Dual-section current waveform corrosion method for improving length consistency of channel holes of medium and high voltage anode aluminum foil

A technology of current waveform and anode aluminum foil, which is applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of uneven length of tunnel holes and hinder the improvement of specific capacitance of aluminum foil, and achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

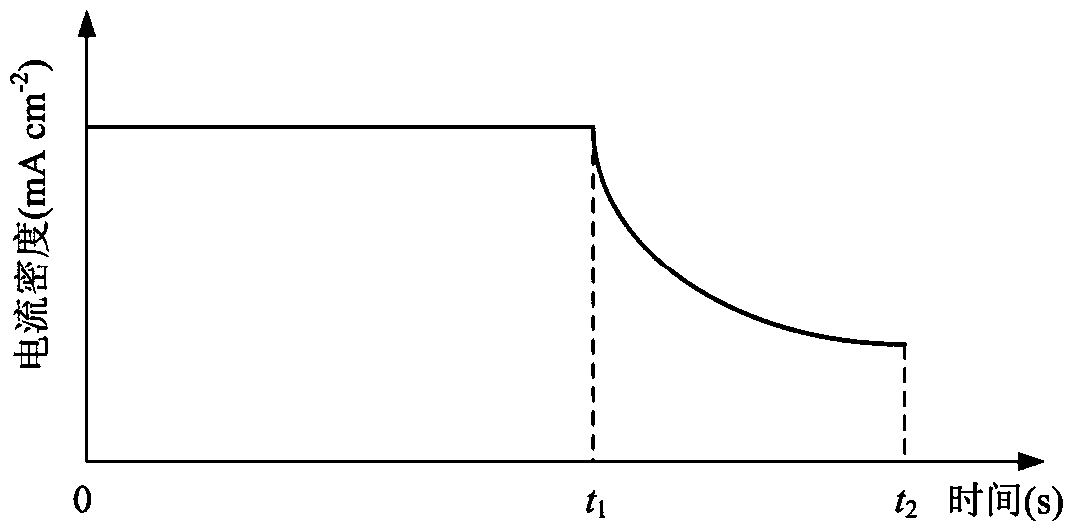

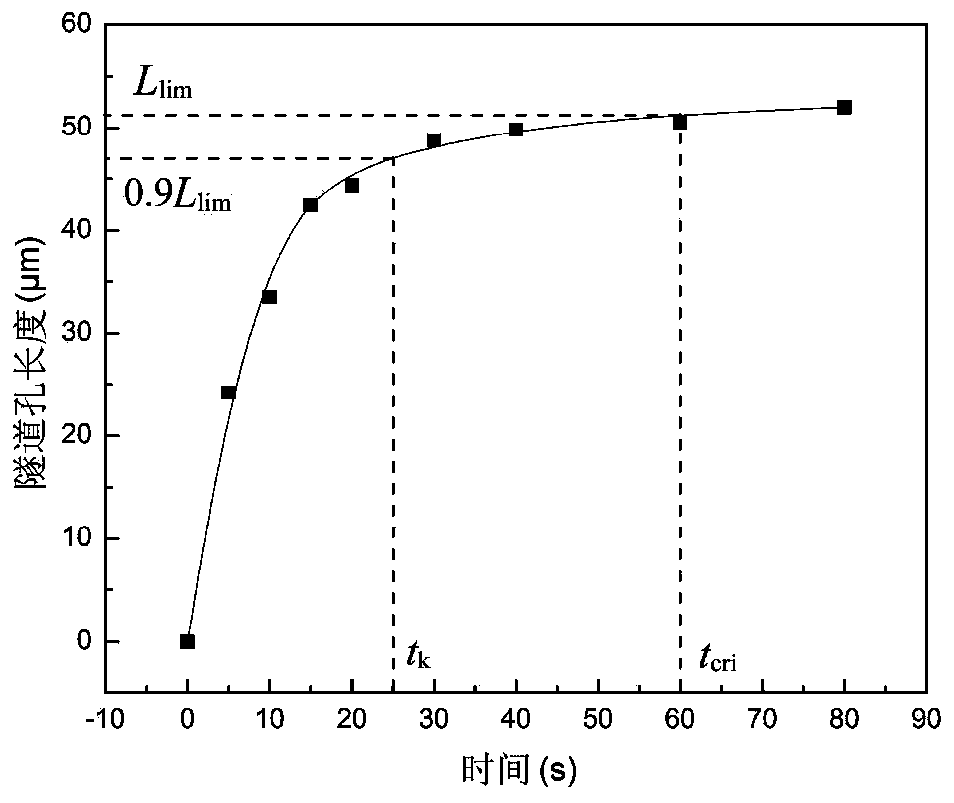

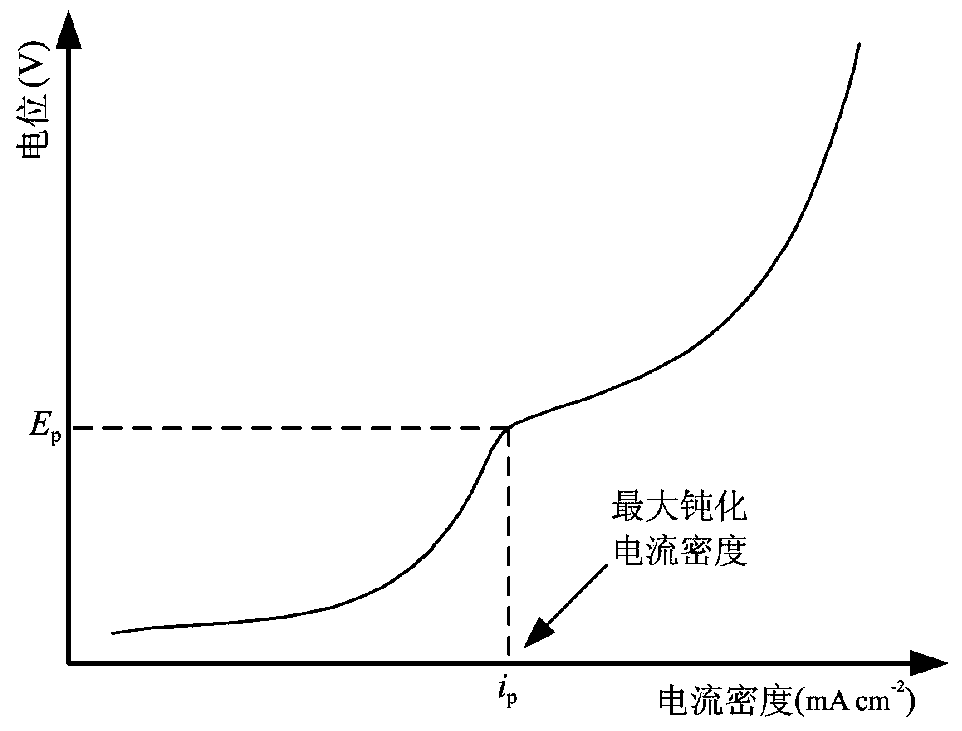

[0033] According to the basic growth law and passivation current density of tunnel holes in the pitting corrosion system at the same temperature as in Comparative Example 1, two stages of attenuation current waveforms are obtained to improve the consistency of tunnel hole lengths. The first stage waveform is a constant current waveform, and the corrosion time The second stage waveform is an exponential decay waveform, the corrosion time is 25s, and the lowest current density at the end is 50mA cm -2 . After the aluminum foil was subjected to the same pretreatment as that of Comparative Example 1, the current waveform was used for pitting corrosion, and the charge density was 25C cm -2 , and then carry out the same hole expansion corrosion, post-treatment and 520V chemical conversion treatment as in Comparative Example 1.

Embodiment 2

