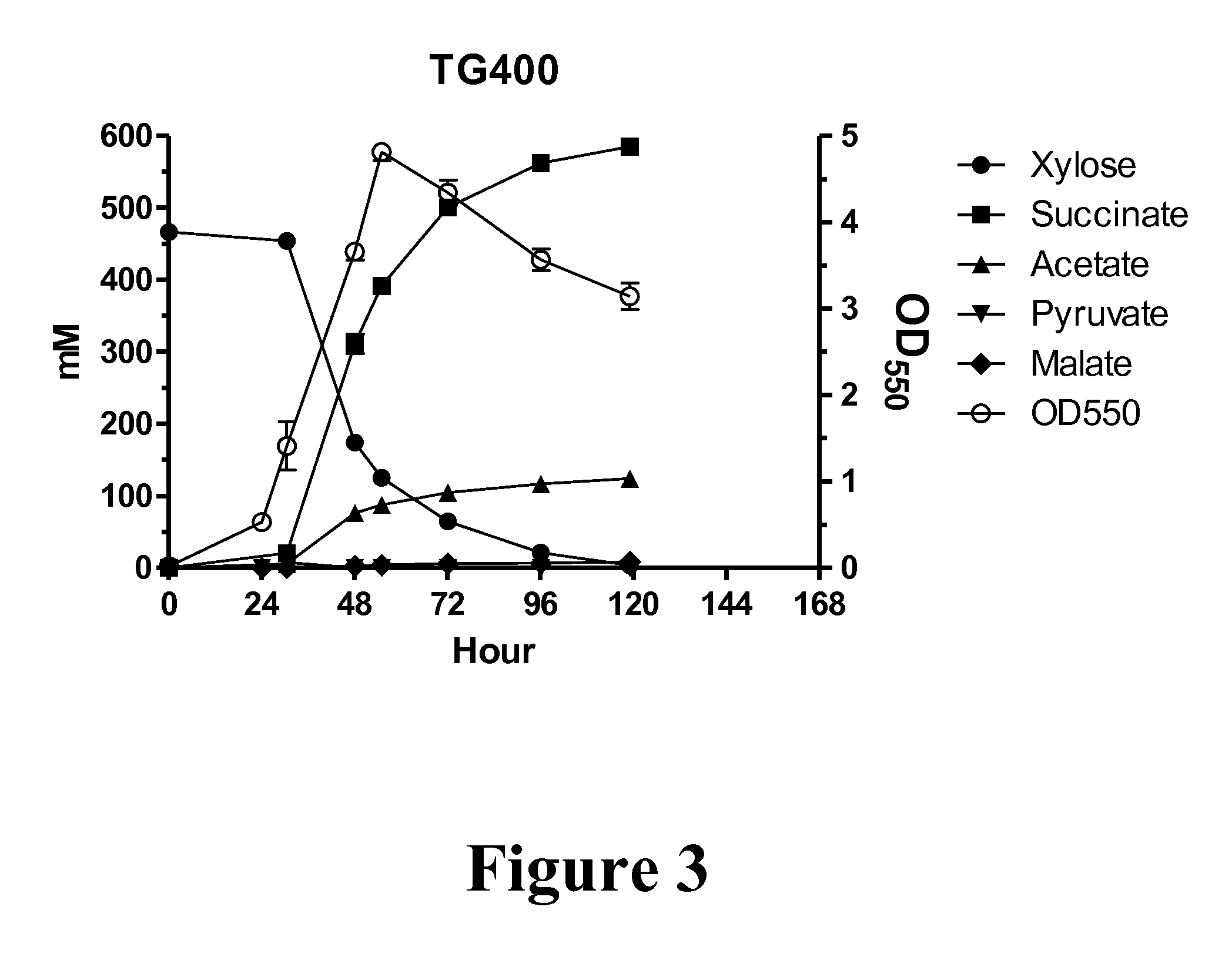

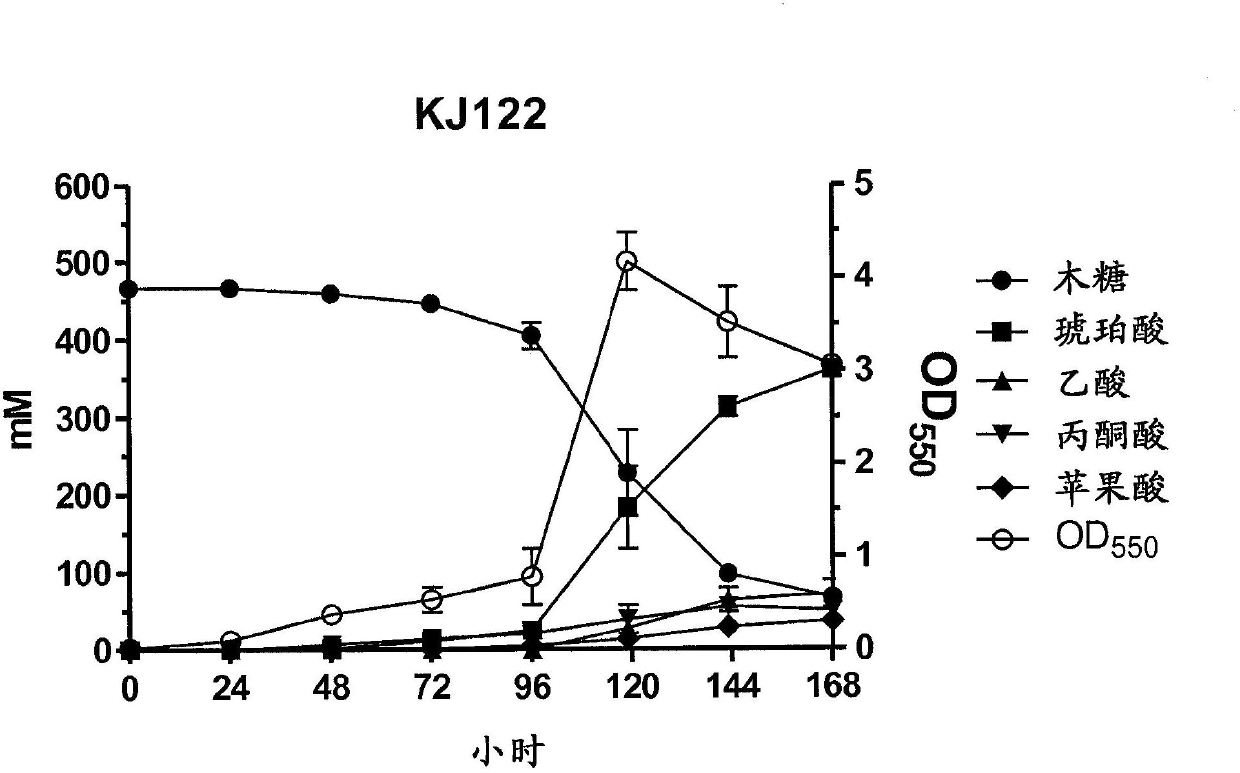

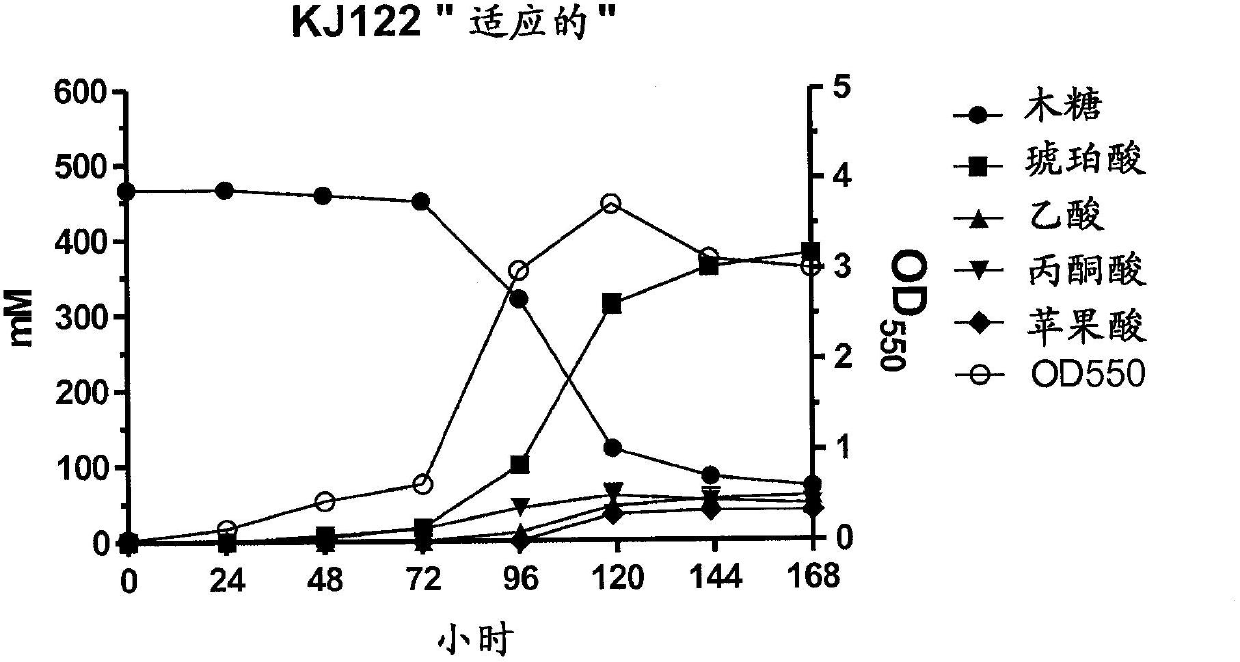

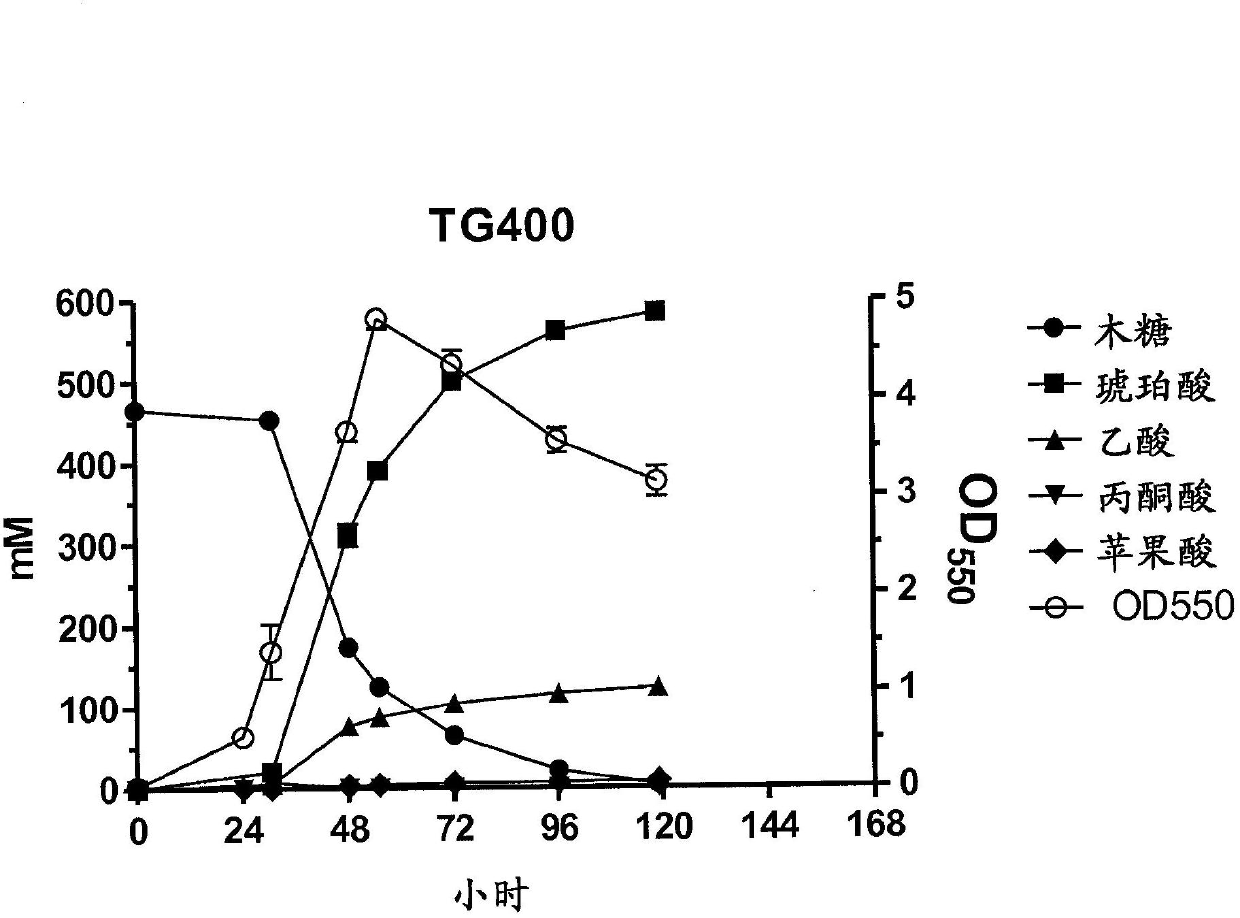

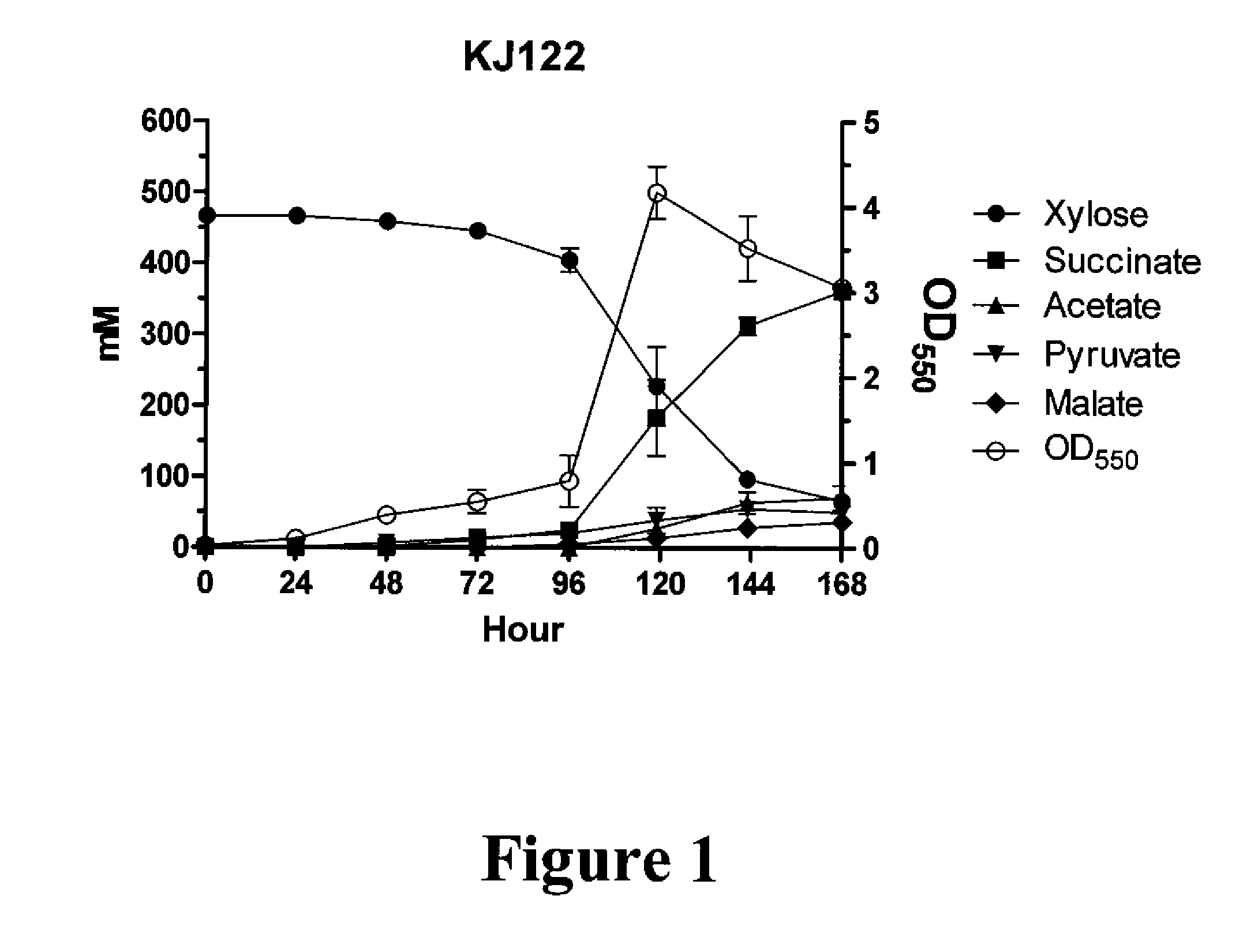

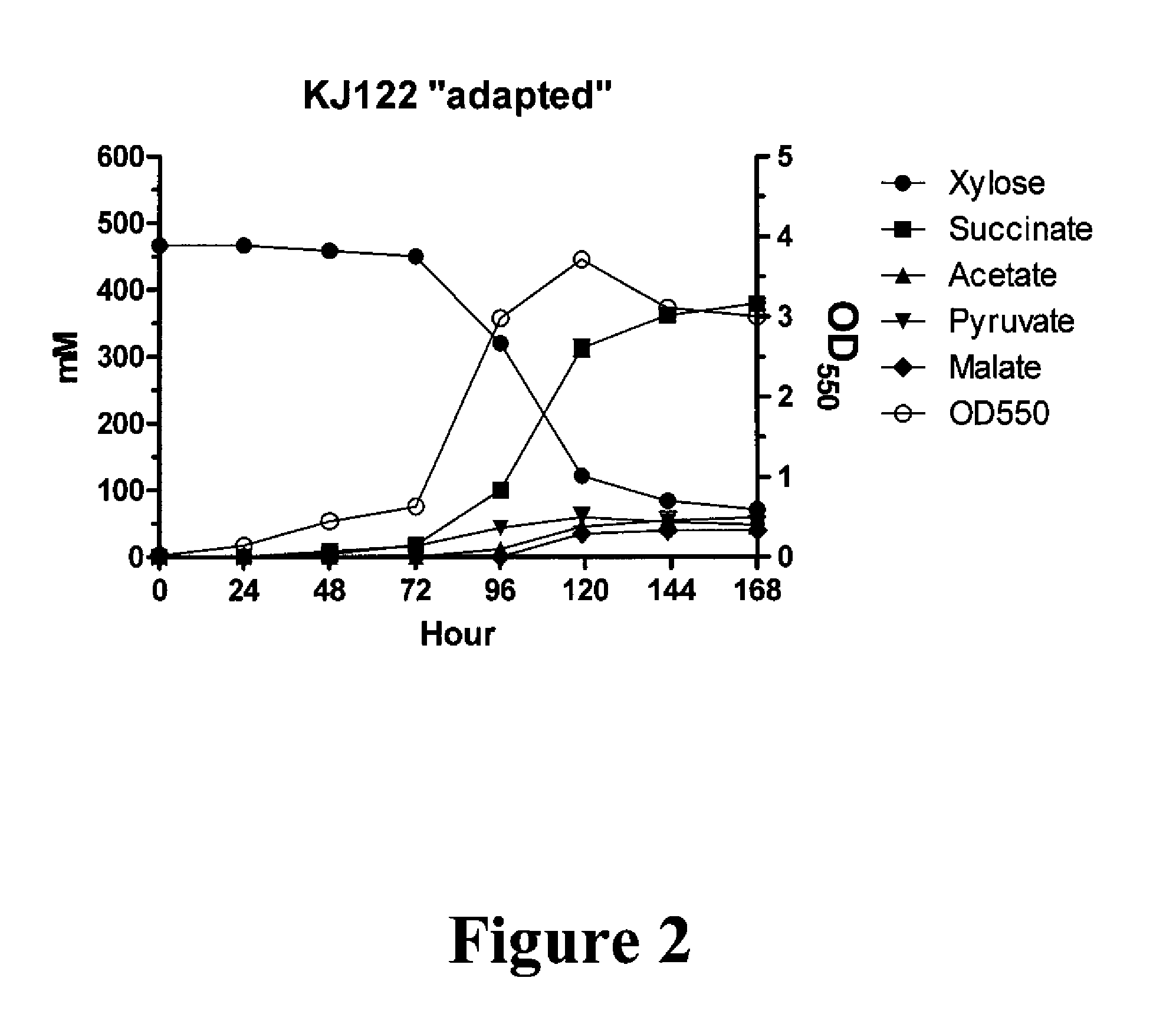

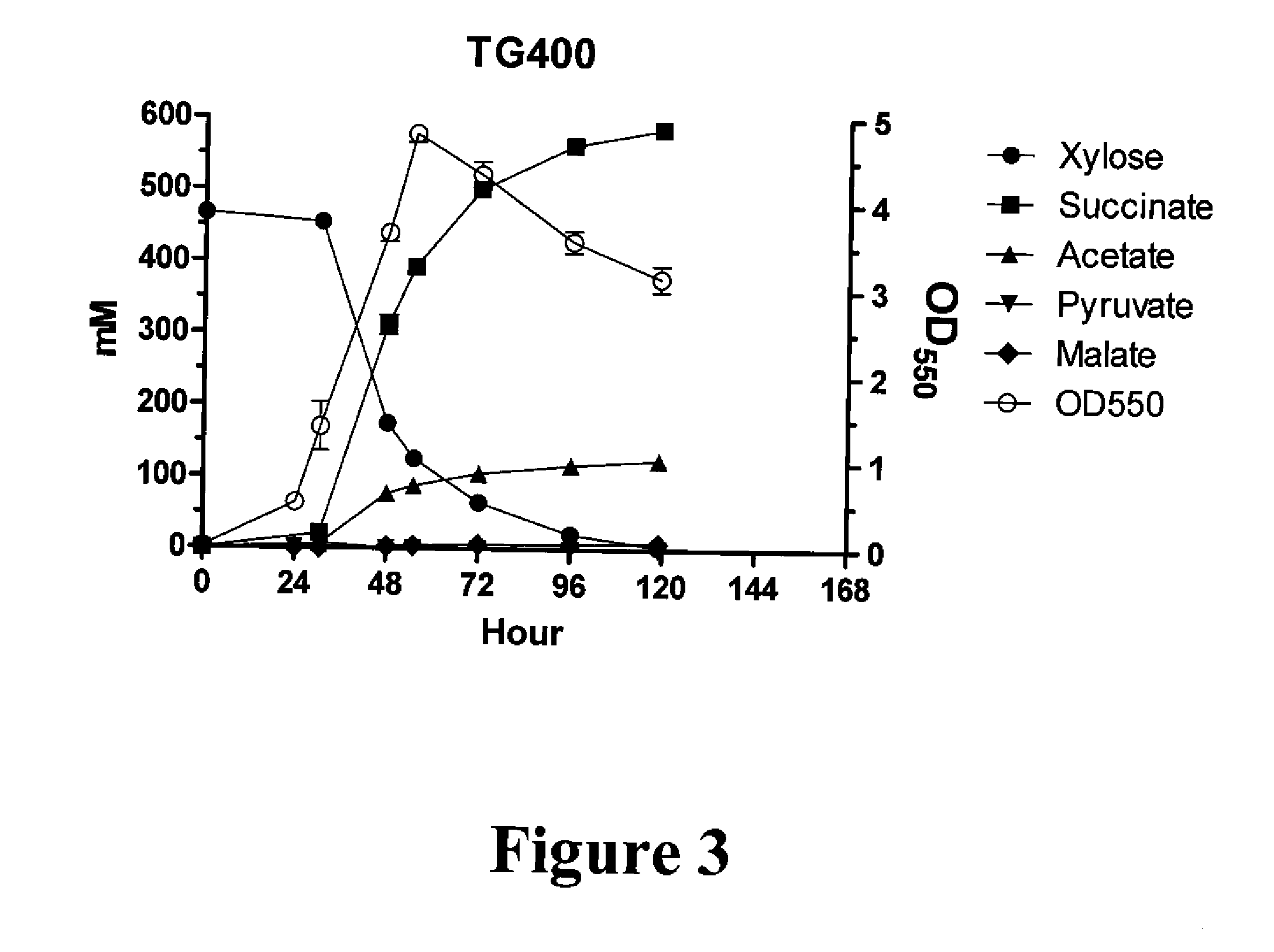

Metabolic evolution of Escherichia coli strains that produce organic acids

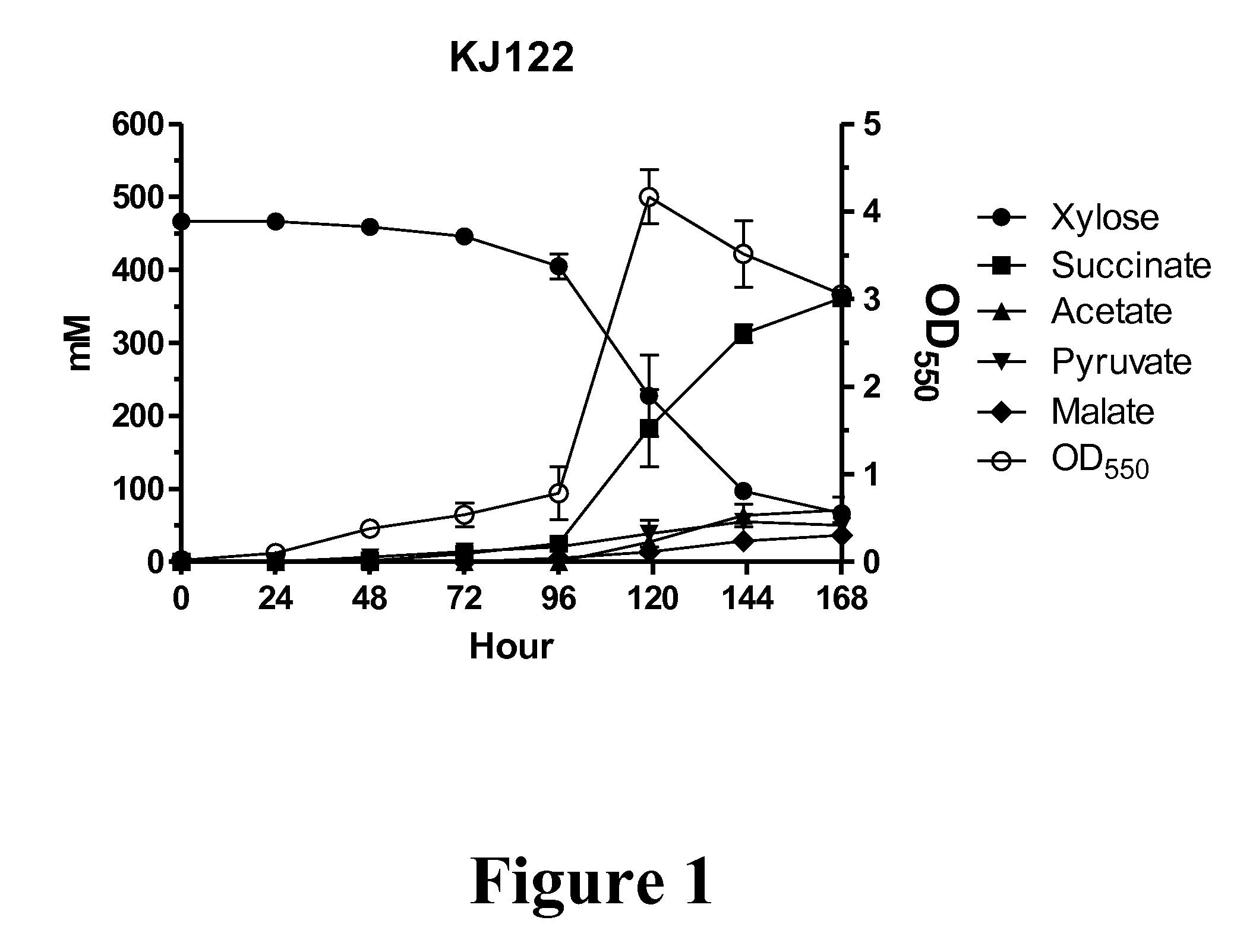

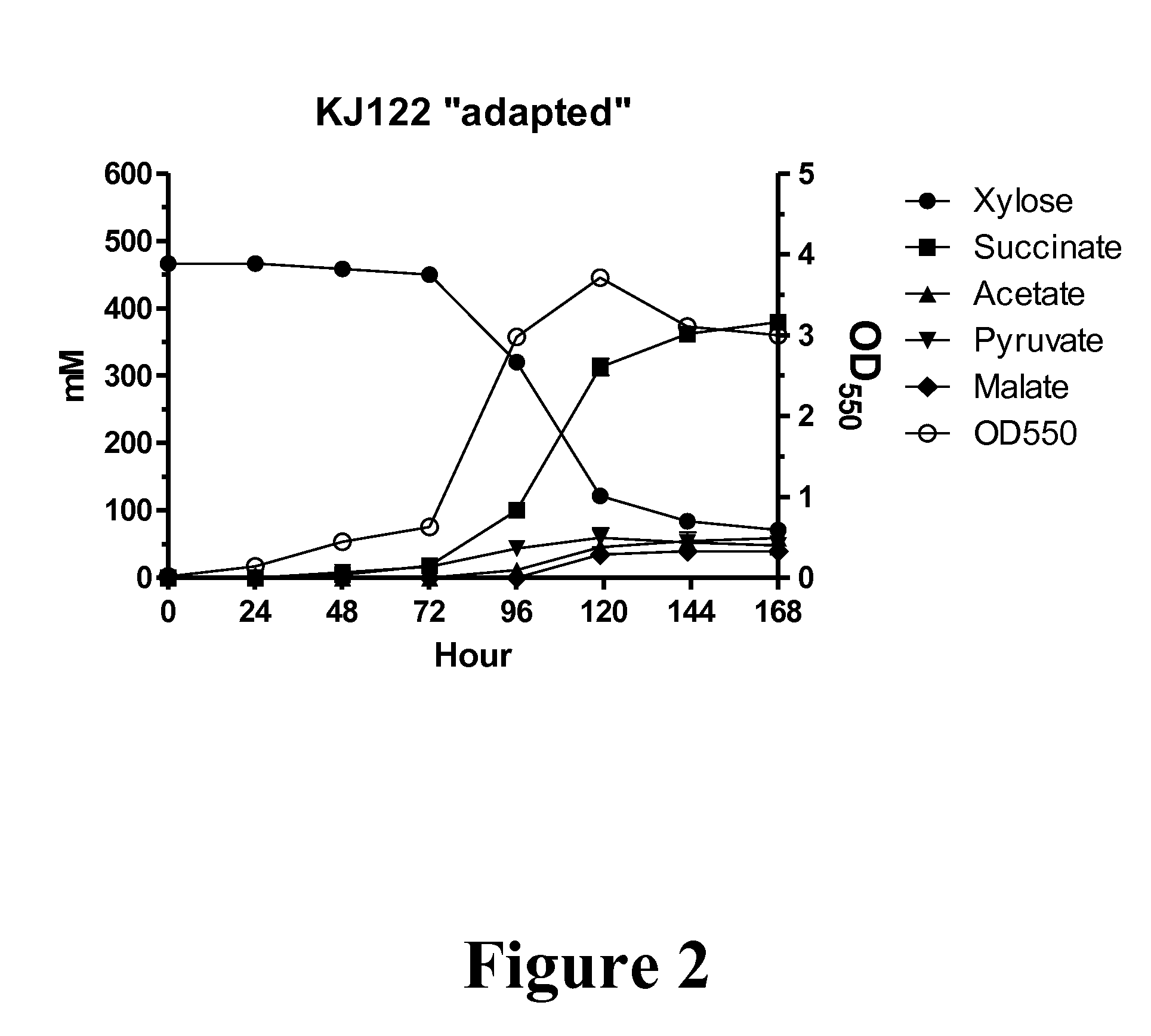

This invention relates to the metabolic evolution of a microbial organism previously optimized for producing an organic acid in commercially significant quantities under fermentative conditions using a hexose sugar as sole source of carbon in a minimal mineral medium. As a result of this metabolic evolution, the microbial organism acquires the ability to use pentose sugars derived from cellulosic materials for its growth while retaining the original growth kinetics, the rate of organic acid production and the ability to use hexose sugars as a source of carbon. This invention also discloses the genetic change in the microorganism that confers the ability to use both the hexose and pentose sugars simultaneously in the production of commercially significant quantities of organic acids.

Owner:PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

Metabolic evolution of escherichis coli strains that produce organic acids

This invention relates to the metabolic evolution of a microbial organism previously optimized for producing an organic acid in commercially significant quantities under fermentative conditions using a hexose sugar as sole source of carbon in a minimal mineral medium. As a result of this metabolic evolution, the microbial organism acquires the ability to use pentose sugars derived from cellulosic materials for its growth while retaining the original growth kinetics, the rate of organic acid production and the ability to use hexose sugars as a source of carbon. This invention also discloses the genetic change in the microorganism that confers the ability to use both the hexose and pentose sugars simultaneously in the production of commercially significant quantities of organic acids.

