Patents

Literature

45results about How to "Realize the coupling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

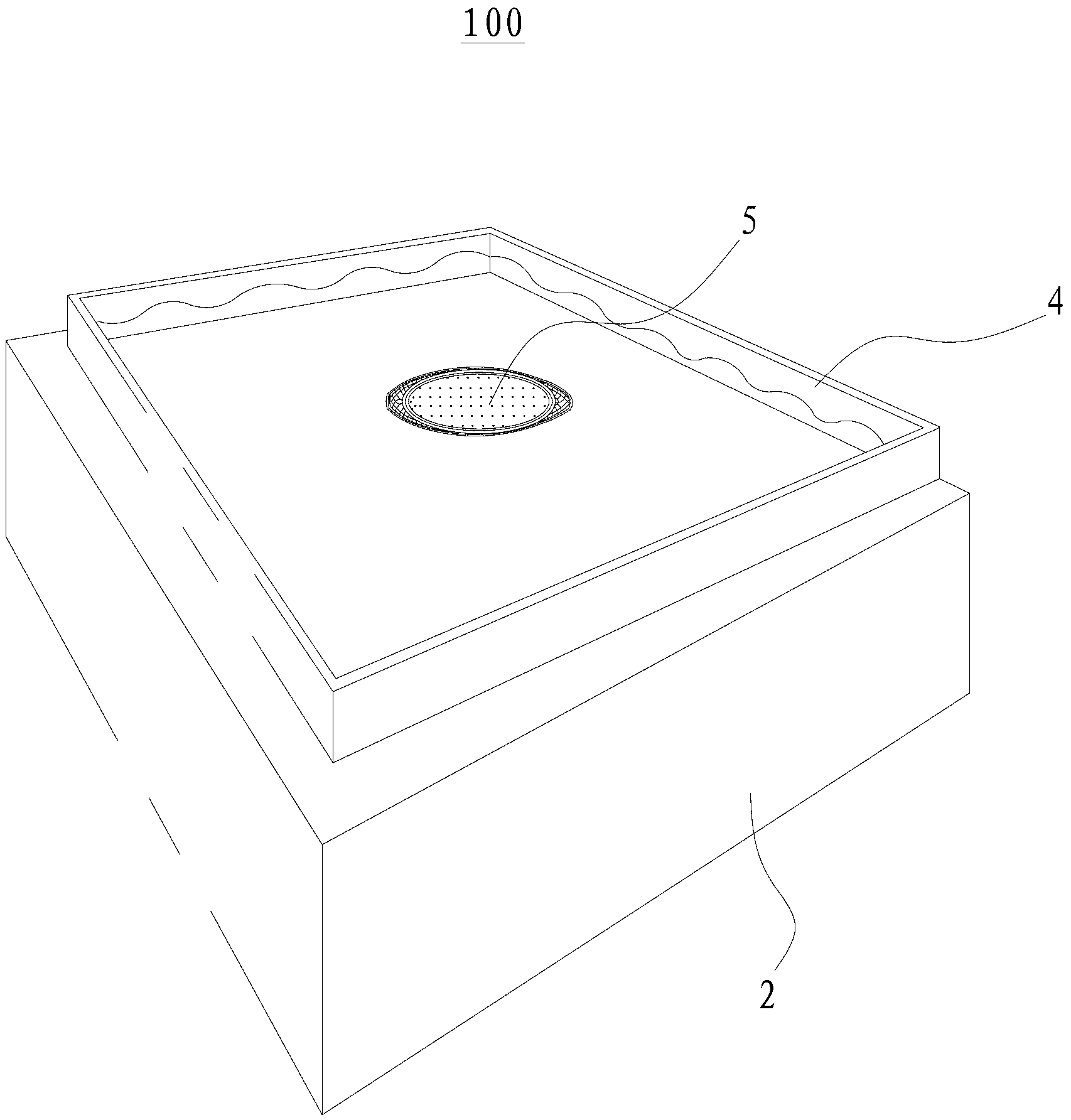

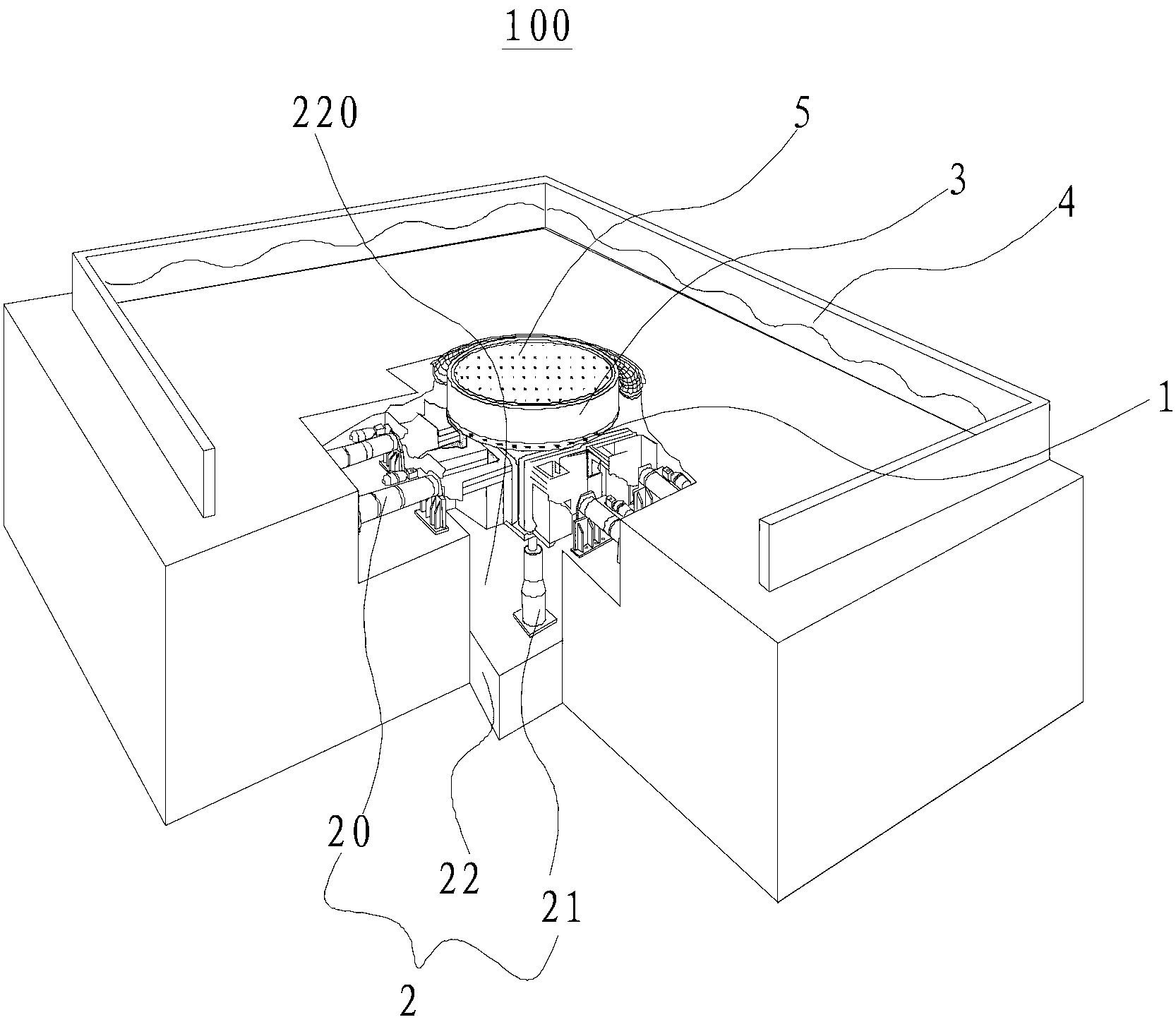

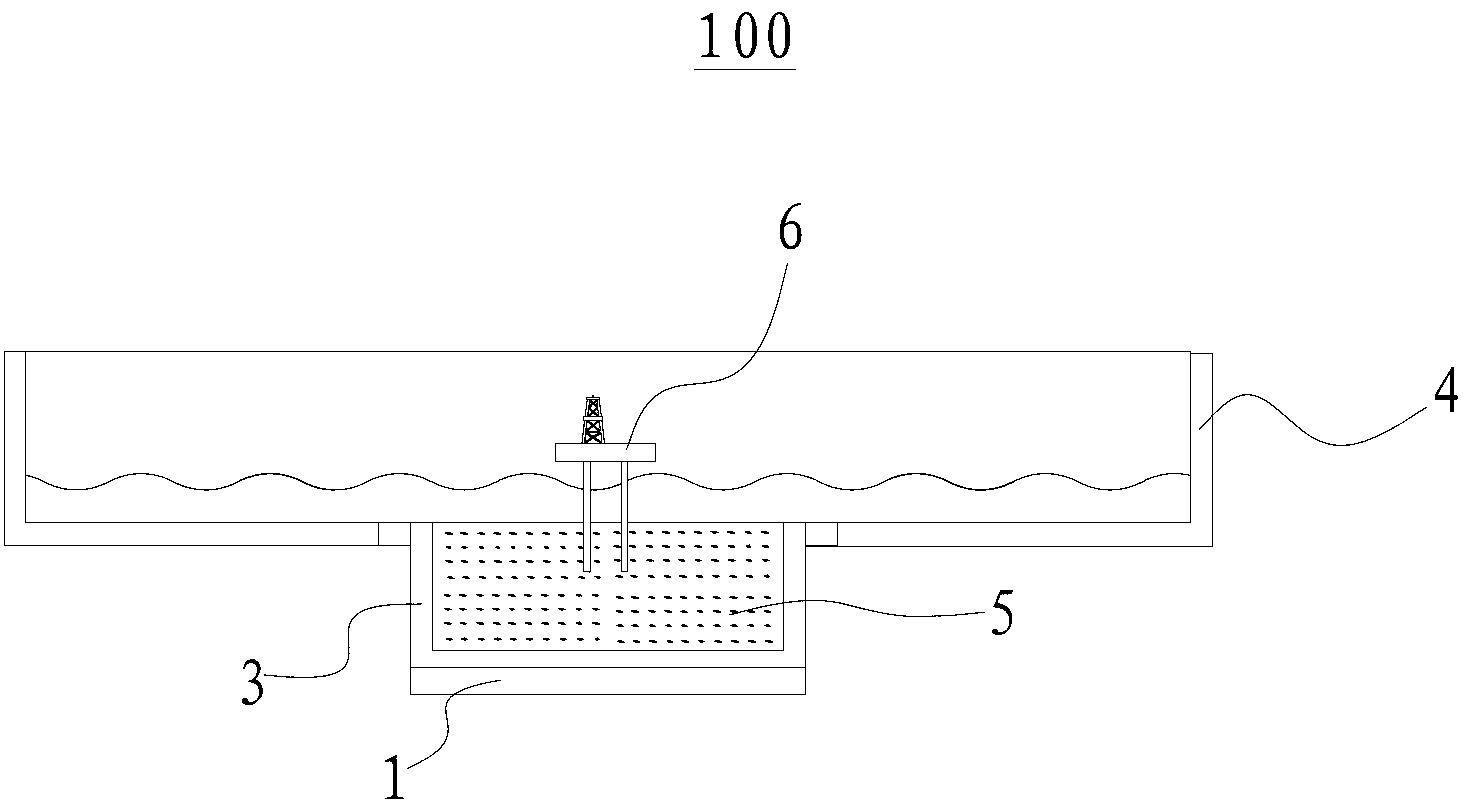

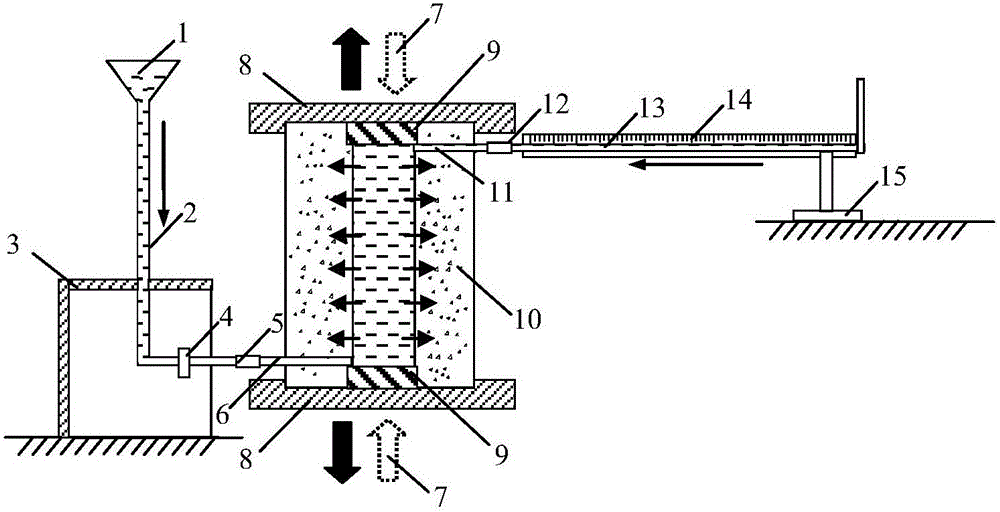

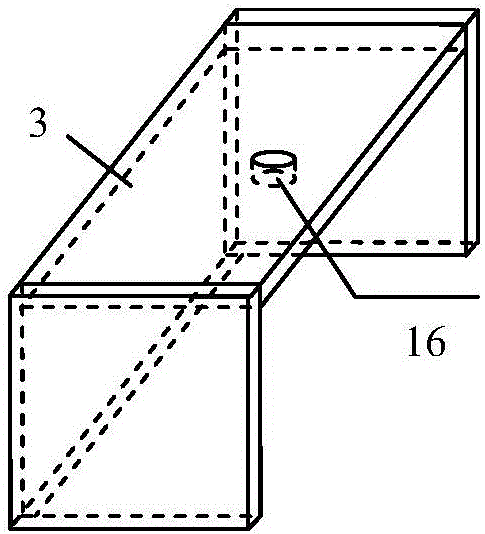

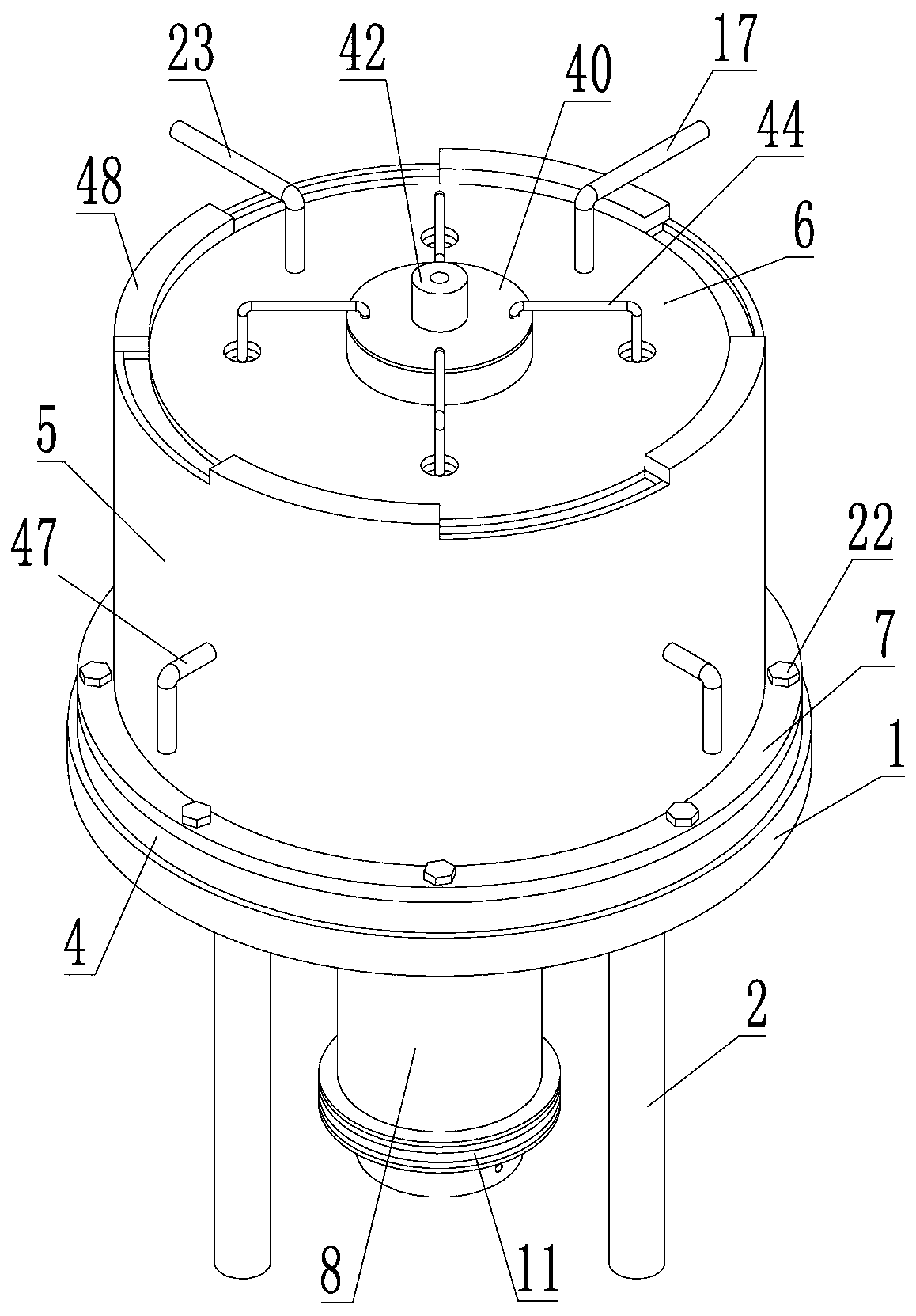

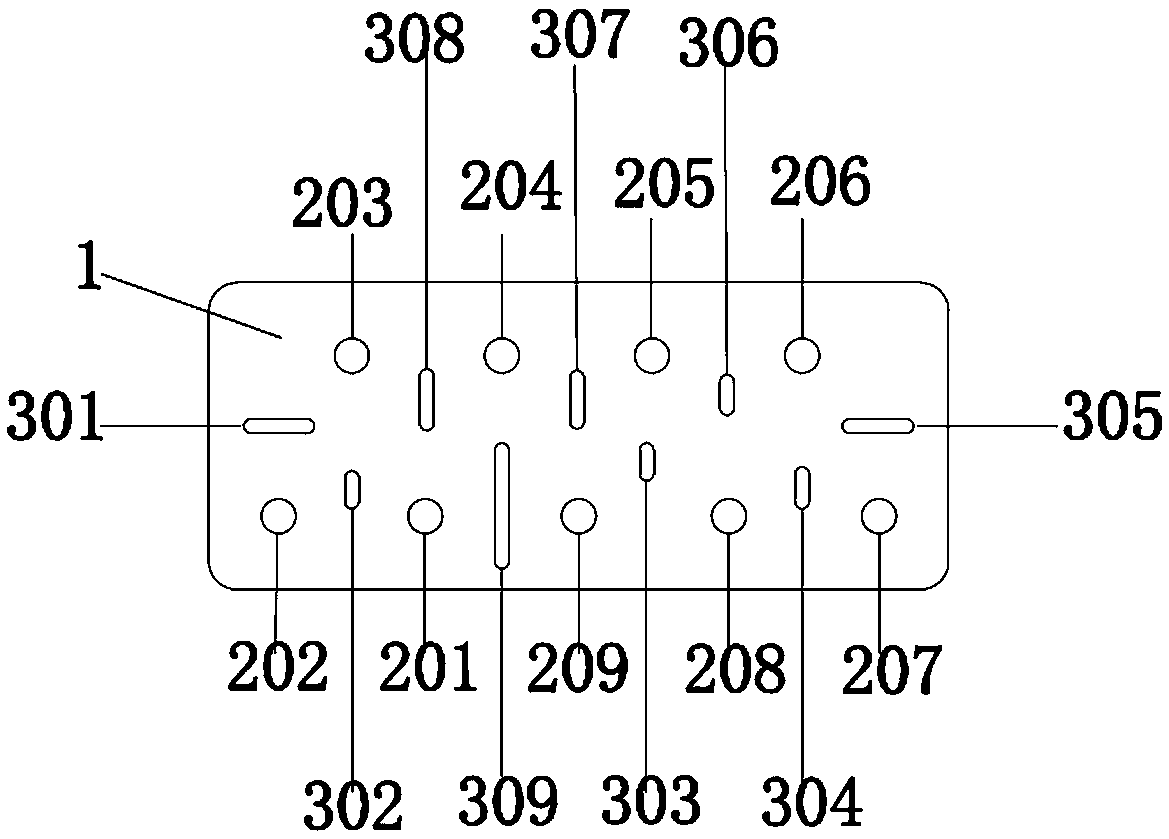

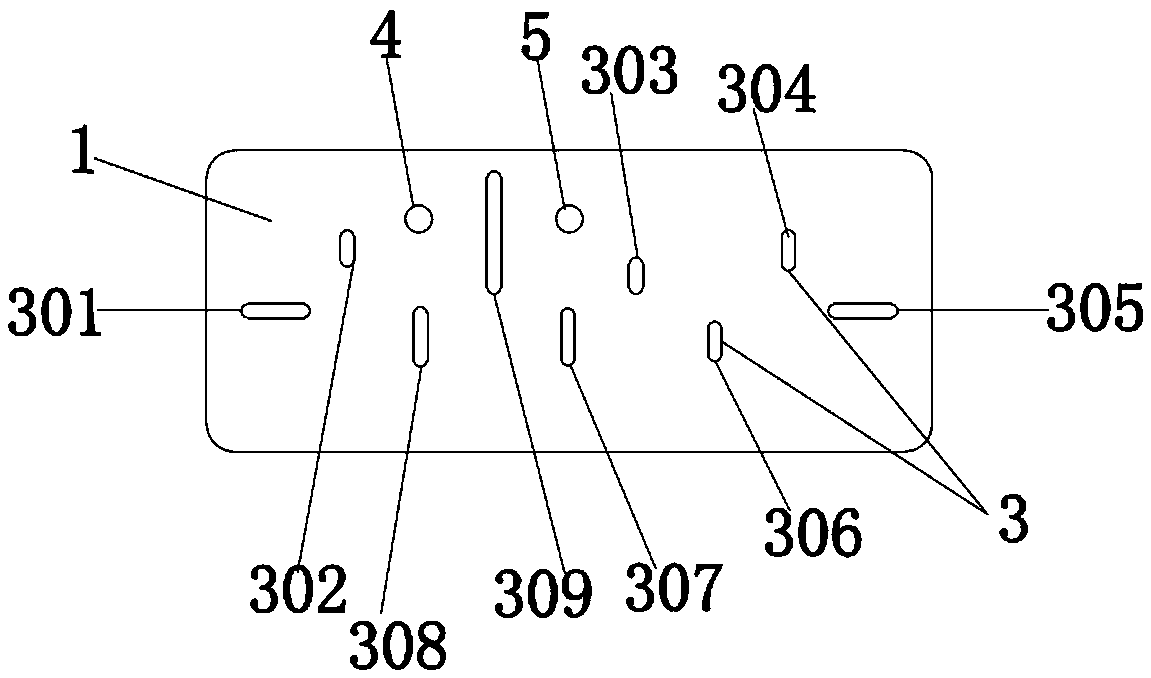

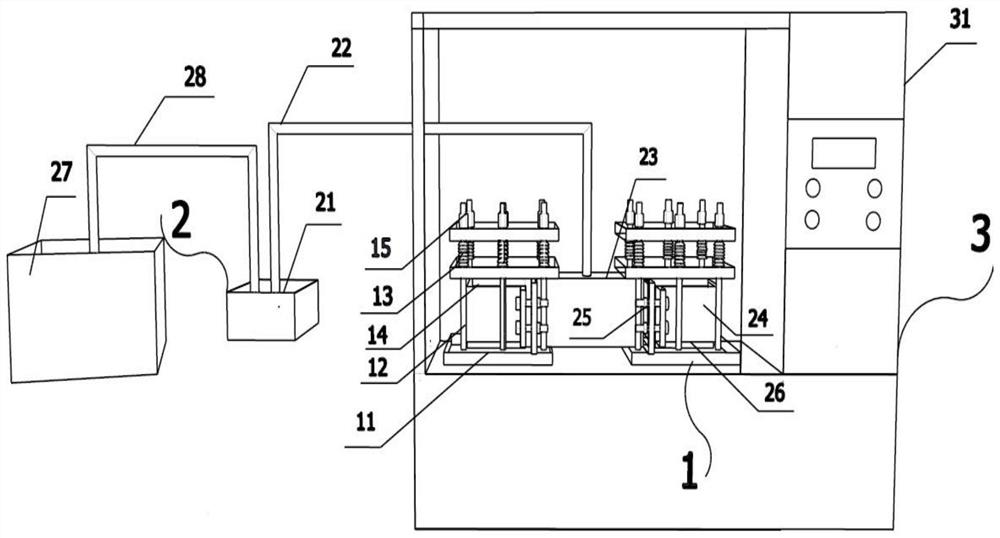

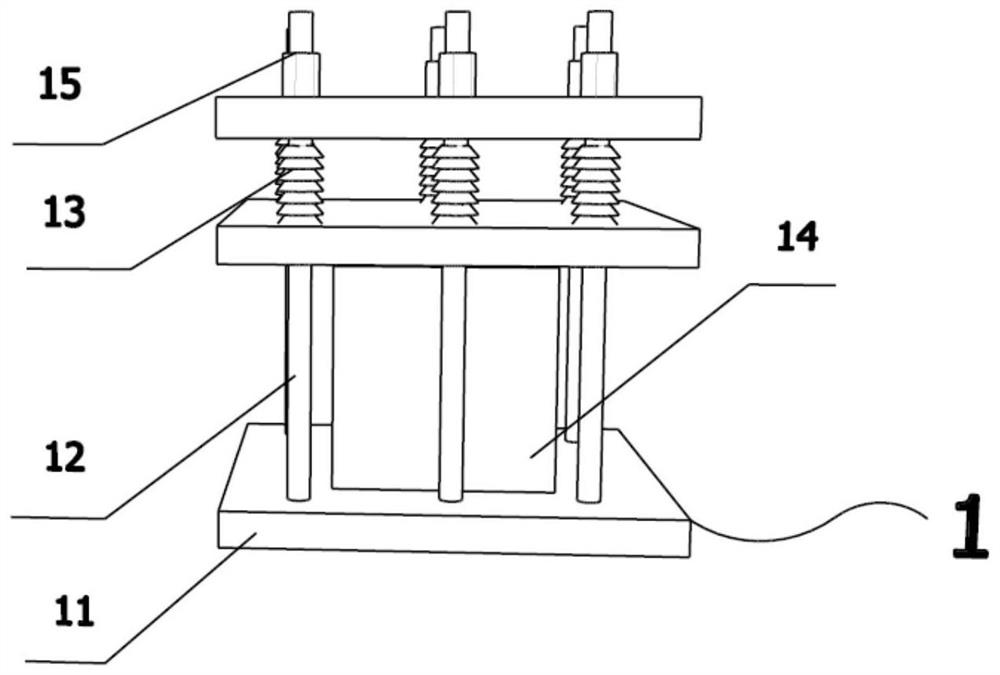

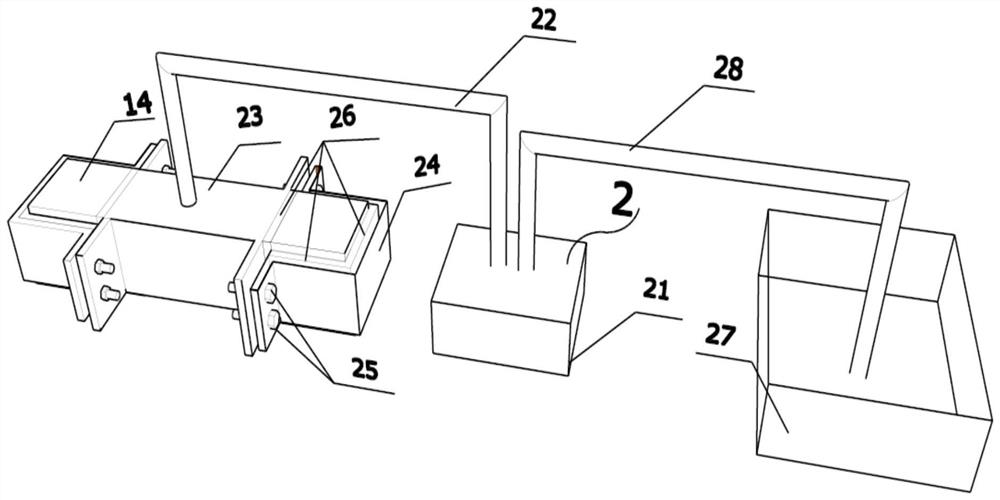

Maritime work vibrating table device

ActiveCN103278304ARealize dynamic interactionRealize the coupling effectHydrodynamic testingShock testingOcean bottomSurface ocean

