Light anti-infrared radiation ablation-resistant composite material added with opacifying agent and preparation method thereof

A composite material and opacifying agent technology, which is applied in the field of preparation of ablation-resistant composite materials, can solve the problems of high density, large ablation amount, uneven ablation, etc., and achieve low density, improved oxidation resistance, and good oxidation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

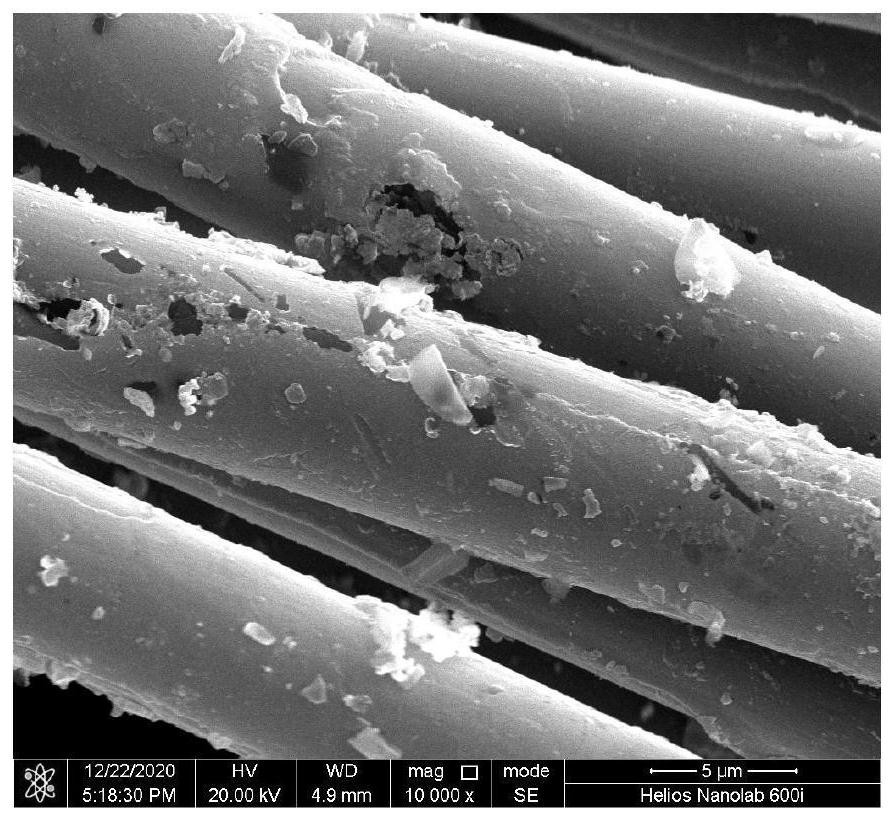

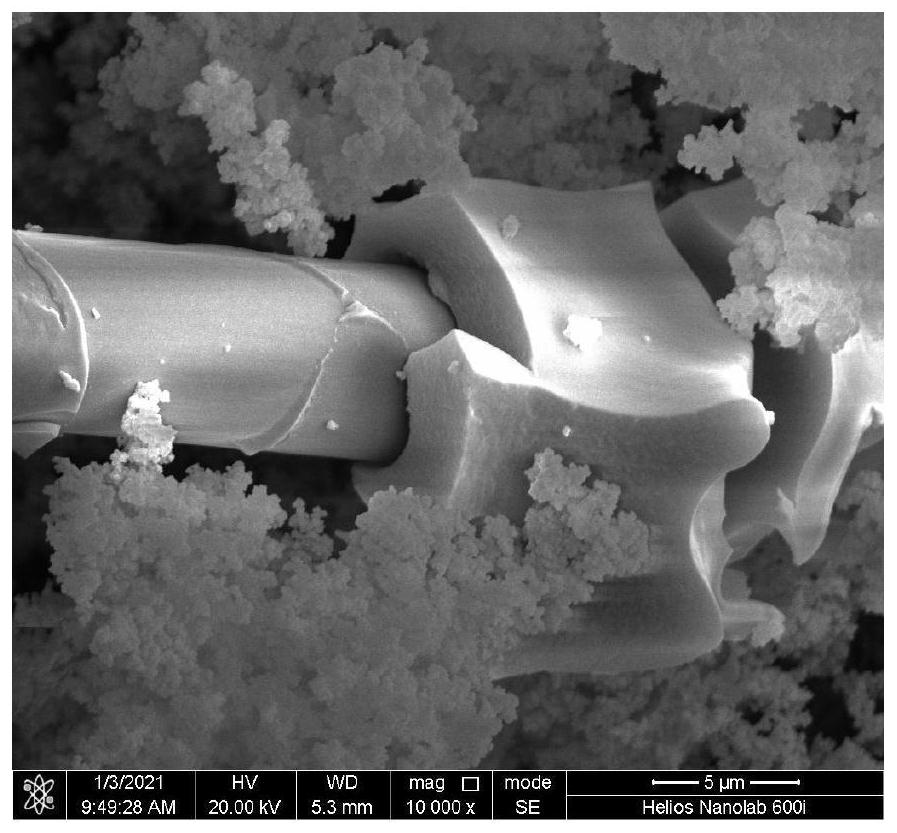

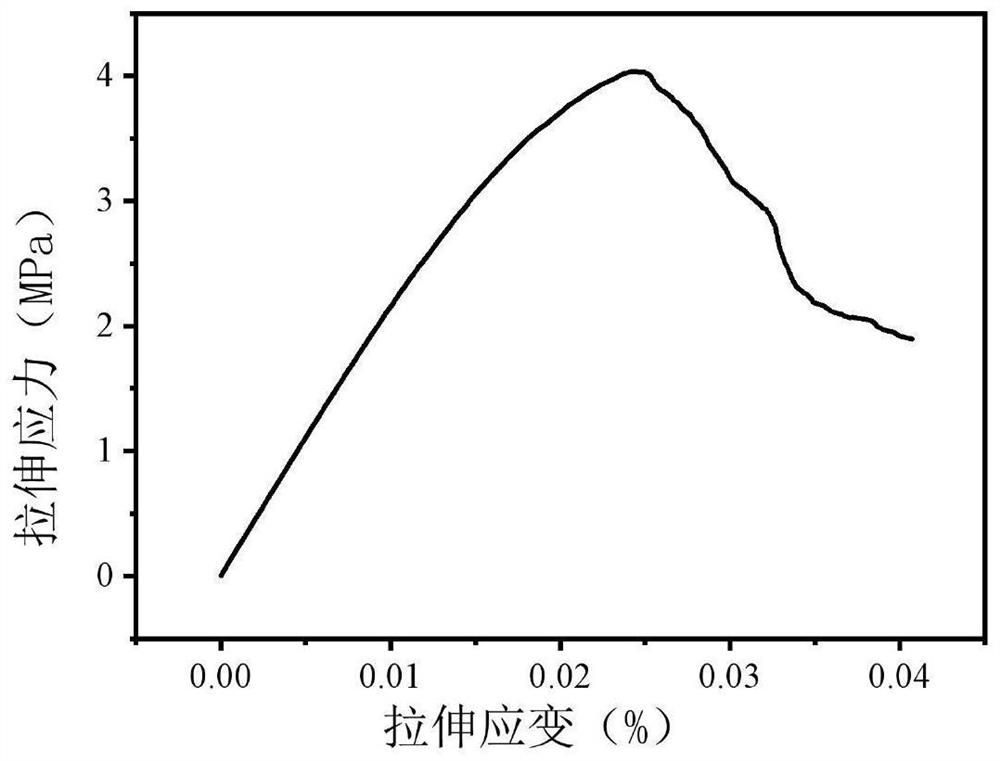

[0036] Example 1: A light-weight, anti-infrared, ablation-resistant composite material that adds a sunscreen in this example consists of a fiber braid and TiO2 filled in the fiber braid. 2 Composed of ceramics, SiOC and phenolic resin, the mass fraction of fiber braids in the composite material is 30%, TiO 2 The mass fraction of ceramics is 6%, the mass fraction of SiOC is 6%, the mass fraction of phenolic resin is 58%, and the density of the composite material is 0.5g / cm 3 ; Wherein the fiber braid is a carbon fiber braid, the carbon fiber is polyacrylonitrile-based carbon fiber, the structure of the fiber braid is a continuous carbon fiber needle-punched structure, and the fiber braid is any layering method, and its density 0.15g / cm 3 , the diameter of single filament is 6μm~7μm, and the needling density is 17 needles / cm 2 , the thickness is 20mm, the length is 200mm, and the width is 200mm.

[0037] The method for preparing a kind of anti-infrared radiation light-weight ...

Embodiment 2

