High-voltage pulse current repair experiment platform and use method thereof

A technology of high-voltage pulse and experimental platform, which is applied in the research field of high-voltage pulse current repair of metal components with defects, can solve problems such as unclear mechanism of metal crack arrest, and achieve the effect of satisfying quantitative loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

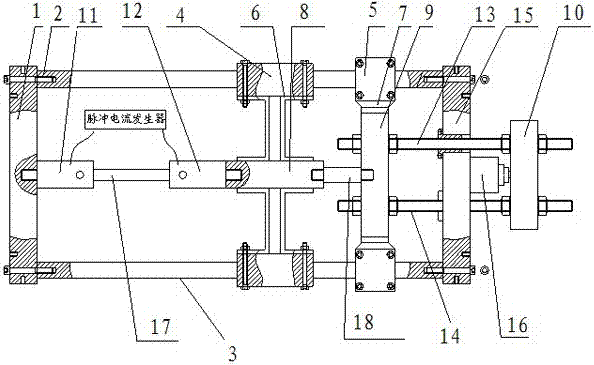

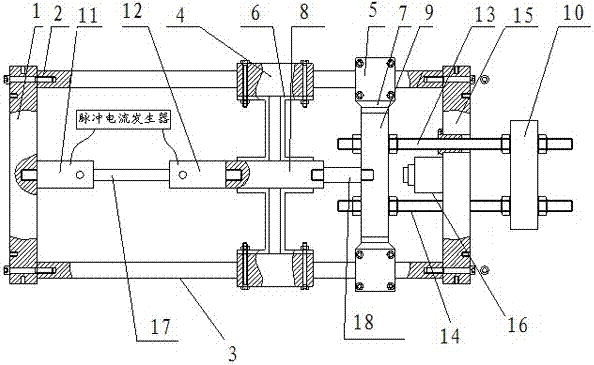

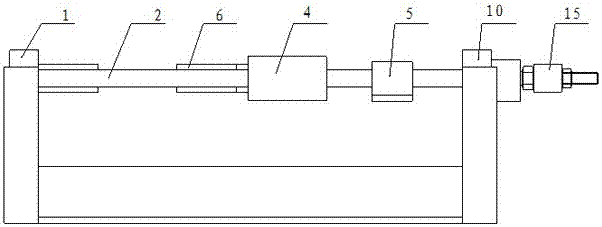

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as Figure 1~2 As shown, a kind of high-voltage pulse current repair experiment platform of the present embodiment includes a fixed bracket 1, a first polished rod 2 and a second polished rod 3 erected in the front and back of the fixed bracket 1 along the transverse direction, and the first polished rod 2 and the second polished rod The two ends of the polished rod 3 are respectively fixed on the fixed bracket 1; the first polished rod 2 and the second polished rod 3 are respectively sleeved with a first slider 4 and a second slider 5; the first polished rod 2 and the first slider 4 of the second polished rod 3 are respectively connected to a first square block 8 via a U-shaped steel 6; 7 is connected with a second square piece 9; A force sensor 18 is connected between the first square piece 8 and the second square piece 9; Also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com