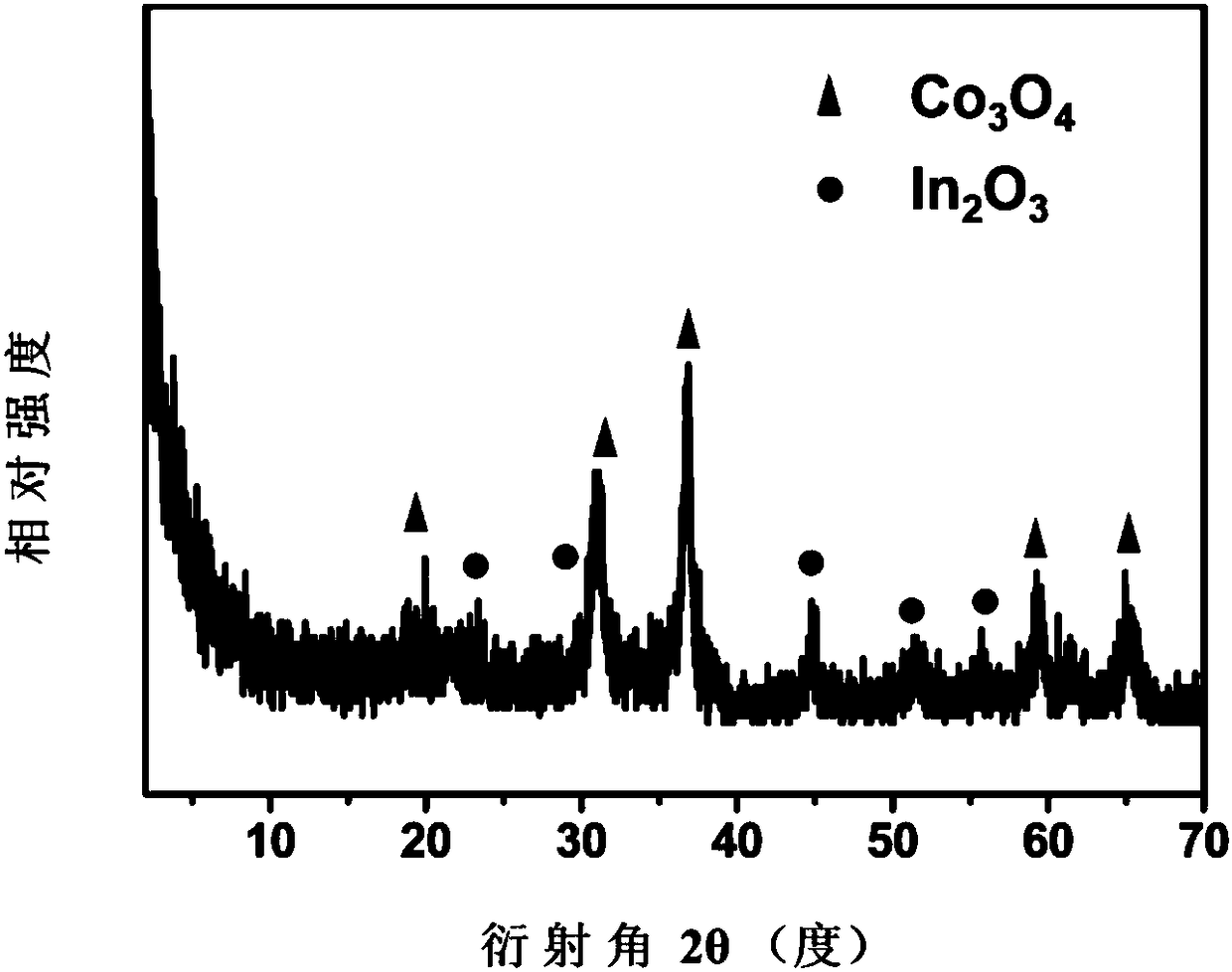

Multilevel structure metal oxide gas sensitive material and preparation method thereof