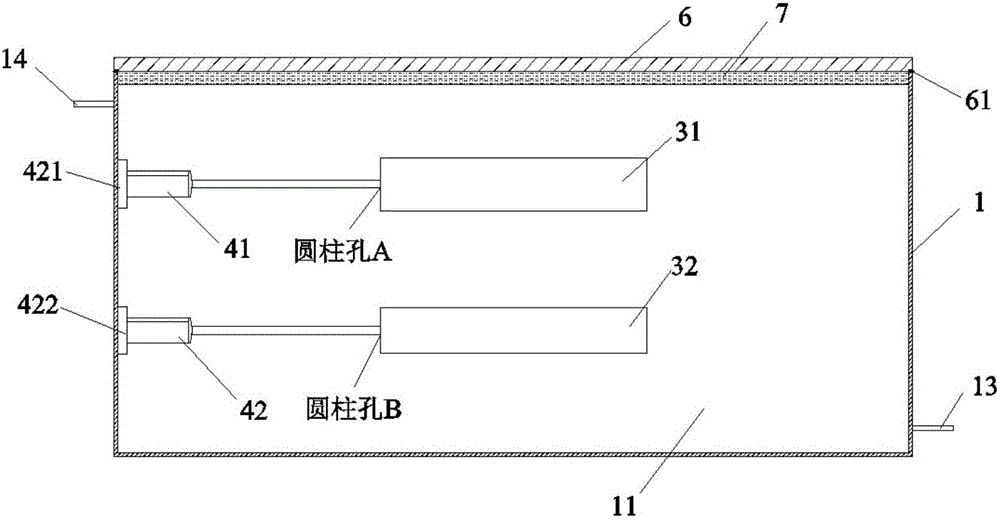

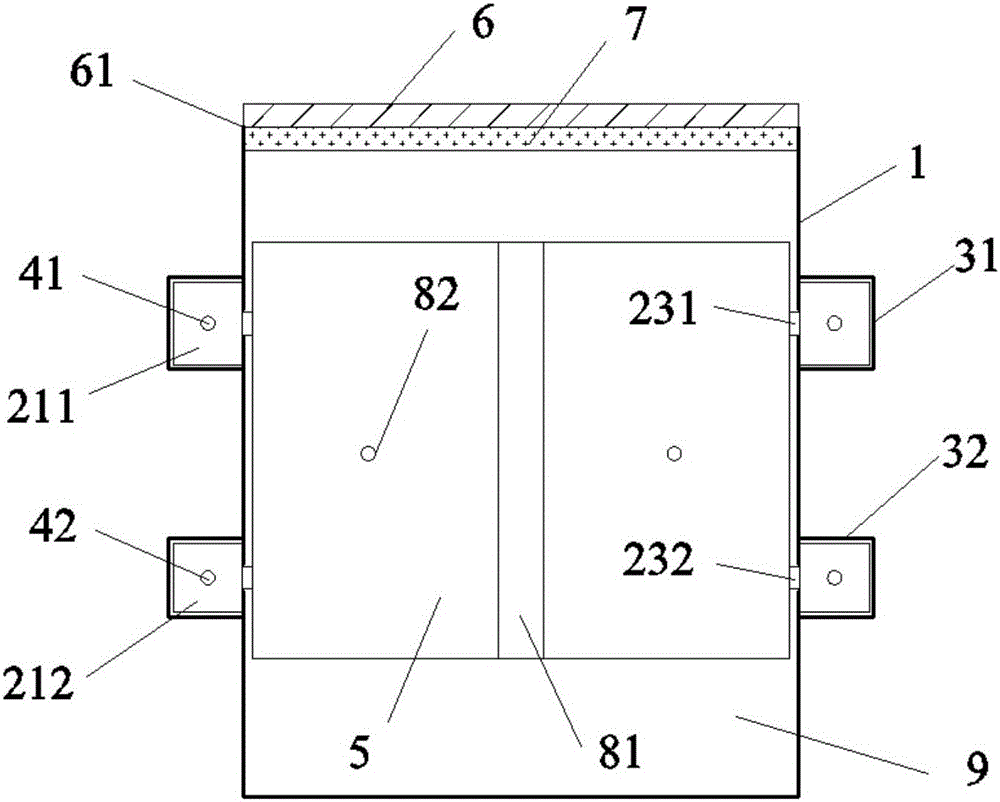

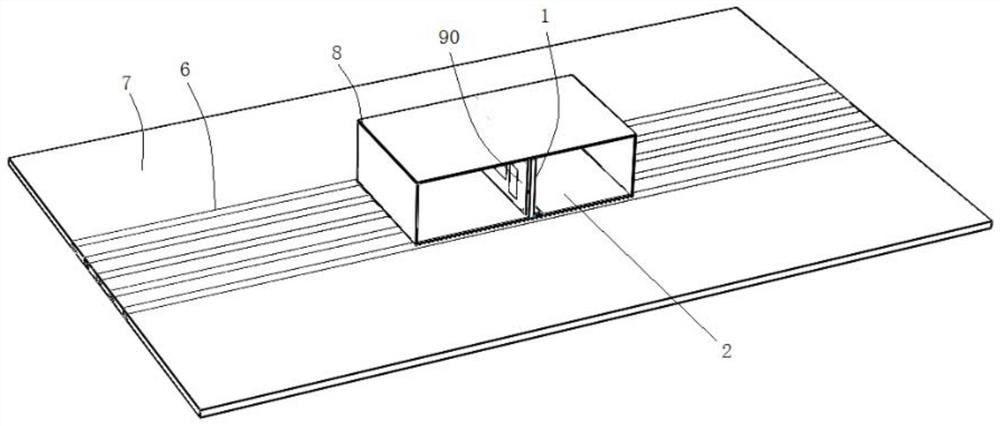

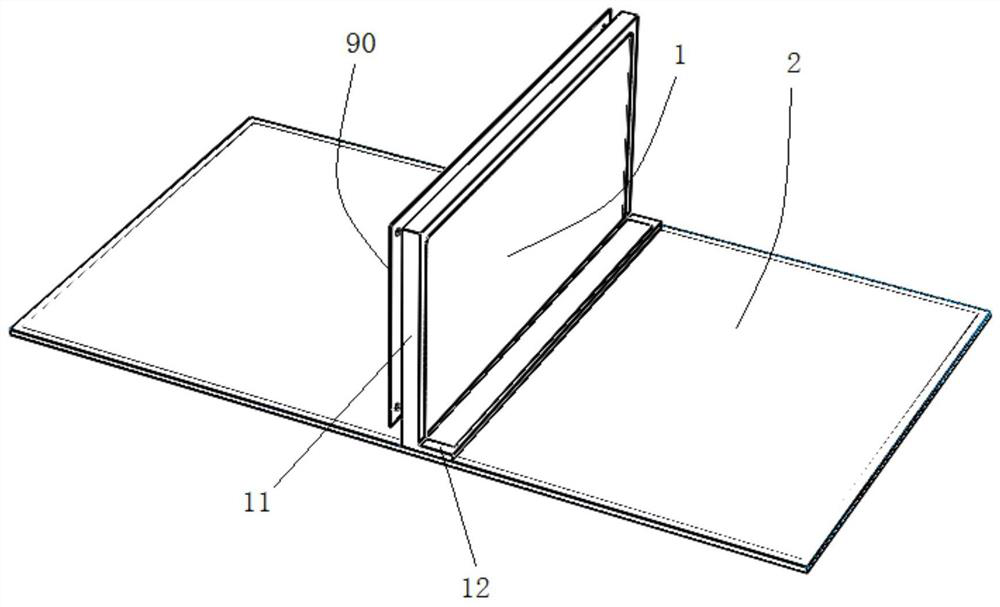

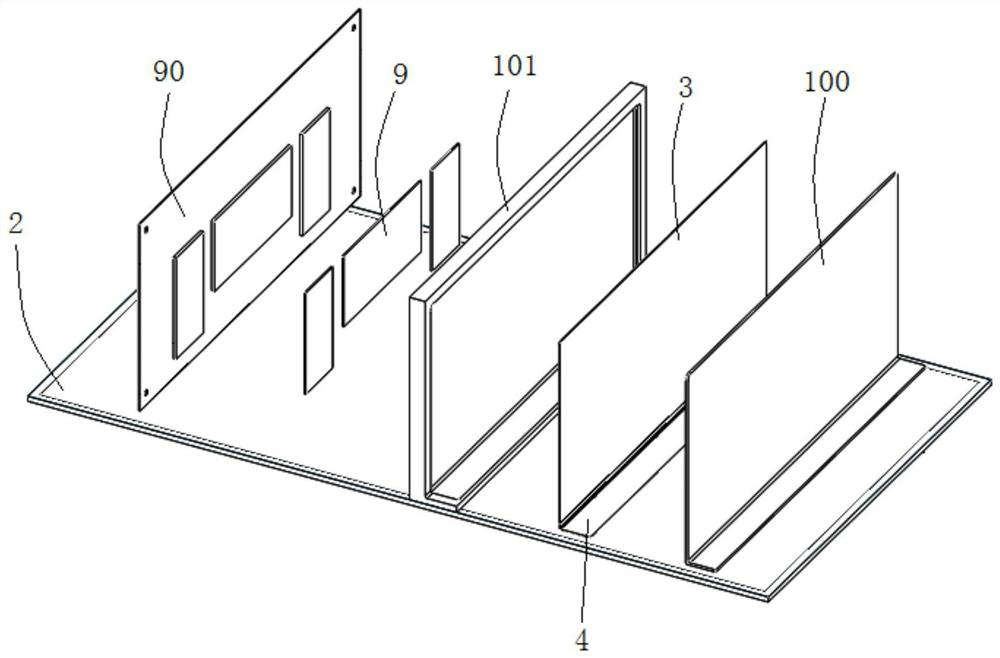

The invention discloses a maritime work vibrating table device which comprises a vibrating table, an actuator, a model soil box and a wave pool. The actuator is connected with the vibrating table and is used for driving the vibrating table to vibrate and controlling the vibrating process of the vibrating table. The model soil box is arranged on the vibrating table, and a seabed soil layer is arranged inside the model soil box. The wave pool is used for generating waves and flow inside the wave pool, an opening is formed in the bottom wall of the wave pool, and the top end of the model soil box is connected with the bottom wall of the wave pool in a sealing mode on the opening so that the wave pool can be communicated with the model soil box through the opening. According to the maritime work vibrating table device, the process of ocean currents, sea waves and strong earthquakes can be represented simultaneously, the dynamic interaction among ocean fluid, undersea strong earthquakes, a maritime work structure and a seabed soil layer can be achieved, the multi-field coupling effect of a typical maritime work structure and a seabed soil layer under the effect of extreme waves, ocean currents and undersea strong earthquakes is achieved, and a large-scale experimental verification platform can be provided for ocean engineering geological prospecting design and a marine construction technology.

Owner:TSINGHUA UNIV

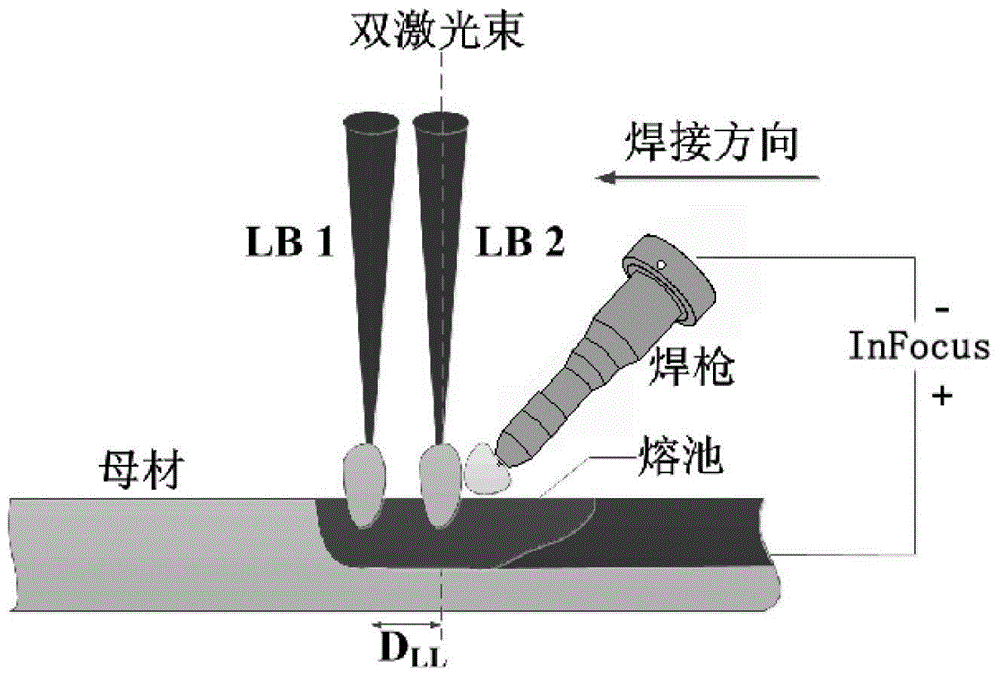

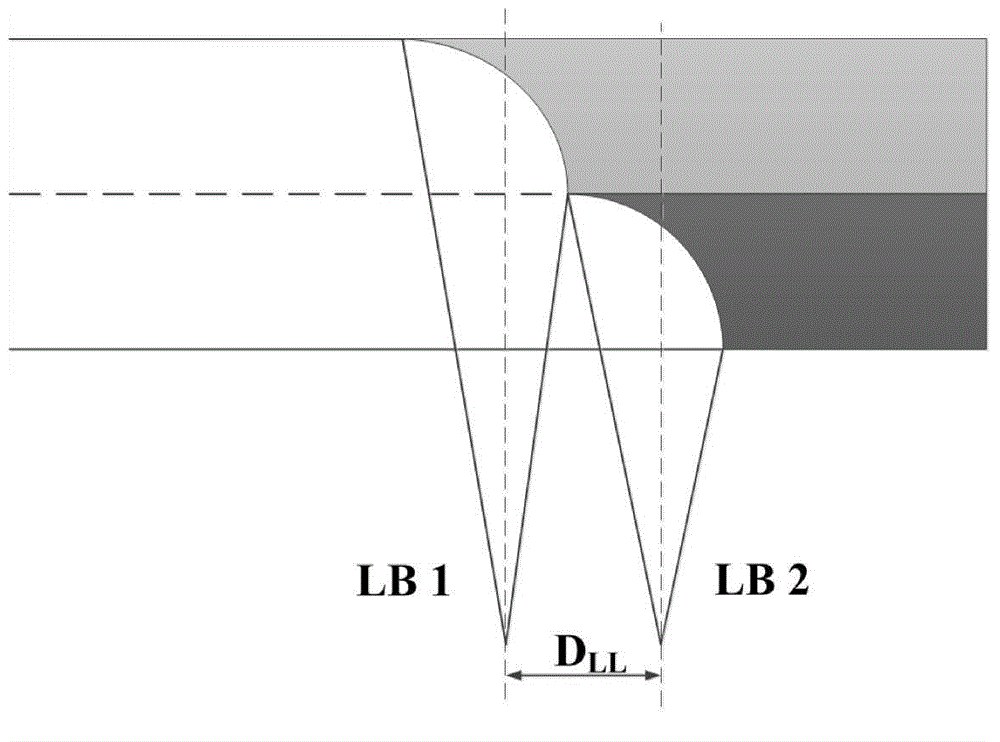

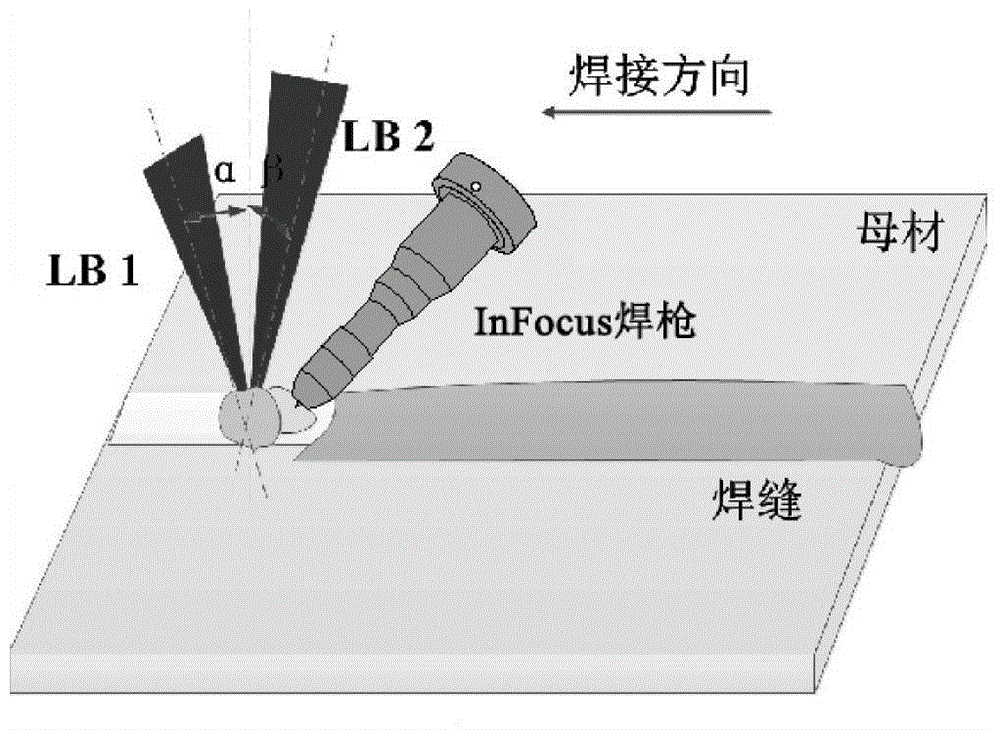

Bifocus laser and InFocus arc hybrid welding method

InactiveCN104985327AImprove energy utilizationIncrease weld penetrationLaser beam welding apparatusElectric arcEngineering

The invention discloses a bifocus laser and InFocus arc hybrid welding method, and relates to a welding method. The method includes the steps that (1) a to-be-welded workpiece is polished or washed; (2) the spot diameter is set to range from 0.1 mm to 0.5 mm, and the defocusing amount ranges from -3 mm to +3 mm; (3) welding parameters are set, wherein the arc current ranges from 50 A to 900 A, an included angle formed between a welding gun and the vertical direction ranges from 25 degrees to 55 degrees, the welding speed ranges from 100 mm / min to 1000 mm / min, the wire feeding speed ranges from 100 mm / min to 600 mm / min, the protection gas is inert gas, and the flow of the protection gas ranges from 15 L / min to 30 L / min; and (4) a switch is started, and laser-InFocus arc welding is carried out. According to bifocus lasers and InFocus, as the InFocus arc fusion depth is larger, and a key hole can be formed through welding, when a medium-thickness plate is welded, the lasers can directly act on the bottom of the key hole generated by the InFocus arc, and the fusion depth is continuously increased.