Owner:PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

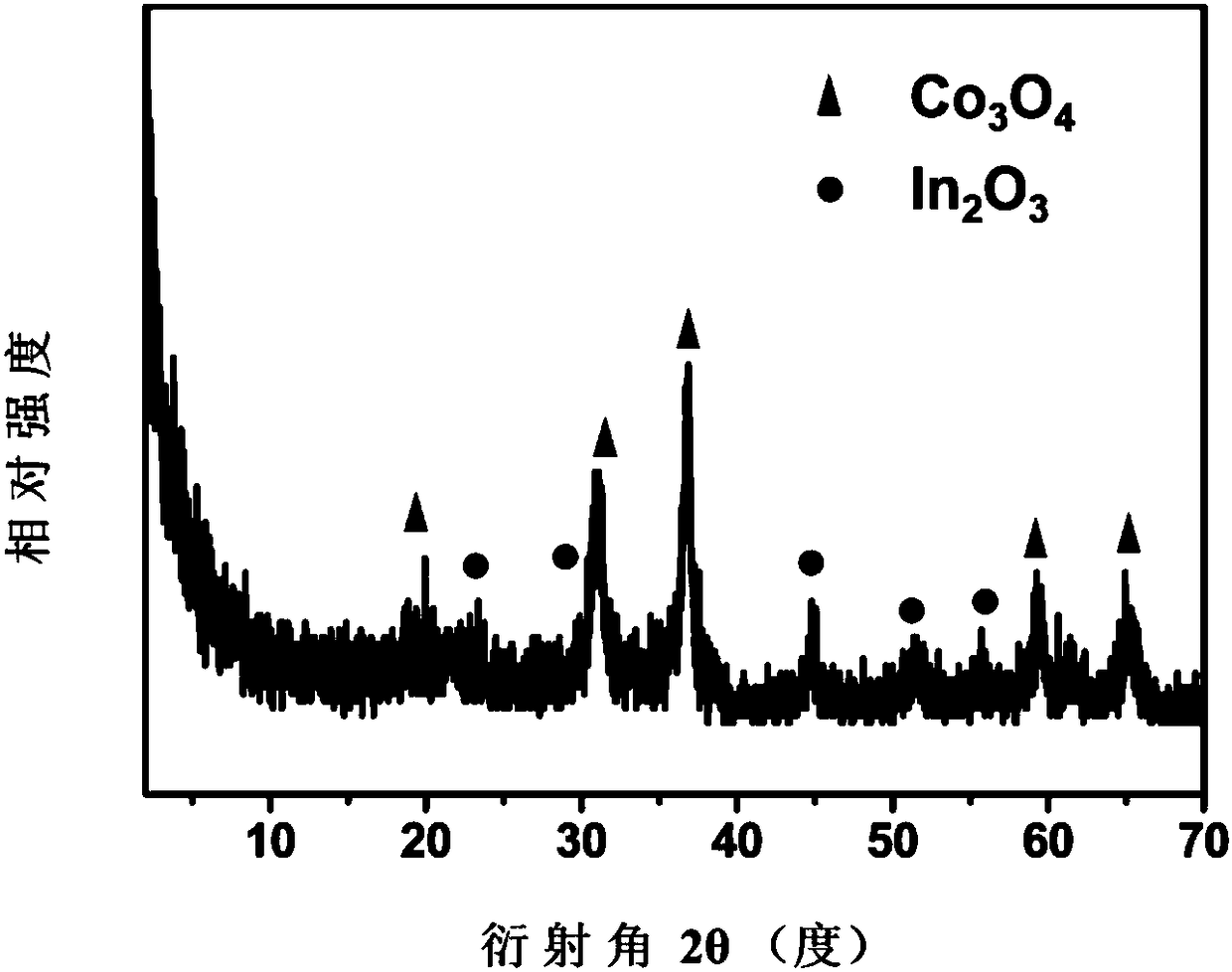

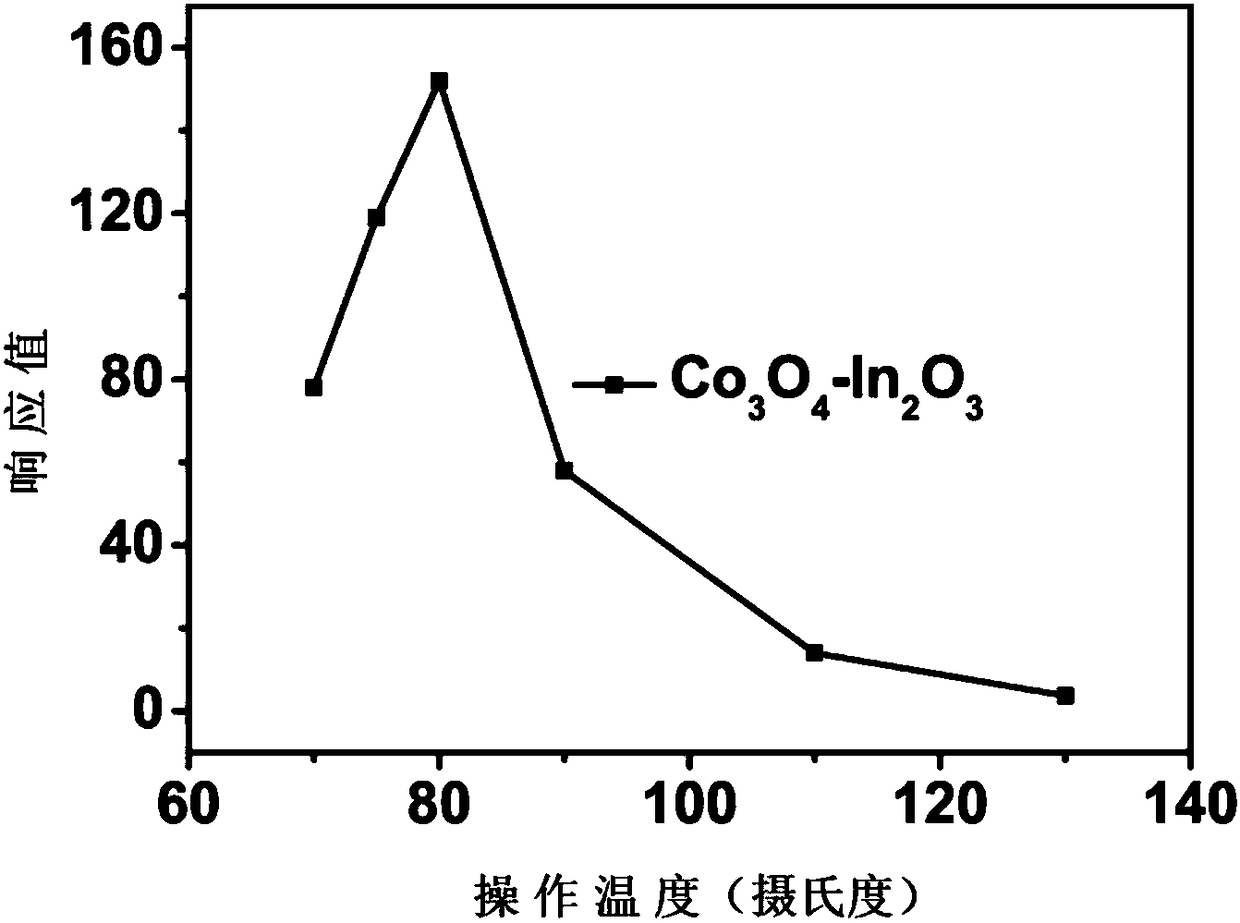

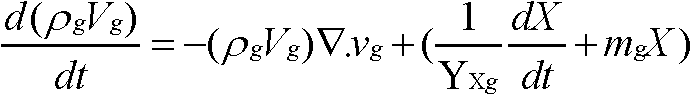

Multilevel structure metal oxide gas sensitive material and preparation method thereof

InactiveCN108585064ALower operating temperatureHigh responseCobalt oxides/hydroxidesMaterial analysisHexamethylenetetramineBiological activation

The invention provides a multilevel structure metal oxide gas sensitive material and a preparation method thereof. Urea or hexamethylenetetramine is used as an alkaline source, the increase rate of the pH value of a reaction system is retarded in virtue of an organic acid as a structure-directing agent, a water and alcohol mixed solvent is used for adjusting the growth kinetics of a wafer, a multilevel structure layered hydroxide precursor assembled by nanosheets is prepared, a multilevel structure complex oxide assembled by the nanosheets is obtained through roasting, then porous nanosheets are obtained by etching MgO or ZnO in the complex oxide through ammonium salt, more surface defects are formed, and the porous multilevel structure metal oxide gas sensitive material with low operationtemperature, high response value and low detection limit is obtained. The thicknesses of the nanosheets of the material are 5 to 20 nm, the specific surface area is 80 to 180 m<2> / g, the pore diameter is concentrated to be 2 to 15 nm, the gas adsorption, diffusion and activation are promoted, and then the gas sensitive material is improved. The method provided by the invention is simple in operation, mild in condition and convenient for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

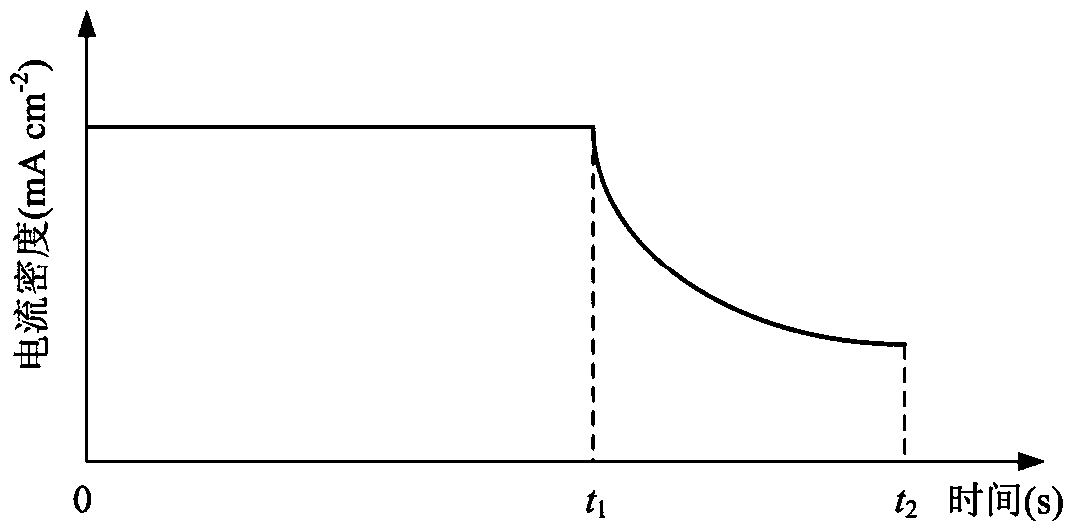

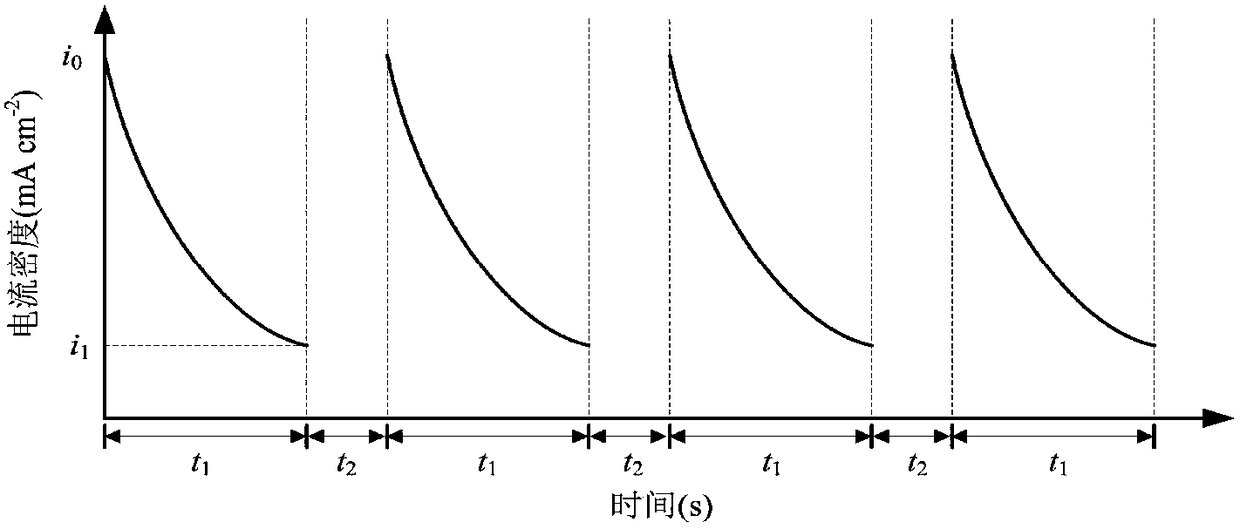

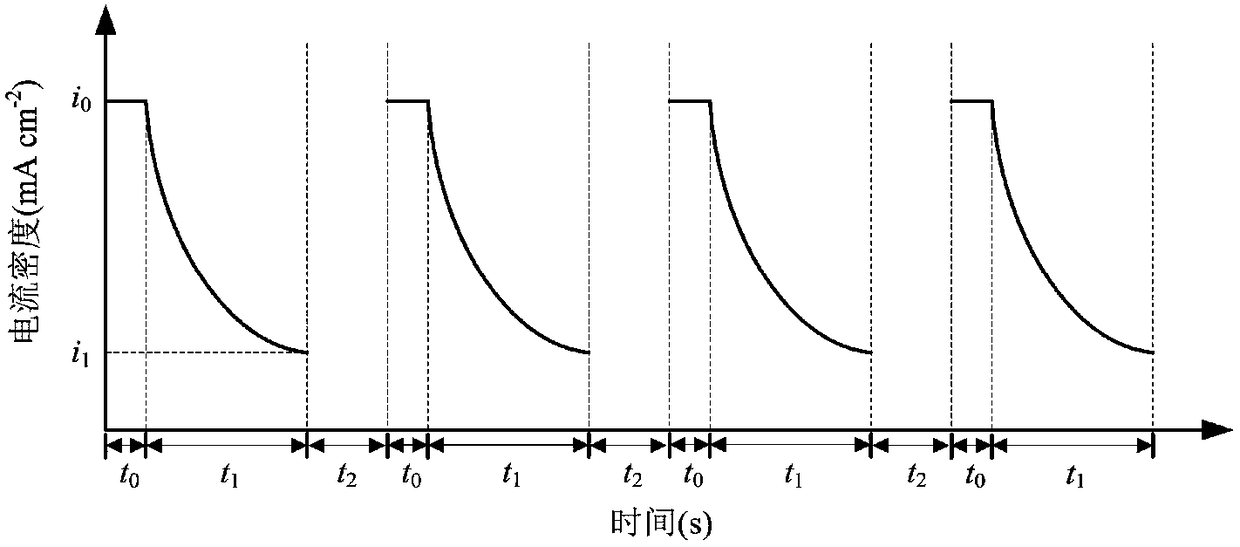

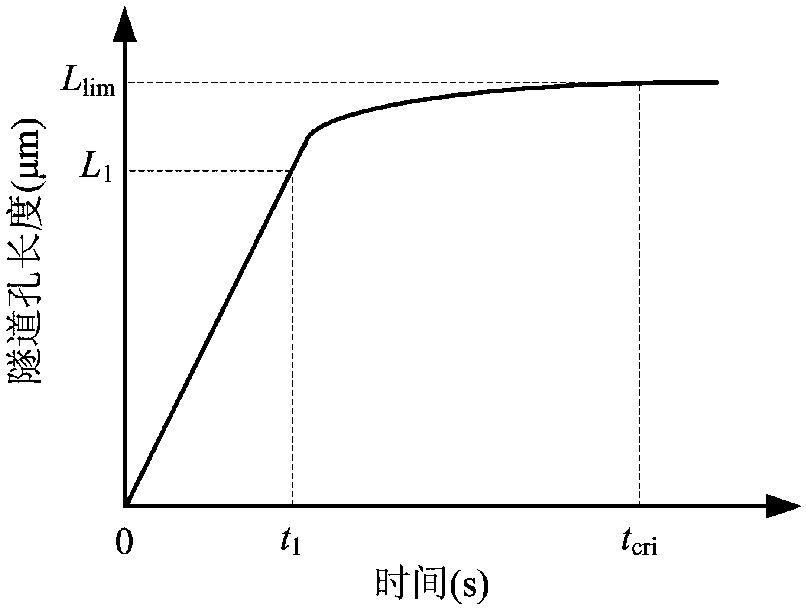

Dual-section current waveform corrosion method for improving length consistency of channel holes of medium and high voltage anode aluminum foil

ActiveCN103745830AImprove consistencyHigh consistency in lengthElectrolytic capacitorsSmall amplitudeCapacitance