[0046] Embodiment 2: A light-weight and ablation-resistant composite material with anti-infrared radiation and added opacifying agent in this embodiment consists of a fiber braid and TiO2 filled in the fiber braid. 2 Composed of ceramics, SiOC and phenolic resin, the mass fraction of the fiber braid in the composite material is 40%, TiO 2 The mass fraction of ceramics is 9%, the mass fraction of SiOC is 9%, the mass fraction of phenolic resin is 42%, and the density of the composite material is 0.5g / cm 3 ; Wherein the fiber braid is a carbon fiber braid, the carbon fiber is polyacrylonitrile-based carbon fiber, the structure of the fiber braid is a continuous carbon fiber needle-punched structure, and the fiber braid is any layering method, and its density 0.20g / cm 3 , the diameter of single filament is 6μm~7μm, and the needling density is 19 needles / cm 2 , the thickness is 23mm, the length is 200mm, and the width is 200mm.

[0047] The method for preparing a light-weight a...

Embodiment 3

[0055] Embodiment 3: A light-weight and ablation-resistant composite material with anti-infrared radiation and added opacifying agent in this embodiment consists of a fiber braid and TiO2 filled in the fiber braid. 2 Composed of ceramics, SiOC and phenolic resin, the mass fraction of the fiber braid in the composite material is 50%, TiO 2 The mass fraction of ceramics is 4%, the mass fraction of SiOC is 5%, the mass fraction of phenolic resin is 41%, and the density of described composite material is 0.3g / cm 3 ; Wherein the fiber braid is a carbon fiber braid, the carbon fiber is polyacrylonitrile-based carbon fiber, the structure of the fiber braid is a continuous carbon fiber needle-punched structure, and the fiber braid is any layering method, and its density 0.15g / cm 3 , the single filament diameter is 6μm~7μm, the needling density is 18 needles / cm 2 , the thickness is 20mm, the length is 200mm, and the width is 200mm.

[0056] A method for preparing an infrared radiati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com