Owner:HARBIN INST OF TECH

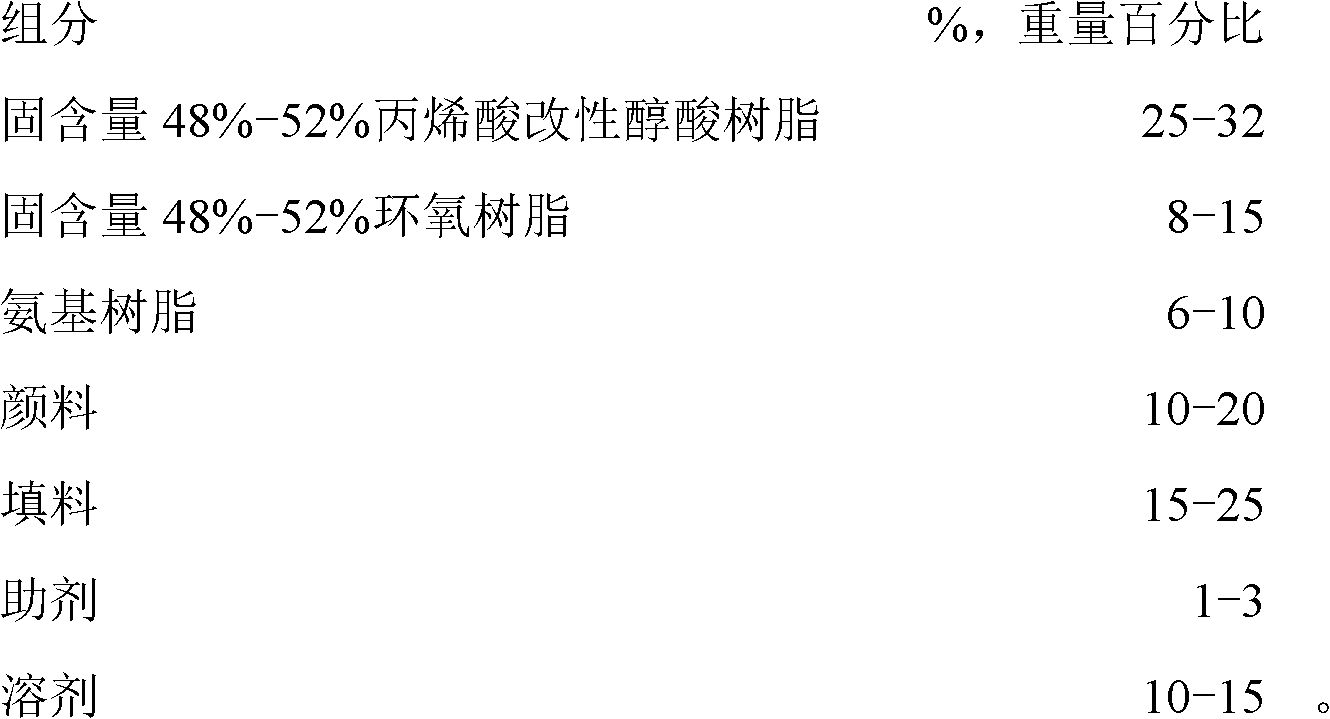

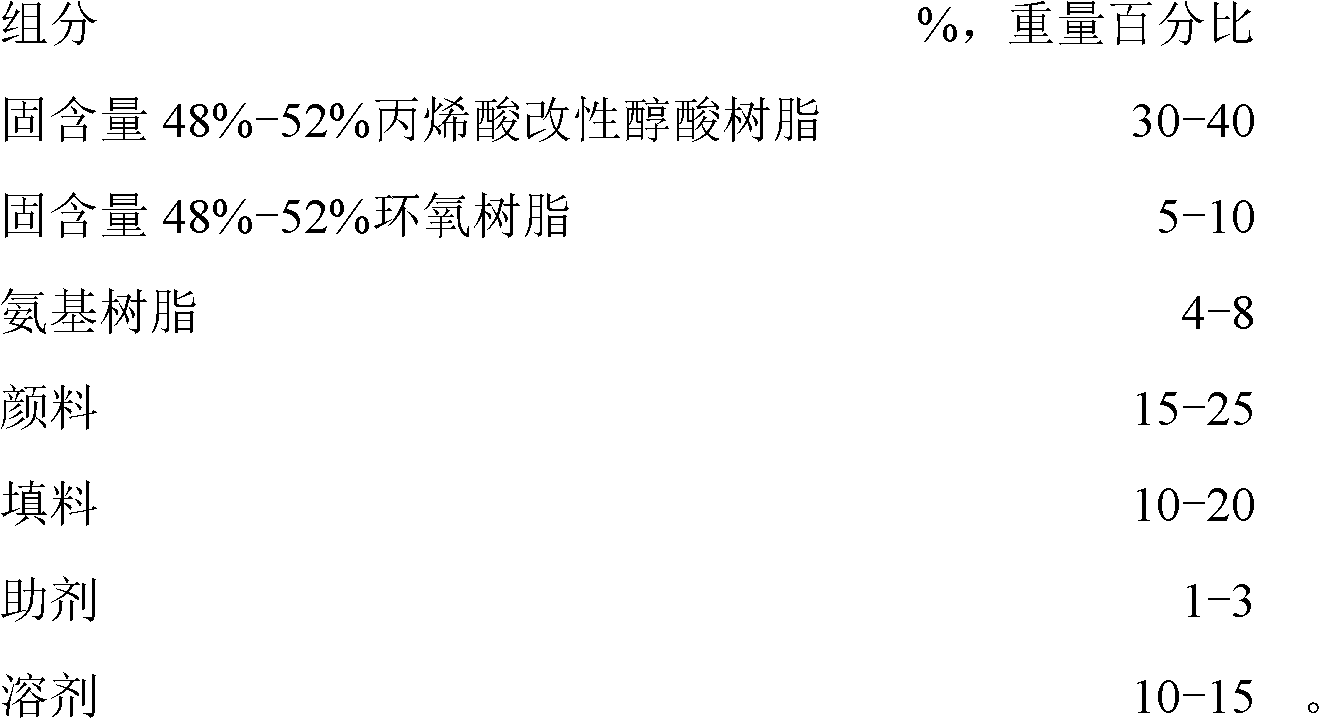

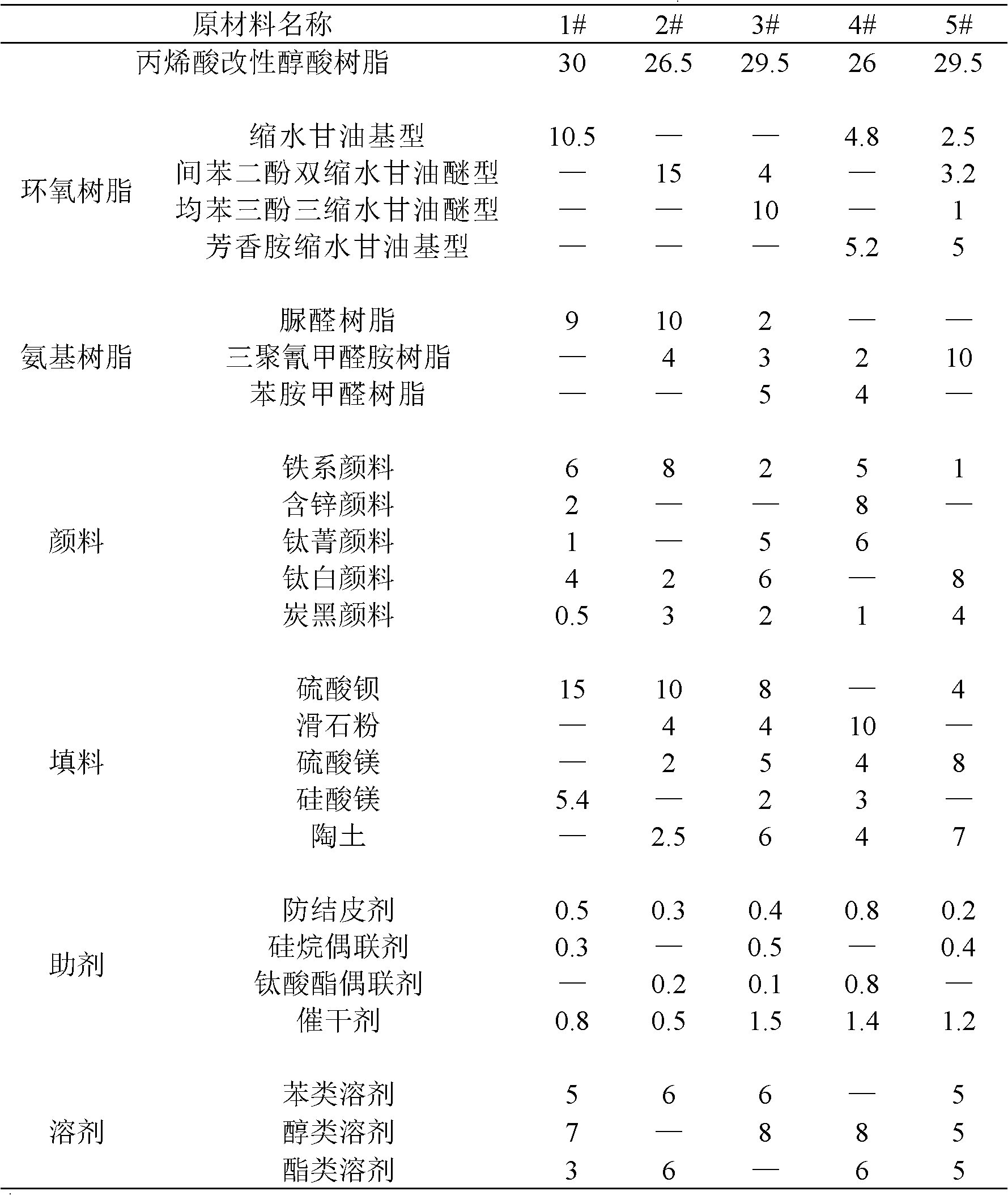

Mirror back protective coating for colored coated mirror

InactiveCN102492356ARealize the coupling effectGood construction performanceEpoxy resin coatingsPolyester coatingsEpoxyHeavy metal compound

The invention discloses a mirror back protective coating for a colored coated mirror. The mirror back protective coating for the colored coated mirror comprises a primer and a finish, wherein the primer comprises 25 to 32 weight percent of acrylic modified alkyd resin with the solid content of 50 percent, 8 to 15 weight percent of epoxy resin with the solid content of between 48 and 52 percent, and 6 to 10 weight percent of amino resin; and the finish comprises 30 to 40 weight percent of acrylic modified alkyd resin with the solid content of 50 percent, 5 to 10 weight percent of epoxy resin with the solid content of between 48 and 52 percent, and 4 to 8 weight percent of amino resin. Heavy metal compounds with anticorrosion performance are not used in the mirror back protective coating, so the coating is environment-friendly. The coating can be prepared by a large-scale curtain coating molding process, can be quickly oven-dried, can be completely cured after being roasted at the temperature of between 80 and 100 DEG C for 4 to 6 minutes, has excellent physical and chemical properties, and is favorable for large-scale industrialized production.

Owner:常州市弘可利办公用品有限公司

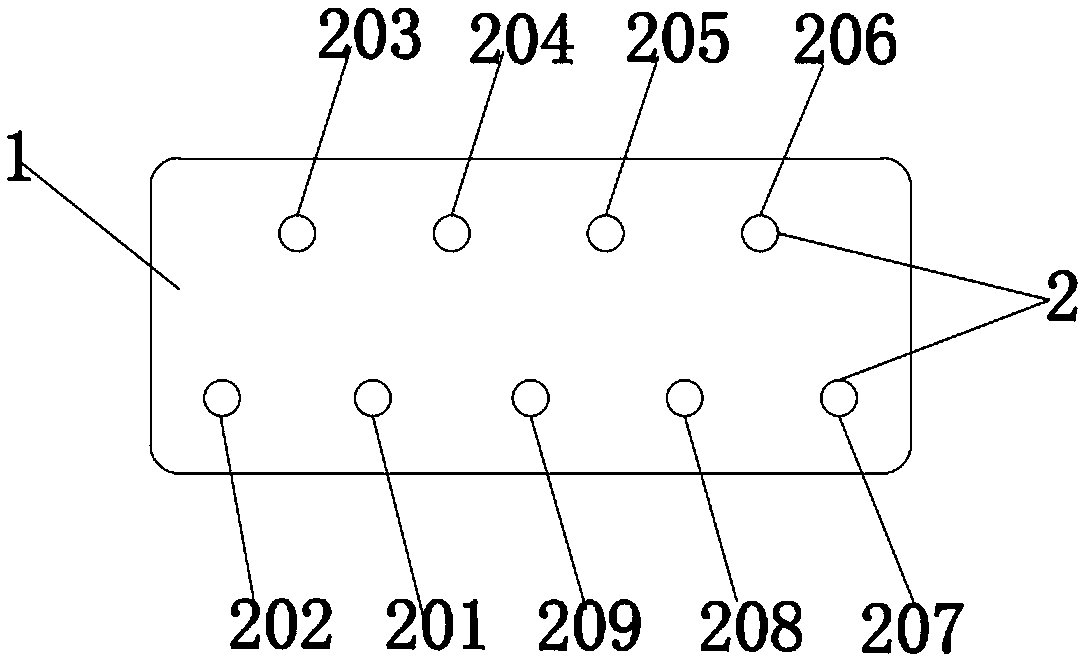

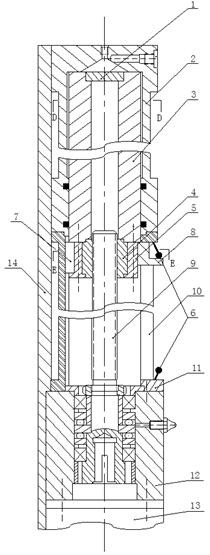

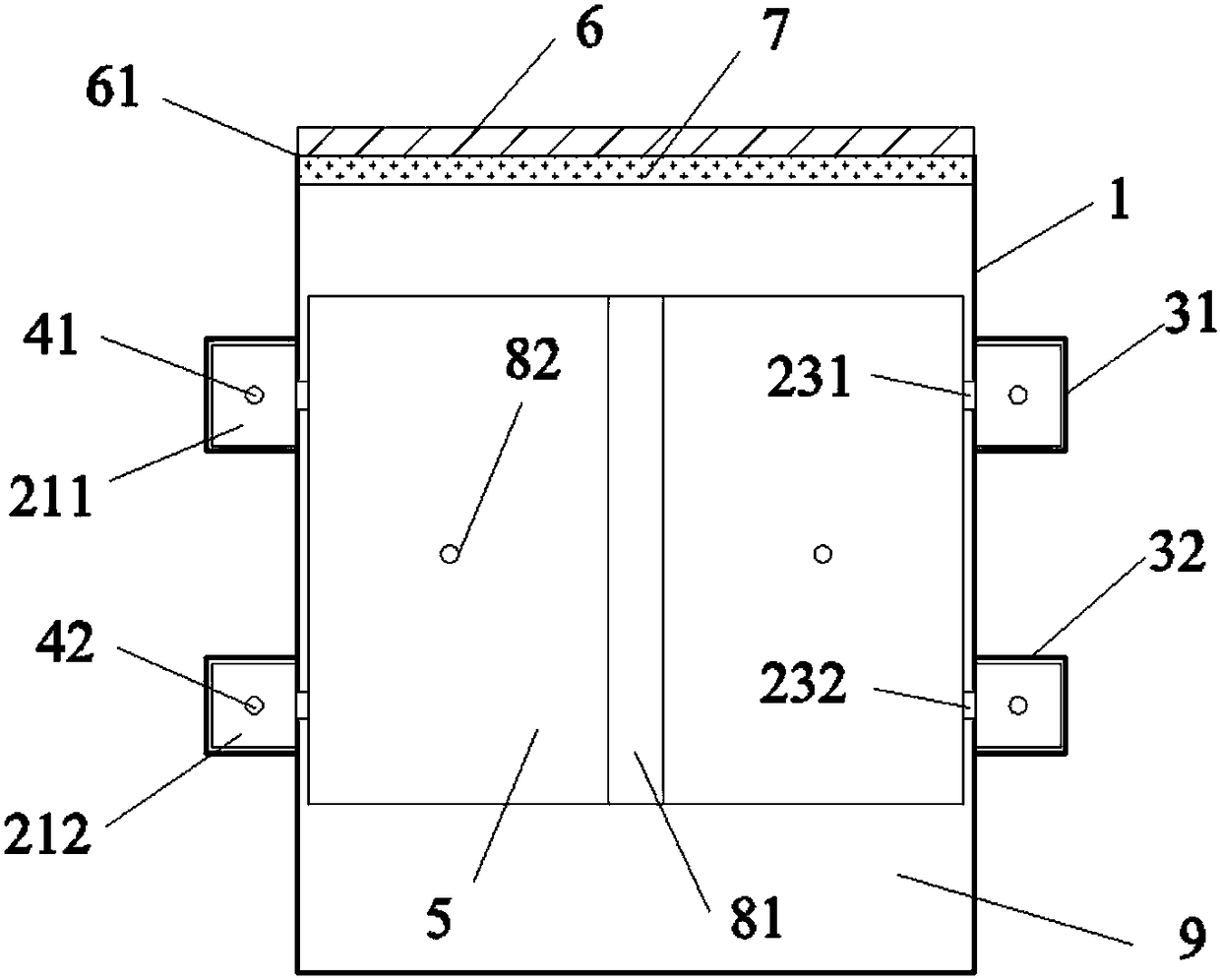

Device and method for testing concrete capillary water absorption under sustained load functions

InactiveCN105866007ASolve the problem of water supplyRealize the coupling effectPermeability/surface area analysisEngineeringTest fixture

The invention aims to solve the problem that an existing testing system is difficult to realize sustained load application on concrete and the coupling process of capillary water absorption and discloses a device and a method for testing the concrete surface capillary water absorption under sustained load functions. The test device comprises a water supply unit, a horizontal observation unit, a hollow test piece unit and a steel plate. The test method comprises the steps that the upper end and the lower end of the hollow test piece unit are sealed, and the hollow test piece unit is connected with a water pipe of the water supply unit and the observation unit and is sealed and fixed; after an observation pipe is adjusted to be level, sustained load is applied and water is injected; the initial value of the position of the water column in the pipe and the variation along the time are recorded and observed. The method is easy to operate, the device structure is ingenious, real-time and continuously accurate measurement of the concrete accumulated water absorption process under the sustained load functions is realized, the accumulated capillary water absorption curve is obtained by the measurement under set time and load functions, and the capillary water absorption test research of the concrete material under the sustained load functions and the durability estimation of a practical engineering structure can be carried out.