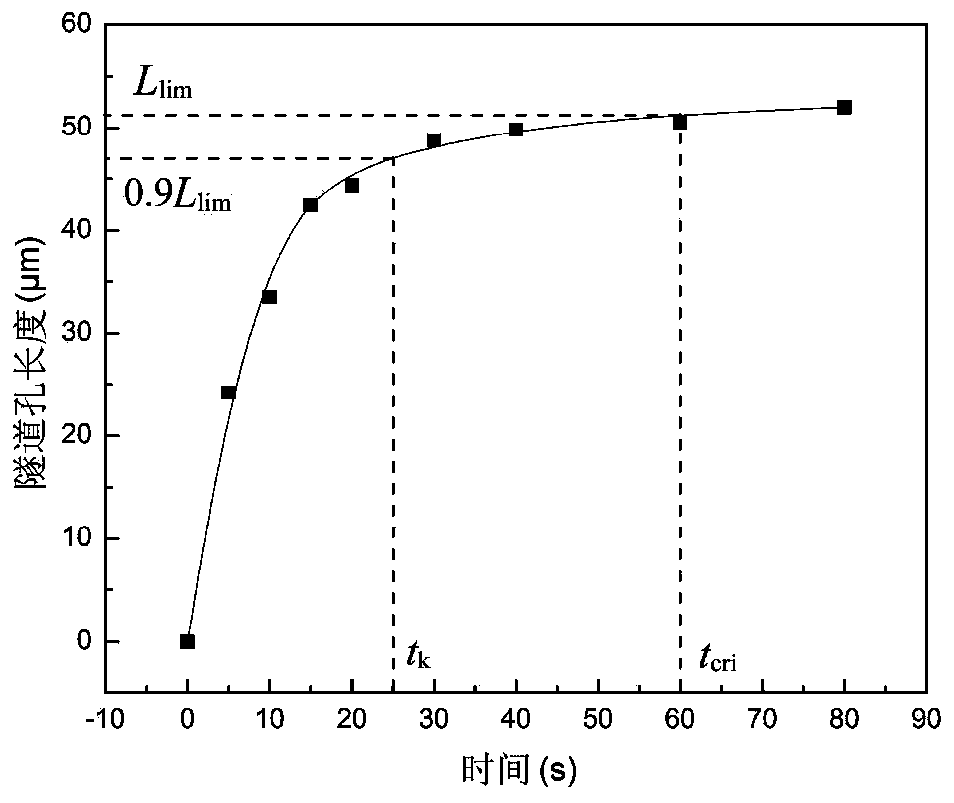

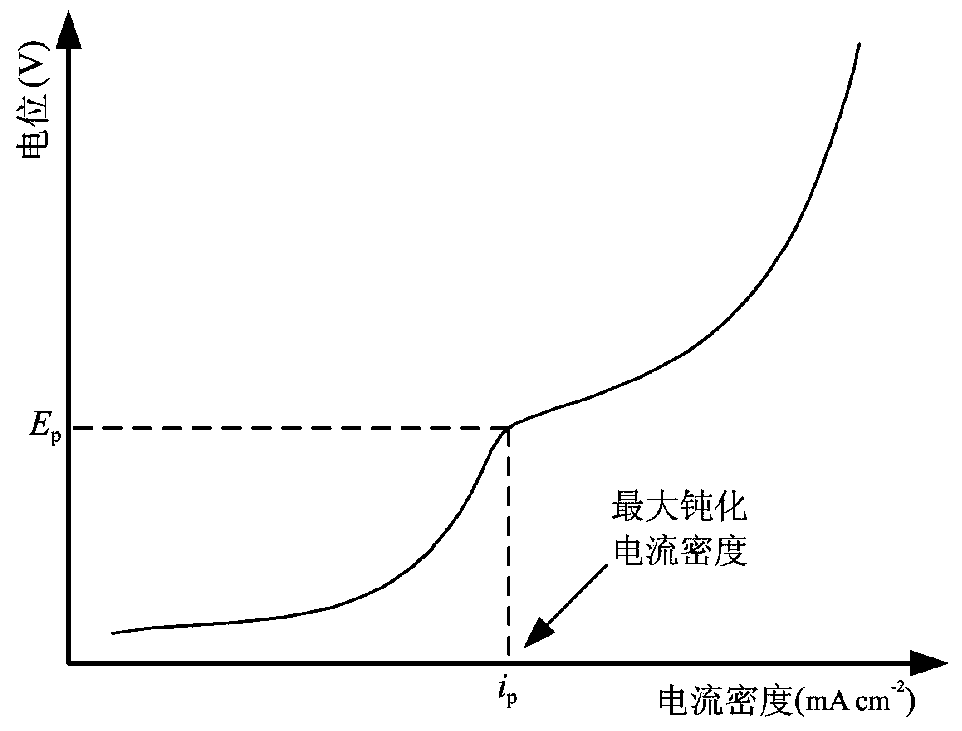

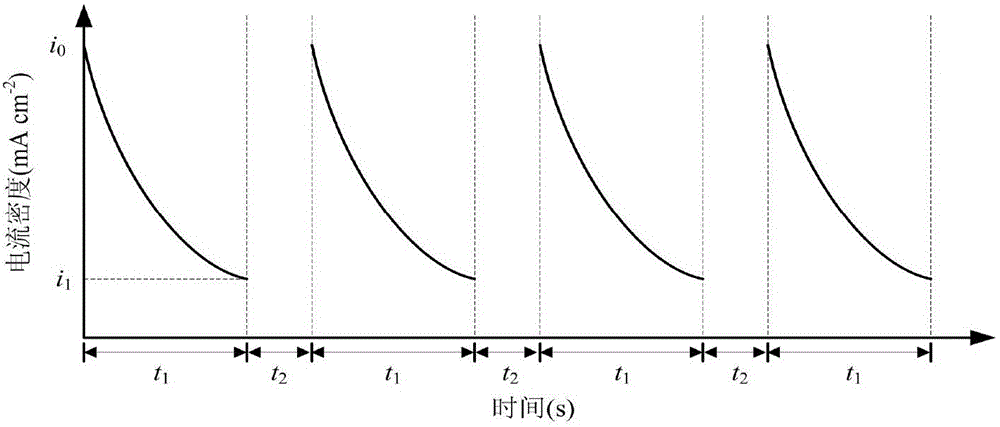

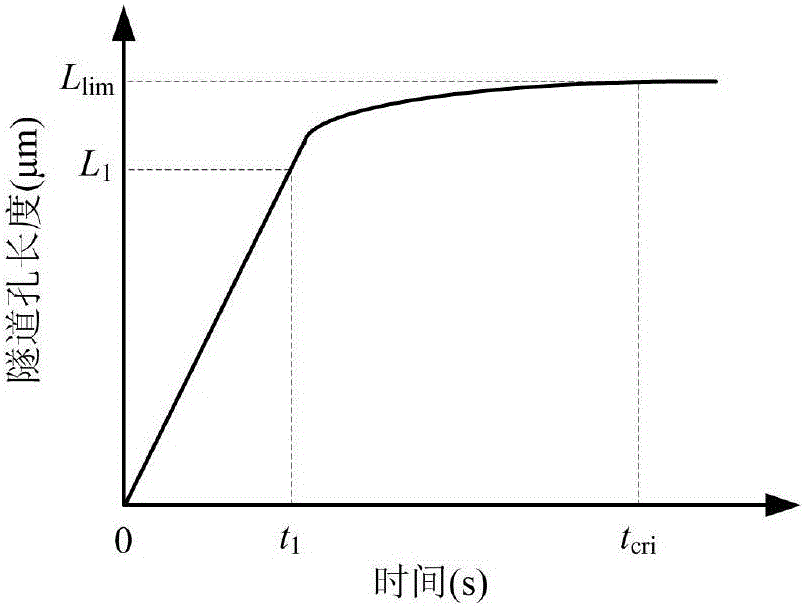

A dual-section current waveform corrosion method for improving the length consistency of channel holes of a medium and high voltage anode aluminum foil comprises the following steps of corroding the aluminum foil by adopting two sections of current waveforms: at the first stage, adopting a constant current or a small-amplitude linear attenuation current to enable the aluminum to generate the channel holes with the needed density, and at the second stage, adopting a linear or exponent form attenuation current waveform to enable the channel holes generated at the first stage to continuously grow to achieve or approach the limit length without generating new channel holes, wherein the corrosion time, the lowest corrosion current density and the current attenuation waveform of the second stage are determined by testing the growth kinetic curve of the channel holes of the aluminum foil in a corrosion solution and the maximum anode passivating current density of the hole generating aluminum foil. According to the dual-section current waveform corrosion method for improving the length consistency of the channel holes of the medium and high voltage anode aluminum foil, the length consistency of the channel holes can be obviously improved, the hole combining phenomenon of the channel holes and corrosion thinning are reduced, and the specific capacitance and the bending resistance of the medium and high voltage aluminum foil are improved.

Owner:新疆广投桂东电子科技有限公司

Hole-creating corrosion method for controlling length and consistency of aluminium foil tunnel hole

ActiveCN105977029AGood length consistencyAdapt to Corrosion NeedsElectrolytic capacitorsMaterials scienceCorrosion

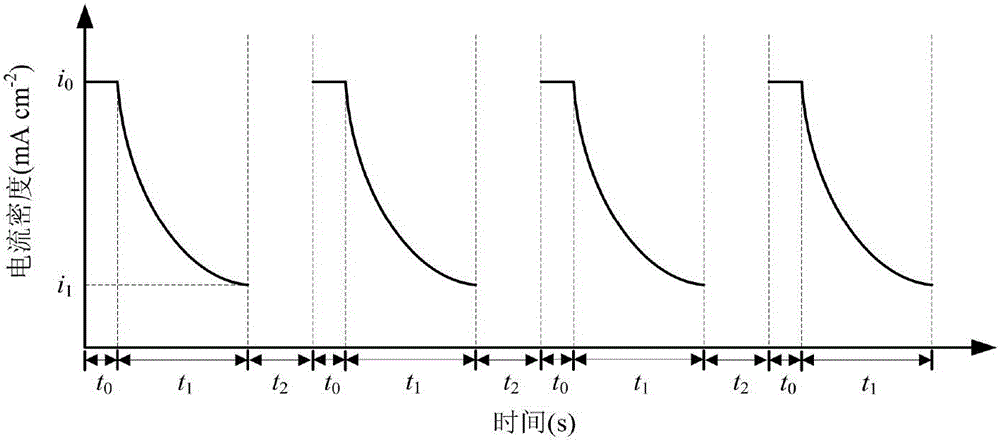

The invention discloses a hole-creating corrosion method for controlling a length and consistency of an aluminium foil tunnel hole. The method comprises steps of pretreatment, hoe-creating corrosion, hole-expanding corrosion, and post treatment. The invention mainly relates to the hole-creating corrosion technology. A tunnel hole growth kinetic curve of an aluminium foil in any hole-creating corrosion system and an anode maximum passivation current density of a hole-creating aluminium foil are tested; according to a needed tunnel hole length, corrosion time for each electrification, a lowest corrosion current density, and a current attenuation waveform are determined; and then an on-off hole-creating corrosion current waveform for controlling a length and consistency of a tunnel hole in a corresponding hole-creating corrosion system is obtained and electrifying corrosion is carried out by using the current waveform. According to the invention, the method is suitable for different hole-creating corrosion systems; corrosion in an aluminium foil can be carried out to obtain tunnel holes having different lengths and good length consistency. Meanwhile, tunnel holes with proper lengths can be formed according to aluminium foil corrosion with different thicknesses, so that the electrostatic specific volume of the aluminium foil can be improved effectively. The corrosion technology is suitable for a multi-V corrosion process; and compared with the one-time electrifying corrosion technology, the corrosion technology enables the production efficiency of the industrial aluminium foil corrosion to be improved obviously.

Owner:新疆广投桂东电子科技有限公司

Efficient cell culture system for hepatitis C virus genotype 7a

Owner:HVIDOVRE HOSPITAL

Metabolic evolution of escherchia coli strains that produce organic acids

This invention relates to the metabolic evolution of a microbial organism previously optimized for producing an organic acid in commercially significant quantities under fermentative conditions using a hexose sugar as sole source of carbon in a minimal mineral medium. As a result of this metabolic evolution, the microbial organism acquires the ability to use pentose sugars derived from cellulosic materials for its growth while retaining the original growth kinetics, the rate of organic acid production and the ability to use hexose sugars as a source of carbon. This invention also discloses the genetic change in the microorganism that confers the ability to use both the hexose and pentose sugars simultaneously in the production of commercially significant quantities of organic acids.

Owner:PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

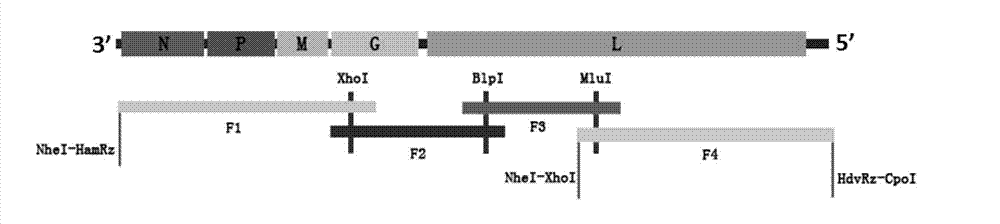

Preparation method of recombination live vector vaccines for diseases of canid and/or feline

The invention provides a method for preparing recombination live vector vaccines for diseases of canid and / or feline based on an RNA (ribose nucleic acid) virus rescuing technique, which is characterized in that a recombination virus expression vector capable of expressing main protective antigens of diseases of the canid and / or the feline based on a reverse genetic manipulation system is established. A rabies virus is conjunctly transfected by the expression vector and assistant plasmids to copy a permissive host cell to rescue the recombination virus, so that multivalent live vector vaccines are prepared. The growth curve of the virus presents that the rescued maternal virus has no obvious difference from the growth kinetic of the recombination virus which expresses the protective antigen genes of main disease pathogens of the canid and / or the feline, and a foundation is established for successfully preparing gene recombination live vector vaccines of main diseases of the canid and / or the feline.

Owner:MILITARY VETERINARY RES INST PLA MILITARY MEDICAL ACAD OF SCI

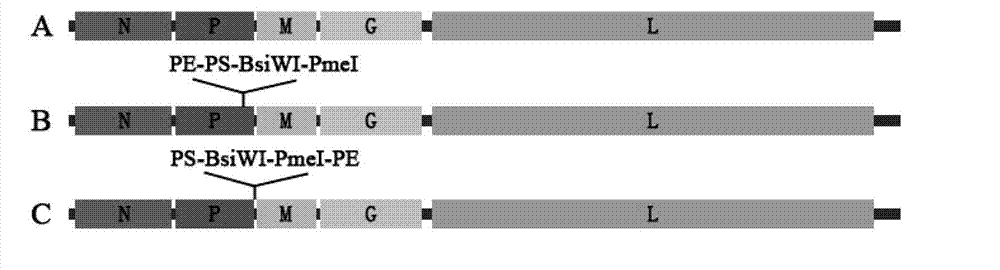

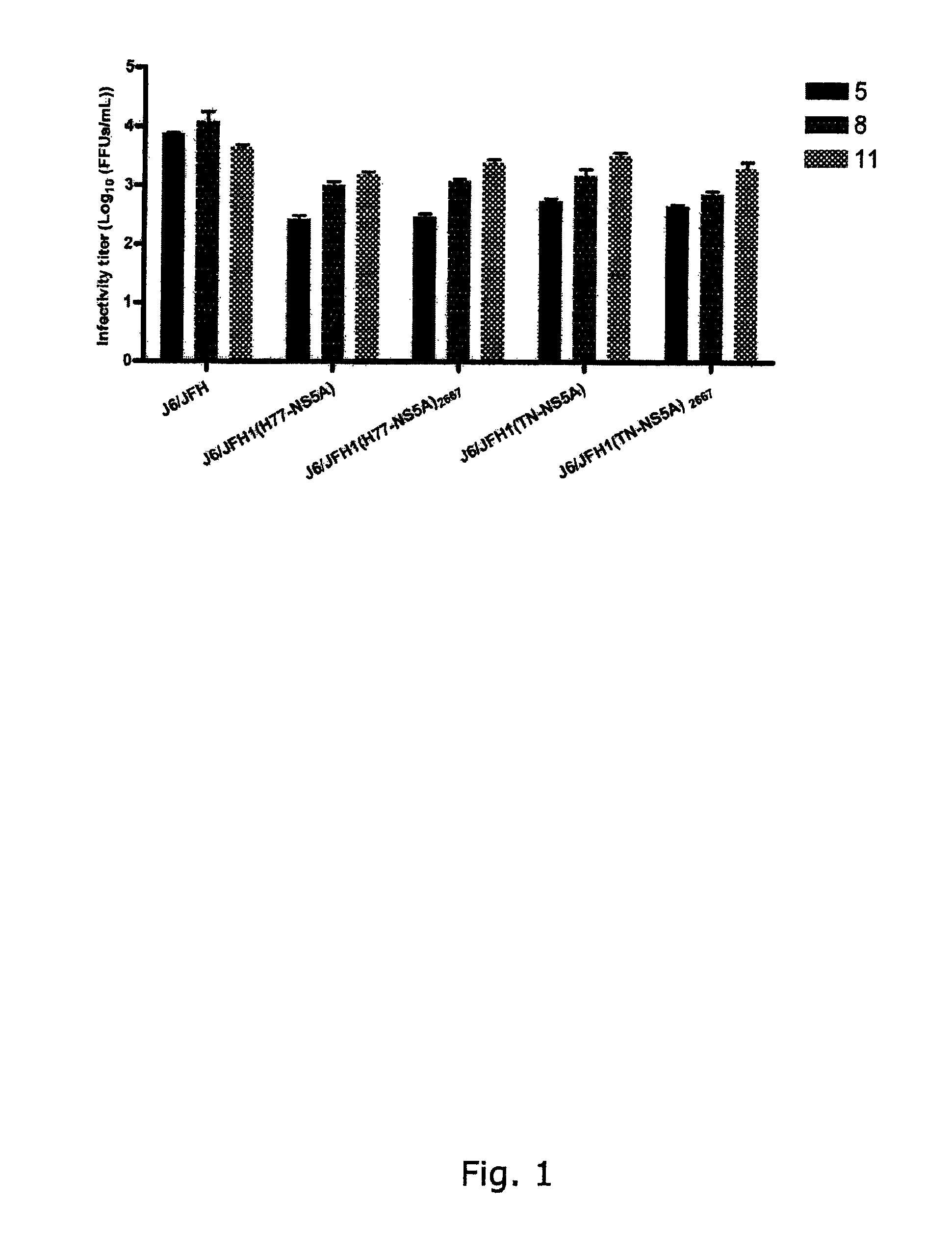

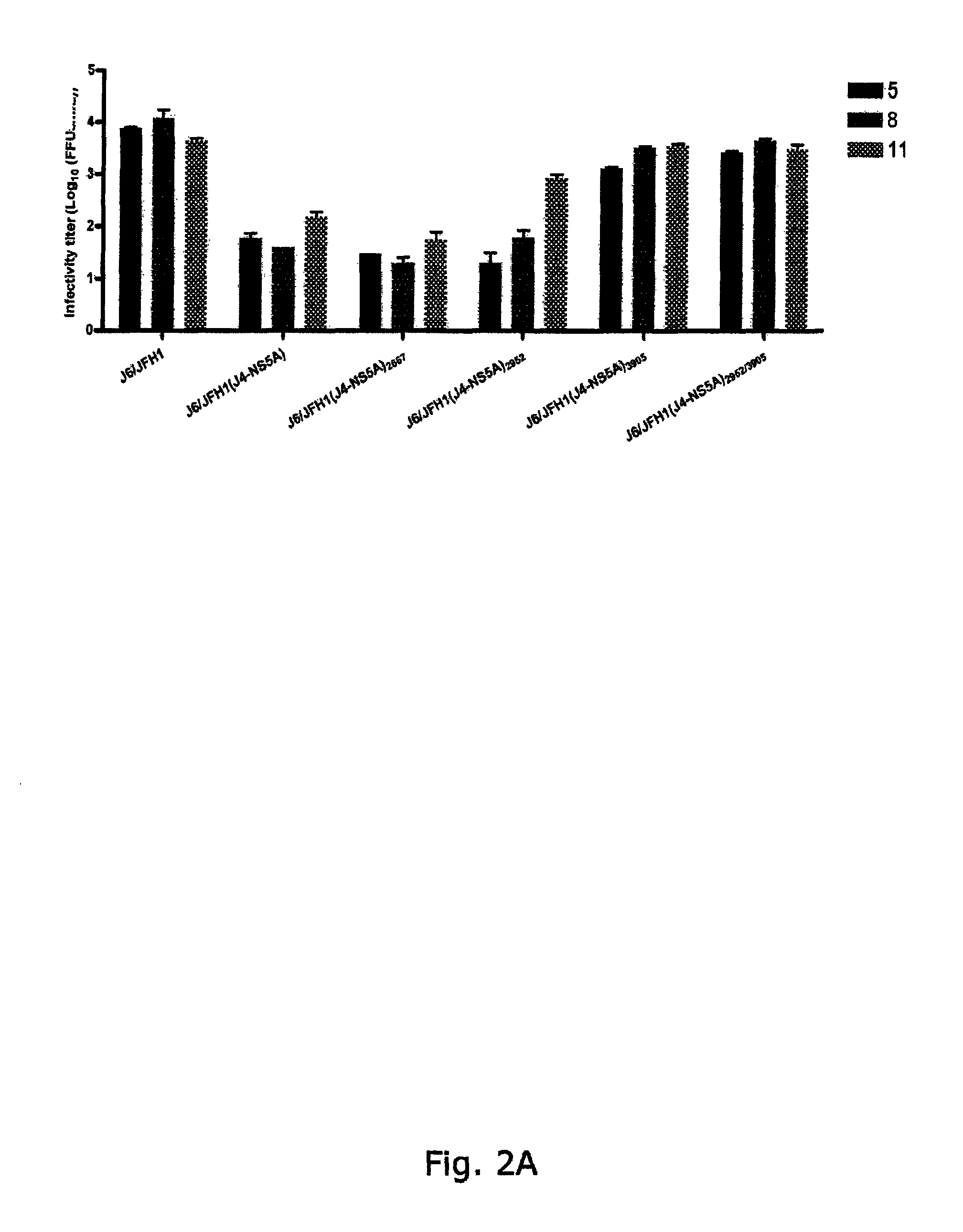

JFH-1 based HCV cell culture systems for NS5A of genotypes 1-7

The present inventors developed hepatitis C virus recombinants expressing NS5A from genotype 1a, 1b, 2a, 3a, 4a, 5a, 6a or 7a in the context of a genotype 2a backbone. Additional recombinants express NS5A and the structural proteins (Core, E1 and E2), p7 and NS2 from genotype 1a, 1b, 3a, 4a, 5a, 6a or 7a in the genotype 2a backbone. Sequence analysis of the recombinants recovered after viral passage in Huh7.5 cells revealed adaptive mutations in NS5A and / or NS3. The importance of these mutations for improved growth kinetics was shown in reverse genetic studies.

