Mirror back protective coating for colored coated mirror

A technology for protecting coatings and coated mirrors, applied in the direction of polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of not being able to meet the production requirements of color coated mirrors and the construction conditions of mirrors, and achieve excellent physical and chemical properties. Conducive to large-scale industrial production, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

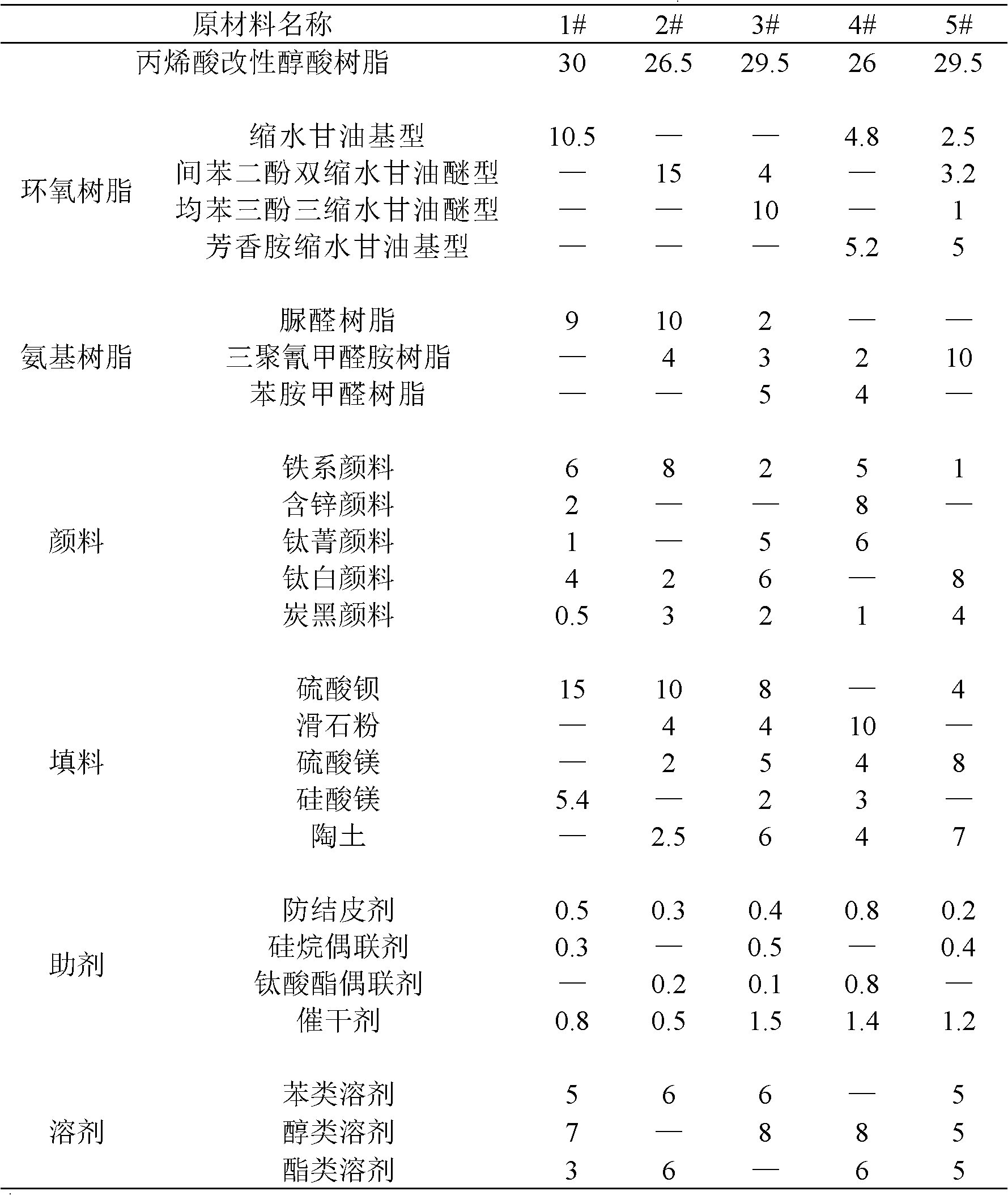

[0035] Put the acrylic modified alkyd resin, epoxy resin, amino resin, pigment, filler, and solvent into the stainless steel tank according to the weight ratio listed in Table 1 and stir evenly, then put it into the sand mill and grind it until the fineness is less than 25 μm, then add various film-forming aids according to the weight percentage in the table, such as: anti-skinning agent, silane coupling agent and / or titanate coupling agent, drier, stir evenly and filter.