Owner:DALIAN UNIV OF TECH

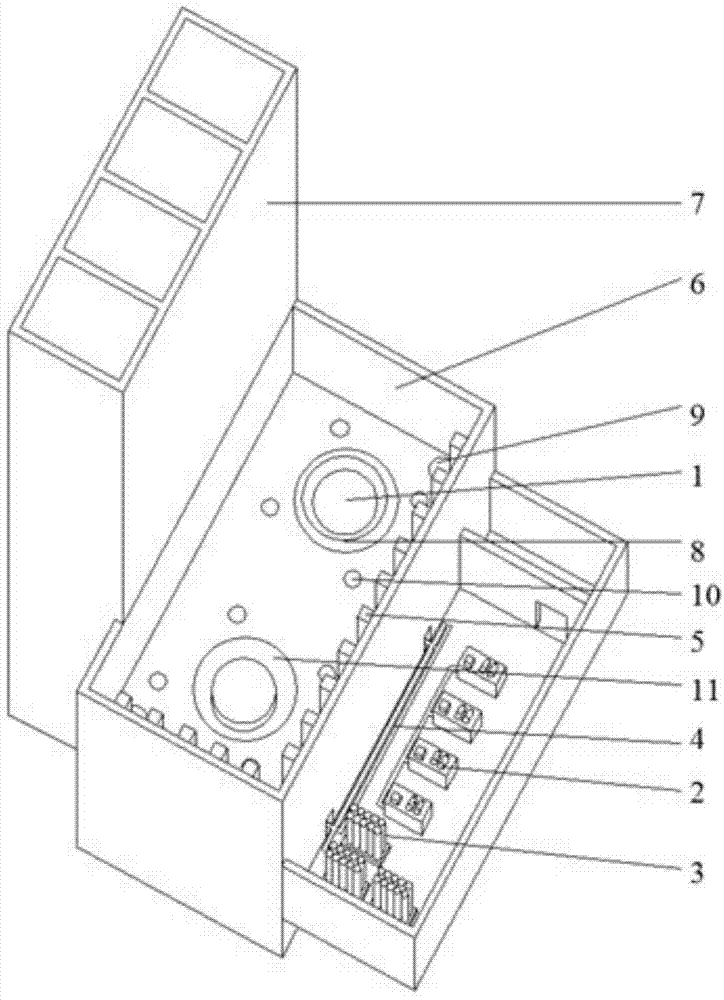

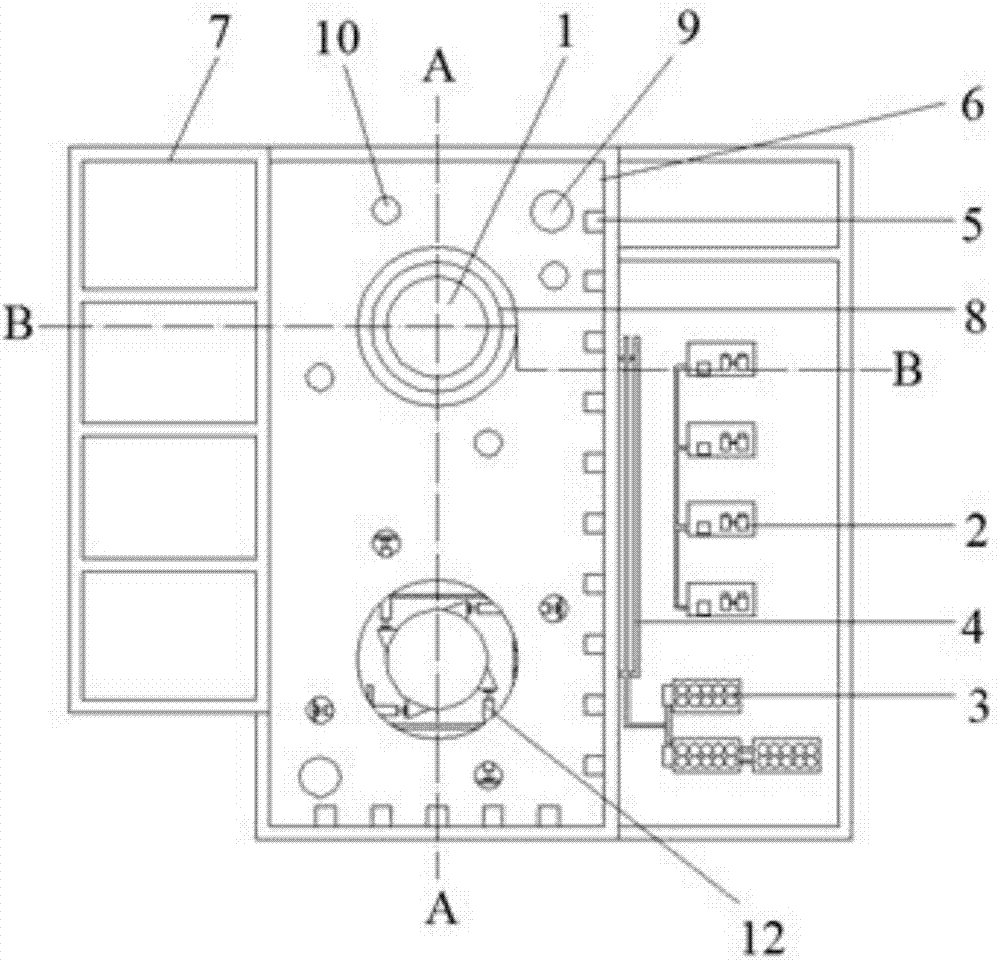

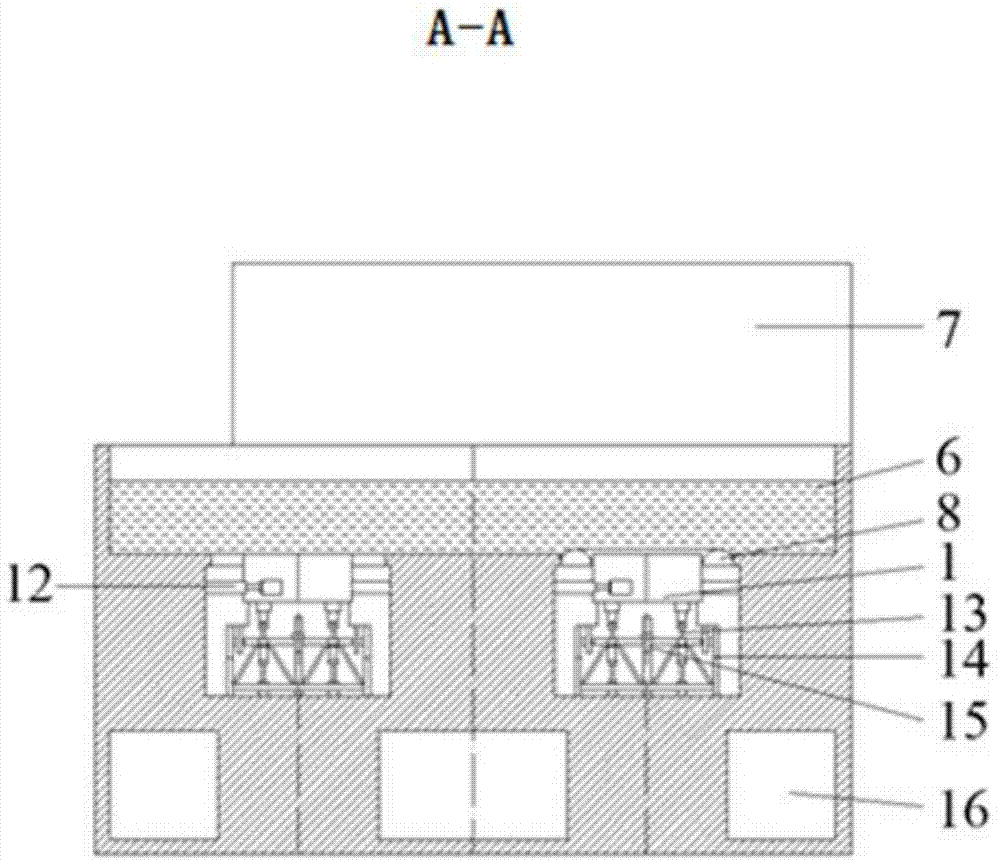

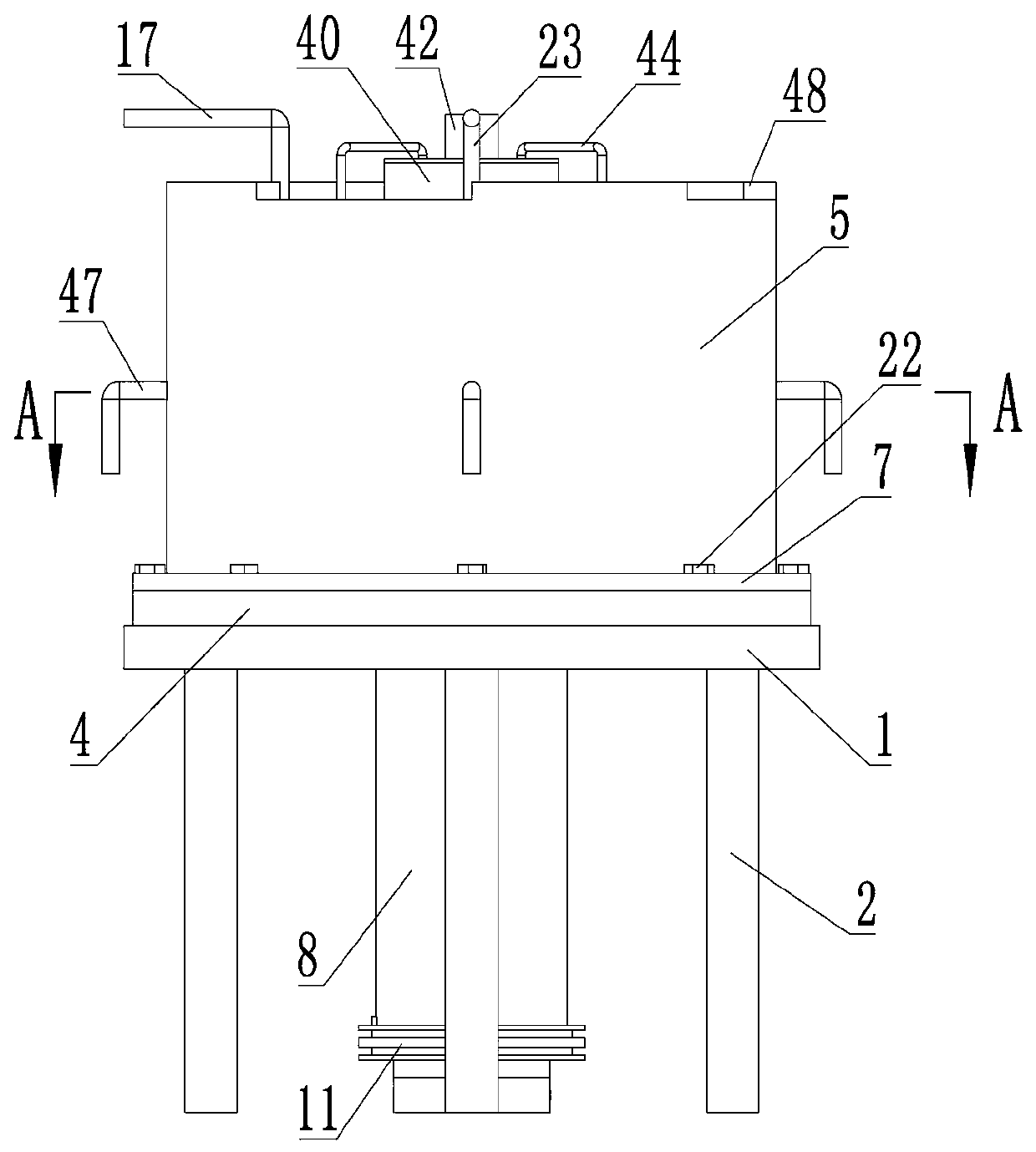

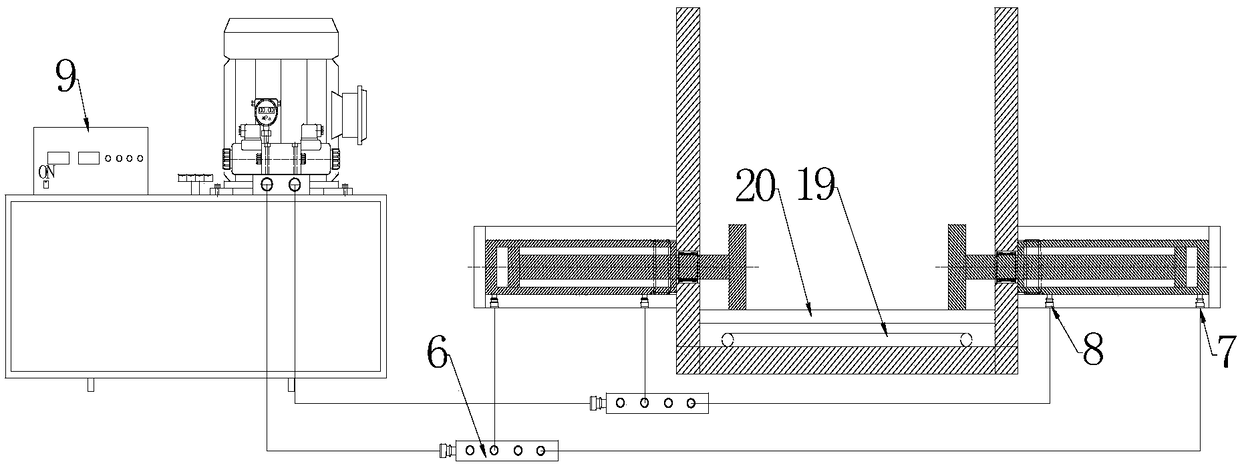

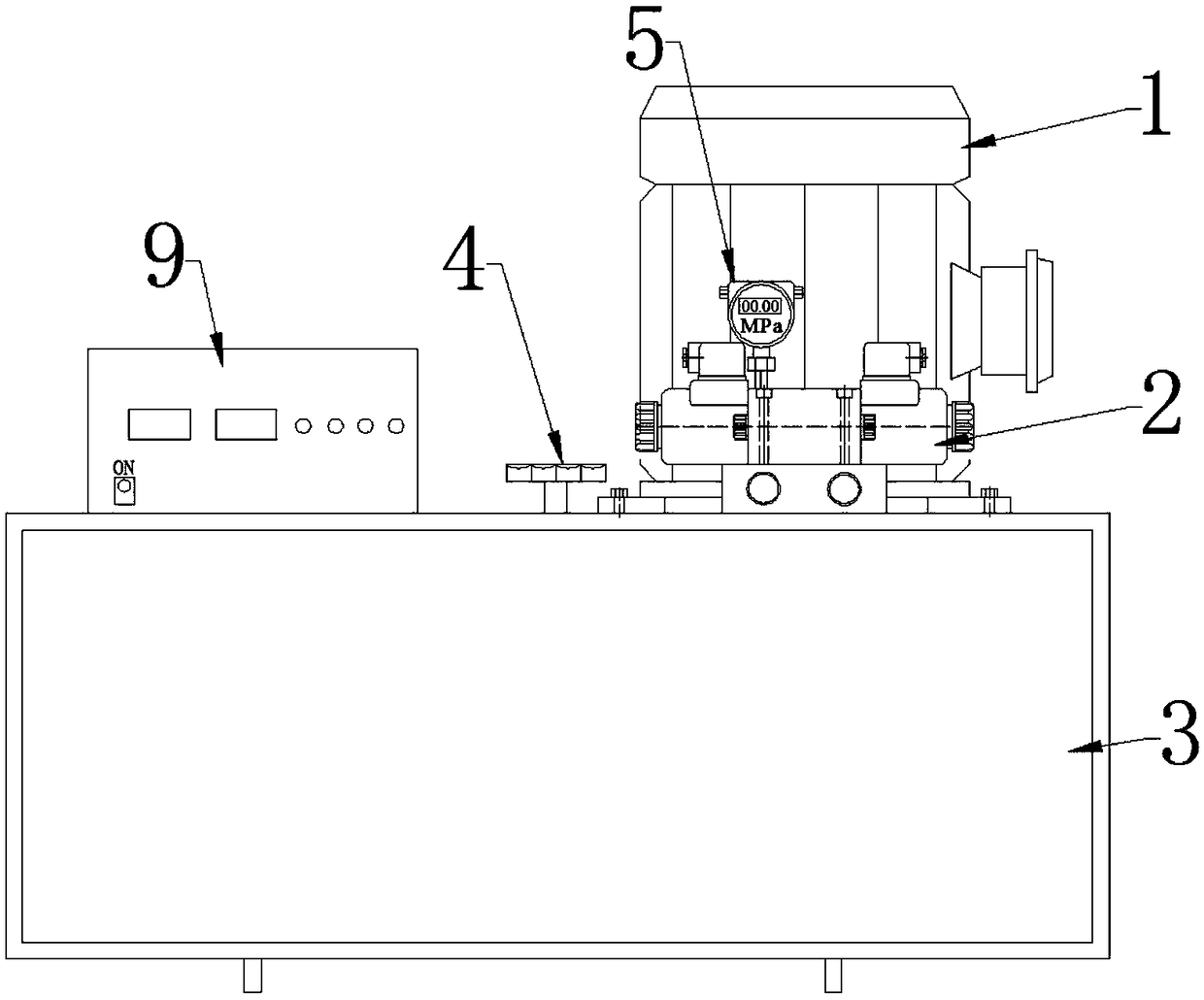

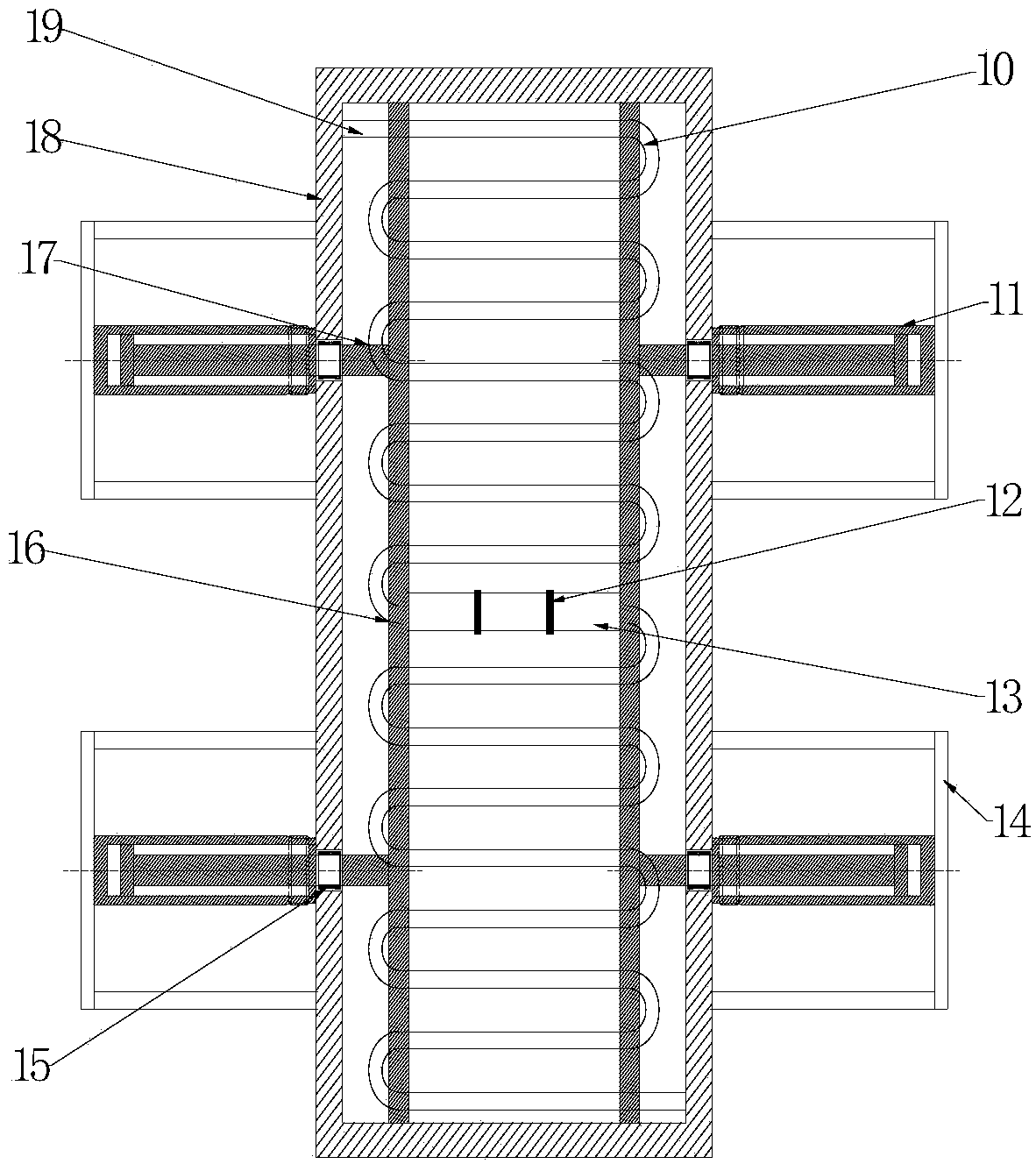

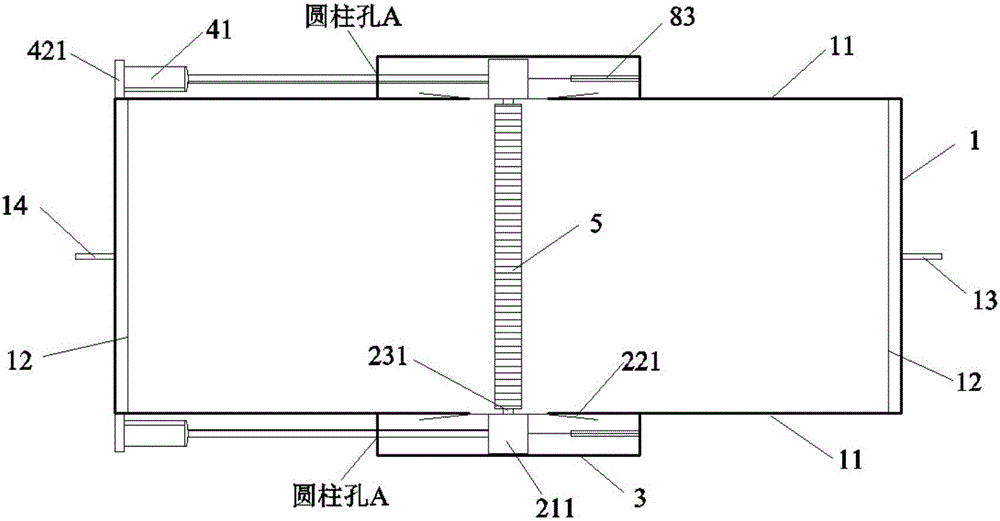

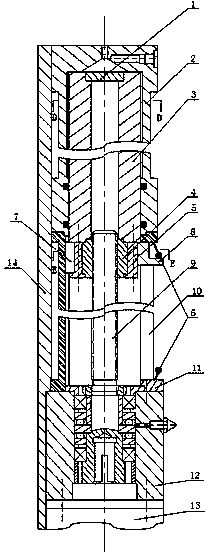

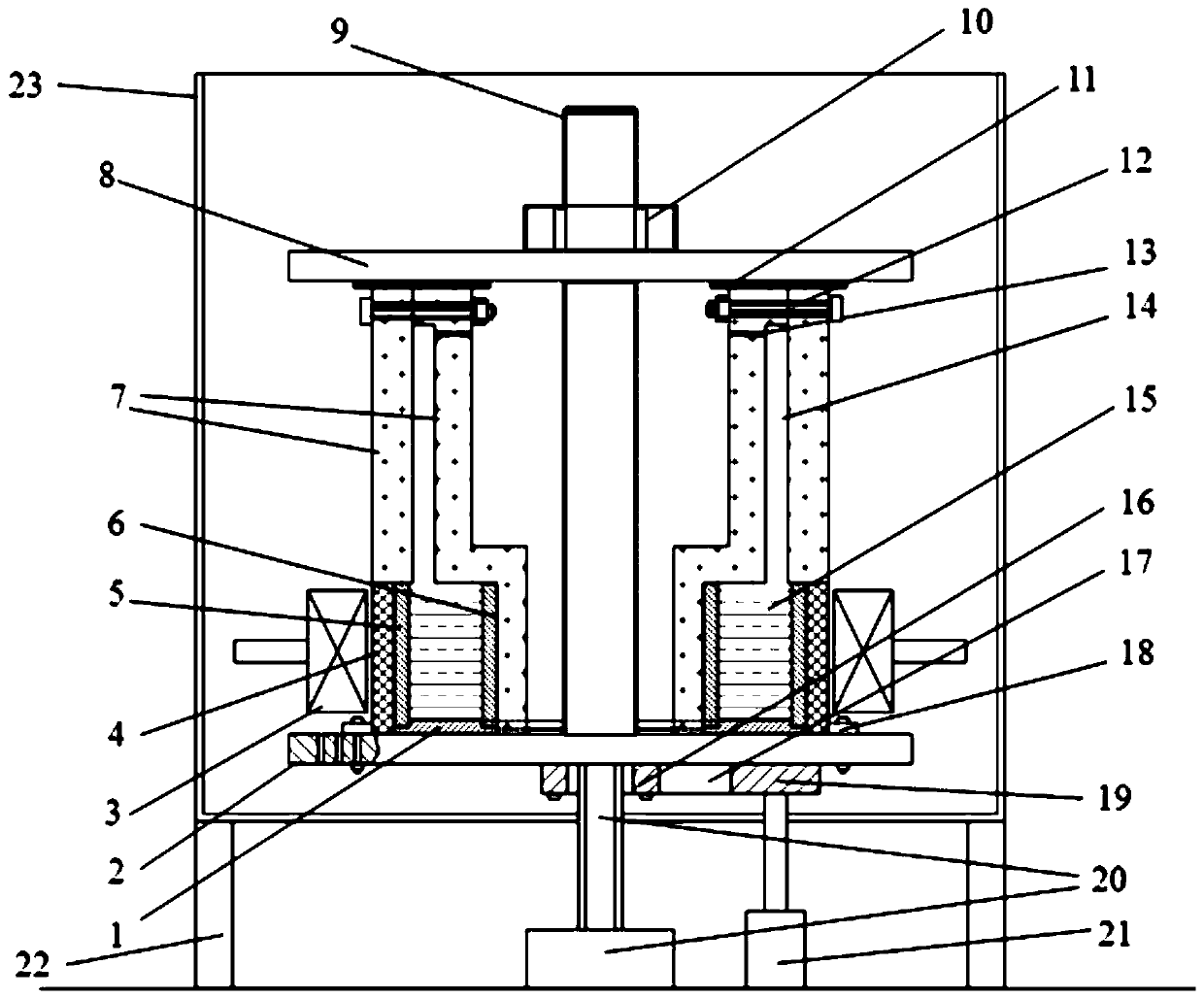

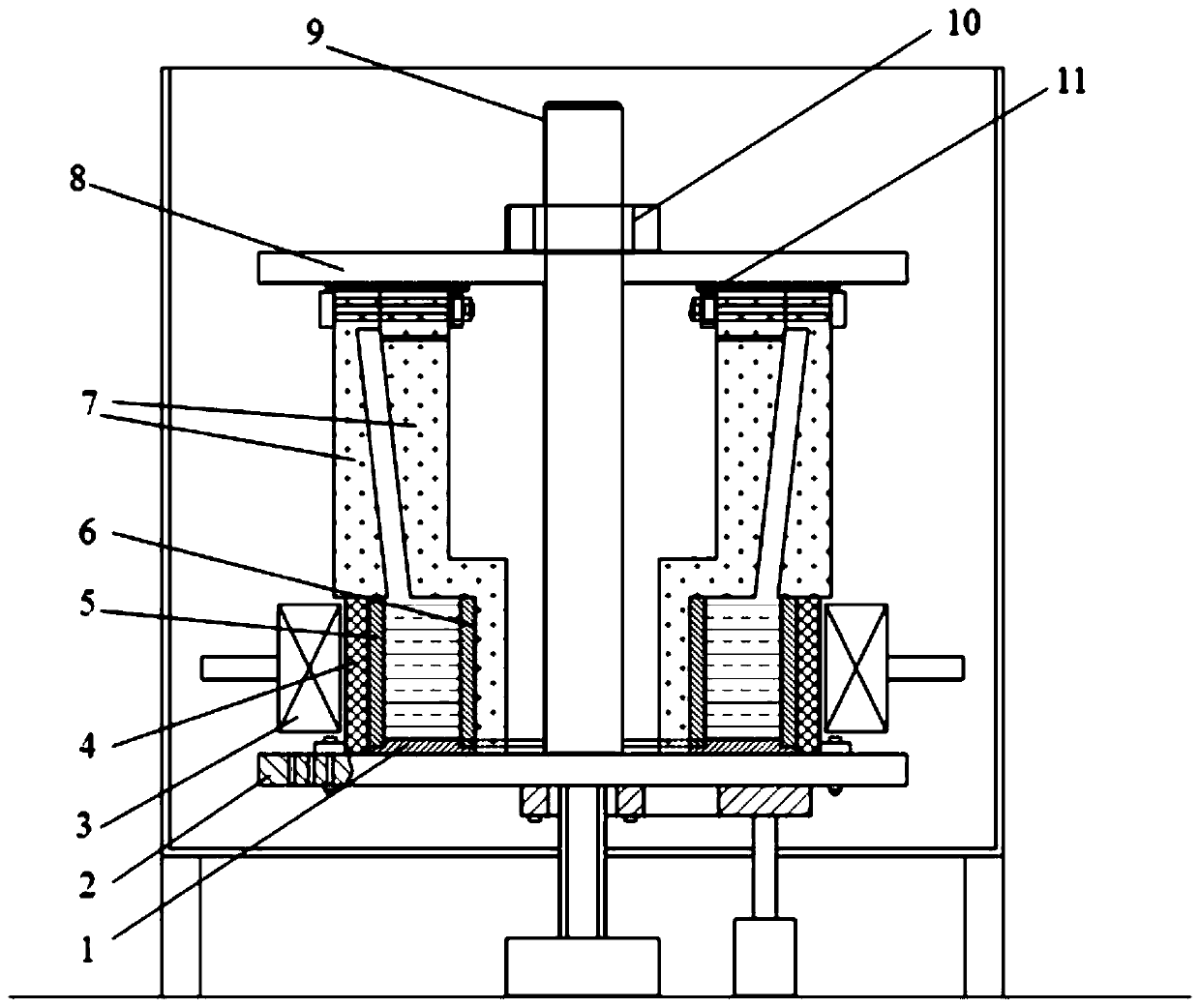

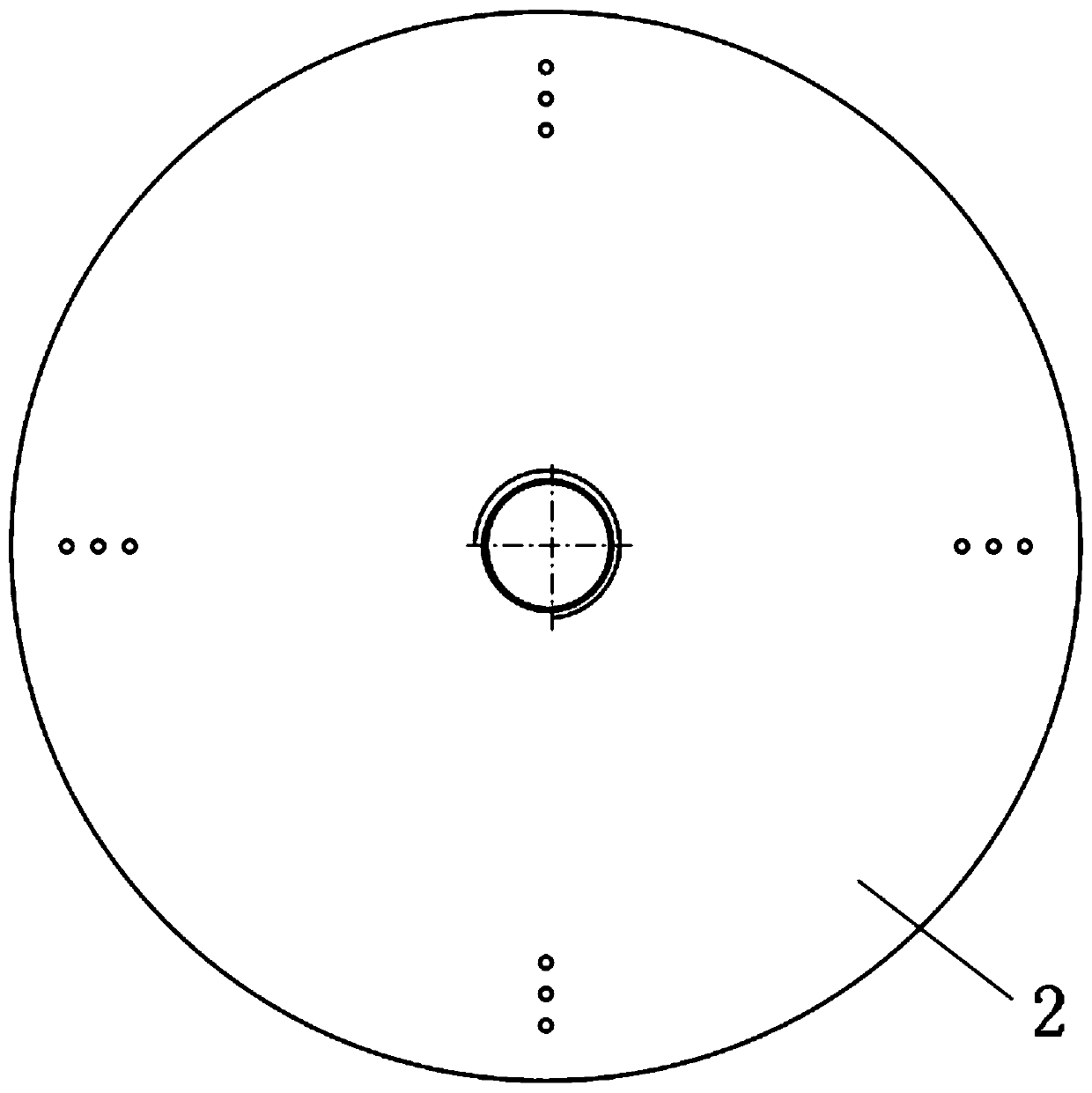

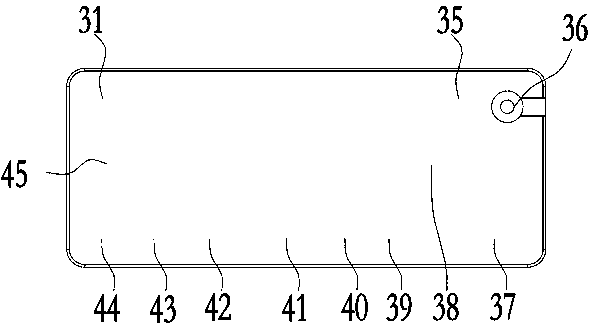

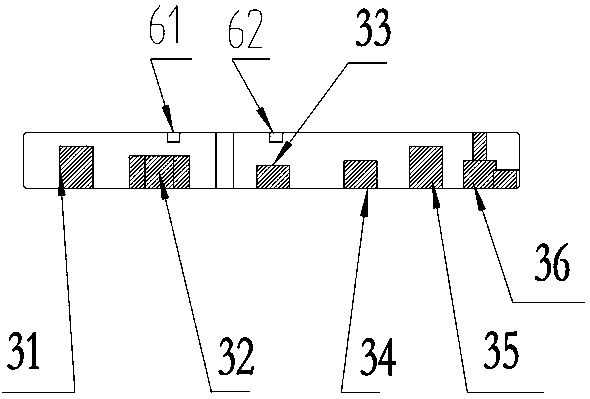

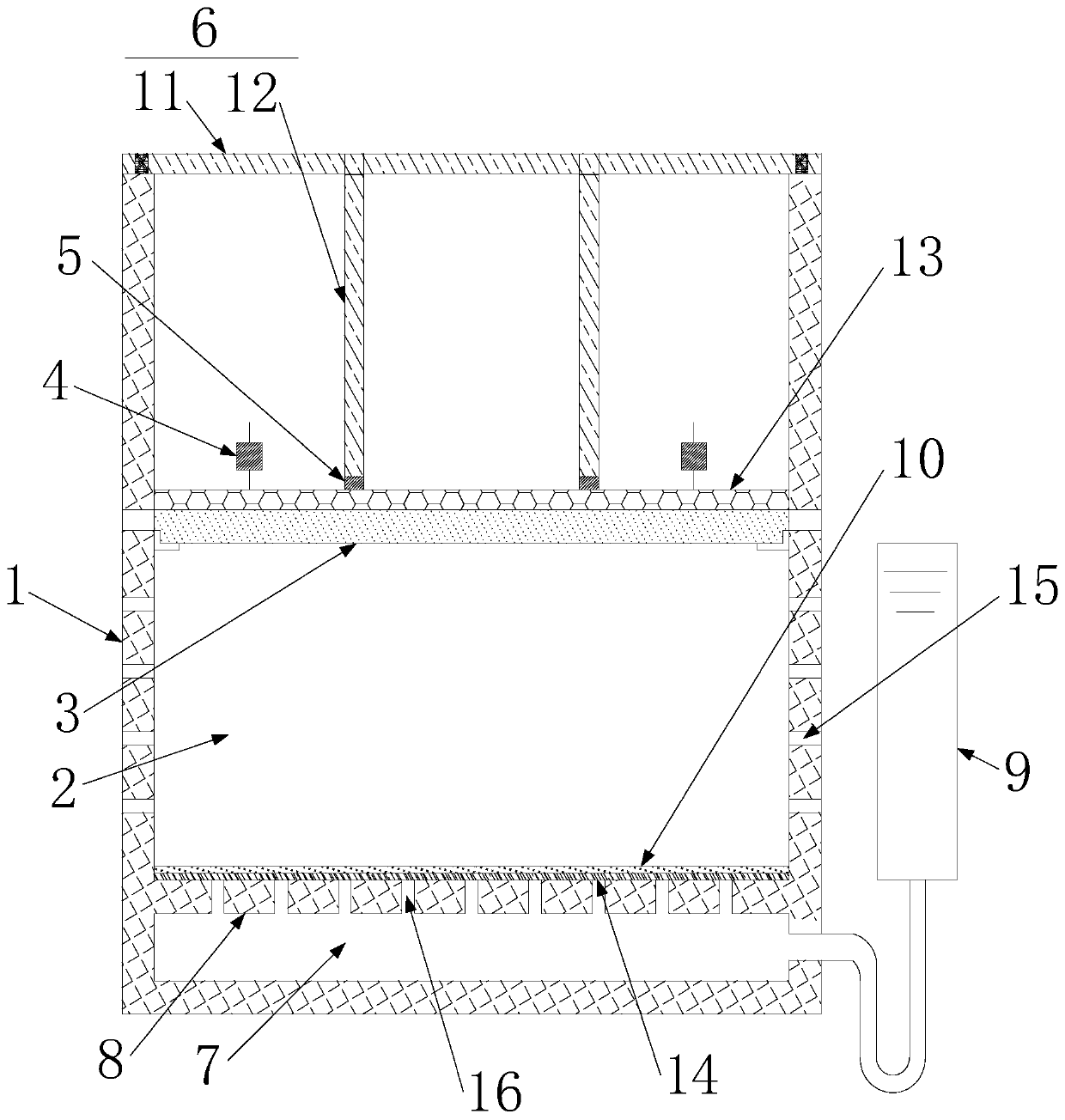

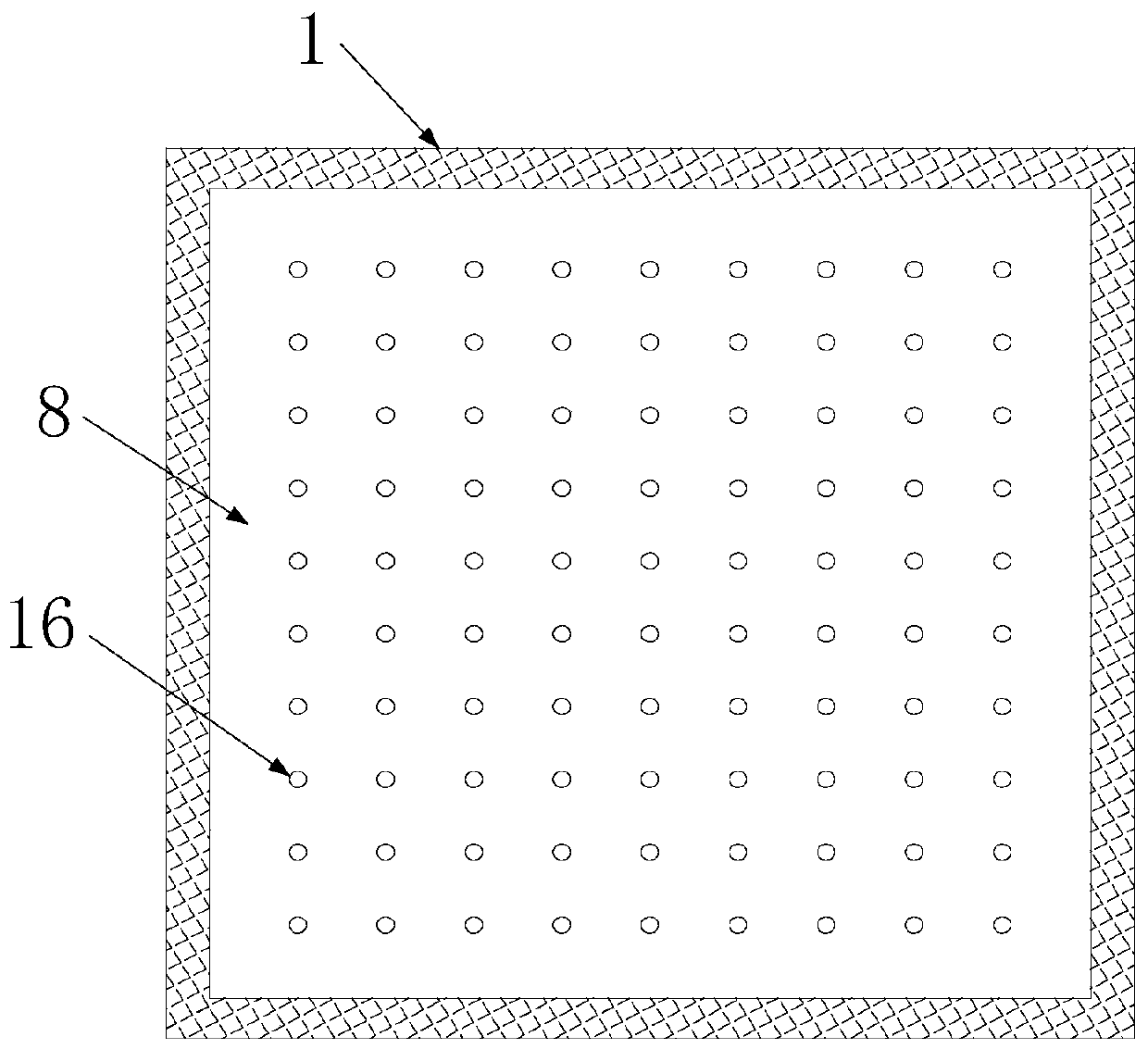

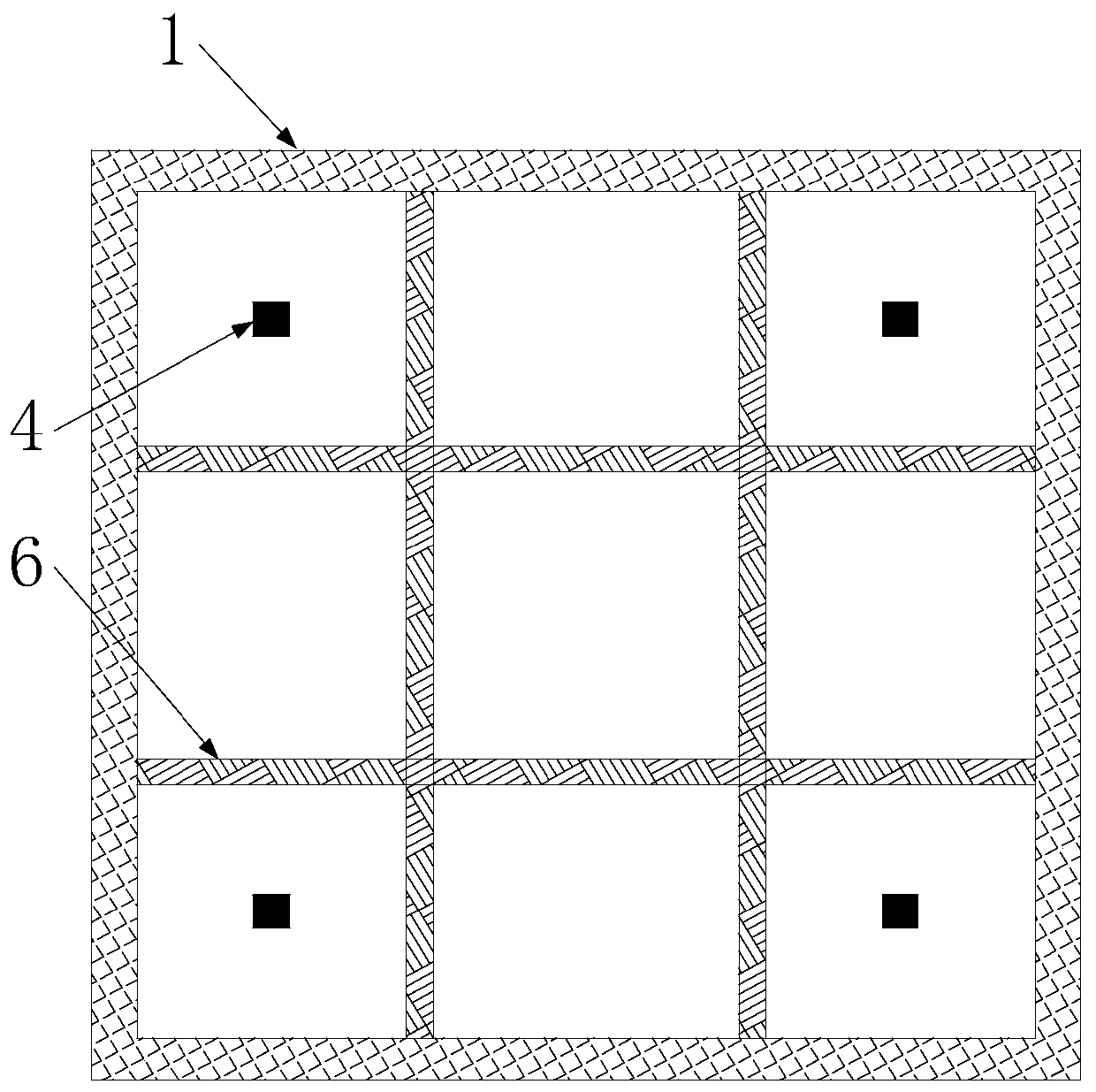

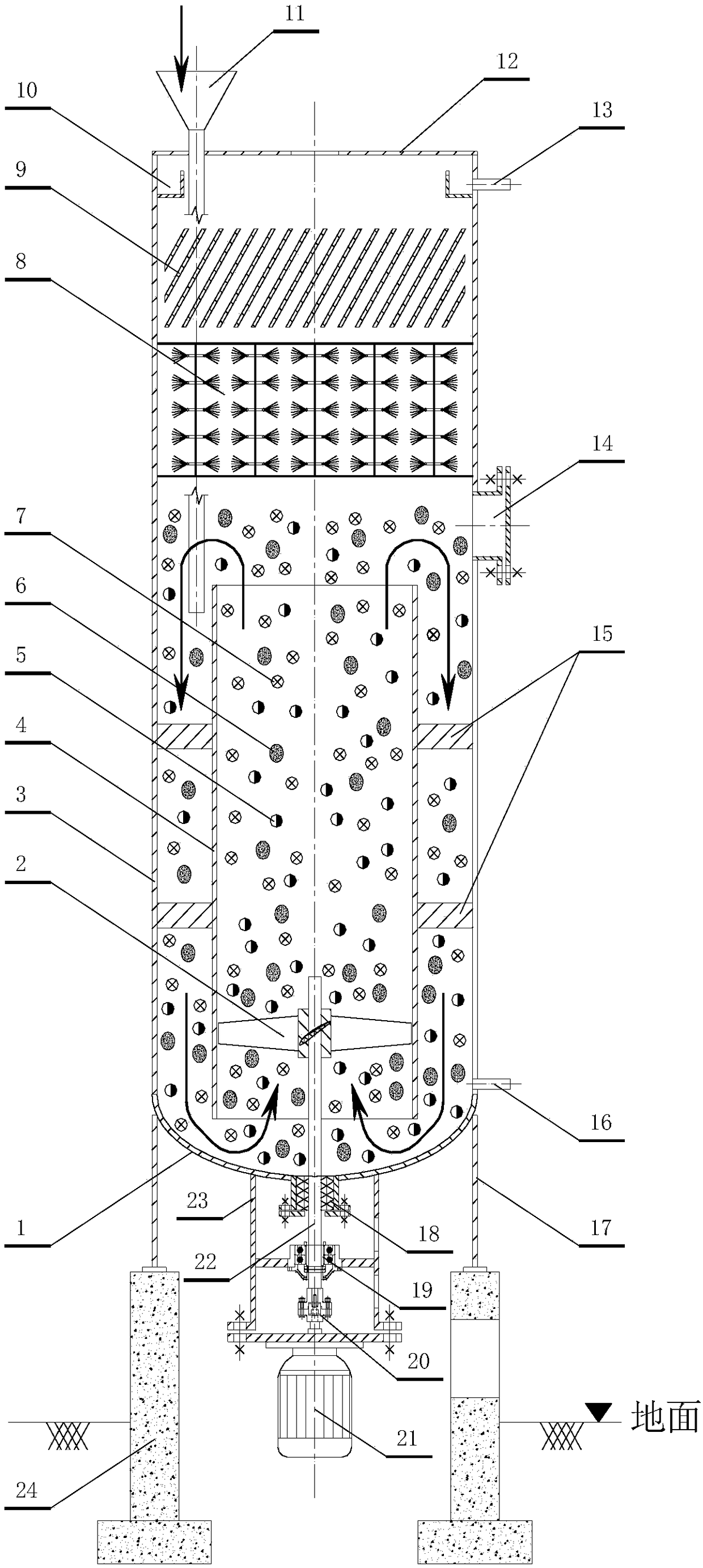

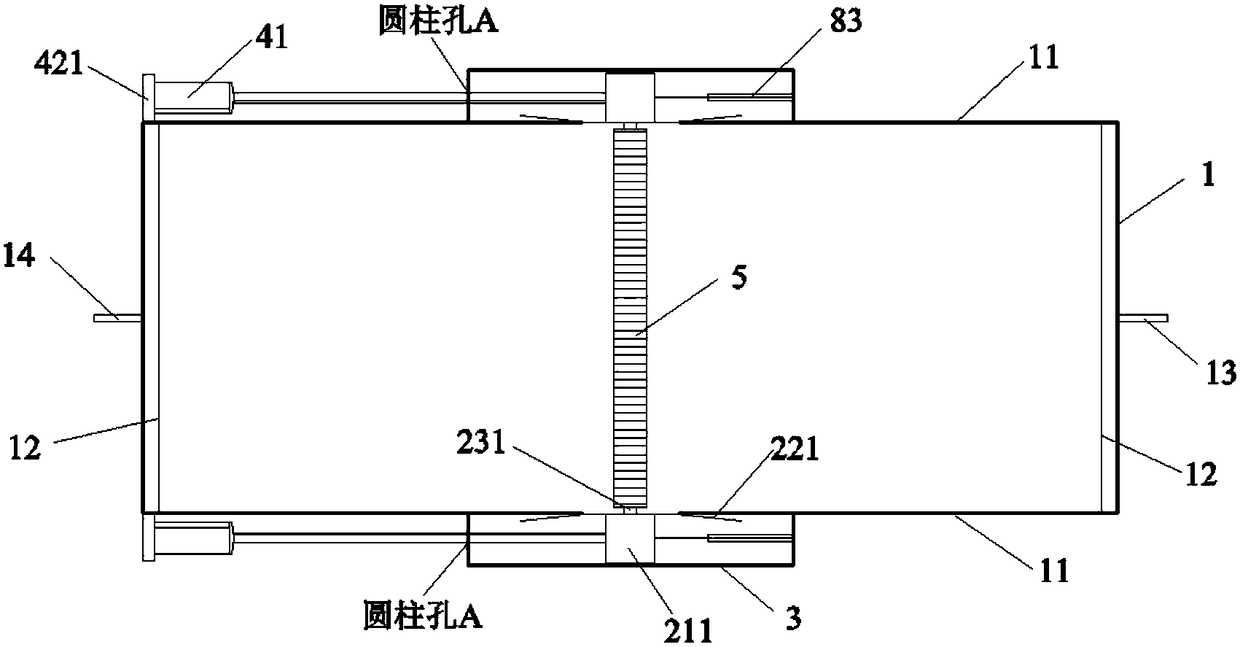

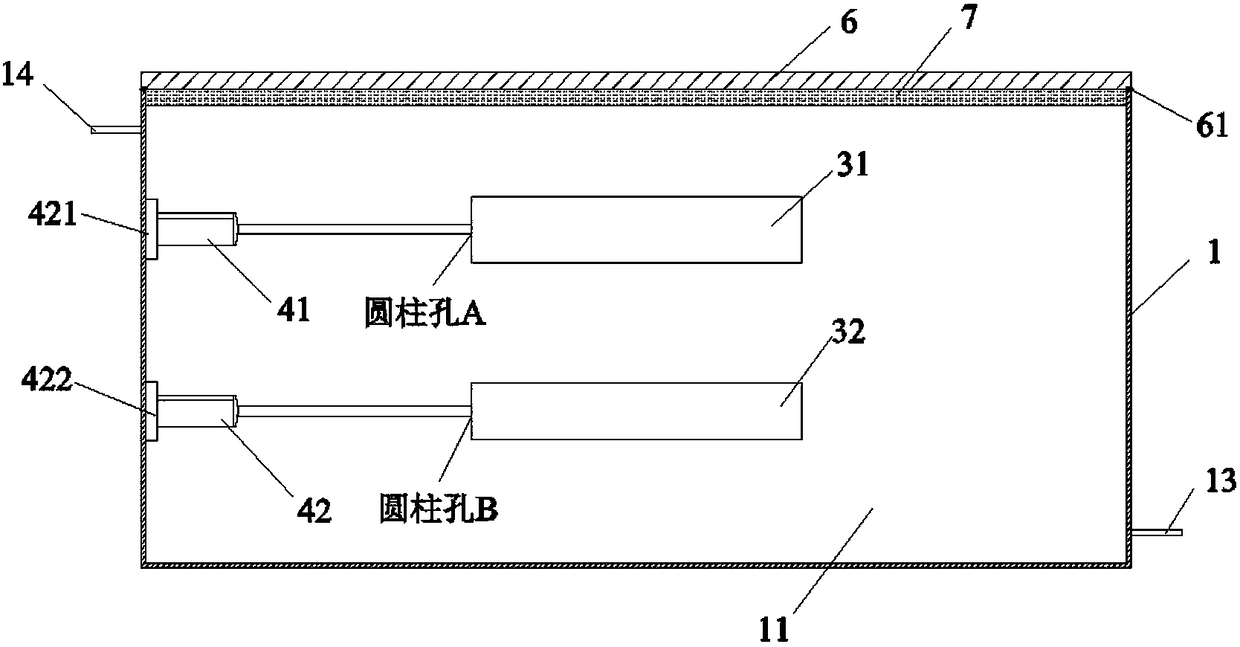

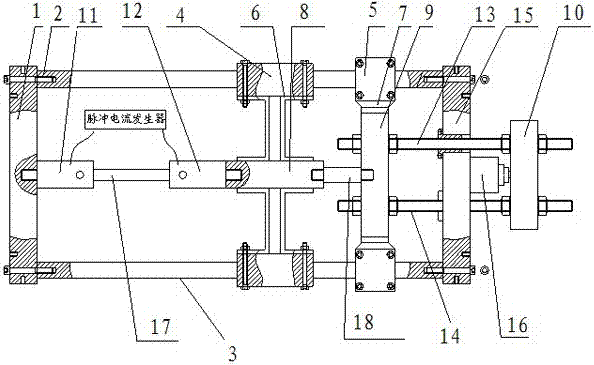

Seismic array of underwater earthquake simulation vibrostand

InactiveCN104849011ARealize the coupling effectHas a long cycleVibration testingEngineeringOperability

The present invention discloses a seismic array of an underwater earthquake simulation vibrostand. The seismic array comprises a seismic array pedestal arranged on a power base, and a deep pool arranged on the seismic array pedestal. Two vibrostand surfaces are arranged in the deep pool. The lower parts of the vibrostand surfaces are provided with a horizontal actuator, a vertical actuator and a guide device arranged via a hydrostatic back-up. One side of the deep pool is provided with a reaction wall, and the other side of the deep pool is provided with an oil transmission pipeline for connecting an oil pump station with an accumulator group. The inner side thereof is provided with a wave maker group. The bottom of the reaction wall and the lower part of the deep pool are respectively provided with manholes. According to the invention, the dynamic test on large engineering structure under the coupling excitation effect of waves, the water flow and the earthquake is realized. meanwhile, the coupling effect of multi-point