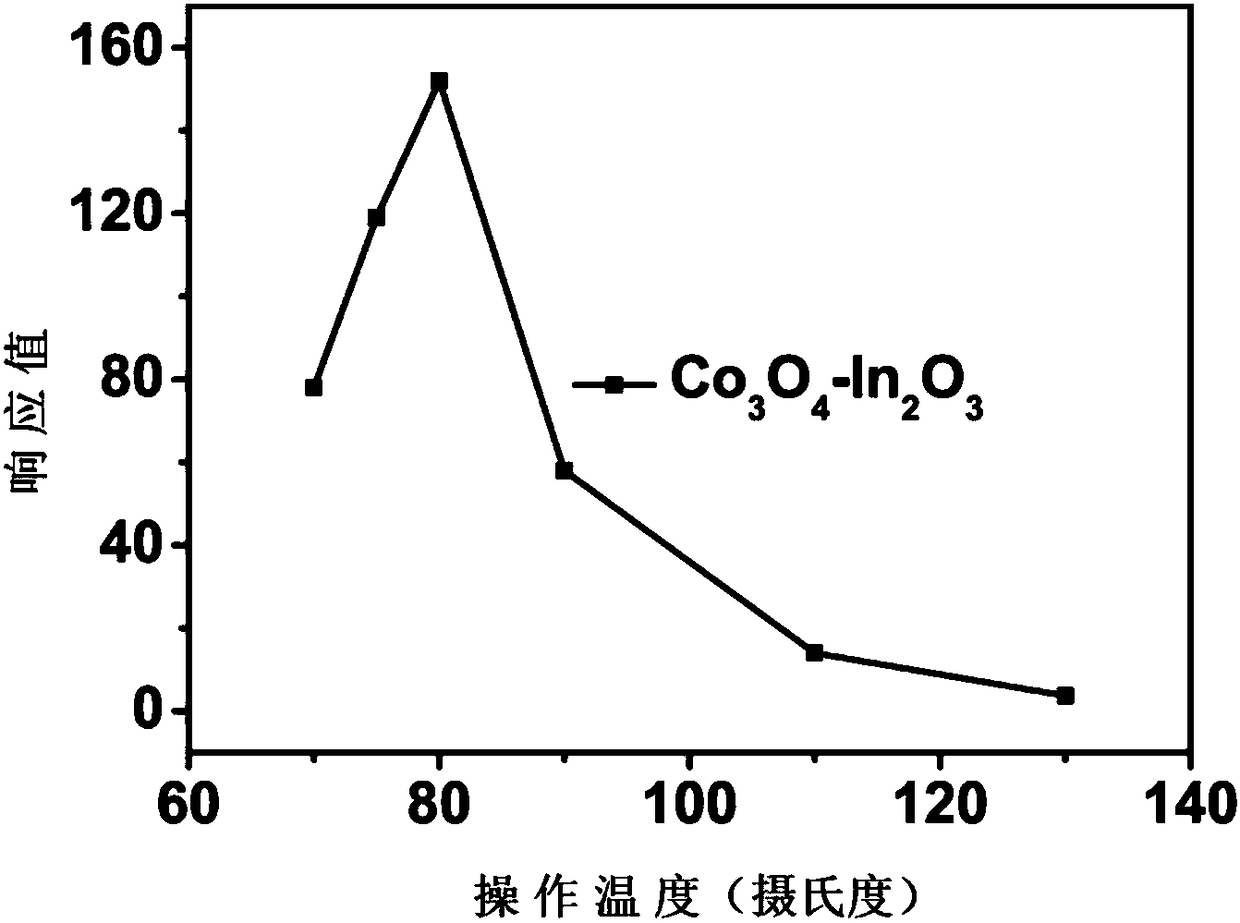

A gas-sensitive material and oxide technology, applied in analytical materials, cobalt oxide/cobalt hydroxide, instruments, etc., can solve the problems of response value lower than 30 and high operating temperature, achieving good linear correlation, low operating temperature, The effect of high response value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step A: take by weighing 2.56g (10.0mmol) Mg(NO 3 ) 2 .6H 2 O, 2.91g (10.0mmol) Co(NO 3 ) 2 .6H 2 O and 0.80g (2.5mmol) In(NO 3 ) 3 .H 2 O was dissolved in 100ml deionized water to make a mixed salt solution; weighed 6.01g (0.1mol) urea was dissolved in 100ml deionized water to make an alkaline solution; weighed 2.76g (20.0mmol) salicylic acid was dissolved in 20ml absolute ethanol A solution is prepared in the mixture; the prepared three solutions are mixed to obtain a mixed solution.

[0036] Step B: Heat the mixed solution obtained in Step A to 90° C. under mechanical stirring, and continue the reaction at this temperature. When the pH value of the solution reaches 7, stop the reaction. After cooling to room temperature, the obtained precipitate was centrifuged and washed 4 times with deionized water and 4 times with ethanol, and then the filter cake was dried at 90°C for 12 hours to obtain a hierarchical structure assembled with layered hydroxide nanosheets ...

Embodiment 2

[0040] Step A: Weigh 1.28g (5.0mmol) Mg(NO 3 ) 2 .6H 2 O, 2.91g (10.0mmol) Co(NO 3 ) 2 .6H 2 O and 1.59g (5.0mmol) In(NO 3 ) 3 .H 2 O was dissolved in 100ml deionized water to make a mixed salt solution; 12.01g (0.2mol) urea was dissolved in 100ml deionized water to make an alkaline solution; 2.76g (20.0mmol) salicylic acid was dissolved in 40ml ethylene glycol A solution is prepared in the mixture; the prepared three solutions are mixed to obtain a mixed solution.

[0041] Step B: Heat the mixed solution obtained in Step A to 100° C. under mechanical stirring, and continue the reaction at this temperature. When the pH value of the solution reaches 8, stop the reaction. After cooling to room temperature, the obtained precipitate was centrifuged and washed 6 times with deionized water and 4 times with ethanol, and then the filter cake was dried at 90°C for 12 hours to obtain a hierarchical structure assembled with layered hydroxide nanosheets Precursor.

[0042] Step ...

Embodiment 3

[0045] Step A: Weigh 2.97g (10.0mmol) Zn(NO 3 ) 2 .6H 2 O, 2.50g (10.0mmol) Cu(SO 4 ) 2 .5H 2 O and 4.04g (10.0mmol) Fe(NO 3 ) 3 .9H 2 O was dissolved in 50ml deionized water to make a mixed salt solution; 14.02g (0.1mol) of hexamethylenetetramine was dissolved in 100ml of deionized water to make an alkaline solution; 5.53g (40.0mmol) of salicylic acid was dissolved in Prepare a solution in 20ml of n-butanol; mix the prepared three solutions to obtain a mixed solution.

[0046] Step B: Heat the mixed solution obtained in Step A to 120° C. under mechanical stirring, and continue the reaction at this temperature. When the pH value of the solution reaches 9, stop the reaction. After cooling to room temperature, the obtained precipitate was centrifuged and washed 6 times with deionized water and 4 times with ethanol, and then the filter cake was dried at 90°C for 12 hours to obtain a hierarchical structure assembled with layered hydroxide nanosheets Precursor.

[0047] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com