Owner:HVIDOVRE HOSPITAL +1

Cell culture system of a hepatitis C genotype 3a and 2a chimera

InactiveUS8945584B2SsRNA viruses positive-senseSugar derivativesHepatitis C virus genotypeHepatitis viral c

A robust and genetically stable cell culture system for Hepatitis C Virus (HCV) genotype 3a is provided. A genotype 3a / 2a (S52 / JFH1) recombinant containing the structural genes (Core, E1, E2), p7 and NS2 of strain S52 was constructed and characterized in Huh7.5 cells. S52 / JFH1 and J6 / JFH viruses passaged in cell culture had comparable growth kinetics and yielded similar peak HCV RNA titers and infectivity titers. Direct genome sequencing of cell culture derived S52 / JFH1 viruses identified putative adaptive mutations in Core, E2, p7, NS3, and NS5A; clonal analysis revealed that all genomes analyzed exhibited different combinations of these mutations. Finally, viruses resulting from transfection with RNA transcripts of five S52 / JFH1 recombinants containing these combinations of putative adaptive mutations performed as efficiently as J6 / JFH viruses in Huh7.5 cells and were all genetically stable after viral passage.

Owner:HVIDOVRE HOSPITAL

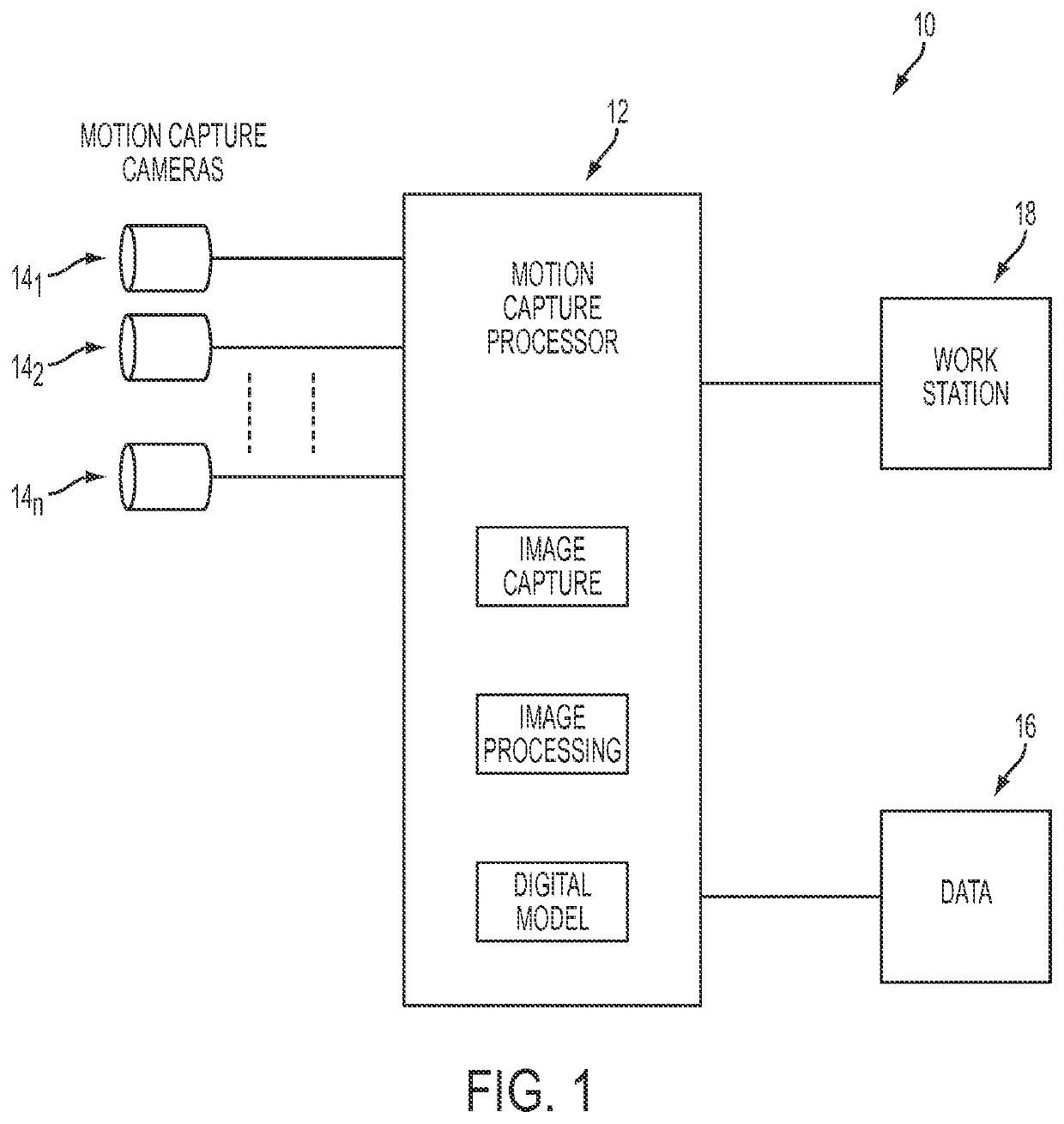

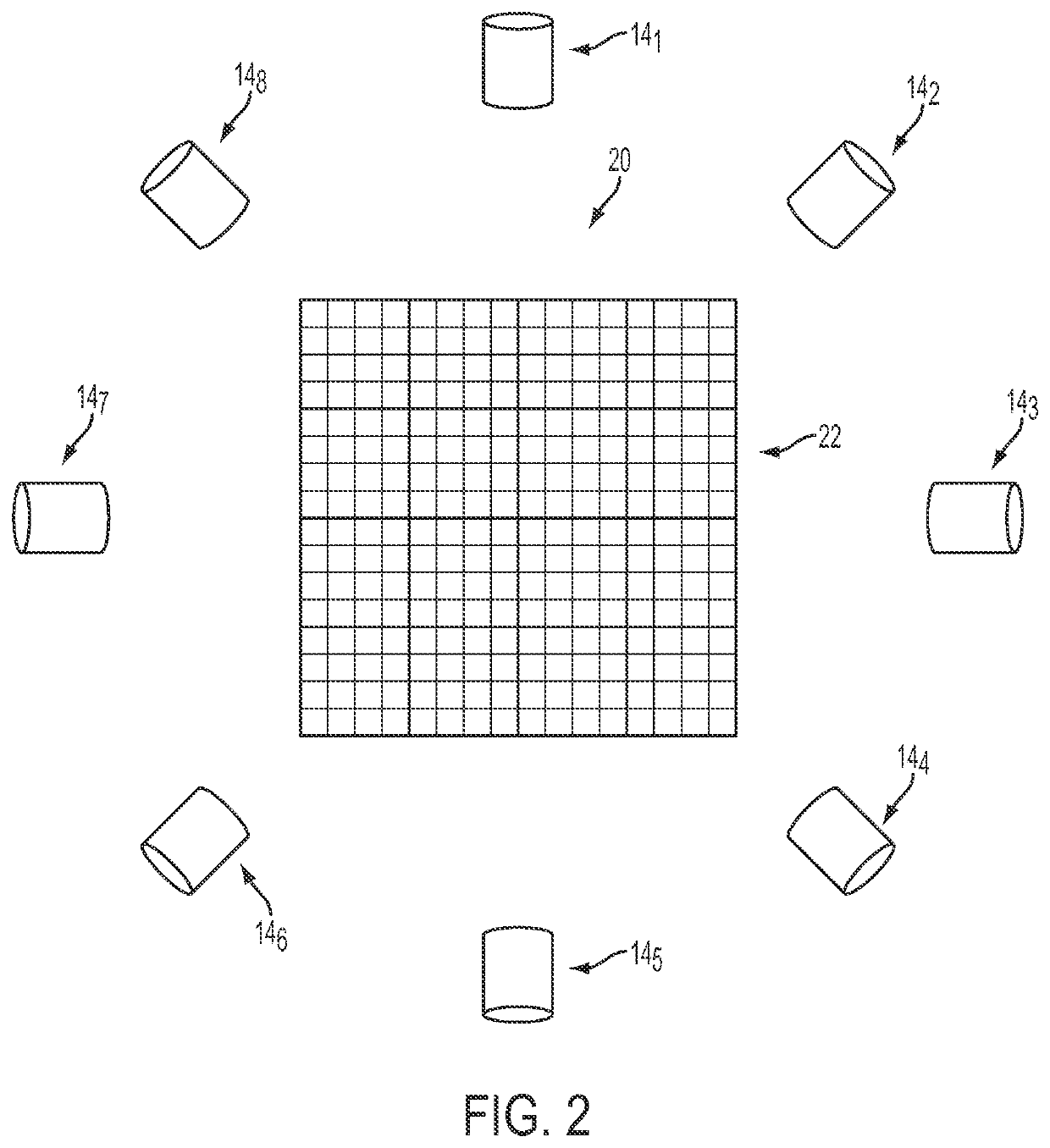

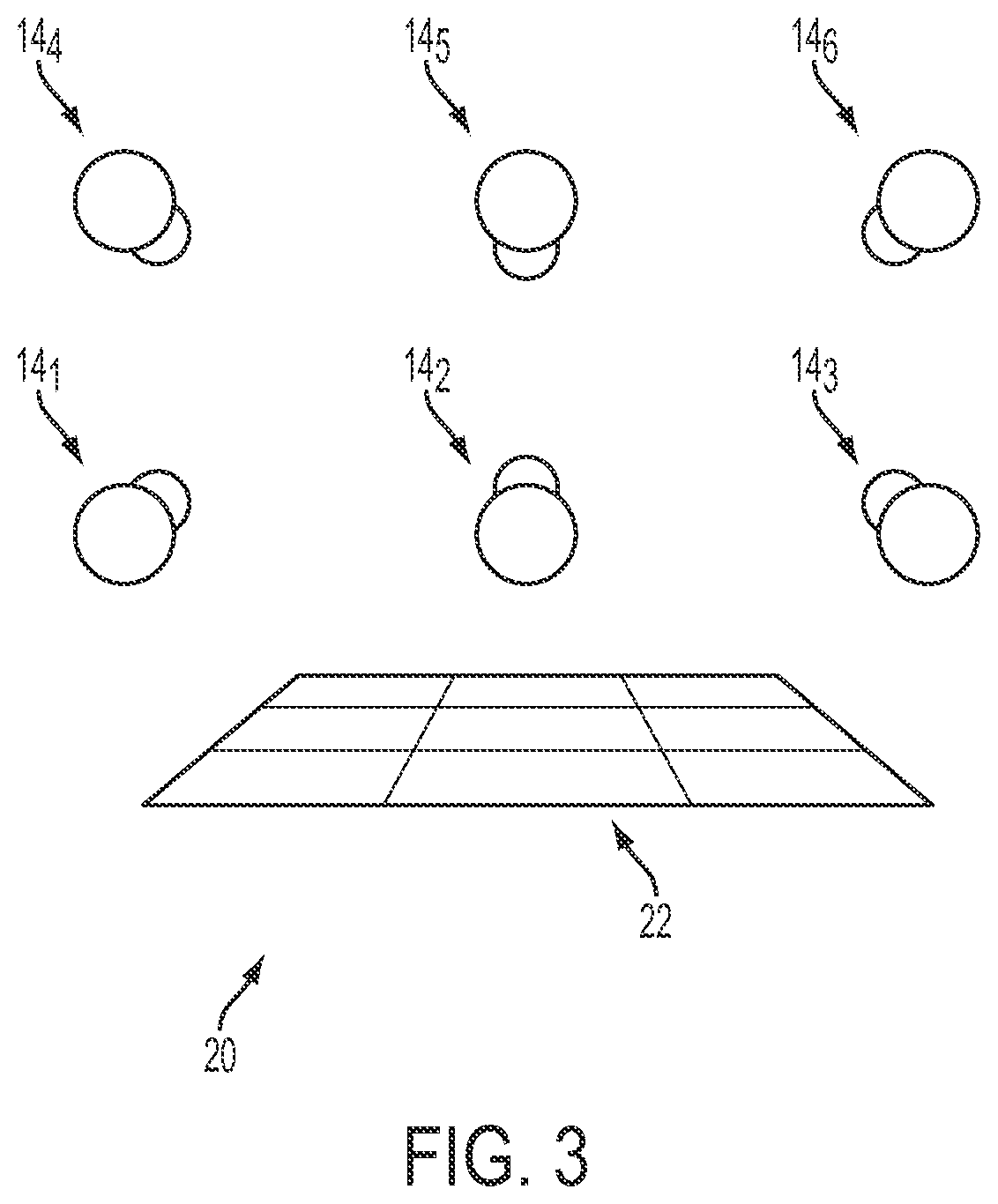

Plant growth kinetics captured by motion tracking

InactiveUS20210307259A1Improve throughputReduce analysisImage analysisCultivating equipmentsGrowth plantGrowth kinetic

Use of motion sensing and tracking equipment to image, monitor, track, and / or determine a parameter of plant growth kinetics (e.g., plant leaf elongation and height growth rate). Some embodiments concern methods for screening plants for the presence of one or more agronomic trait(s), and / or to study the growth kinetics of particular plants and cultivars, for example, in an automated high-throughput platform.

Owner:DOW AGROSCIENCES LLC

Metabolic evolution of escherichia coli strains that produce organic acids

This invention relates to the metabolic evolution of a microbial organism previously optimized for producing an organic acid in commercially significant quantities under fermentative conditions using a hexose sugar as sole source of carbon in a minimal mineral medium. As a result of this metabolic evolution, the microbial organism acquires the ability to use pentose sugars derived from cellulosic materials for its growth while retaining the original growth kinetics, the rate of organic acid production and the ability to use hexose sugars as a source of carbon. This invention also discloses the genetic change in the microorganism that confers the ability to use both the hexose and pentose sugars simultaneously in the production of commercially significant quantities of organic acids.

Owner:PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

Multiple frequency sputtering for enhancement in deposition rate and growth kinetics of dielectric materials

Owner:APPLIED MATERIALS INC

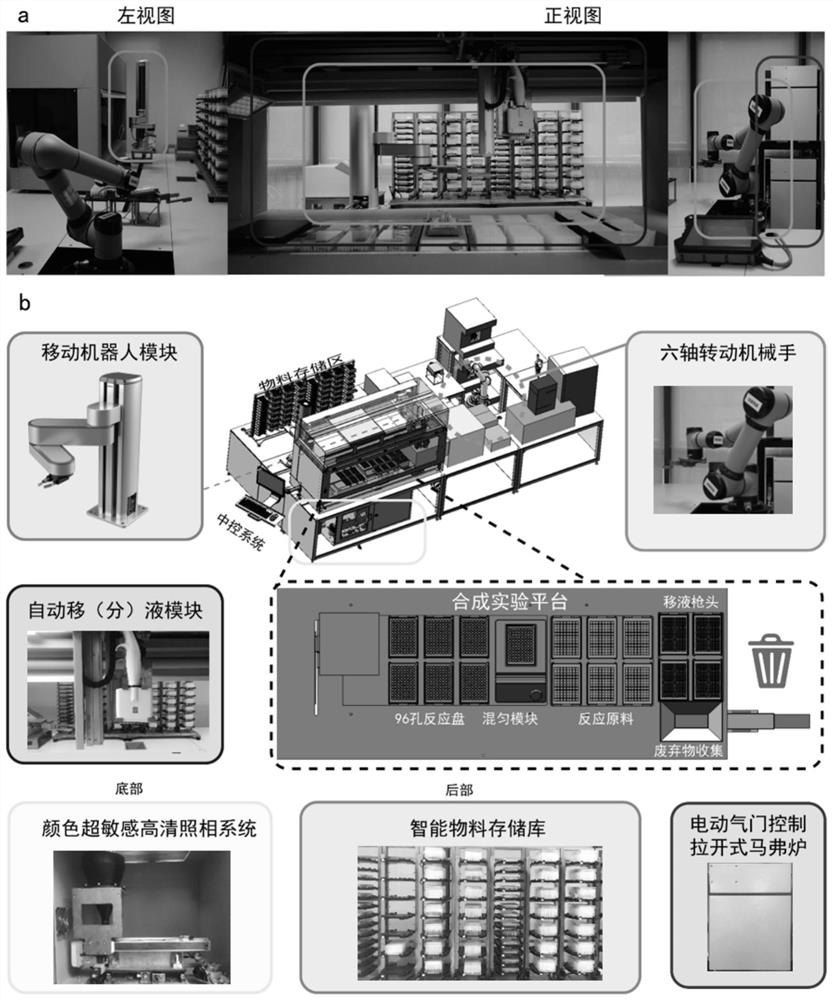

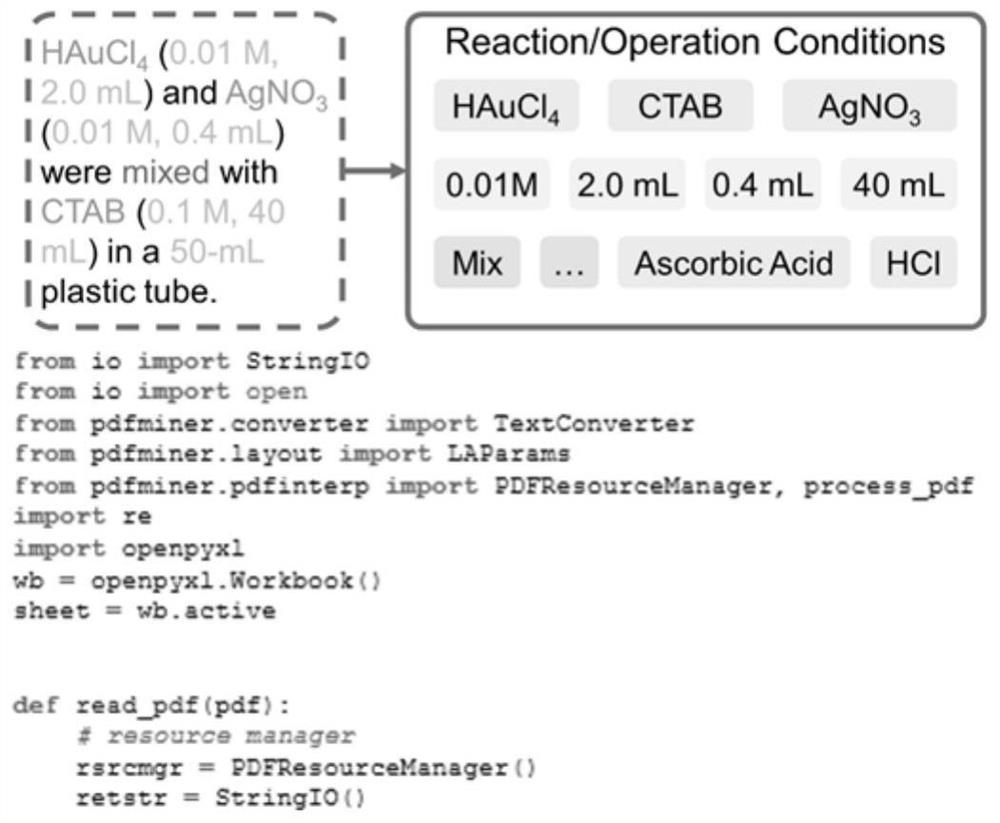

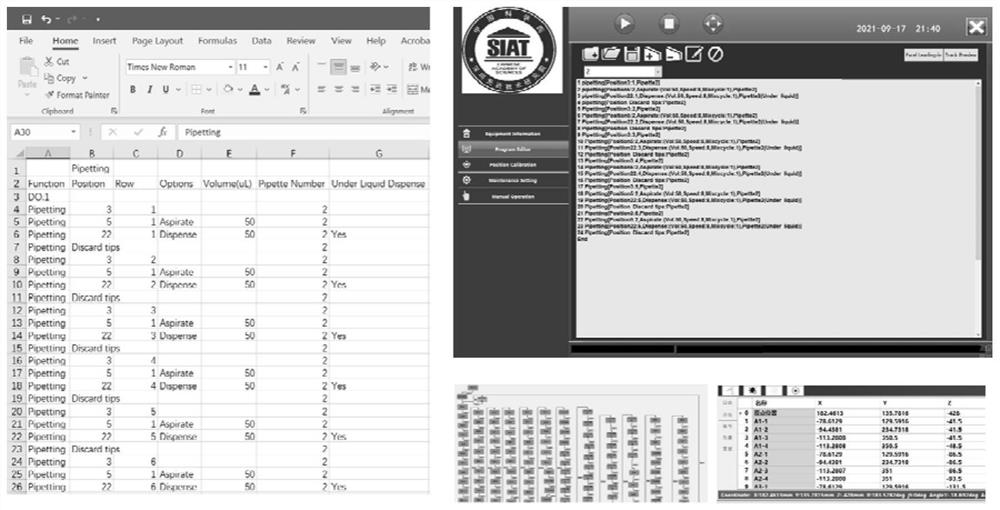

Programmable rational design method for whole process of nanocrystal material mathematical model, database and AI algorithm