and multi-dimensional earthquake and wave power is realized. The seismic array is long in period, large in displacement, good in high-frequency seismic property and higher in operability. The synchronous / asynchronous control of two vibrostands, the generation of waves and seawater, and the synchronous / asynchronous control of the vibrostand seismic array excitation are realized.

Owner:TIANJIN UNIV

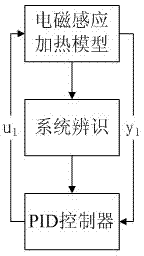

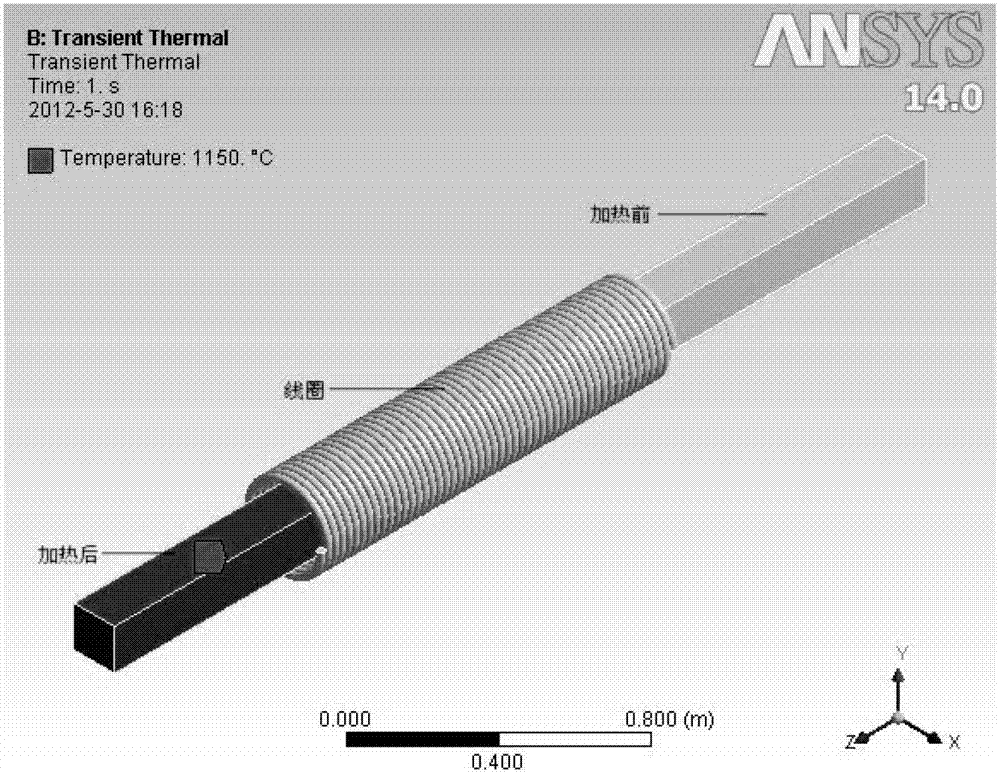

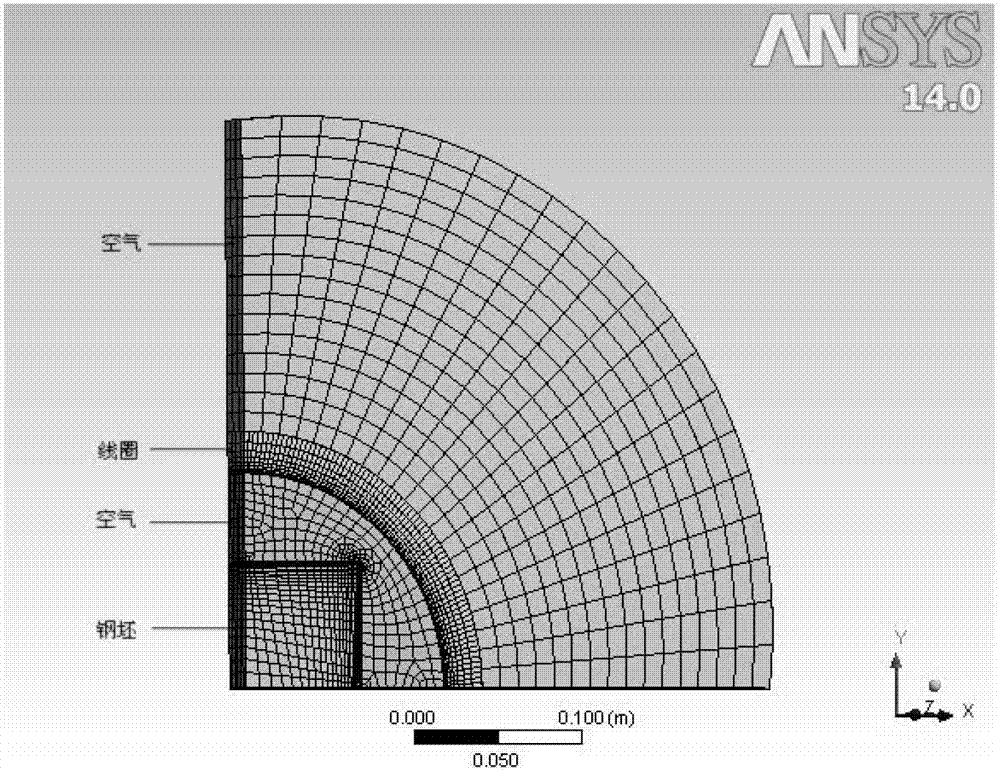

Induction heating closed loop simulation method based on finite element model and system identification

ActiveCN102778844AOvercome disadvantages that cannot be directly used for controlRealize the coupling effectSimulator controlLoop controlElement model

The invention discloses an induction heating closed loop simulation method based on finite element model and system identification. The method adopts ANSYS software to build a billet electromagnetic induction heating finite element model, and the simulation of billet induction heating process is realized through solving the model, thus obtaining the simulation data. The system input and output time history which is obtained through the finite element simulation is used for substituting the experimental data, a least square system identification method is adopted to process the input and output time history, and thus, system response characteristic parameters are obtained; then, a proportion integration differentiation (PID) feedback controller is designed on the basis of the model; and finally, an ansys parameter design language (APDL) is adopted to introduce the PID feedback controller into the finite element model, so the simulation process of an induction heating closed loop system is realized. The method takes the advantages of the induction heating finite element model, realizes the coupling of electromagnetic induction heating and a control system, can greatly improve the simulation precision, and facilitates the advanced performance analysis of induction heating closed loop control.