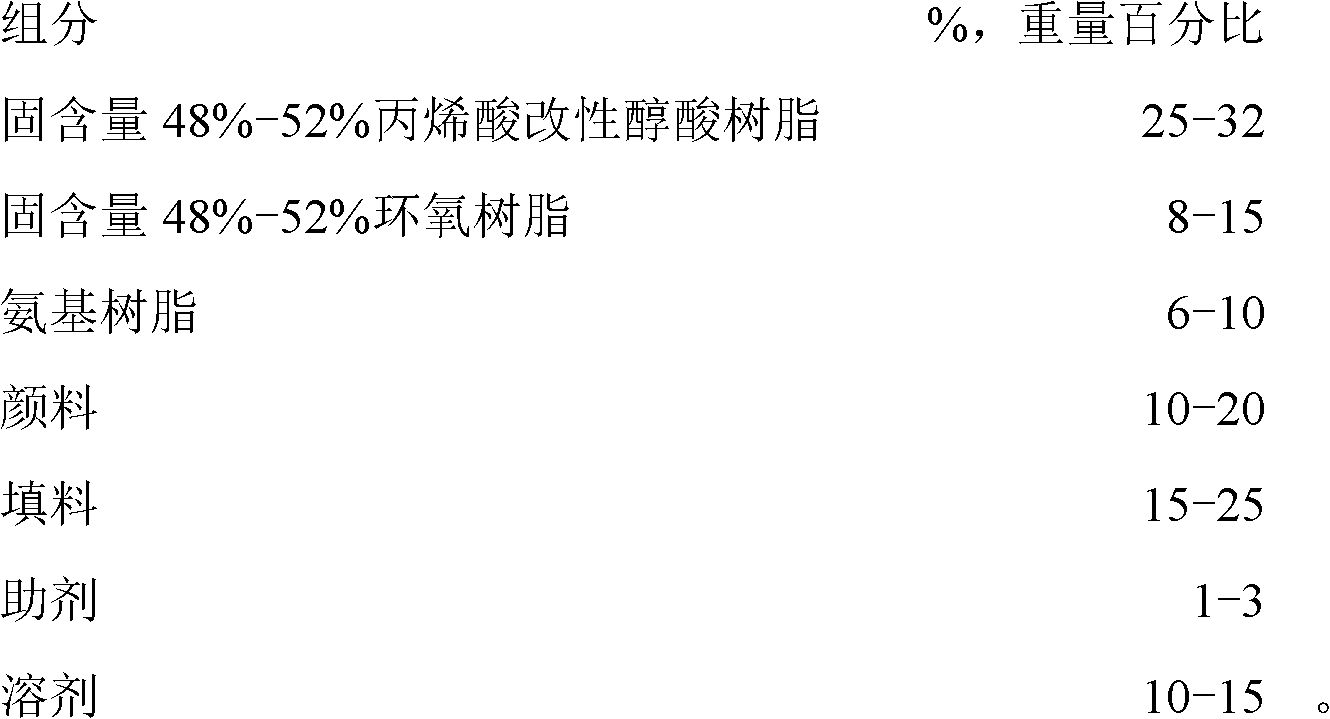

[0036] Table 1 Primer ingredient list (percentage by weight)

[0037]

Embodiment 2

[0039]Put the modified alkyd resin, acrylate resin, phenolic resin, cross-linking resin, pigment, filler, and solvent into the stainless steel cylinder according to the weight ratio listed in Table 2 and stir evenly, then put it into the sand mill and grind it until If the fineness is less than 25μm, add various film-forming aids according to the weight percentage in the table, such as: anti-skinning agent, silane coupling agent and / or titanate coupling agent, drier, stir evenly and filter.