PendingCN114329906AFully automatic synthesisDesign optimisation/simulationAlgorithmMathematical model

The invention relates to a programmable rational design method for a mathematical model, a database and an AI algorithm whole process of a nanocrystal material. Specifically, the invention discloses a full-process programmable rationality-based robot auxiliary device which comprises a nanocrystal preparation reaction execution module, a nanocrystal reaction liquid information acquisition module and a data storage and calculation module. Growth kinetic research of nanocrystals is realized through the equipment, a growth kinetic model and a related database are established, and a programmable rational design method is realized through machine learning. The equipment provided by the invention is full-automatic and higher in parallelism and accuracy, and reliable results can be realized under different experimental conditions verified by the equipment provided by the invention.

Owner:SHENZHEN INST OF ADVANCED TECH

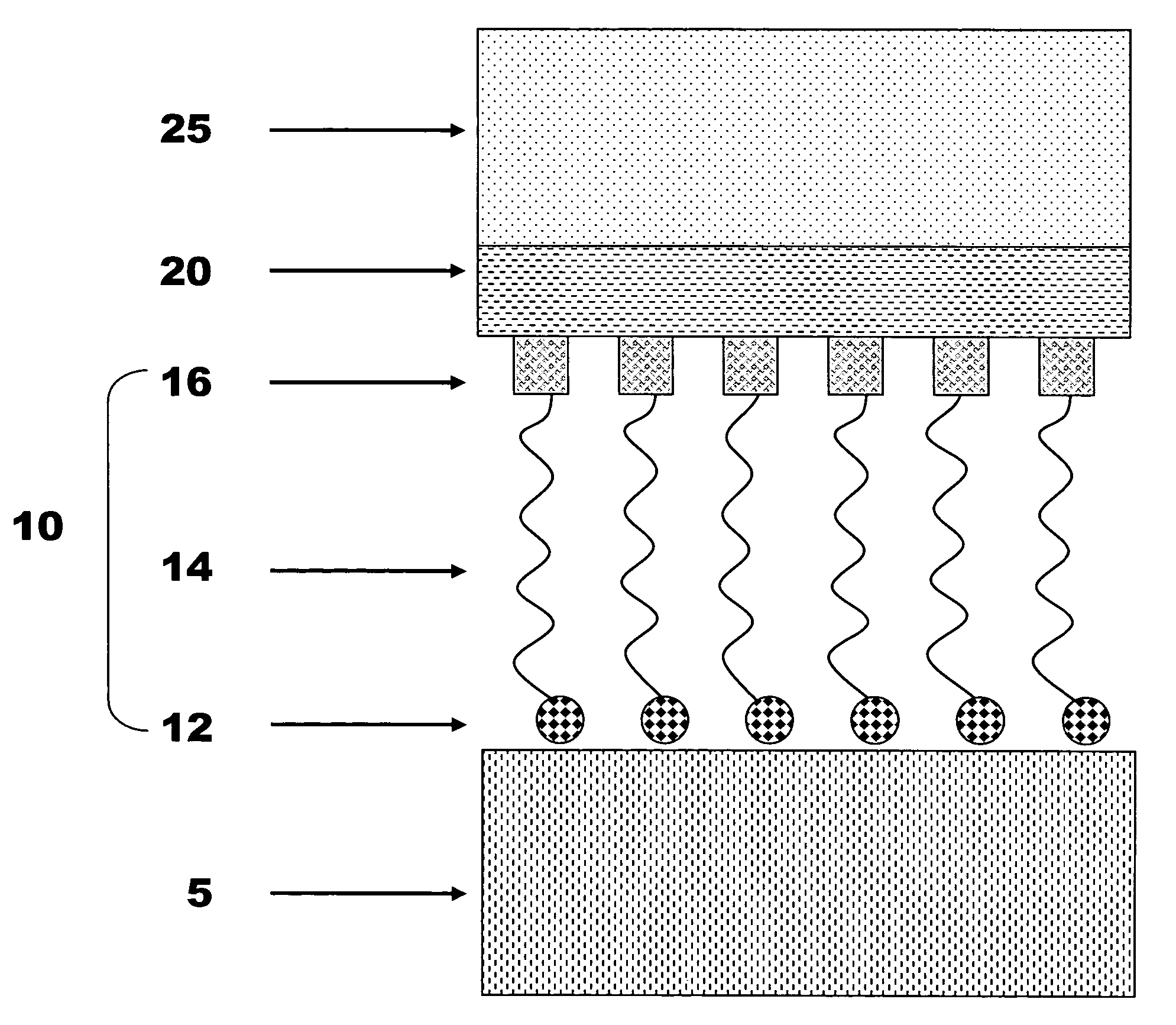

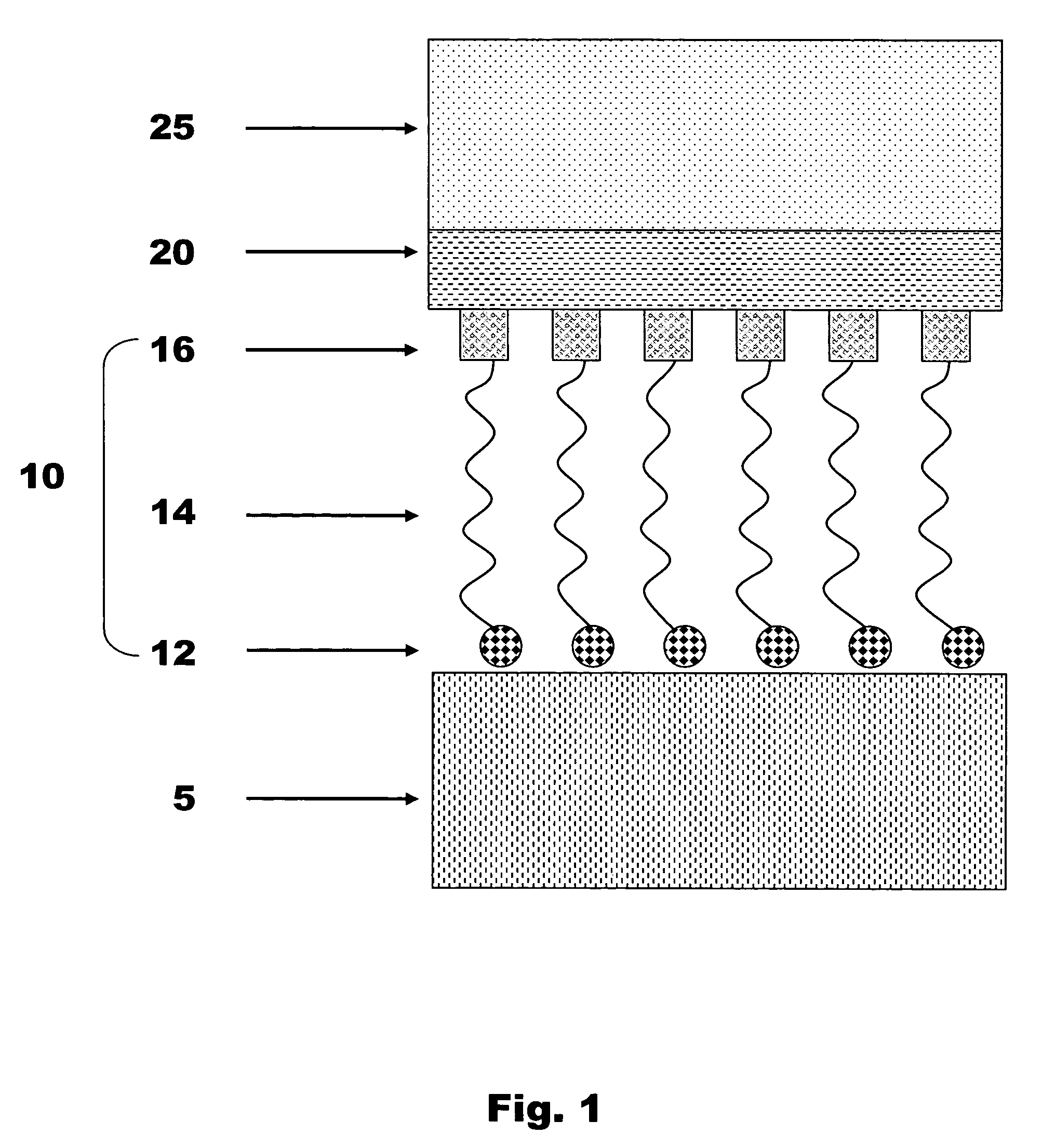

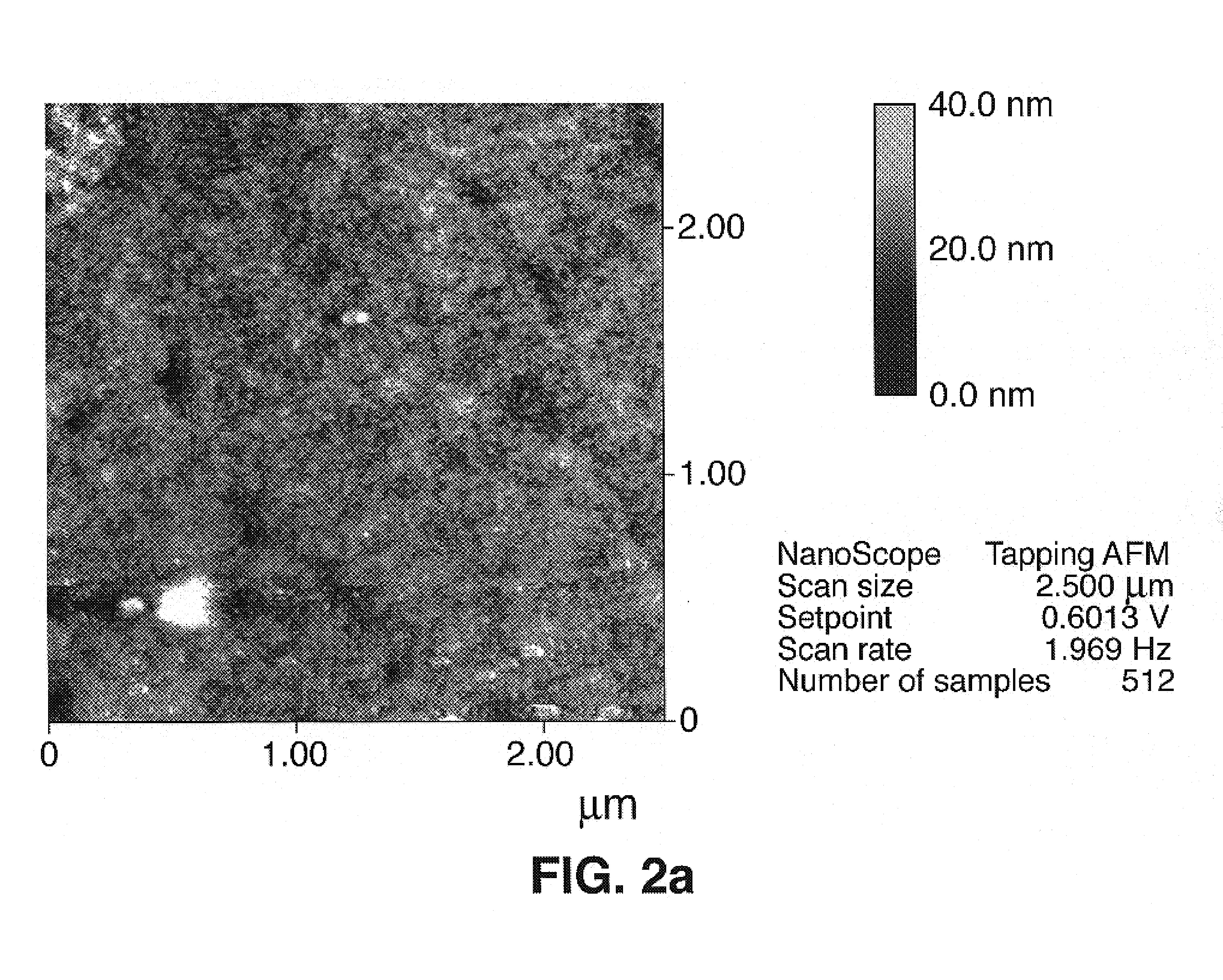

Method for fabricating hafnia films

InactiveUS7258745B2Material nanotechnologyPolycrystalline material growthCross-linkSelf-assembled monolayer

The present invention comprises a method for fabricating hafnia film comprising the steps of providing a substrate having a surface that allows formation of a self-assembled monolayer thereon via covalent bonding; providing an aqueous solution that provides homogeneous hafnium ionic complexes and hafnium nanoclusters wherein the aqueous solution is capable of undergoing homogeneous precipitation under controlled conditions for a desired period of time at a controlled temperature and controlled solution acidity for desired nanocluster nucleation and growth kinetics, desired nanocluster size, desired growth rate of film thickness and desired film surface characteristics. The method further comprising forming the self-assembled monolayer on the surface of the substrate wherein the self-assembled monolayer comprises a plurality of hydrocarbon chains cross-linked together along the surface of the substrate, the hydrocarbon chains being uniformly spaced from one another and wherein each of the hydrocarbon chains having a functional anchoring group at a first end of the chain covalently bonded with the surface of the substrate and each of the hydrocarbon chains having a functional terminating group projected away from the surface wherein the functional terminating group provides a bonding site for the hafnium film to grow; and exposing the substrate to the aqueous solution for a desired period of time at a controlled temperature wherein the hafnium ionic complexes and the hafnium nanoclusters are deposited on the bonding site of the functional terminating group thereby forming the hafnia film wherein the hafnium bonded to the hydrocarbons and to one another provide a uniform ordered arrangement defined by the uniform arrangement of the hydrocarbons.