Owner:杭州四达电炉成套设备有限公司

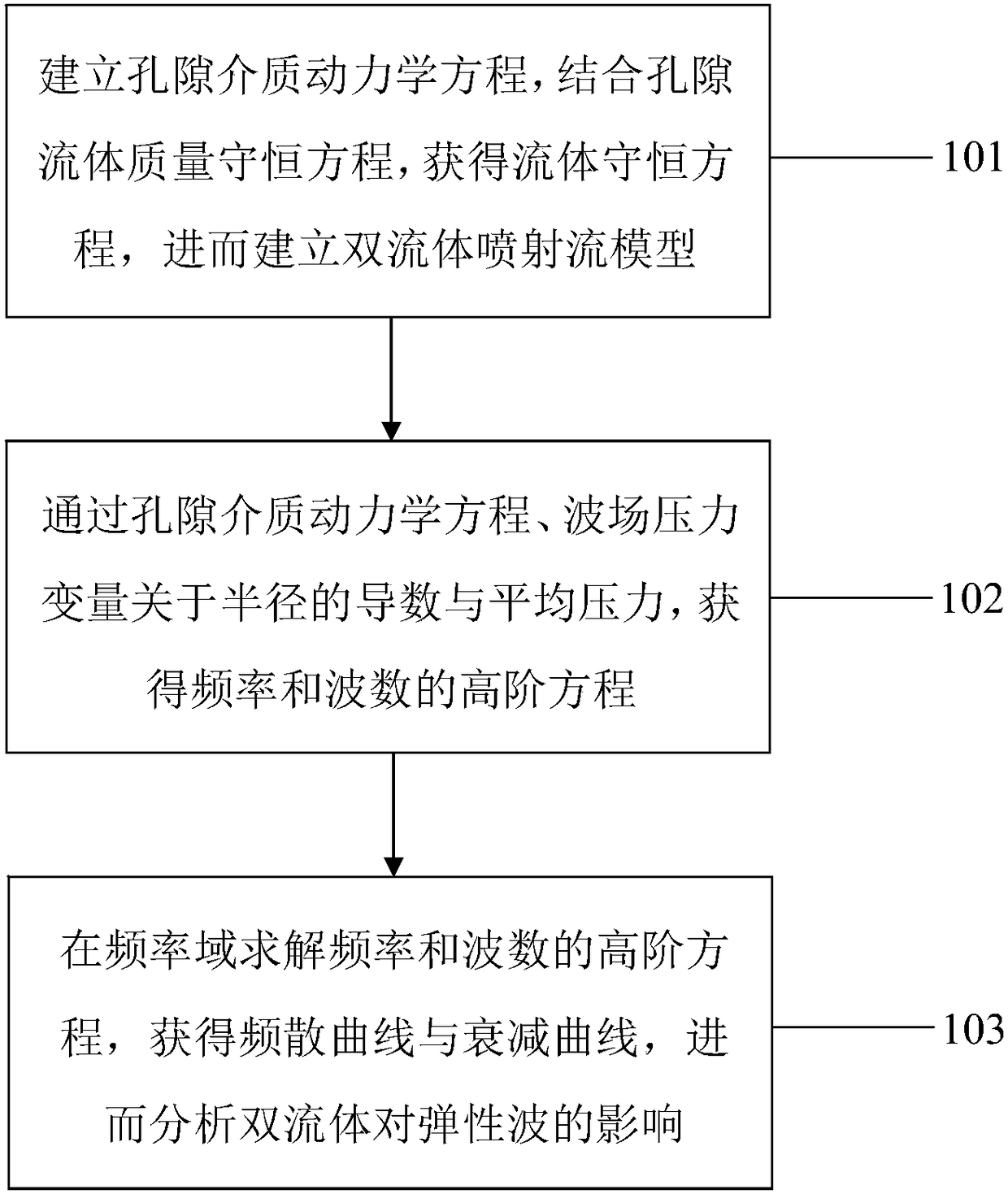

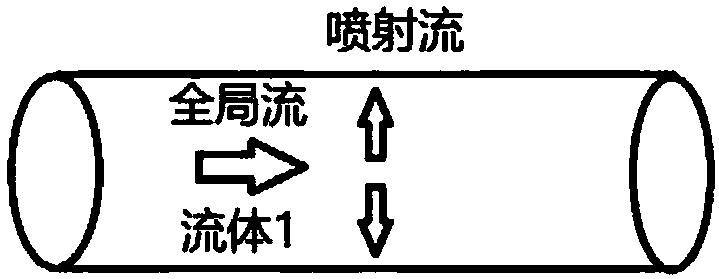

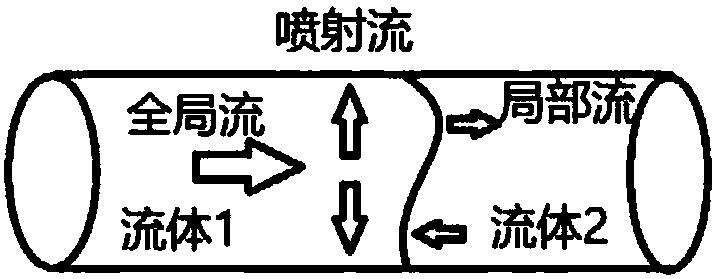

Elastic wave evaluating method of two-fluid jet flow model and computer-readable storage medium

The invention discloses an elastic wave evaluating method of a two-fluid jet flow model and a computer-readable storage medium. The method comprises: establishing a porous medium dynamics equation based on a single-fluid, single-porosity jet flow model, combining with a porous fluid mass conservation equation to obtain a fluid conservation equation, and then establishing the two-fluid jet flow model; obtaining a higher-order equation of frequency and wavenumber by the porous medium dynamics equation, a derivative of a wave field pressure variable with respect to a radius and an average pressure based on the two-fluid jet flow model; and solving the higher-order equation of frequency and wavenumber in a frequency domain, obtaining a dispersion curve and an attenuation curve, and then analyzing the influence of the two-fluid on the elastic wave. According to the elastic wave evaluating method of the two-fluid jet flow model and the computer-readable storage medium, a petrophysical modelincluding a partially saturated dual porosity medium with macro-mesoscopic-microscopic three dimensions and a plaque jet flow mechanism is established, a comprehensive interpretation of wave field energy dissipation mechanism is realized, and propagation velocities of seismic waves in porous rock medium are predicted based on the model.

Owner:CHINA PETROLEUM & CHEM CORP +1

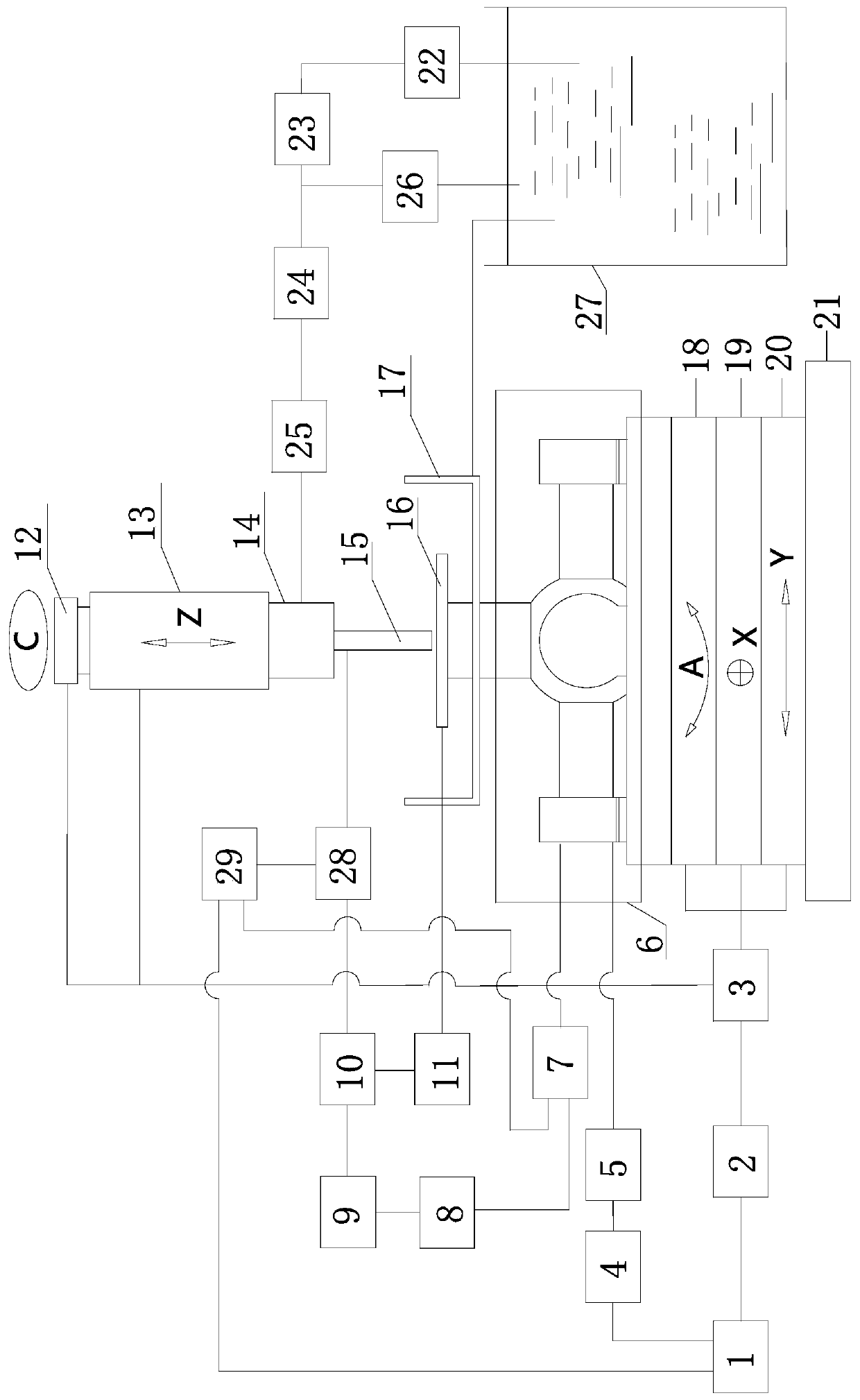

Ultrasonic modulation discharge-electrolysis high-efficiency milling system

The invention discloses an ultrasonic modulation discharge-electrolysis high-efficiency milling system, and belongs to the technical field of special machining. The ultrasonic modulation discharge-electrolysis high-efficiency milling system consists of an ultrasonic vibration control system, a multi-axis machine tool control system, a composite machining power supply control system and an electrolyte circulation system, wherein corresponding machining tracks are matched according to the profile characteristics of an anode workpiece; the machining tracks can be subjected to vector decomposition; the machining tracks are converted into control input quantity of the ultrasonic vibration control system and the multi-axis machine tool control system, the accurate synchronization of the millingprocess and the ultrasonic vibration is achieved; the ultrasonic vibration amplitude is detected in real time through a displacement sensor; the control input quantity serving as the composite machining power supply control system is processed through the programmable controller, the coupling effect of a variable voltage process and the ultrasonic vibration process is achieved, and the removal efficiency of the anode material and the stability of the machining process can be improved; and high-speed high-pressure electrolyte fluid provided by the electrolyte circulation system is directly conveyed into a machining gap through a rotary joint, so that the mass transfer efficiency of the fluid in the gap is enhanced, and the efficient composite machining with a smaller gap is achieved.

Owner:YANGZHOU UNIV

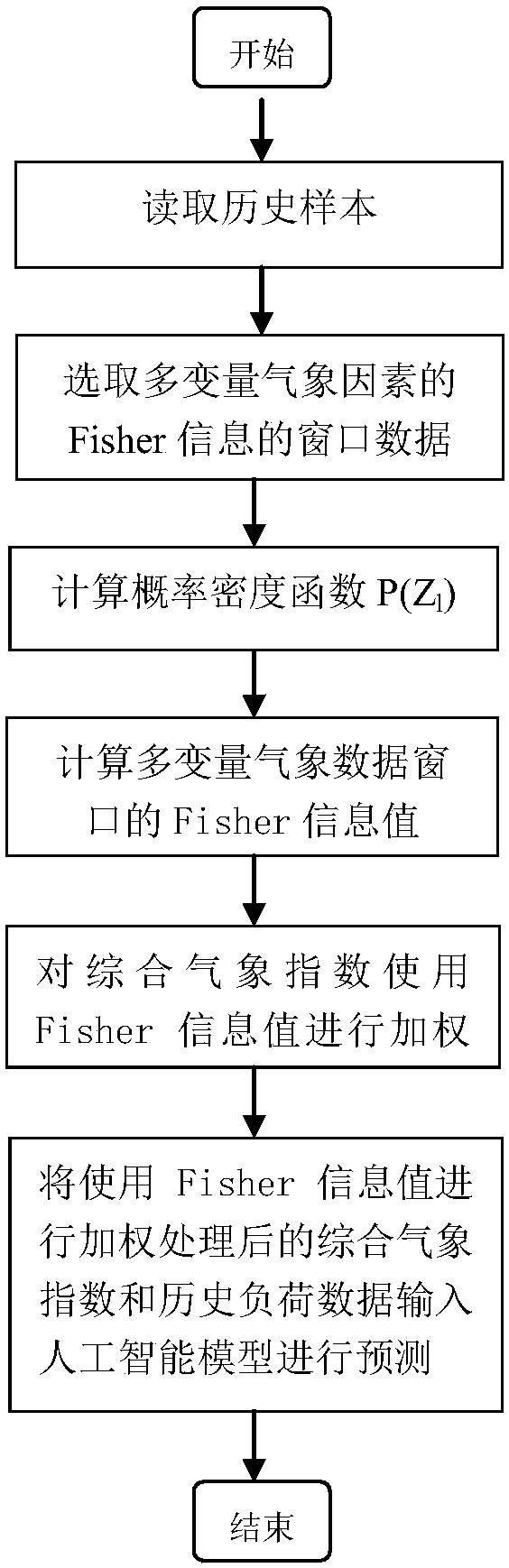

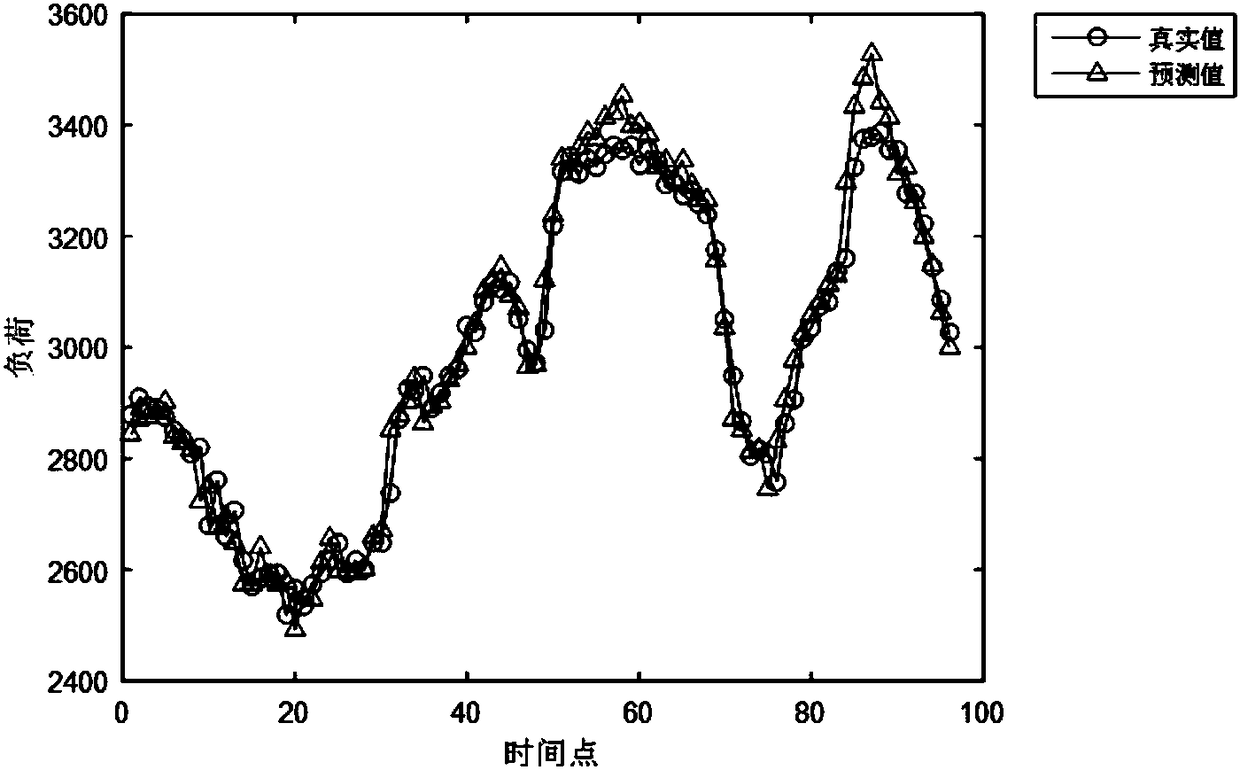

Short-term load processing method based on multidimensional meteorological factors of Fisher information processing

InactiveCN108171380ARealize the coupling effectAchieving a cumulative effectForecastingInformation processingShort terms

The invention relates to a short-term load processing method based on multidimensional meteorological factors of Fisher information processing, comprising the following steps: analyzing historical sample data to obtain multidimensional meteorological factor Fisher information window data of a corresponding load; calculating the Fisher information value of the multidimensional meteorological factorFisher information window data on the basis; weighting the Fisher information value to obtain input variables of Fisher information weighting; and inputting the input variables and historical load data to an artificial intelligence prediction model. The comprehensive index is weighted through calculation of multidimensional meteorological factor Fisher information, so as to realize the coupling effect and cumulative effect of multiple meteorological factors on a load and realize accurate prediction of a weather-sensitive load.

Owner:JIANGSU UNIV

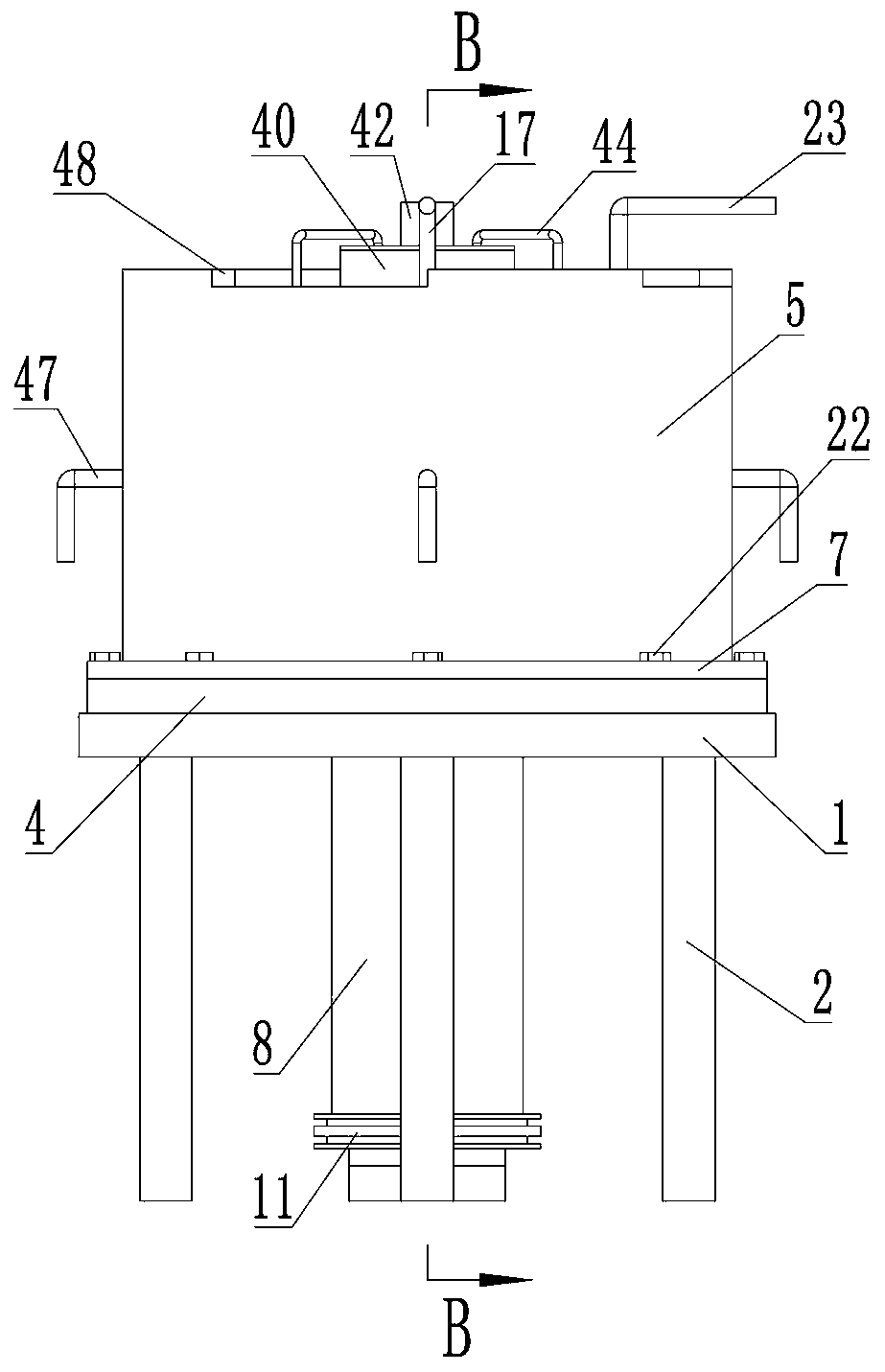

True triaxial experiment device and method capable of simulating radial pressure

PendingCN111579382AAchieving true triaxial stress conditionsHighlight substantive featuresMaterial strength using tensile/compressive forcesRock coreElectric machinery

The invention discloses a true triaxial experiment device capable of simulating radial pressure. The device comprises a horizontal fixed chassis and a gear motor; the bottom of the horizontal fixed chassis is fixedly connected with a plurality of supporting columns arranged in a circumferential array; an experiment box body is rotationally arranged on the upper surface of the horizontal fixed chassis; a rock core test piece is placed in the experiment box body; the left-right horizontal direction of the experiment box body is taken as an x direction; the front-back horizontal direction of theexperiment box body is used as a y direction; an x-direction pressing mechanism is arranged on the left side of the interior of the experiment box body with the vertical direction of the experiment box body as the z direction; a y-direction pressing mechanism is arranged on the front side of the interior of the experiment box body; a z-direction pressing mechanism is arranged at the bottom of theexperiment box body; and the bottom of the experiment box body is in transmission connection with a main shaft of a gear motor through a belt transmission mechanism. Stress and pore pressure of a rockcore in three-axis directions can be simulated, thickened oil thermal recovery is simulated by injecting hot steam into the rock core test piece, and a complex seepage test is realized by rotating the experiment box body.

