Ultrasonic modulation discharge-electrolysis high-efficiency milling system

A technology of milling processing and control system, which is applied in the fields of ultrasonic modulation discharge-electrolytic high-efficiency milling processing system and ultrasonic composite electrolytic milling processing system, can solve problems such as difficult to meet the needs of high-efficiency processing of complex parts, and achieve broad market application potential and easy operation. , the effect of enhancing the mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

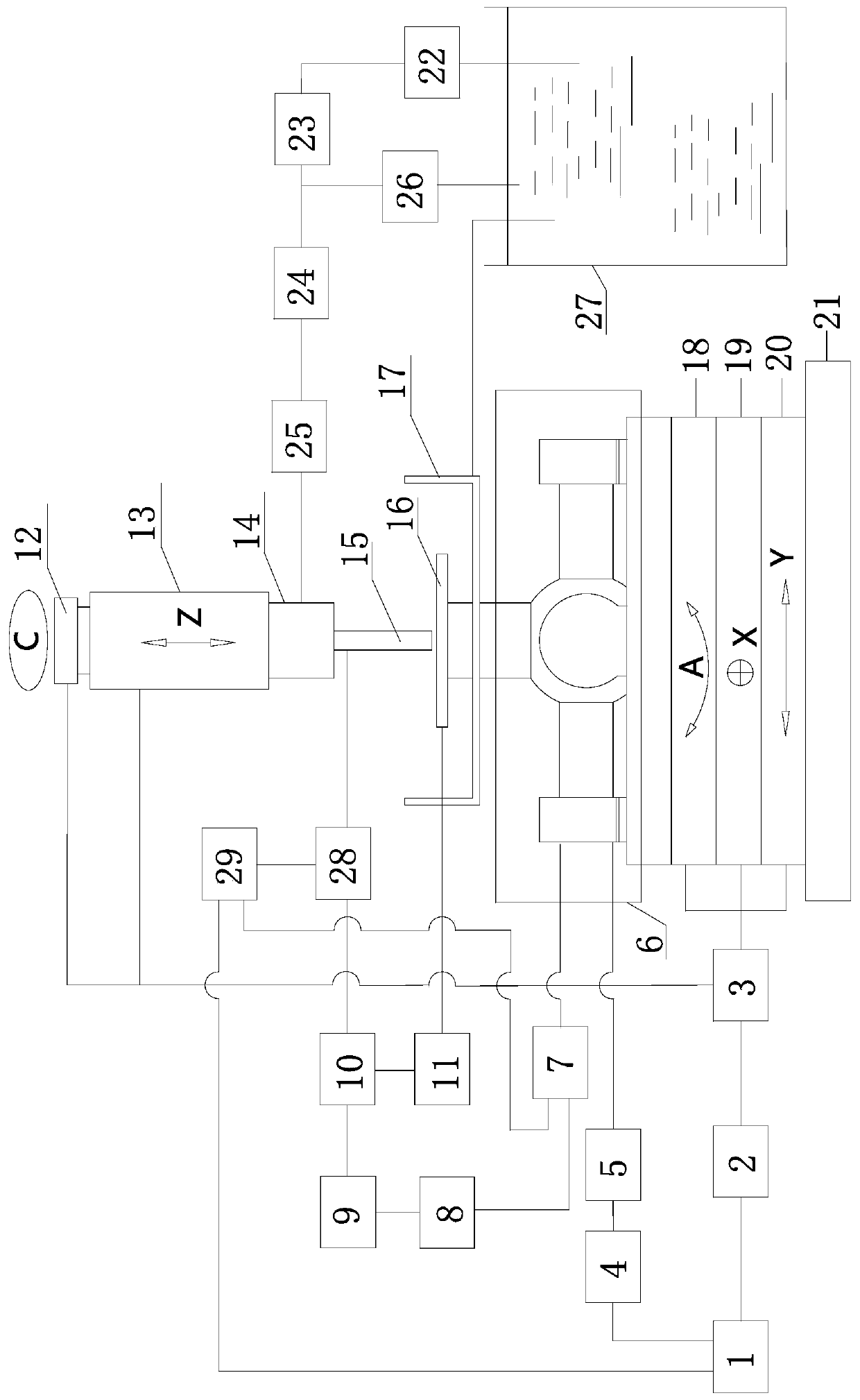

[0022] Such as figure 1 As shown, an ultrasonic modulation discharge-electrolysis high-efficiency milling processing system consists of a multi-axis machine tool control system, an ultrasonic vibration control system, a composite processing power supply control system, a working fluid circulation system, and a processing parameter detection and control system.

[0023] Such as figure 1 As shown, an ultrasonic modulation discharge-electrolysis high-efficiency milling system, the multi-axis machine tool control system consists of a control computer 1, a CNC controller 2, a servo motor 3, a C-axis rotation mechanism 12, a Z-axis feed mechanism 13, and an A-axis rotation mechanism. Mechanism 18, X-axis feed mechanism 19 and Y-axis feed mechanism 20 are connected; C-axis rotation mechanism 12 and Z-axis feed mechanism 13 drive the machining spindle of the machine tool; A-axis r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com