Owner:UT BATTELLE LLC

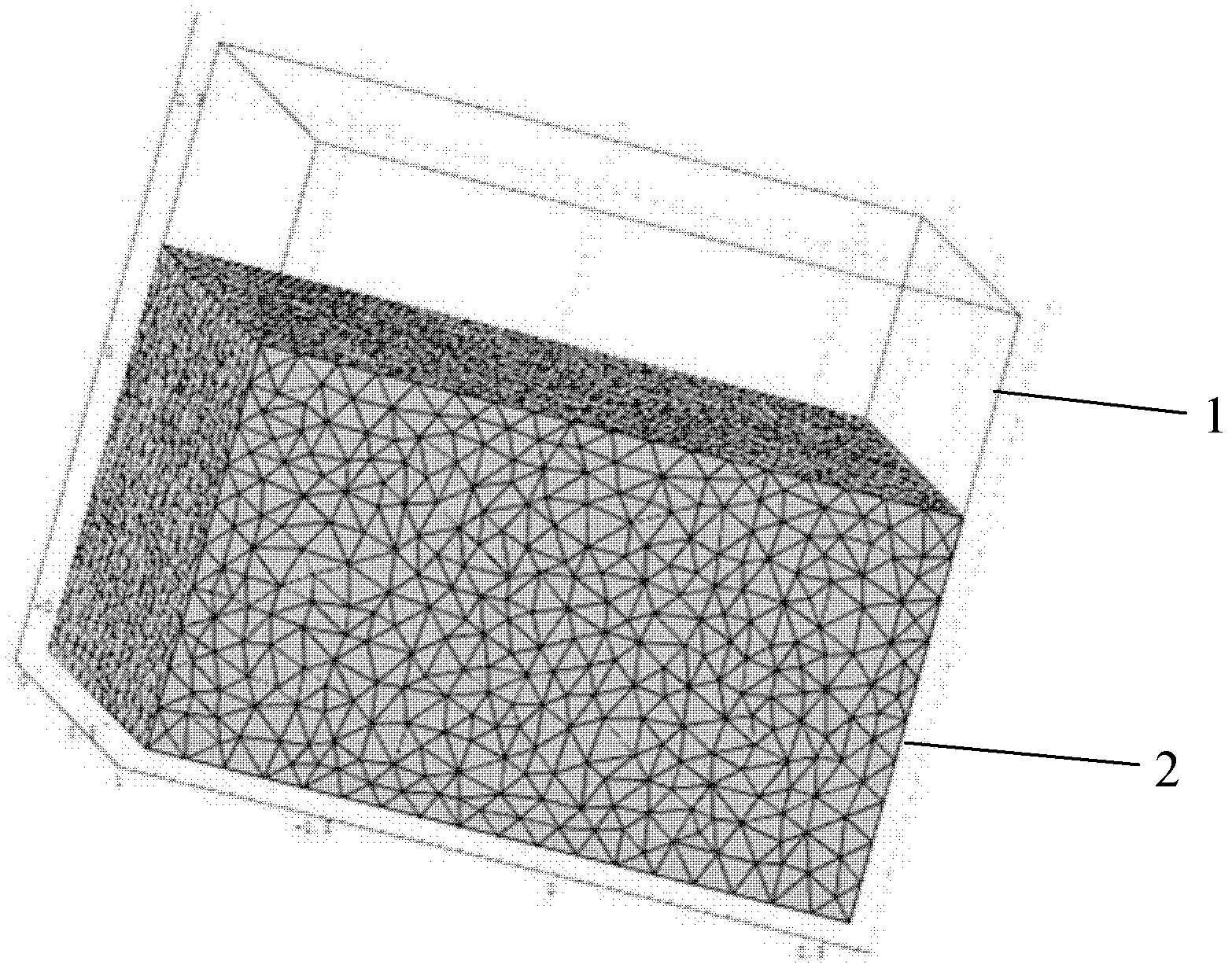

Method for optimizing loading way of solid-state fermentation substrate

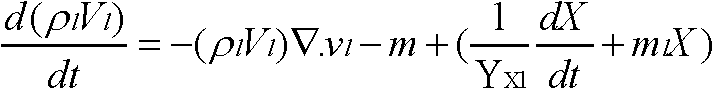

The invention discloses a method for optimizing loading way of solid-state fermentation substrate, specially a heat and mass transfer numerical analysis system for solid-state fermentation and a physical parameter system for solid-state fermentation substrate, comprising: establishing a mass-heat-bioreactor coupling model for the solid-state fermentation substrate, combining with computational fluid dynamics software, forming a numerical analysis system for solid-state fermentation; measuring the physical parameter of the fermentation substrate, growth kinetics parameter of the production strain and the fermentation operating parameter; through above numerical analysis system, obtaining the gas, heat, and biomass distribution regularity in the substrate bed and in the surrounding environment, so as to further judge the better size and proportional range of the substrate bed and the surrounding environment. The analysis system can be used for optimizing loading way of solid-state fermentation substrate, which can help improve the production efficiency of solid-state fermentation and enlarge the engineering scale.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

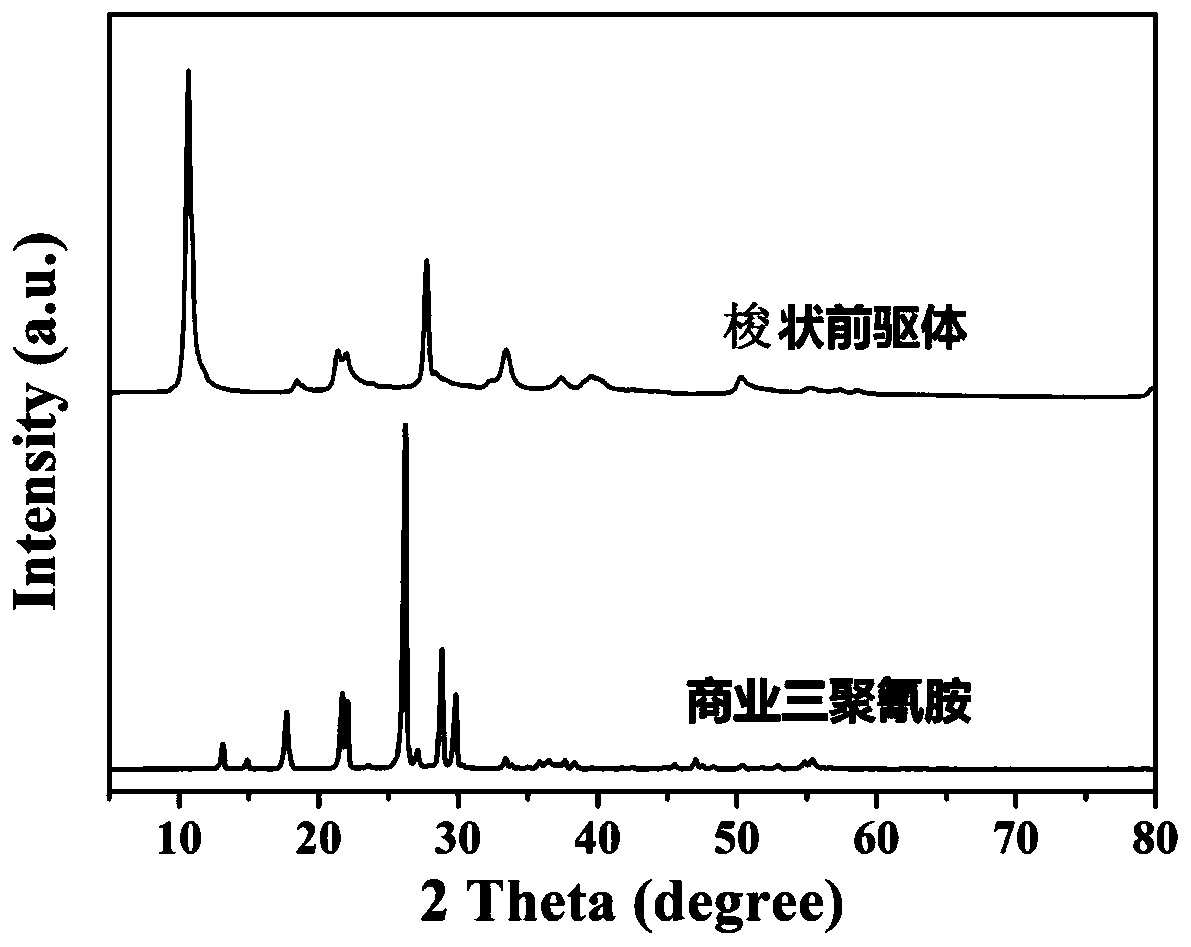

Hollow fusiform carbon nitride micrometer structure and preparation method and application thereof

ActiveCN110743597AGood repeatabilityUniform size distributionPhysical/chemical process catalystsNitrogen-metal/silicon/boron binary compoundsCarbon nitrideGrowth kinetic

The invention discloses a hollow fusiform carbon nitride micrometer structure and a preparation method and application thereof. The preparation method comprises the preparation steps: nitrogen-containing organic precursors are dispersed in water and subjected to hydrothermal pretreatment at 180-210 DEG C; after the temperature is decreased to be 60-120 DEG C, a reaction still is opened, transparent reaction liquid is transferred into other containers to be stirred, and white precursors are precipitated; and the white precursors are calcinated under gas protection, and the hollow fusiform carbon nitride micrometer structure is obtained. Through a method for controlling a precipitation mode of the precursors, the growth kinetics process of the precursors is changed, and a hollow fusiform carbon nitride material is synthesized for the first time; and hollow fusiform carbon nitride synthesized through the method is uniform in morphology, and the visible-light response area of the hollow fusiform carbon nitride is expanded, in the aspect of visible-light photocatalytic hydrogen production, the hydrogen production property of the hollow fusiform carbon nitride is qualitatively improved compared with pure flaky carbon nitride, and the hollow fusiform carbon nitride micrometer structure has important application in the fields of photocatalysis and the like.

Owner:UNIV OF JINAN

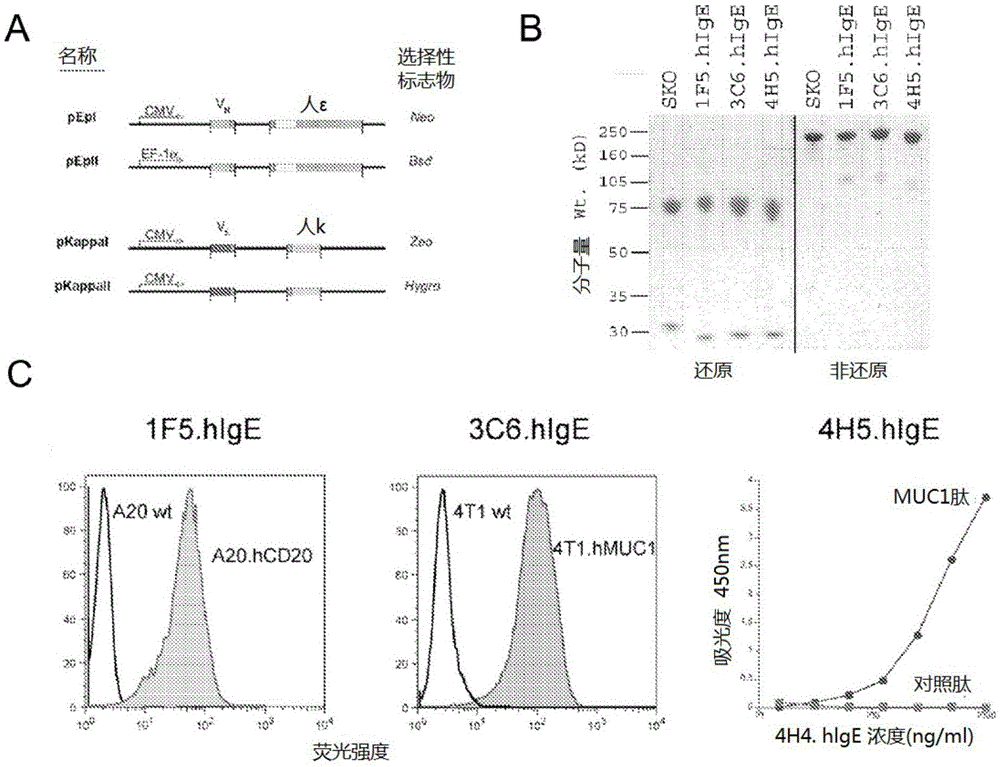

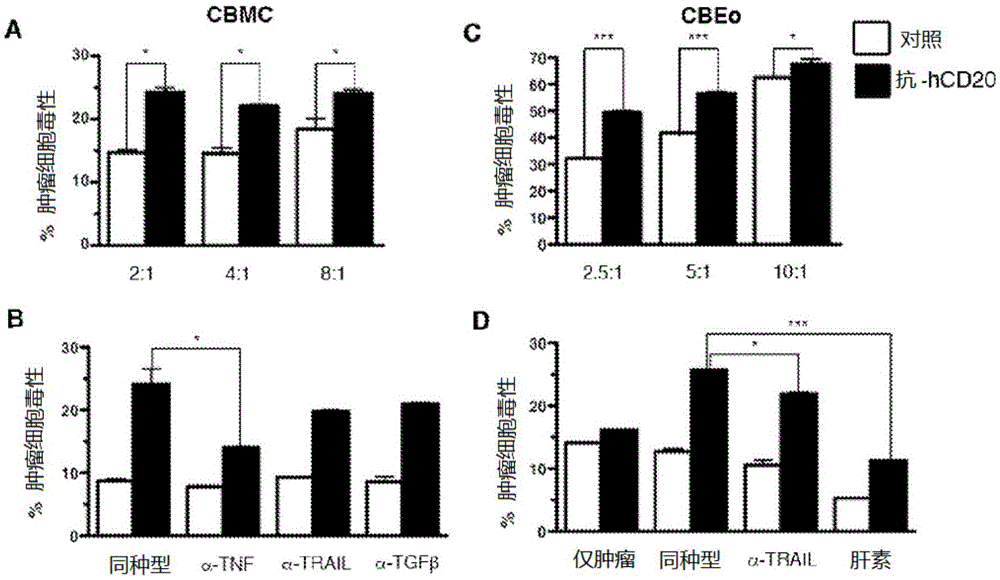

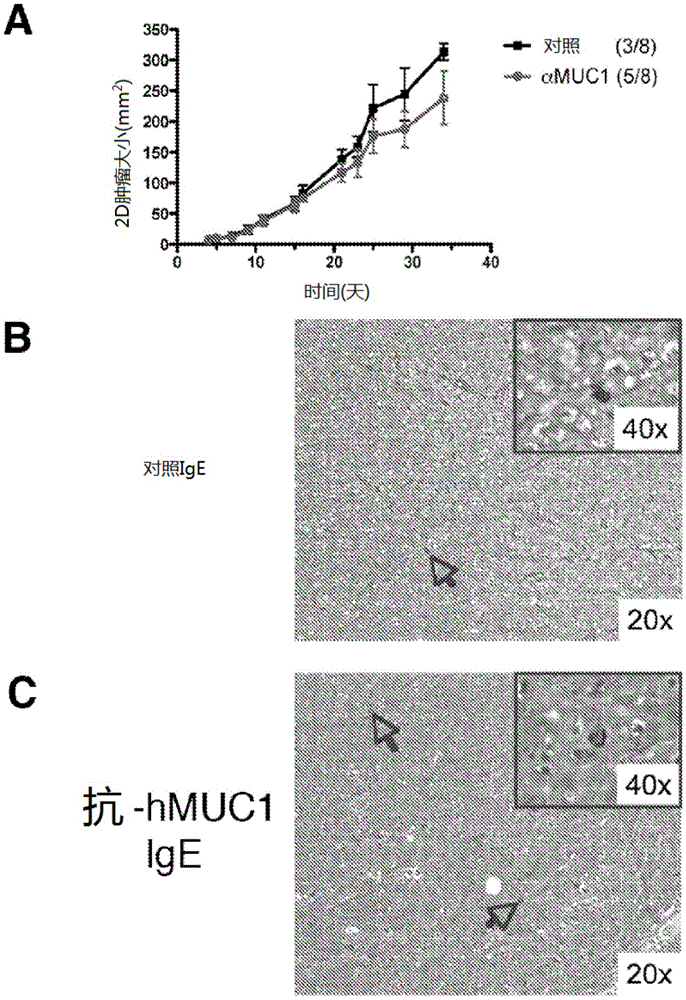

IgE antibodies for the inhibition of tumor metastasis

ActiveCN105431205AInhibition of the ability to mediate tumor metastasisAbility to inhibit metastasisAntibody ingredientsImmunoglobulinsLymphatic SpreadCancer cell

The present invention provides novel IgE antibodies useful for inhibiting or preventing metastatic cancer. Also provided are methods to inhibit tumor metastasis by modulating the activity of at least one non-tumor cell, treating a patient to inhibit or prevent the appearance of tumor metastases derived from a primary solid tumor, treating established metastatic carcinoma, reducing metastasis of carcinoma cells, and reducing the growth kinetics of a primary solid tumor or a metastasized cell or tumor.

Owner:斯坦福大学董事会

Method for defoaming in organism aerobic batch cultivation

InactiveCN101810945ANovel ideaGood defoaming effectTreatment using aerobic processesSustainable biological treatmentCulture fluidSludge

For solving the problem that a large amount of air bubbles are generated in an organism aerobic batch cultivation process, the invention, based on the knowledge of microorganism growth kinetics and micro ecological kinetics, develops an active defoaming method for controlling foam generation. Obviously differing from the passive defoaming method or foam end control methods represented by defoamers and defoaming devices, the method effectively controls the generation of foam by allowing part of mixed liquid in an original building to run in the traditional inlet and outlet water pipes in a backflow and circulation mode, namely a fake continuous running mode, and by controlling parameters such a backflow speed and an upflow speed in a reaction structure. The method avoids using a defoamer or defoaming device and polluting culture liquid with the defoamer, retains the structure of the original structure, saves investment cost to a maximum degree, and meets the requirements for cost-effect combination and low operation cost in actual operation. The method is mainly suitable to be used for removing foam generated in a sludge batch aerobic culture process in the field of waste water biological treatment and an aerobic batch fermentation process in the field of biological fermentation.

Owner:BEIJING NORMAL UNIVERSITY

Spirofluorenexanthene disubstituted carbazole based organic nanometer material and preparation method thereof

InactiveCN108409723AAchieving controllable equipmentEasy to operateMaterial nanotechnologyOrganic chemistry methodsOctahedronOxygen

The invention relates to a spirofluorenexanthene disubstituted carbazole based organic nanometer material and a preparation method thereof. A typical reprecipitation method is utilized to prepare nanocrystals, and control of growth kinetics is realized by regulating a supersaturation degree of a target compound in the crystallization process, so that a series of organic nanometer crystals with uniform size and controllable morphology are produced, and the morphology transformation process of the organic nanometer crystals from two-dimensional rhombic nanosheets to three-dimensional long octahedrons is discovered.