Owner:PETROCHINA CO LTD

Composite CuNiIn powder, preparation method and application thereof

ActiveCN108425085AHigh strengthImprove the binding effectMolten spray coatingTransportation and packagingThermal sprayingUltimate tensile strength

The invention discloses composite CuNiIn powder, a preparation method and an application thereof. The composite CuNiIn powder comprises a dispersion strengthening phase and a self-lubricating phase. The preparation method comprises the following steps that ball milling and mixing on In powder, nickel-coated molybdenum disulfide powder and A12O3 dispersion strengthening Cu powder are carried out soas to prepare mixed raw materials; a spray drying granulator is adopted to carry out centrifugal atomization granulation on the mixed raw materials to prepare dried granules; and vacuum sintering iscarried out on the dried particles, and then the dried particles are crushed and screened to obtain the composite CuNiIn powder. The composite CuNiIn powder can be prepared into a composite CuNiIn coating containing the dispersion strengthening phase and the self-lubricating phase by adopting a thermal spraying method. The distribution state of the self-lubricating phase is changed, the strength and the toughness of the coating are improved, the generation of micro-cracks of the coating is effectively avoided, the self-lubricating service life of the coating is prolonged, and the composite CuNiIn powder has a good application value in the industries of aviation engines, gas turbines and the like.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Device for applying prestress to rock sample in freezing and thawing test

PendingCN109142084ARealize the coupling effectEasy to operateWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesControl systemCoupling

The invention discloses a device for applying prestress to a rock sample in freezing and thawing test. The device comprises a freezing and thawing test box, a hydraulic system and a control system, asample supporting frame and a freezing pipe are arranged in the freezing and thawing test box, a left pressing plate and a right pressing plate are arranged on the left side and the right side of thetop of the sample supporting frame and pushed by the hydraulic system to oppositely draw close or keep away from each other to load or unload the sample, and the control system is in control connection with the hydraulic system. By the aid of the device for applying prestress to the rock sample in the freezing and thawing test, the prestress is applied to the sample during freezing and thawing, and the resistance of the rock sample in freezing and thawing and load coupling environments is comprehensively assessed.

Owner:CENT SOUTH UNIV

Built-in retaining wall type soil pressure seepage effect test method

ActiveCN105954099ARealize the coupling effectPrecise control angleMaterial strength using tensile/compressive forcesPore water pressureEngineering

The present invention discloses a built-in retaining wall type soil pressure seepage effect test method. The method comprises the steps of A, completing the azimuth adjustment and the soil filling of a rigid retaining wall inside a box; B, injecting water into the box through a water inlet pipe by means of a water pump; C, infiltrate the water into the soil through the porous plate of the water inlet pipe in the box; D, blocking the water inlet pipe and an exhaust pipe, and standing; E, controlling the movement of the rigid retaining wall through upper and lower jacks; F, acquiring the pressure of the pore water through a pore pressure probe to obtain the result of the active soil pressure and the passive soil pressure under the seepage effect. A test device is composed of a box, an upper sliding block, a lower sliding block, an upper sliding groove, a lower sliding groove, an upper jack, a lower jack, a rigid retaining wall, a vertical bearing plate, a flexible loading water bag, a film type pressure sensor, a pore pressure probe and a displacement sensor. The device is convenient in operation, high in efficiency and energy-saving. Meanwhile, the requirements of testing active and passive soil pressures under the seepage effect are met.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Unsaturated soil water-gas motion combined determination triaxial apparatus

ActiveCN111413263AReal-time monitoring of changesInvestigate humidification deformation characteristicsPermeability/surface area analysisSuction stressAxial pressure

The invention discloses an unsaturated soil water-gas motion combined determination triaxial apparatus. The triaxial apparatus comprises an actuating system, a seepage pressure chamber and a control system for controlling the actuating system and the seepage pressure chamber, wherein the seepage pressure chamber comprises a frame formed by combining a base, a stand column and a cross beam; a hydraulic mechanism is mounted in the center of the base; the top of the hydraulic mechanism abuts against the bottom of the test piece seat; a confining pressure cylinder which is used for containing a test piece and is provided with a confining pressure air inlet pipe is arranged on the test piece seat; an upper pressure head and a sample holder are respectively arranged at the upper part and the lower part of the confining pressure cylinder; a pressure rod is immovable when axial pressure is applied, an upper pressure head is ejected, argil plates and waterproof breathable films are arranged onthe lower surface of the upper pressure head and the upper surface of the sample holder in a crossed manner, and the argil plates and the waterproof breathable films are respectively connected with water-phase and gas-phase volume and pressure controllers through pressure sensors. The water-gas two-phase permeability coefficient of the soil sample can be measured under the condition of controllingthe matrix suction of the soil sample, and the change characteristics of the matrix suction along the height direction of the soil sample can be quantitatively described.

Owner:XIAN UNIV OF TECH

In-situ centrifugal casting device and centrifugal casting method for thin-wall alloy castings with circular ring sections

The invention provides an in-situ centrifugal casting device and a centrifugal casting method for thin-wall alloy castings with circular ring sections, and relates to the centrifugal casting device and the centrifugal casting method for the alloy castings. The centrifugal casting device and the centrifugal casting method aim at optimizing tedious processes of traditional centrifugal casting, eliminating potential safety hazards during melt transferring and pouring, reducing defects such as casting cold shut, inclusion and pores, avoiding waste of alloys in pouring gates, improving the production efficiency and reducing cost. In the in-situ centrifugal casting device, alloy raw materials are loaded in a graphite heater fixed to a bottom plate, a heat preservation barrel is placed outside the heater, an induction heating coil is arranged outside the heat preservation barrel, a casting mold is arranged on the tops of the heater and the heat preservation barrel, a limiting guide column isfixed to the circle center position of the bottom plate, and by twisting an axial limiting nut, an upper pressing plate can be moved downwards to press all parts, between the upper pressing plate andthe bottom plate, together with the bottom plate. According to the in-situ centrifugal casting method, the alloy raw materials are molten in the centrifugal device, a mold cavity of the casting mold is full filled with the alloy raw materials under the effect of centrifugal force, the alloy raw materials are solidified and formed, and coupling of in-situ smelting and in-situ centrifugation is achieved.

Owner:HARBIN INST OF TECH

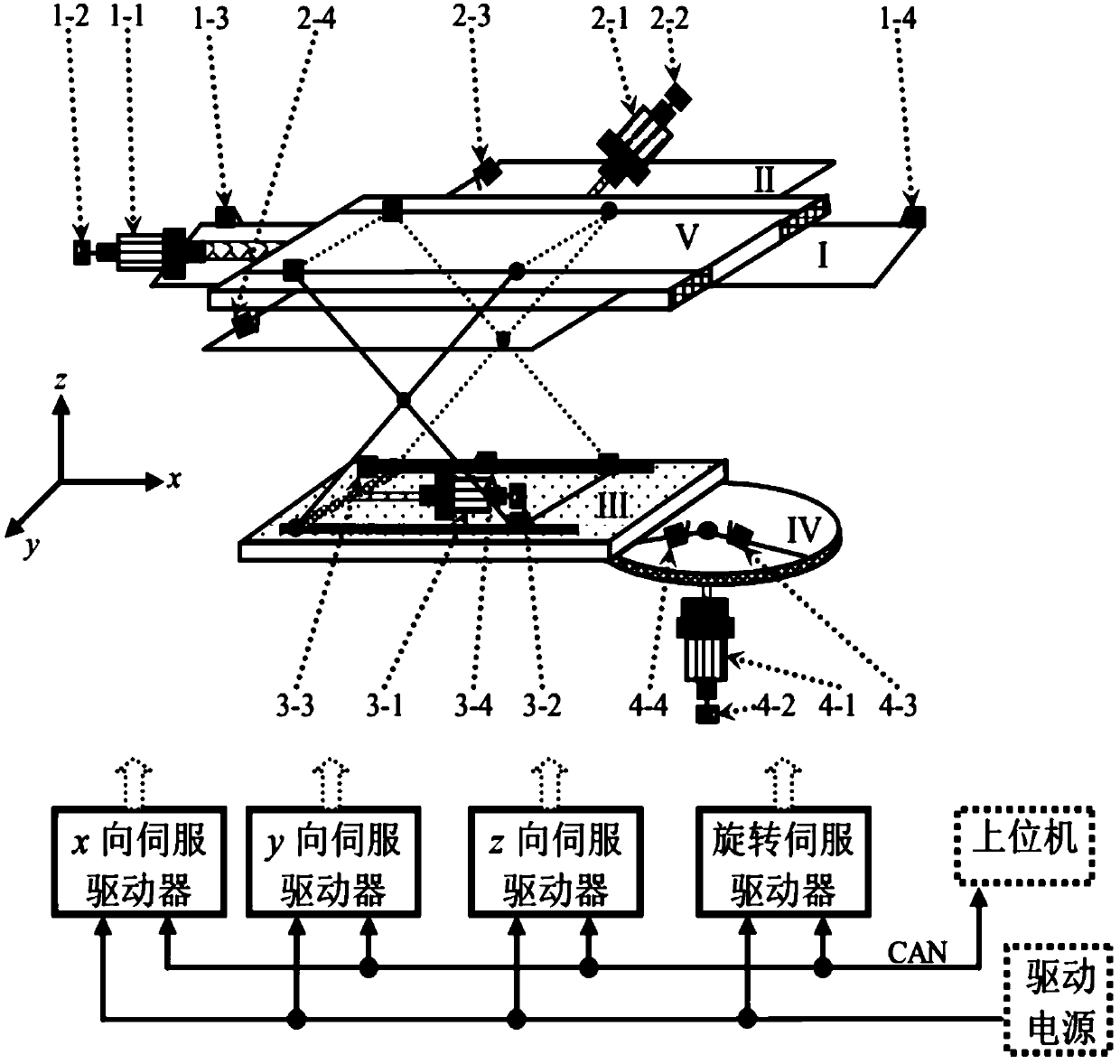

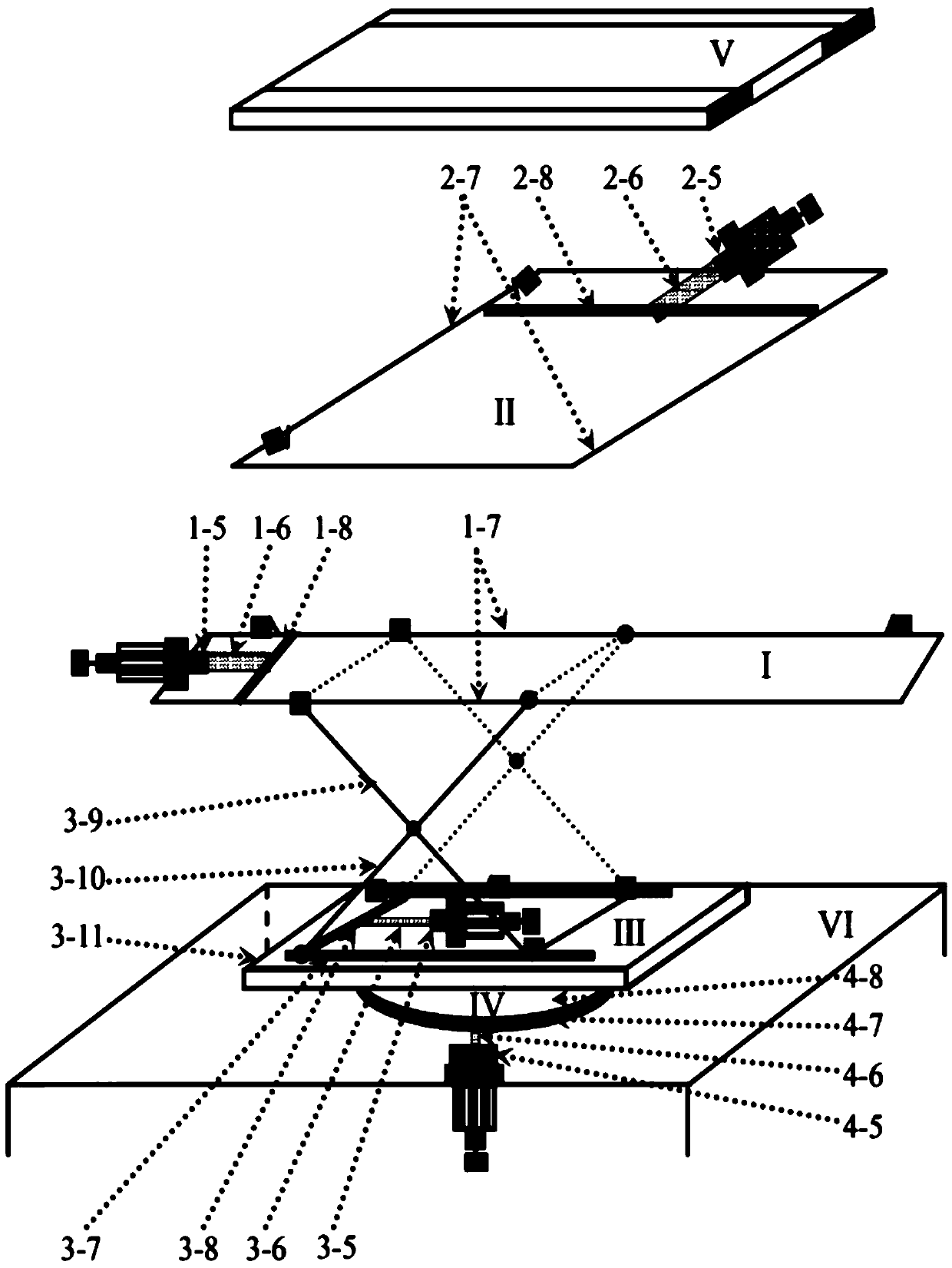

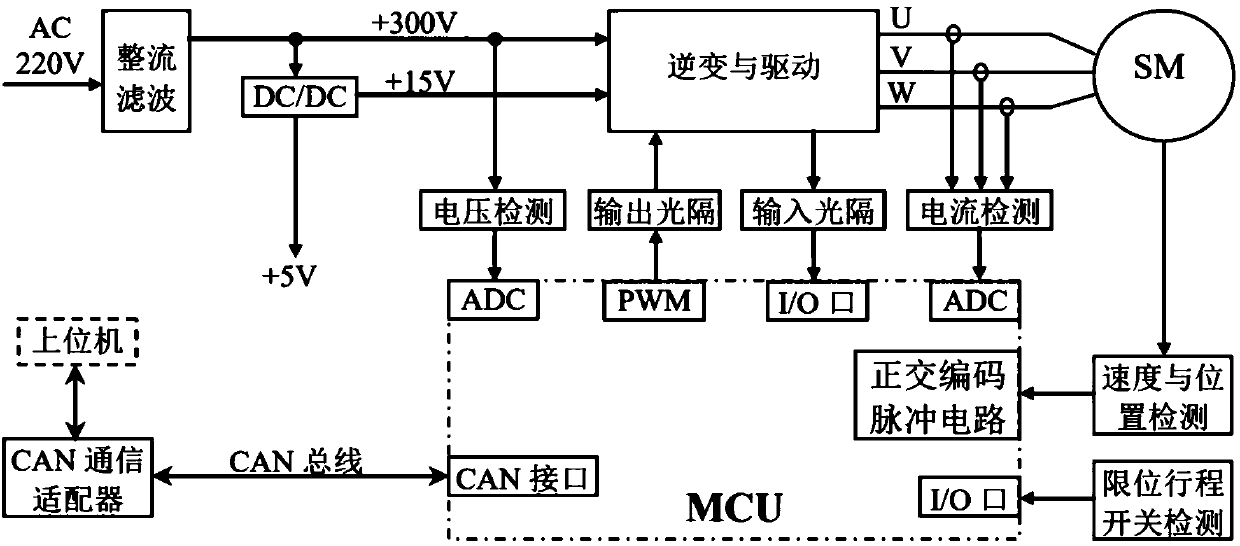

Radiotherapy simulation treatment bed based on multi-servo control

PendingCN111282166ARealize the coupling effectReduce couplingX-ray/gamma-ray/particle-irradiation therapyRadiation DosagesLoop control

The invention discloses a radiotherapy simulation treatment bed based on multi-servo control. The treatment bed comprises an x-direction moving mechanism, a y-direction moving mechanism, a z-directionlifting mechanism, a rotating mechanism, a treatment bed board and a treatment bed lower supporting frame. Electric energy is provided by the driving power supply, the upper computer is connected with the x-direction servo driver, the y-direction servo driver, the z-direction servo driver and the rotary servo driver through a CAN bus to achieve parallel control over the x-direction moving mechanism (I), the y-direction moving mechanism, the z-direction lifting mechanism and the rotary mechanism, and therefore accurate control over the bed board of the treatment bed is achieved. The inventionhas the beneficial effects that synchronous and independent closed-loop control of each servo motor is realized; the coupling between the motors is reduced, the positioning accuracy and positioning precision of the treatment bed are effectively improved, the minimum error coincidence of a focus part and a treatment radiation field area is realized, the radiation field shape and the target area center required by treatment are optimal, and the radiation dose absorption of important organs of a patient is reduced to the maximum extent.

Owner:吴小明

Dielectric waveguide filter

PendingCN111313131AEasy to implement cross-coupled structureRealize the coupling effectWaveguide type devicesResonant cavityTransmission zeros

The invention provides a dielectric waveguide filter. The filter comprises a dielectric block, a resonant cavity group, an input port, an output port and a negative coupling hole structure, a surfaceof the dielectric block is covered with a layer of metal silver, the input port and the output port are arranged on a surface of one side of the dielectric block in parallel, a topological structure of a new negative coupling structure is adopted, and a plurality of cross coupling structures can be achieved easily through the resonant cavities which are distributed in a scattered mode. Meanwhile,the coupling structures are special-shaped groove structures which are sequentially arranged in the length direction of the dielectric block, grooves are flexibly arranged, the coupling effect betweenvarious cavities is achieved, and therefore, the filter with asymmetric left and right transmission zeros is achieved. Moreover, the coupling structures of adjacent resonant cavities can be realized,and a cross coupling structure of non-adjacent cavities can also be realized, i.e., the cross coupling between the cross resonant cavities is realized, the problem that a transmission zero point withstronger coupling cannot be realized is avoided, and the whole structure is stable and reliable.

Owner:TONGYU COMM INC

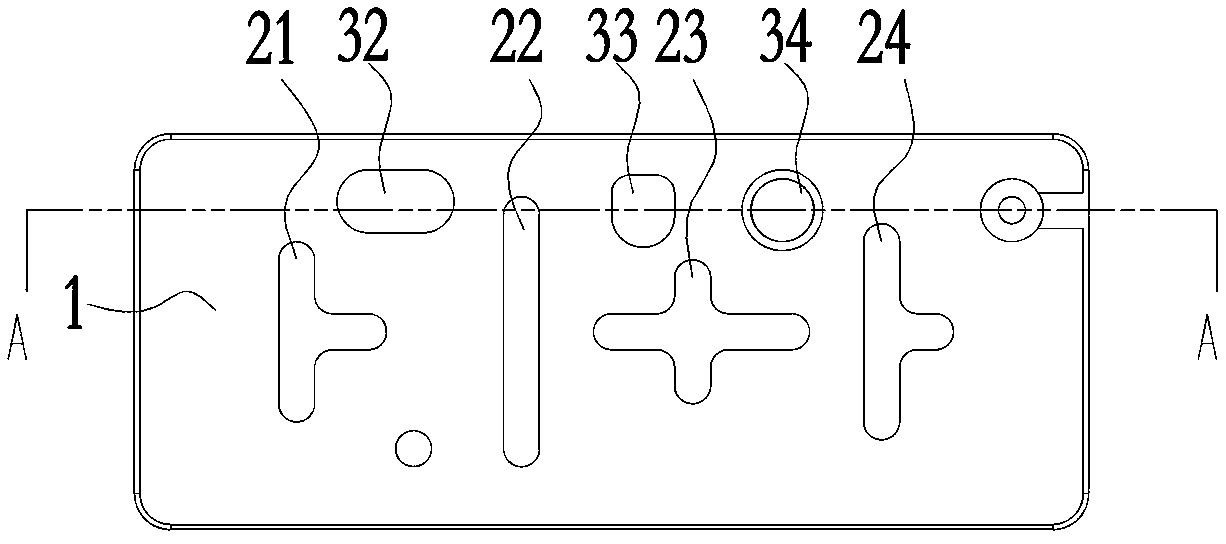

Ceramic dielectric filled waveguide filter

PendingCN110400996ANovel structureGuaranteed performance indicatorsWaveguide type devicesResonant cavityDielectric

The invention relates to a ceramic dielectric filled waveguide filter. The ceramic dielectric filled waveguide filter adopts a staggered-resonant cavity topology structure. The filter includes a ceramic dielectric block, a resonant cavity group, grooves, an input port and an output port, wherein the ceramic dielectric block is provided with the resonant cavity group, the resonant cavity group includes multiple resonant cavities arranged in parallel in a staggered manner in two vertical layers, one individual resonant cavity of the upper layer is located on a central axis between two adjacent resonant cavities in the lower layer, a groove used for adjusting the coupling amount of the adjacent cavities is arranged between every two adjacent resonant cavities in the same layer, a groove usedfor adjusting the coupling amount of the adjacent cavities is arranged between two resonant cavities at the same side end portions of different layers, and the cross-coupling amount of two interlacedresonant cavities on the same diagonal lines of different layers is jointly adjusted through two interlaced grooves on another diagonal line. The filter is advantaged in that multiple cross-coupling structures are achieved through the staggered resonant cavities, a variety of cavity-to-cavity coupling effects are achieved through the grooves, and the filter with left and right transmission zero asymmetry is achieved.

Owner:TONGYU COMM INC

Frost heaving measuring instrument capable of achieving hydrothermal coupling effect

ActiveCN110763718ARealize the hydrothermal coupling effectRealize the coupling effectMaterial thermal analysisTemperature controlSoil science

A frost heaving measuring instrument capable of achieving a hydrothermal coupling effect comprises a sample loading system, a refrigerating system and a data acquisition system. The sample loading system comprises an assembly frame, the assembly frame is provided with a sample placing chamber, and a water supplementing structure used for supplementing water to a sample is arranged on the assemblyframe. The frost heaving measuring instrument is ingenious in structure and reasonable in design, a heat conduction plate is connected with a refrigerating machine, the heat conduction plate providescooling capacity to achieve temperature control for a sample and increase the humidity of a test soil sample through the water supplementing structure arranged on the assembly frame when needed. The water content, the temperature and the like of the sample can be regulated and controlled, a plurality of sensors are mounted on the assembly frame, and parameters such as the temperature, the water content, the frost heaving force and the frost heaving displacement of the sample can be determined. The coupling effect of water, heat, force and other factors can be achieved, the frost heaving measuring instrument is accurate in test result and scientific and rigorous, and is provided with the water supplementing structure to supplement water to the sample so as to timely change the water contentof different soil layers of the sample.

