True triaxial experiment device and method capable of simulating radial pressure

An experimental device, radial pressure technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as simulation, formation pore pressure cannot be added, and formation pressure cannot be performed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

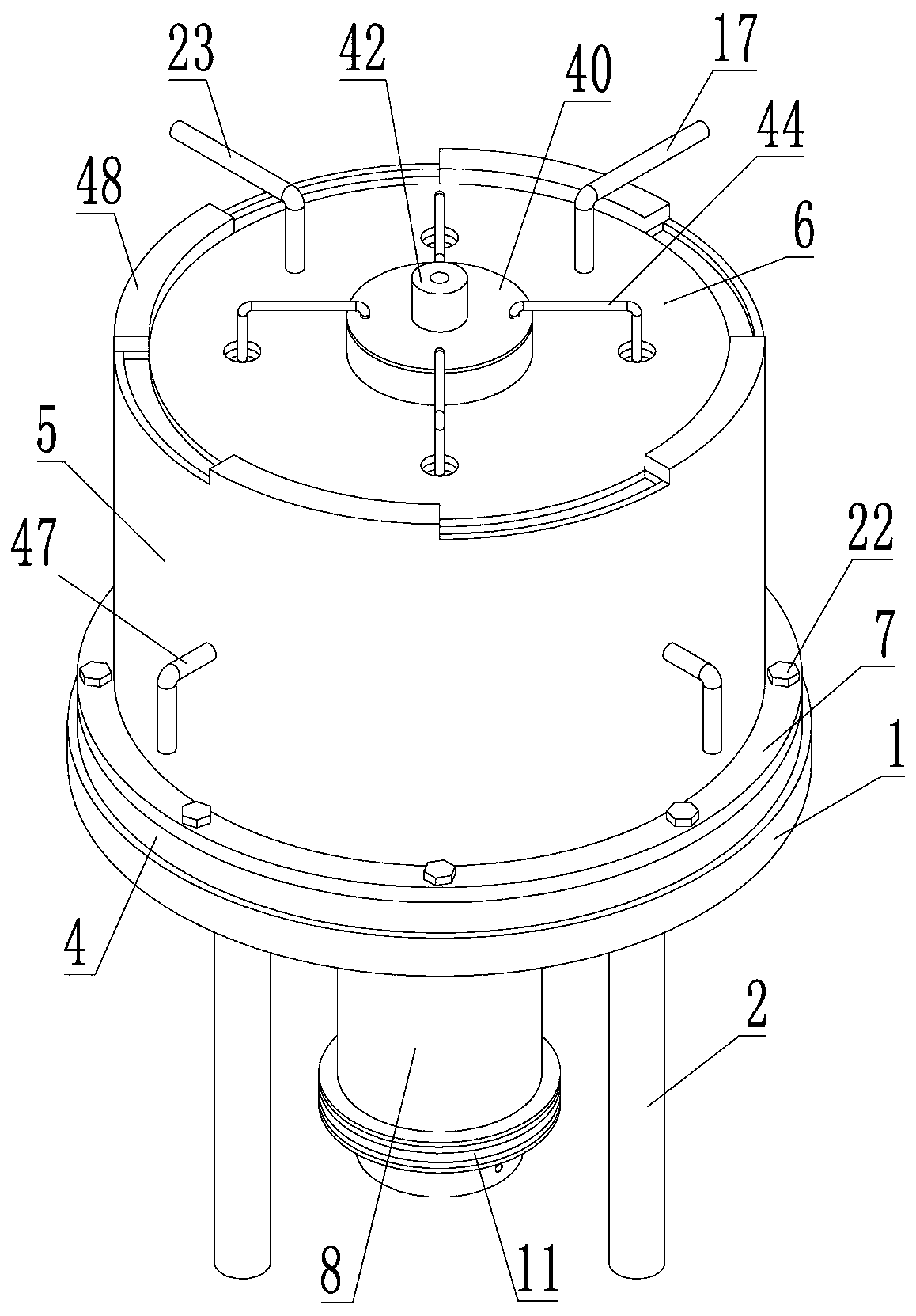

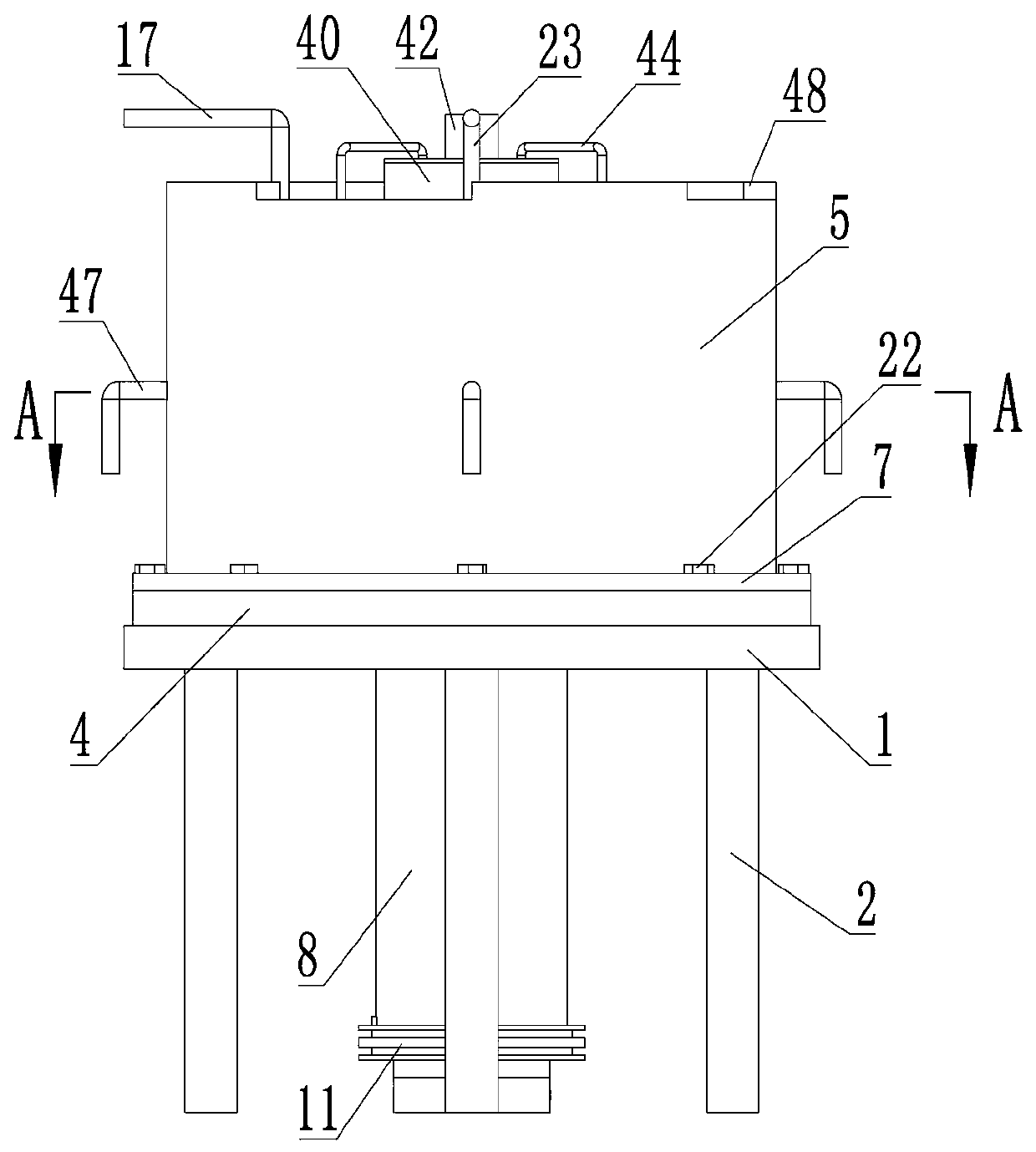

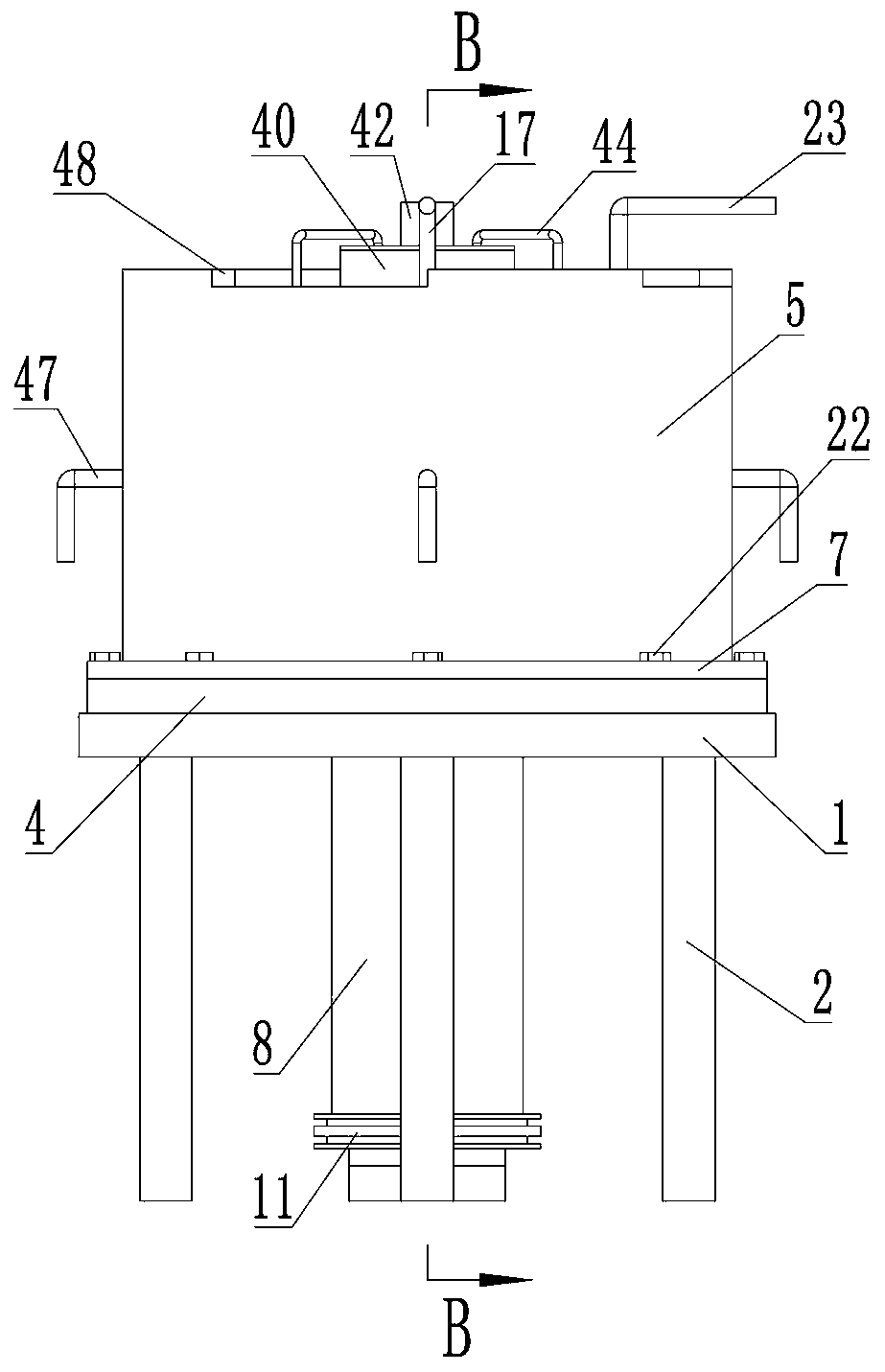

[0055] Embodiments of the present invention are further described below with reference to the accompanying drawings.

[0056] like Figure 1-Figure 13 As shown in the figure, a true three-axis experimental device that can simulate radial pressure includes a horizontally fixed chassis 1 and a geared motor. An experimental box is arranged in rotation, and a core specimen 3 is placed in the experimental box. The left and right horizontal directions of the experimental box are taken as the x direction, the front and rear horizontal directions of the experimental box are taken as the y direction, and the up and down vertical directions of the experimental box are taken as the y direction. In the z direction, the left side of the experimental box is provided with an x-direction pressure mechanism, the inner front side of the experimental box is provided with a y-direction pressure mechanism, and the bottom of the experimental box is provided with a z-direction pressure mechanism. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com