Built-in retaining wall type soil pressure seepage effect test method

A test method and earth pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of not fully considering the physical properties of soil, and the differences between water and soil calculation and cost-effectiveness are not well resolved, and achieve savings. The effect of human and material cost and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below according to accompanying drawing:

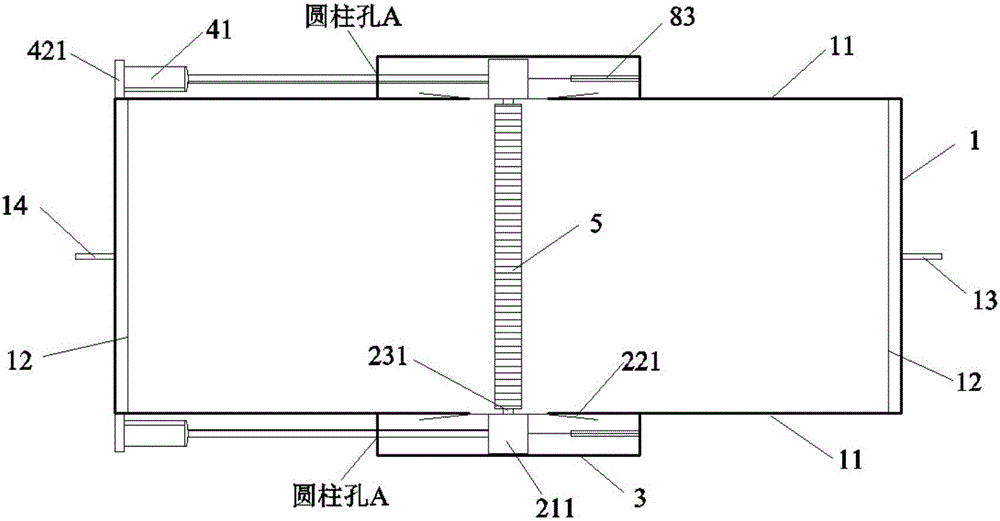

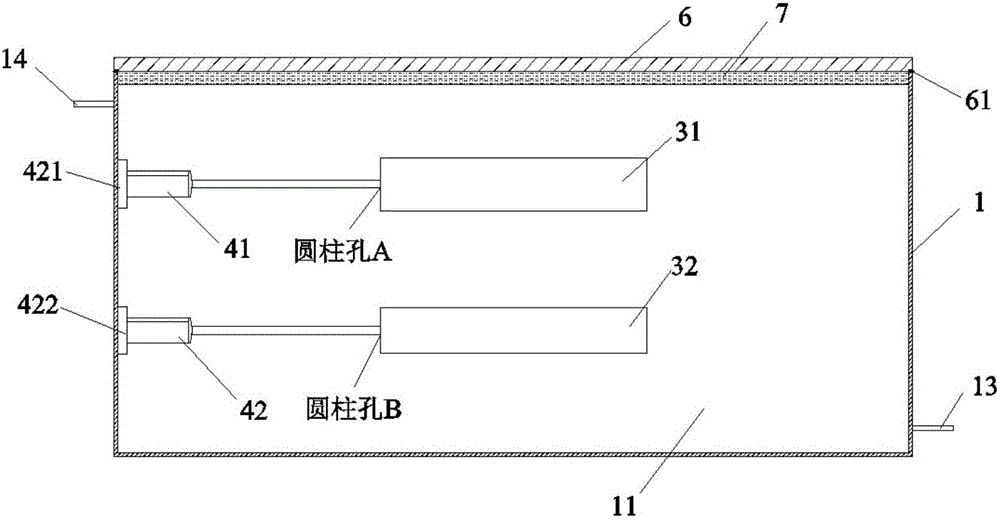

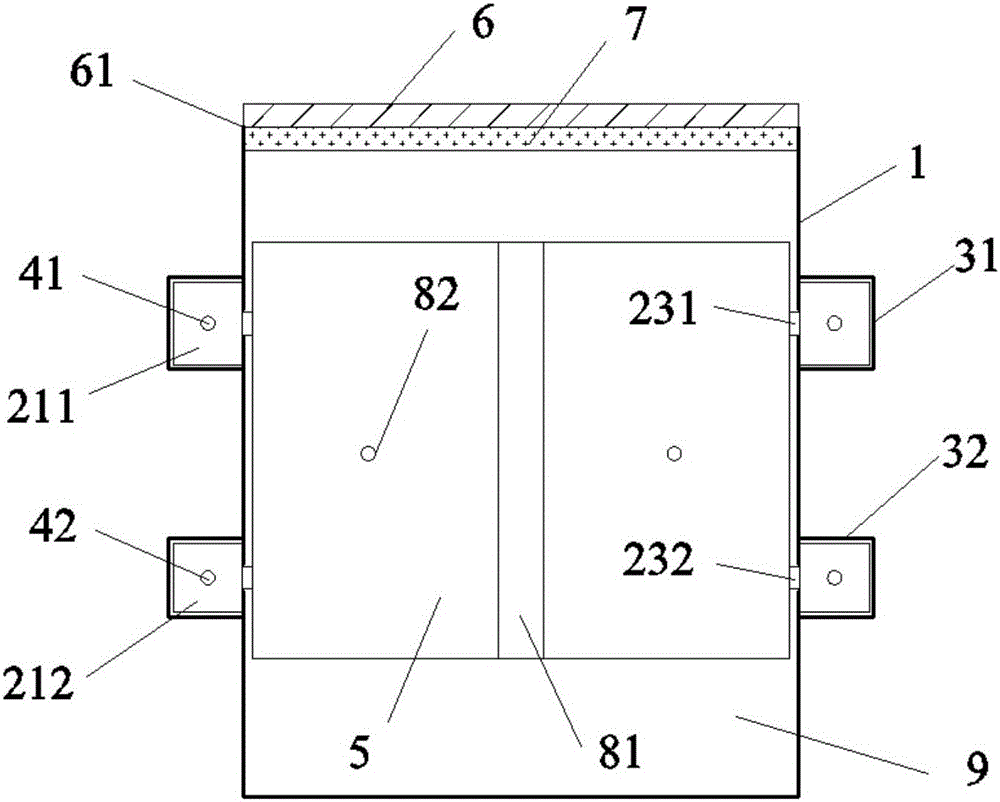

[0032] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 It can be known that a built-in retaining wall earth pressure seepage effect test method includes the following steps:

[0033] 1. Complete the orientation adjustment of the rigid retaining wall 5 and the filling of the soil body 9 in the box body 1, place the flexible loading water bag 7, fix the vertical pressure bearing plate 6 on the box body 1, and fix the vertical pressure bearing plate 6 on the box body 1. Connect a ring of sealing tape 61 between the box body 1 to prevent water loss and water pressure errors during the test, and pressurize the flexible loading water bladder 7 to 200 or 250 or 300 or 350 or 400kPa according to the test requirements;

[0034] 2. Connect the water pump to the water inlet pipe 13 on the tank 1, inject water into the tank 1 from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com