Method for controlling atmospheric plasma spraying of easily-oxidized coating under atmosphere open environment

A technology for controlling atmosphere and plasma spray gun, applied in coating, metal material coating process, melting spray plating, etc., can solve the problems of easy change of substrate performance, limited change of coating composition, easy oxidation of powder, etc. Anti-oxidation and anti-ablation properties of the coating, ensuring purity and performance, and inhibiting the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

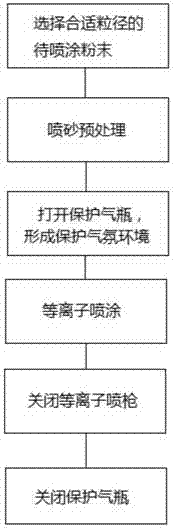

[0033] The spraying powder is a composite powder of zirconium boride and silicon carbide, the mass ratio of the two is 1:1, and the particle size range is 20 μm to 80 μm.

[0034] (1) Firstly, the surface of the substrate material is pre-sandblasted with a dry sandblasting machine. The blasting material is No. 24 white corundum particles with a particle size of 850 μm, so as to ensure the bonding strength and coating quality between the coating and the substrate.

[0035] (2) Open the argon gas bottle connected to the above-mentioned protective gas flow channel, expansion gas flow channel and vortex channel, control the pressure of the protective gas argon to 0.5MPa, and the flow rate to be 15SCFH. A protective atmosphere environment is formed between the materials, and the argon gas from the expansion airflow channel expands the range of the formed protective atmosphere environment, while the argon gas from the vortex channel forms a vortex protective atmosphere outside the sp...

Embodiment 2

[0039] The spraying powder is a composite powder of hafnium boride and zirconium carbide, the mass ratio of the two is 2:1, and the particle size range is 5 μm to 63 μm.

[0040] (1) Firstly, the surface of the substrate material is pre-sandblasted with a dry sandblasting machine. The blasting material is No. 24 white corundum particles with a particle size of 850 μm, so as to ensure the bonding strength and coating quality between the coating and the substrate.

[0041] (2) Open the argon gas bottle connected to the above-mentioned protective gas flow channel, expansion gas flow channel and vortex channel, control the pressure of the protective gas argon to 0.3MPa, and the flow rate to be 5SCFH. A protective atmosphere environment is formed between the materials, and the argon gas from the expansion airflow channel expands the range of the formed protective atmosphere environment, while the argon gas from the vortex channel forms a vortex protective atmosphere outside the spra...

Embodiment 3

[0045] The spraying powder is a composite powder of zirconium boride and zirconium carbide, the mass ratio of the two is 1:3, and the particle size range is 45 μm to 100 μm.

[0046] (1) Firstly, the surface of the substrate material is pre-sandblasted with a dry sandblasting machine. The blasting material is No. 24 white corundum particles with a particle size of 850 μm, so as to ensure the bonding strength and coating quality between the coating and the substrate.

[0047] (2) Open the argon gas bottle connected to the above-mentioned protective gas flow channel, expansion gas flow channel and vortex channel, control the pressure of the protective gas argon to 1.0MPa, and the flow rate to be 30SCFH. A protective atmosphere environment is formed between the materials, and the argon gas from the expansion airflow channel expands the range of the formed protective atmosphere environment, while the argon gas from the vortex channel forms a vortex protective atmosphere outside the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com