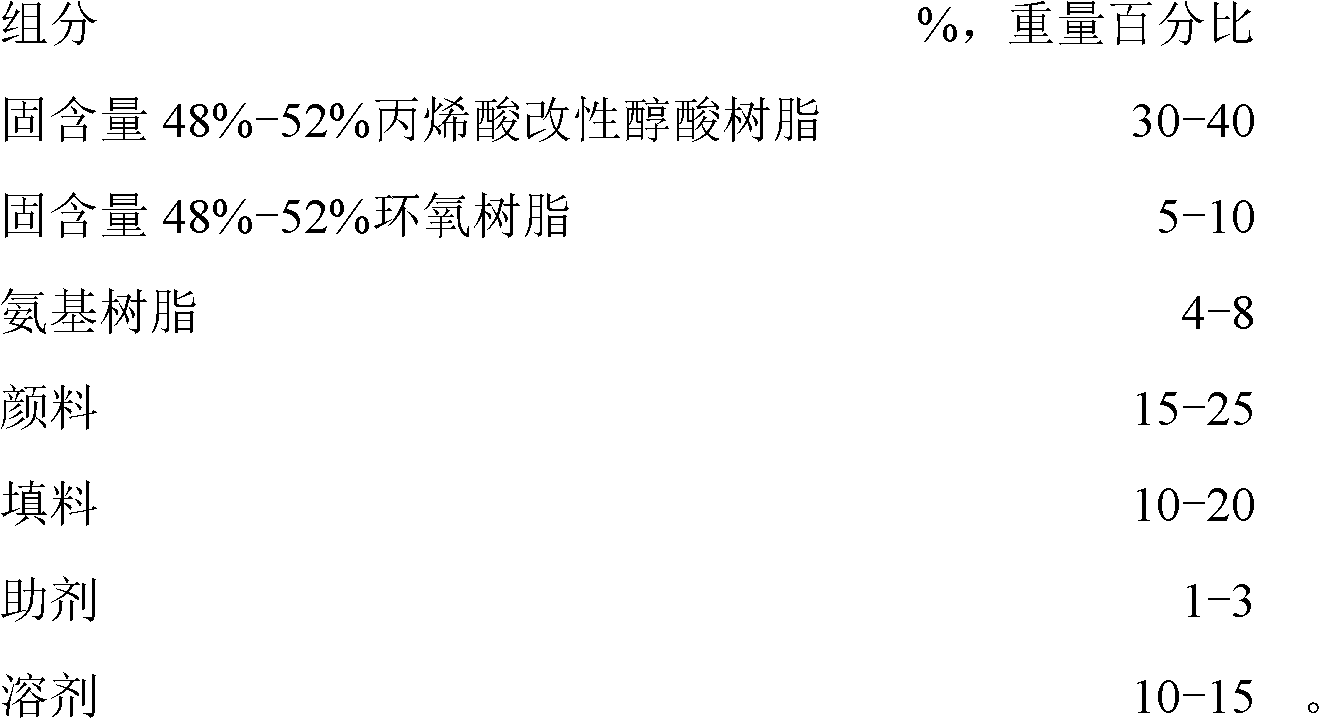

[0040] Table 2

[0041]

Embodiment 3

[0043] The primer and topcoat of the present invention are diluted with xylene to a construction viscosity of 25s-35s (coated with -4 cups, 25°C) during construction, fully stirred evenly, then poured into the paint drenching tank, and adjusting the width of the drenching paint knife Make the dry film meet the specified requirements. The color coating layer is firstly sprayed with a primer and then a top coat. After drying at about 80°C-100°C for 4 minutes to 6 minutes, it is tested that the paint film performance of the mirror back protective coating used for the color coated mirror reaches the table. 3 performance indicators.

[0044] table 3

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com