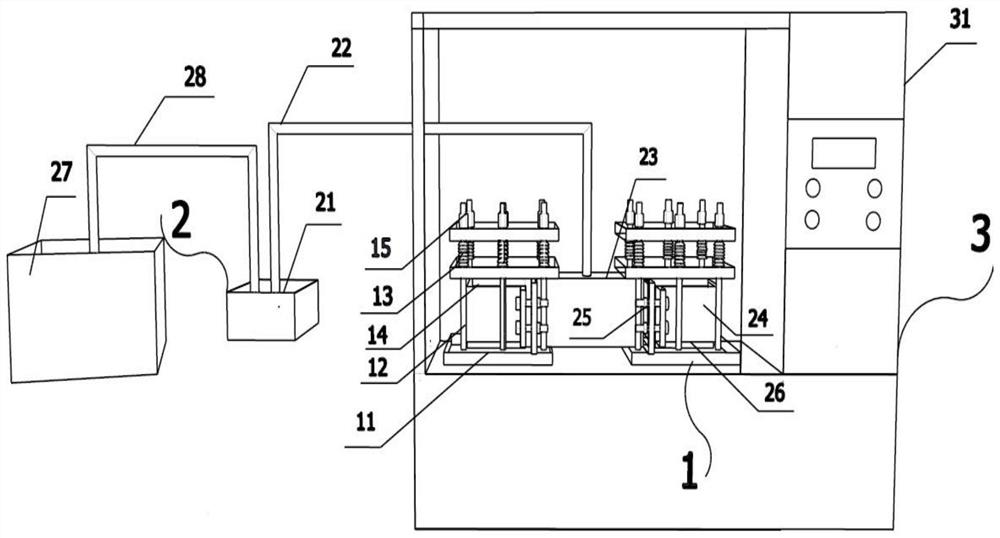

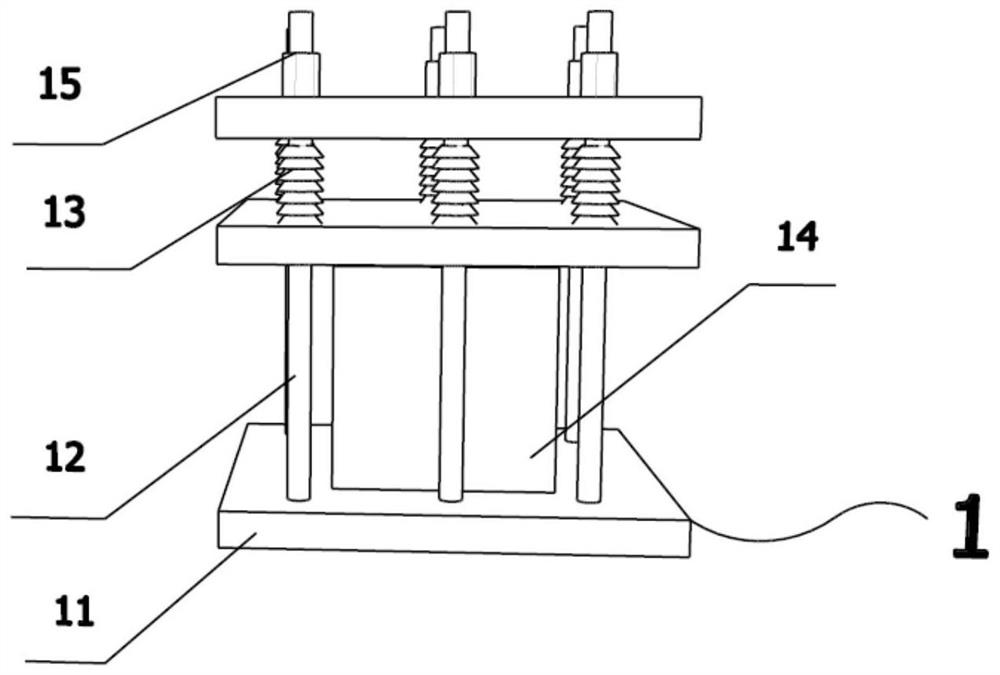

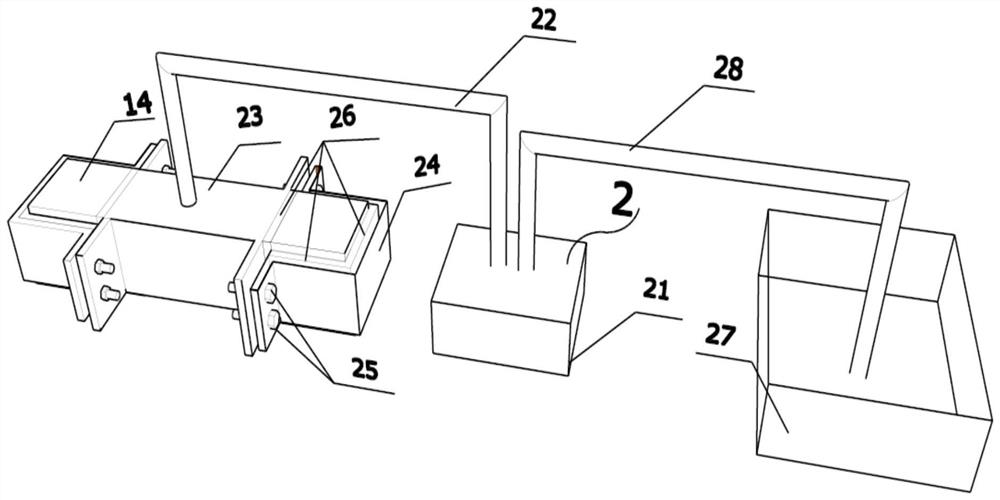

A test method for the medium transmission test device of concrete under the coupled action of temperature-osmotic pressure-load

A test device, osmotic pressure technology, applied in the direction of measurement device, permeability/surface area analysis, strength characteristics, etc., to achieve the effect of small device size, convenient movement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this example, an ultra-high-performance concrete sample with a water-binder ratio of 0.16 is used. The size is 100mm×100mm×100mm. The shape of the test block is a cube. It is taken out after steam curing for 3 days. The experimental solution in the application example is NaCl with a concentration of 10%. For the solution, the temperature of the experiment is 30°C, the osmotic pressure is 4MPa, and the stress ratio is 0.3 (ratio of required stress and concrete strength).

Embodiment 2

[0053] In this example, an ultra-high-performance concrete sample with a water-binder ratio of 0.16 is used. The size is 100mm×100mm×100mm. The shape of the test block is a cube. It is taken out after steam curing for 3 days. The experimental solution in the application example is NaCl with a concentration of 10%. For the solution, the experimental temperature is 70°C, the osmotic pressure is 4MPa, and the stress ratio is 0.3.

Embodiment 3

[0055] In this example, an ultra-high-performance concrete sample with a water-binder ratio of 0.16 is used. The size is 100mm×100mm×100mm. The shape of the test block is a cube. It is taken out after steam curing for 3 days. The experimental solution in the application example is NaCl with a concentration of 10%. For the solution, the experimental temperature is 30°C, the osmotic pressure is 2MPa, and the stress ratio is 0.3.

[0056] Figure 5 It is the change curve of water pressure with time. It can be seen that after 7 days of continuous action, the water pressure remains basically unchanged, indicating that the device has excellent airtightness. Figure 6-Figure 8 These are the chloride ion concentration distribution curves inside the concrete obtained in Examples 1 to 3 of the above-mentioned examples. It can be seen that the change trend of the chloride ion concentration is basically consistent with the results obtained in similar studies, and after changing parameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com