[0035] According to the basic growth law and passivation current density of the tunnel hole in the pitting corrosion system at the same temperature as in Comparative Example 1, two stages of attenuation current waveforms are obtained to improve the consistency of the tunnel hole length. The first stage waveform is a small-amplitude linear decay current waveform , the corrosion time is 60s, the waveform of the second stage is an exponential decay waveform, the corrosion time is 25s, and the minimum current density at the end is 50mA cm -2 . After the aluminum foil was subjected to the same pretreatment as that of Comparative Example 1, the current waveform was used for pitting corrosion, and the charge density was 25C cm -2 , and then carry out the same hole expansion corrosion, post-treatment and 520V chemical conversion treatment as in Comparative Example 1.

Embodiment 3

[0037] According to the basic growth law and passivation current density of tunnel holes in the pitting corrosion system at the same temperature as in Comparative Example 1, two stages of attenuation current waveforms are obtained to improve the consistency of tunnel hole lengths. The first stage waveform is a constant current waveform, and the corrosion time 60s, the waveform of the second stage is a linear attenuation waveform, the corrosion time is 25s, and the lowest current density at the end is 50mA cm -2 . After the aluminum foil was subjected to the same pretreatment as that of Comparative Example 1, the current waveform was used for pitting corrosion, and the charge density was 25C cm -2 , and then carry out the same hole expansion corrosion, post-treatment and 520V chemical conversion treatment as in Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com