Owner:NANJING UNIV OF POSTS & TELECOMM

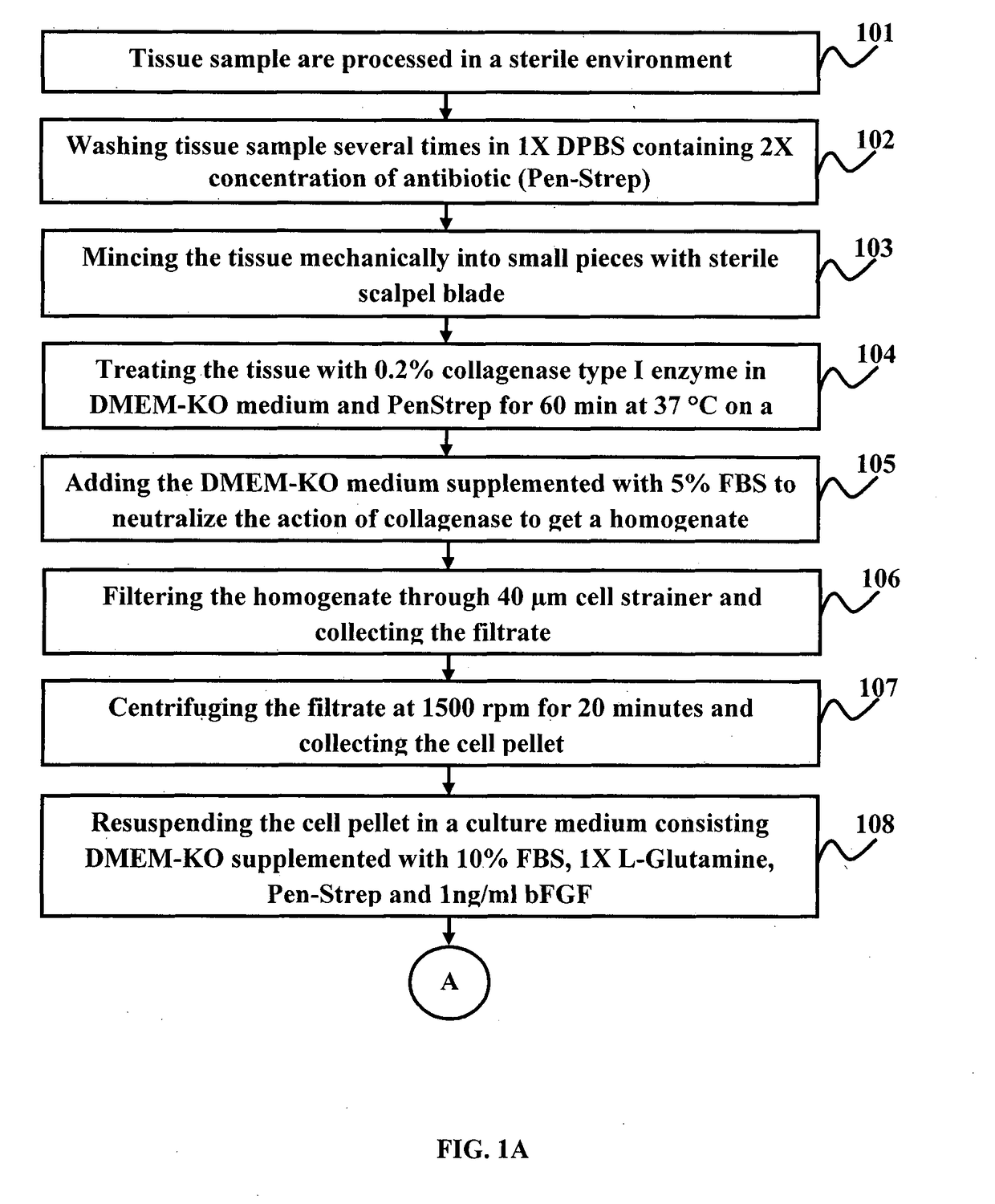

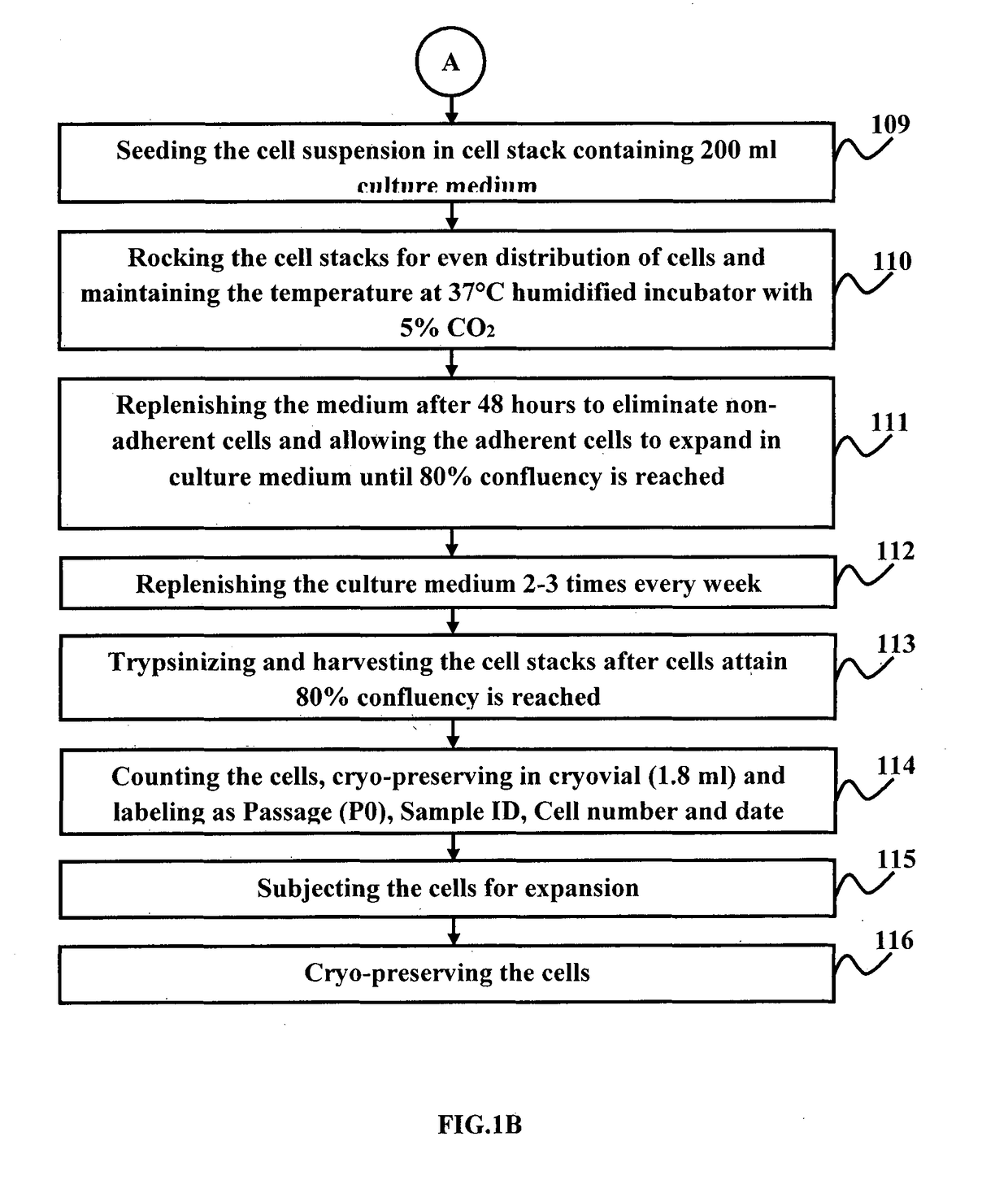

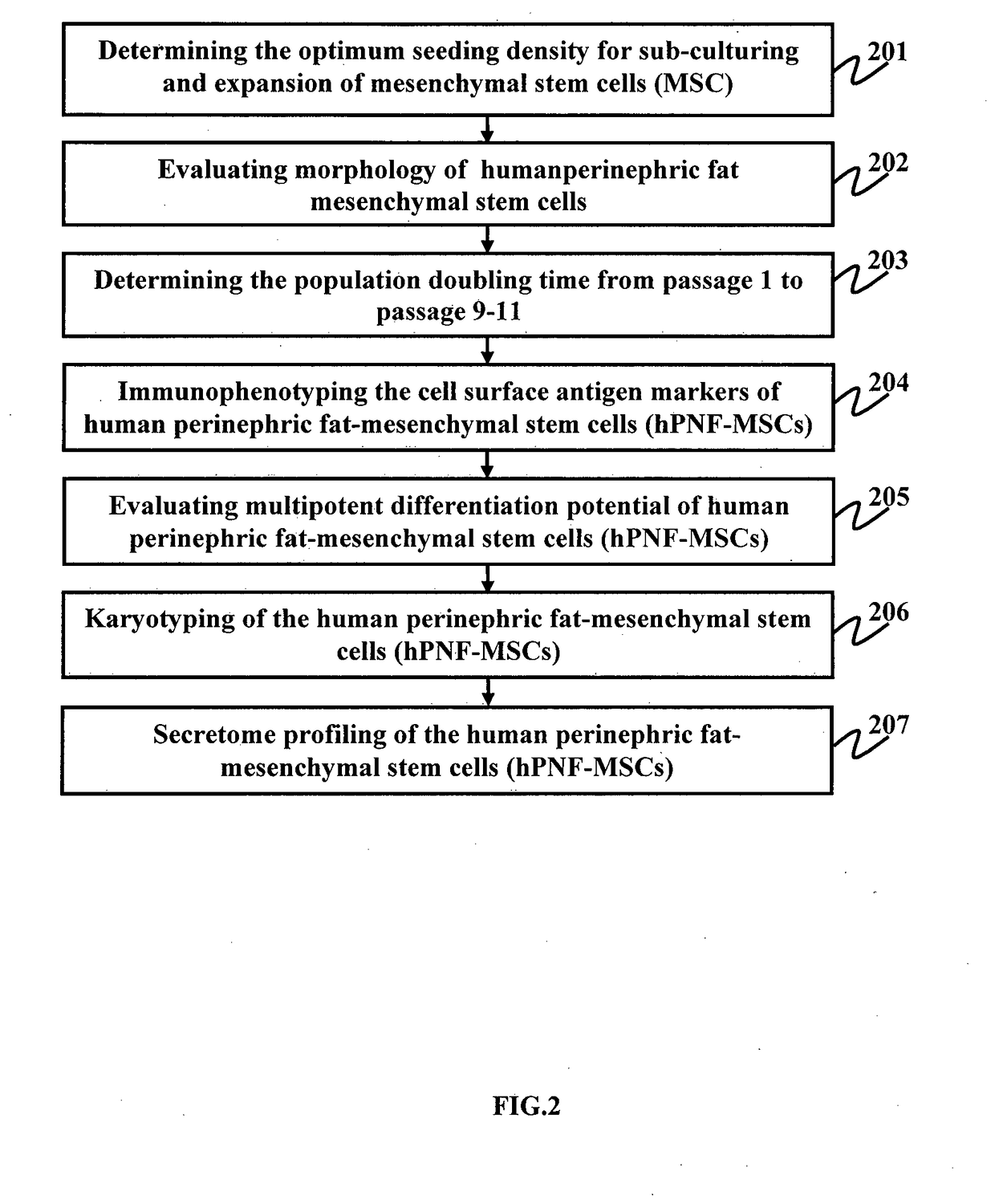

A method for the regeneration and differentiation of human perinephric fat derived mesenchymal stromal cells into astroglial, renal, neuronal and pancreatic progenitor cells

InactiveUS20190055519A1Confirms the differentiation of the hPNF-MSCsPositive expressionCell dissociation methodsPancreatic cellsProgenitorCytokine

The embodiments of the present invention provide a method for the regeneration and differentiation of human perinephric fat derived mesenchymal stromal cells (hPNF-MSCs) into astroglial, renal, neuronal progenitor cells and pancreatic islet cells. The hPNF-MSCs are advantageous over bone marrow or other stem cell source due to the abundance and ease of isolation. The perinephric fat derived stromal cells are used in the treatment of neurodegenerative disorder, renal disorder and pancreatic malfunction. The method for the regeneration and differentiation of hPNF-MSCs includes isolation of the human perinephric fat derived stromal cells followed by expansion of the stem cells and cryopreservation. The cells are characterized by morphological evaluation of hPNF-MSC, growth kinetics, immunophenotypic evaluation, differentiation potential analysis, karyotyping and secretome profiling (cytokines, chemokines, and growth factors). The stem cells are differentiated into astroglial cells, neural cells renal cells and pancreatic islet cells.

Owner:NEELAM KRISHMAN VENKATARAMANAA

A pore corrosion method for controlling the length and consistency of tunnel holes in aluminum foil

ActiveCN105977029BGood length consistencyAdapt to Corrosion NeedsElectrolytic capacitorsCorrosionStatic electricity

The invention discloses a hole-creating corrosion method for controlling a length and consistency of an aluminium foil tunnel hole. The method comprises steps of pretreatment, hoe-creating corrosion, hole-expanding corrosion, and post treatment. The invention mainly relates to the hole-creating corrosion technology. A tunnel hole growth kinetic curve of an aluminium foil in any hole-creating corrosion system and an anode maximum passivation current density of a hole-creating aluminium foil are tested; according to a needed tunnel hole length, corrosion time for each electrification, a lowest corrosion current density, and a current attenuation waveform are determined; and then an on-off hole-creating corrosion current waveform for controlling a length and consistency of a tunnel hole in a corresponding hole-creating corrosion system is obtained and electrifying corrosion is carried out by using the current waveform. According to the invention, the method is suitable for different hole-creating corrosion systems; corrosion in an aluminium foil can be carried out to obtain tunnel holes having different lengths and good length consistency. Meanwhile, tunnel holes with proper lengths can be formed according to aluminium foil corrosion with different thicknesses, so that the electrostatic specific volume of the aluminium foil can be improved effectively. The corrosion technology is suitable for a multi-V corrosion process; and compared with the one-time electrifying corrosion technology, the corrosion technology enables the production efficiency of the industrial aluminium foil corrosion to be improved obviously.

Owner:新疆广投桂东电子科技有限公司

Preparation method of recombination live vector vaccines for diseases of canid and/or feline

The invention provides a method for preparing recombination live vector vaccines for diseases of canid and / or feline based on an RNA (ribose nucleic acid) virus rescuing technique, which is characterized in that a recombination virus expression vector capable of expressing main protective antigens of diseases of the canid and / or the feline based on a reverse genetic manipulation system is established. A rabies virus is conjunctly transfected by the expression vector and assistant plasmids to copy a permissive host cell to rescue the recombination virus, so that multivalent live vector vaccines are prepared. The growth curve of the virus presents that the rescued maternal virus has no obvious difference from the growth kinetic of the recombination virus which expresses the protective antigen genes of main disease pathogens of the canid and / or the feline, and a foundation is established for successfully preparing gene recombination live vector vaccines of main diseases of the canid and / or the feline.

Owner:MILITARY VETERINARY RES INST PLA MILITARY MEDICAL ACAD OF SCI

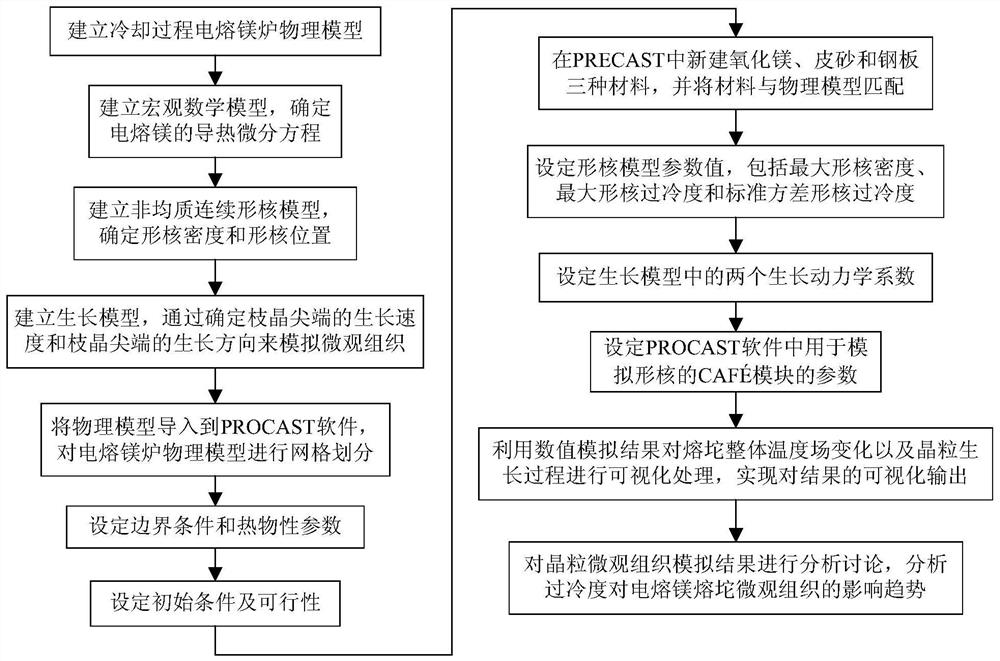

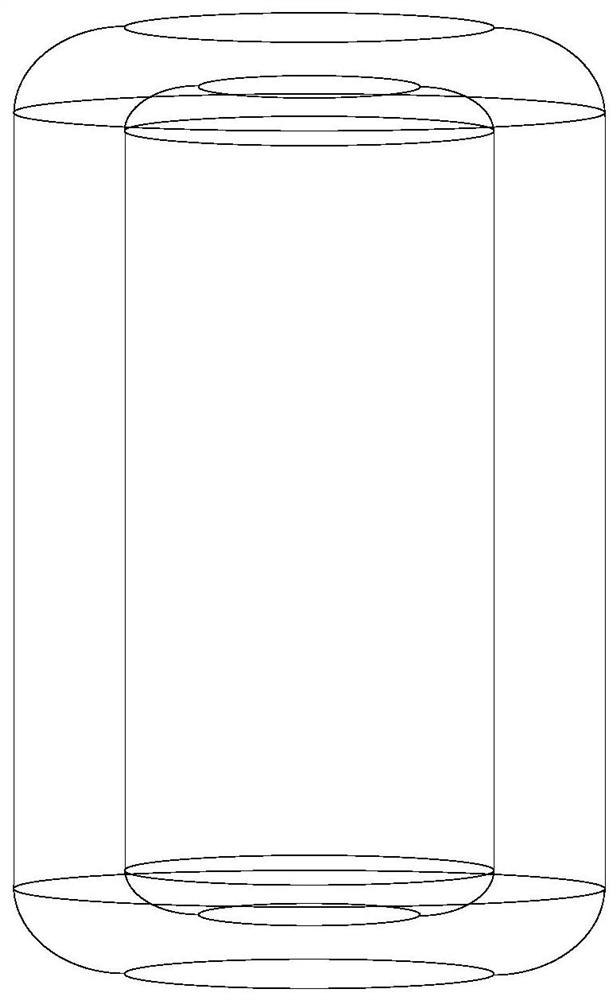

A numerical simulation method for improving the crystalline quality of fused magnesium lumps

ActiveCN107423460BQuality improvementReduce the number of experimentsDesign optimisation/simulationSpecial data processing applicationsMaterial resourcesPericlase

The invention provides a numerical simulation method for improving the crystal quality of fused magnesium molten lumps, and relates to the technical field of quality optimization of fused magnesium products. This method first establishes a macro-micro unified model that couples macro-heat transfer, micro-nucleation and growth kinetics, and then uses PROCAST software to numerically simulate the temperature field and microstructure during the cooling and solidification process of fused magnesium. The changes in the overall temperature field of the lump and the grain growth process were visualized and the results analyzed and discussed, and the trend of the influence of supercooling on the microstructure of the fused magnesium lump was analyzed. The present invention performs mathematical physical modeling and numerical simulation on the heat exchange and microstructure formation process during the cooling and solidification process of the fused magnesium lump. By controlling parameters such as heat exchange conditions, the structure is understood and controlled based on its solidification law. Formation, preparation for the production of high-grade periclase, effectively reducing the number of experiments, saving manpower and material resources, thereby improving the quality of actual production of periclase products.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com