Owner:ANHUI UNIV OF SCI & TECH

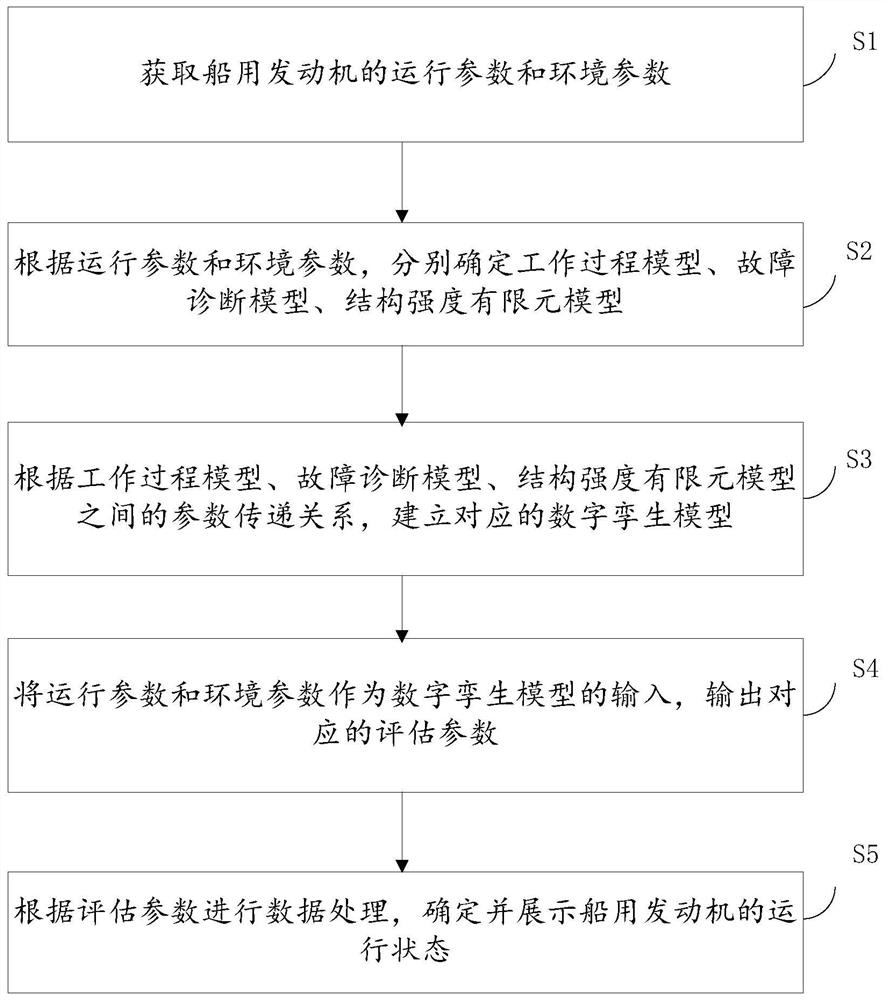

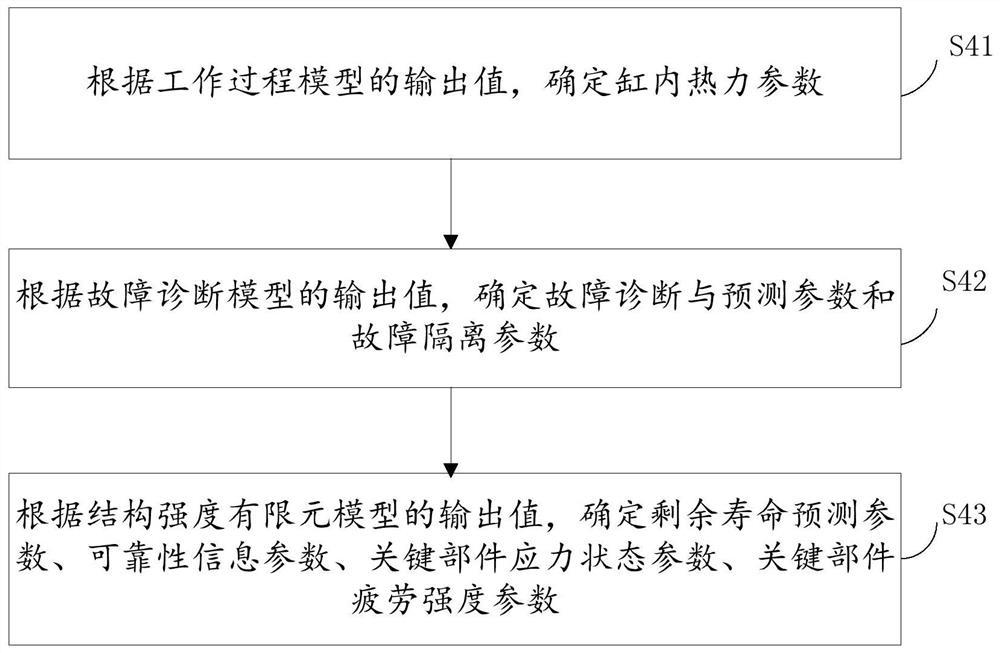

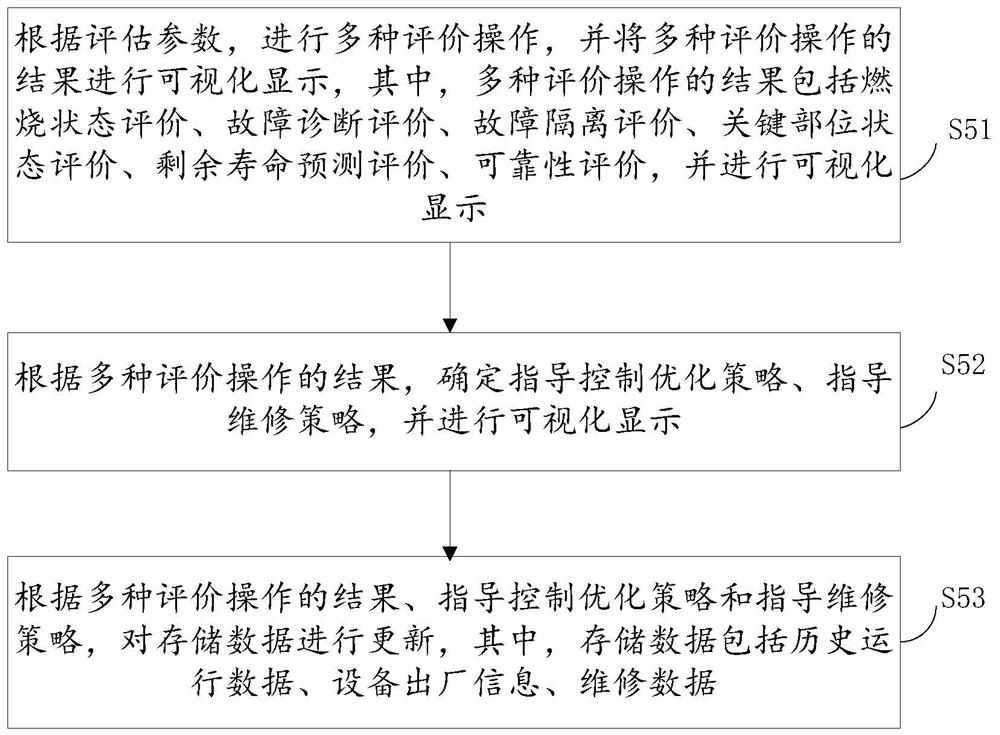

Marine engine state evaluation method and system based on digital twinning

ActiveCN113033055AFully consider the coupling relationshipAchieve forecastEngine testingDesign optimisation/simulationElement modelControl engineering

The invention relates to a marine engine state evaluation method and system based on digital twinning. The method comprises the steps: acquiring operation parameters and environment parameters of a marine engine; according to the operation parameters and the environment parameters, determining a working process model, a fault diagnosis model and a structural strength finite element model; establishing a corresponding digital twinborn model according to a parameter transmission relationship among the working process model, the fault diagnosis model and the structural strength finite element model; taking the operation parameters and the environment parameters as input of a digital twinborn model, and outputting corresponding evaluation parameters; and performing data processing according to the evaluation parameters, and determining and displaying the operation state of the marine engine. According to the method, the digital twinborn model is established to predict and diagnose the running states of the whole engine and the working parts, so that information fusion among various signals is completed, the coupling relation among the parts is fully considered, and more accurate and comprehensive diagnostic analysis is carried out.

Owner:WUHAN UNIV OF TECH

Loading cycle anaerobic organism water treatment device and enhanced anaerobic water treatment method

ActiveCN108394992ARealize the coupling effectEnhanced interphase mass transferWater contaminantsBiological treatment apparatusPetrochemicalPetroleum

The invention discloses a loading cycle anaerobic organism sewage treatment device and an enhanced anaerobic water treatment method applying the loading cycle anaerobic organism sewage treatment device. The device comprises a treatment container, wherein a loading cycle main reaction area is arranged in the treatment container; liquid flow inner circulation is built in the loading cycle main reaction area, and iron powder and activated carbon are added; the iron powder, the activated carbon and granule sludge in sewage jointly participate in the liquid flow inner circulation. The liquid flow inner circulation realizes interphase high-efficient mass transfer of the suspended-state iron powder, the activated carbon and the granule sludge; the iron powder and the activated carbon build a micro electric field; refractory organic pollutants are acted by an oxidation-reduction effect of the micro electric field, a reduction effect of zero-valent iron, activated carbon adsorption and an anaerobic organism coupling effect, so that the biotoxicity and the biological inhibition of refractory organic waste water in the petrochemical industry field are effectively reduced, and the oxidation efficiency and the biological response rate of anaerobic organisms are improved.

Owner:NORTHEAST GASOLINEEUM UNIV +1

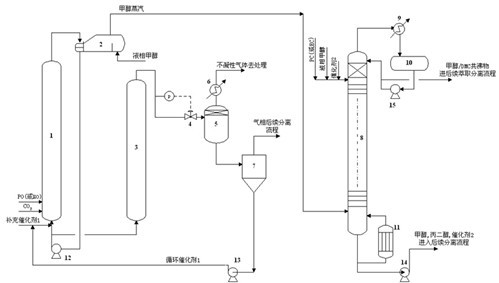

Energy-saving and consumption-reducing method for producing dimethyl carbonate by transesterification method

PendingCN113387811ATo achieve the purpose of heat transferReduce consumptionOrganic compound preparationChemical recyclingProcess engineeringPropylene carbonate

The invention relates to an energy-saving and consumption-reducing method for producing dimethyl carbonate by a transesterification method, the method comprises the following steps: reaction heat from heat released in a process of synthesizing propylene carbonate (or ethylene carbonate) is removed by reacting propylene oxide (or ethylene oxide) with CO2 through a kettle type evaporator by methanol gasification; the vaporized methanol goes into the transesterification reaction distillation column, the thermal load of the reactive distillation tower is reduced, and the energy-saving effect is achieved. The method has the advantages of simple flow and low investment, optimizes the production process of the dimethyl carbonate by the transesterification method, and can reduce the steam consumption by more than 10% compared with a production device with the same scale.

Owner:EAST CHINA UNIV OF SCI & TECH

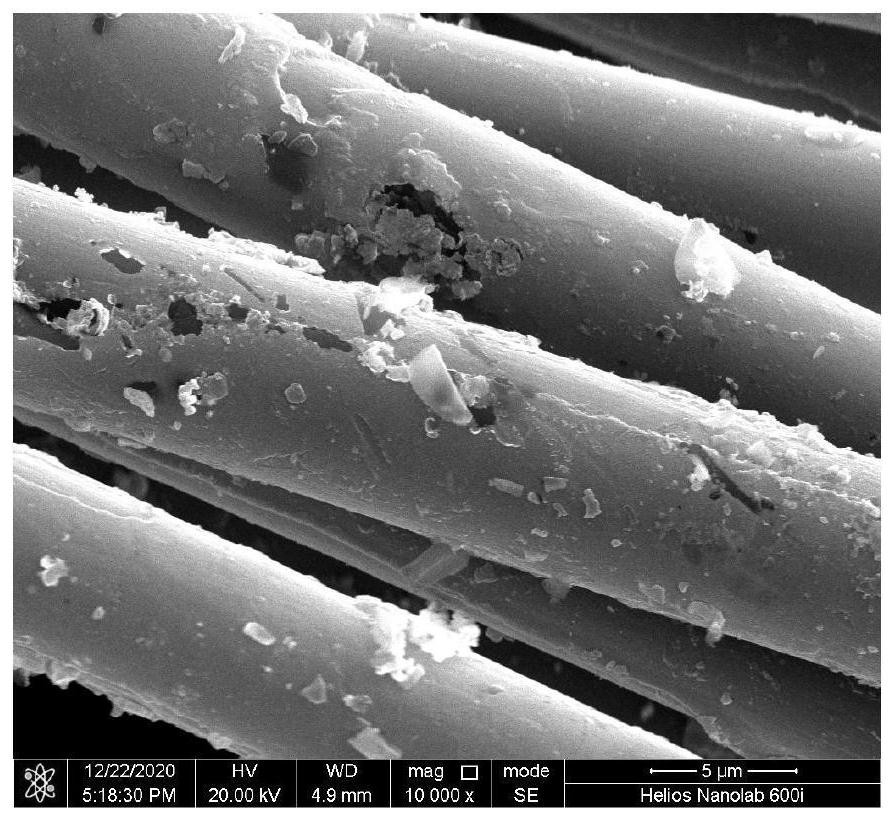

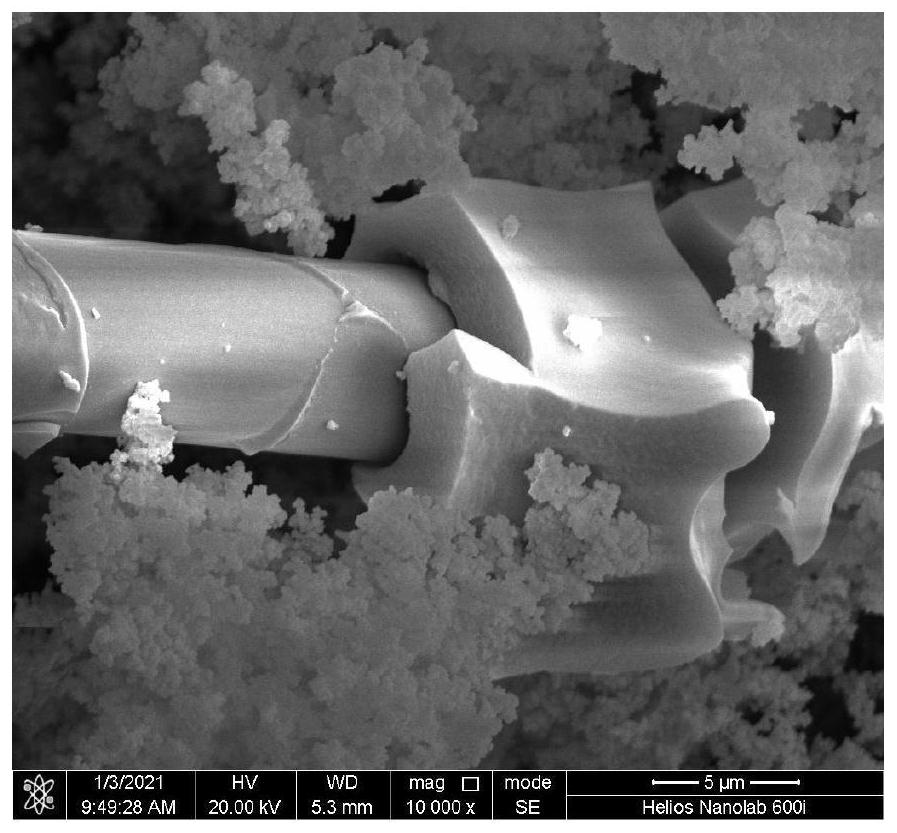

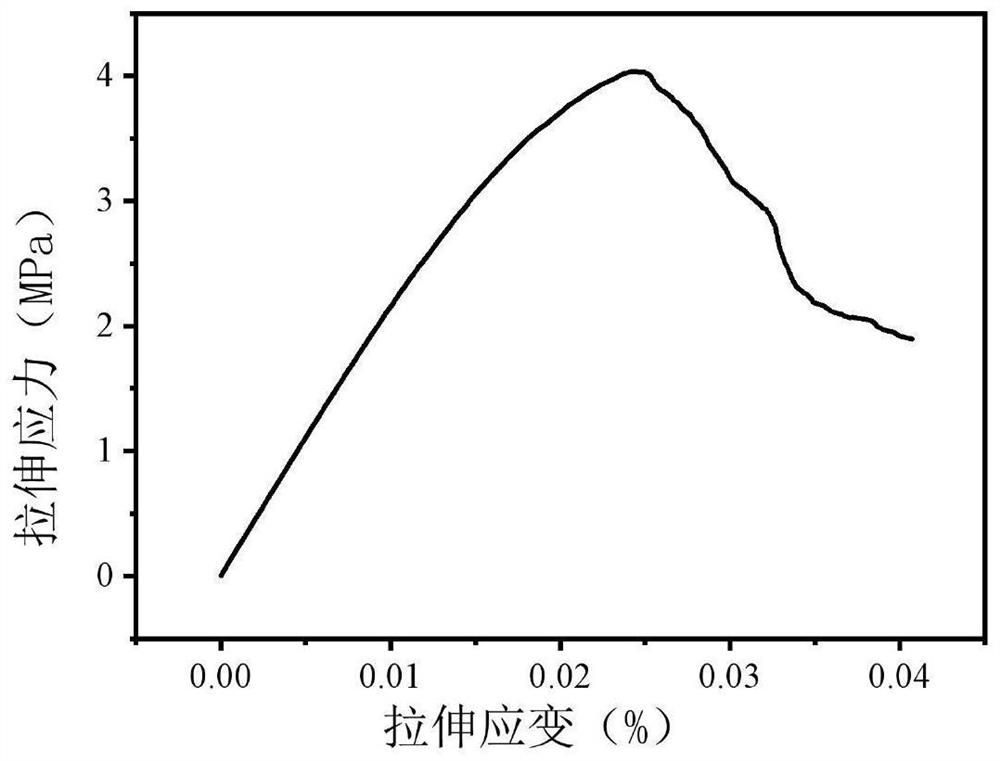

Light anti-infrared radiation ablation-resistant composite material added with opacifying agent and preparation method thereof

PendingCN112851383AImproved thermal radiation resistanceImprove anti-ablation performanceFiberGraphite

The invention relates to a light anti-infrared radiation lightweight ablation-resistant composite material added with an opacifier and a preparation method thereof. The invention belongs to the field of preparation of ablation-resistant composite materials. The invention aims to solve the technical problems of large ablation amount, non-uniform ablation and large density of the existing ablation-resistant composite material. The invention discloses the light anti-infrared radiationablation-resistant composite material added with an opacifier. The composite material is composed of a fiber woven body, and TiO2 ceramic, SiOC and phenolic resin which are filled in the fiber woven body. The method comprises the following steps: step 1, preparing a TiO2-containing woven body; step 2, preparing a weaving body containing SiOC; step 3, preparing the light ablation-resistant woven body; and 4, performing solvent replacement and drying. The density of the prepared composite material is 0.30-0.90 g / cm<3>, the room-temperature heat conductivity is 0.093-0.230 W / m.K, the longitudinal tensile strength is 3.59-5.38 MPa, and the longitudinal compression strength is 1.48-11.02 MPa. In a graphite plate radiation heating examination test, the composite material shows non (micro) ablation and good heat insulation and appearance retention capabilities.

Owner:HARBIN INST OF TECH

A test method for the medium transmission test device of concrete under the coupled action of temperature-osmotic pressure-load

ActiveCN113109159BRealize the coupling effectSmall sizeMaterial strength using tensile/compressive forcesPermeability/surface area analysisClassical mechanicsLiquid storage tank

The invention discloses a medium transmission test device and method for concrete under the coupled action of temperature-osmotic pressure-load, which includes a loading device and a hydraulic pressure device. The loading device includes a press, an upper steel plate and a lower plate for clamping a test block. Steel plates, fasteners connecting the upper and lower steel plates, the upper steel plate includes a first steel plate and a second steel plate, and a spring is set on the screw between the first steel plate and the second steel plate; the hydraulic pressure device includes a liquid storage tank, a pressing A pump, a liquid storage tank, a connecting pipe connecting the pressure pump and the liquid storage tank, and a connecting pipe connecting the pressure pump and the liquid storage tank; the liquid storage tank is provided with an open end, and the tank mouth of the open end is fixedly connected with the side of the test block. The invention realizes the coupling effect of load-temperature-osmotic pressure of concrete, can better simulate the complex and harsh environment of underground concrete, and provides an effective device support for the research on the durability of concrete under complex and harsh conditions.

Owner:SOUTHEAST UNIV

Triaxial instrument for joint determination of water-air movement in unsaturated soil

ActiveCN111413263BReal-time monitoring of changesInvestigate humidification deformation characteristicsPermeability/surface area analysisSuction stressAxial pressure

The invention discloses an unsaturated soil water-gas motion combined determination triaxial apparatus. The triaxial apparatus comprises an actuating system, a seepage pressure chamber and a control system for controlling the actuating system and the seepage pressure chamber, wherein the seepage pressure chamber comprises a frame formed by combining a base, a stand column and a cross beam; a hydraulic mechanism is mounted in the center of the base; the top of the hydraulic mechanism abuts against the bottom of the test piece seat; a confining pressure cylinder which is used for containing a test piece and is provided with a confining pressure air inlet pipe is arranged on the test piece seat; an upper pressure head and a sample holder are respectively arranged at the upper part and the lower part of the confining pressure cylinder; a pressure rod is immovable when axial pressure is applied, an upper pressure head is ejected, argil plates and waterproof breathable films are arranged onthe lower surface of the upper pressure head and the upper surface of the sample holder in a crossed manner, and the argil plates and the waterproof breathable films are respectively connected with water-phase and gas-phase volume and pressure controllers through pressure sensors. The water-gas two-phase permeability coefficient of the soil sample can be measured under the condition of controllingthe matrix suction of the soil sample, and the change characteristics of the matrix suction along the height direction of the soil sample can be quantitatively described.

Owner:XIAN UNIV OF TECH

Test method for seepage effect of earth pressure with built-in retaining wall

ActiveCN105954099BRealize the coupling effectPrecise control angleMaterial strength using tensile/compressive forcesPore water pressureEngineering

The present invention discloses a built-in retaining wall type soil pressure seepage effect test method. The method comprises the steps of A, completing the azimuth adjustment and the soil filling of a rigid retaining wall inside a box; B, injecting water into the box through a water inlet pipe by means of a water pump; C, infiltrate the water into the soil through the porous plate of the water inlet pipe in the box; D, blocking the water inlet pipe and an exhaust pipe, and standing; E, controlling the movement of the rigid retaining wall through upper and lower jacks; F, acquiring the pressure of the pore water through a pore pressure probe to obtain the result of the active soil pressure and the passive soil pressure under the seepage effect. A test device is composed of a box, an upper sliding block, a lower sliding block, an upper sliding groove, a lower sliding groove, an upper jack, a lower jack, a rigid retaining wall, a vertical bearing plate, a flexible loading water bag, a film type pressure sensor, a pore pressure probe and a displacement sensor. The device is convenient in operation, high in efficiency and energy-saving. Meanwhile, the requirements of testing active and passive soil pressures under the seepage effect are met.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

A kind of composite cuniin powder and its preparation method and application

ActiveCN108425085BSuitable for anti-fretting damage protectionHigh strengthMolten spray coatingTransportation and packagingCrazingBall mill

The invention discloses a composite CuNiIn powder and its preparation method and application. The composite CuNiIn powder contains a dispersion strengthening phase and a self-lubricating phase at the same time. The preparation method comprises: In powder, nickel-coated molybdenum disulfide powder, Al 2 o 3 Dispersion-strengthened Cu powder is ball-milled and mixed to obtain mixed raw materials. The mixed raw materials are centrifugally atomized and granulated by a spray drying granulator to obtain dry granules; the dried granules are vacuum sintered, and then crushed and sieved to obtain composite CuNiIn powder. The composite CuNiIn powder can be prepared into a composite CuNiIn coating containing a dispersion strengthening phase and a self-lubricating phase by a thermal spraying method. The invention changes the distribution state of the self-lubricating phase, improves the strength and toughness of the coating, effectively avoids the generation of micro-cracks in the coating, improves the self-lubricating life of the coating, and has good advantages for industries such as aeroengines and gas turbines. Value.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

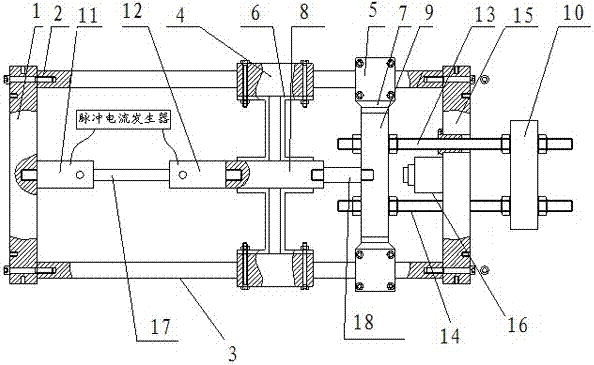

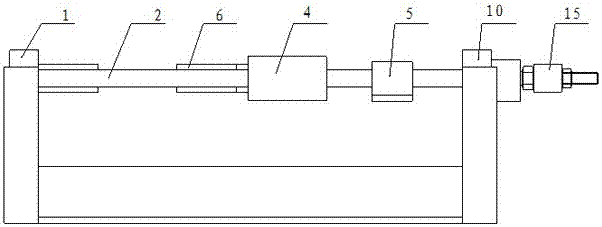

High-voltage pulse current repair experiment platform and use method thereof

PendingCN107097037ARealize the coupling effectRealize crack arrest experimentHigh voltage pulseEngineering

The invention relates to a high-voltage pulse current repair experiment platform and a use method of the high-voltage pulse current repair experiment platform. The high-voltage pulse current repair experiment platform comprises a fixed support, a first polish rod and a second polish rod. The first polish rod and the second polish rod are each sequentially sleeved with a first sliding block and a second sliding block. The first sliding blocks of the first polish rod and the second polish rod are connected with a first square block piece through U-shaped steel. The second sliding blocks of the first polish rod and the second polish rod are connected with a second square block piece through L-shaped steel. A force sensor is connected between the first square block piece and the second square block piece. The high-voltage pulse current repair experiment platform further comprises a first clamping piece and a second clamping piece. The first clamping piece and the second clamping piece are connected with pulse current generators. The first clamping piece is fixed to the fixed support. The second clamping piece is fixedly connected with the first sliding blocks. A second square block is driven by a drive mechanism to transversely move along the first polish rod and the second polish rod. The high-voltage pulse current repair experiment platform and the use method of the high-voltage pulse current repair experiment platform have the beneficial effects that quantitative loading is conducted on an experiment metal component, a high-voltage pulse current is exerted on the experiment metal component, the force-pulse current coupling function is achieved, and then the metal component is repaired.

Owner:FUZHOU UNIVERSITY

A kind of preparation method of composite Raman photonic crystal microsphere

ActiveCN106950616BIncreased sensitivityRealize the coupling effectOptical elementsWater bathsMicrosphere

The invention discloses a method for preparing composite Raman photonic crystal microspheres, belonging to the technical fields of biomedical research, environmental monitoring and clinical detection. Mix ethanol solution of zinc acetate, ethanol solution of sodium hydroxide and silicon dioxide photonic crystal microspheres, stir and react in a constant temperature water bath to obtain zinc oxide nanoparticles-coated silicon dioxide photonic crystal microspheres; Diol solution and ZnO nanoparticles-coated silica photonic crystal microspheres were mixed, and then AgNO 3 Aqueous solution and NaBH 4 The aqueous solution is stirred and reacted in a constant temperature water bath to prepare a composite Raman photonic crystal microsphere. Prepared three-dimensional ordered Ag / ZnO / SiO 2 Photonic crystal microsphere material with uniform and regular shape. The invention has the characteristics of simple preparation method, low cost, high sensitivity, good repeatability, high stability, good surface enhancement effect and the like.

Owner:YANGZHOU UNIV

Heat dissipation device and electronic equipment with same

PendingCN112074150AImprove heat transfer performanceImprove temperature uniformityModifications using liquid coolingEngineeringMechanical engineering

The invention discloses a heat dissipation device and electronic equipment with the heat dissipation device. The heat dissipation device comprises a first base body with an inner accommodating cavity,and a second base body with an accommodating cavity, wherein the first base body comprises a cooling part corresponding to a heat source and a connecting part combined and fixed on the second base body; and the inner accommodating cavity comprises a first chamber corresponding to the cooling part and a second chamber corresponding to the connecting part, and the first chamber and the second chamber communicate with each other to form the inner accommodating cavity. The heat dissipation device further comprises: a first capillary core component fixed in the first chamber; a second capillary core component fixed in the second chamber; and a third capillary core component fixed in the accommodating cavity of the second base body, wherein the opposite adjacent ends of the first capillary corecomponent and the second capillary core component are connected and communicate with each other, and the inner accommodating cavity and the accommodating cavity are each filled with a cooling workingmedium. Efficient heat transfer and soaking of a case structure serving as the heat source in different spatial directions are achieved.

Owner:航天科工空间工程发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com