Energy-saving and consumption-reducing method for producing dimethyl carbonate by transesterification method

A technology of dimethyl carbonate and transesterification, used in the preparation of carbonate/haloformate, chemical instruments and methods, preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

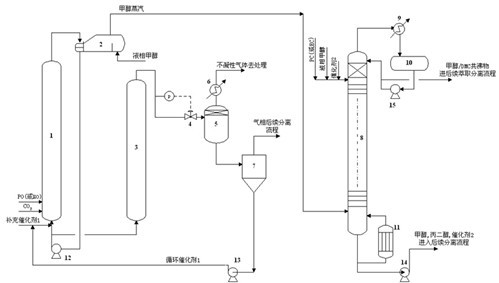

[0037] The specification of the straight tube reactor (1) is Φ450×20000mm, and the size of the adiabatic reactor (3) is Φ400×20000mm. Both reactors adopt the operation mode of bottom-in and top-out. First fill up the propylene carbonate containing 50kg composite ionic liquid catalyst in the straight tube reactor (1), start to feed the raw materials propylene oxide and carbon dioxide after the temperature rises and boosts the pressure, the feed rate of propylene oxide is 500kg / h, the amount of carbon dioxide The feed rate is 417kg / h, the top discharge of the straight tube reactor (1) enters the tube side of the evaporative cooler (2), and 740kg / h of liquid phase methanol is pumped into the shell side, and the methanol enters after gasification To the lower part of the reactive distillation tower (8), the reaction temperature of the straight tube reactor (1) is controlled at 135~140°C, and the reaction pressure is controlled at 4.5MPa; the reaction material enters the flash tank ...

Embodiment 2

[0040] The specification of the straight tube reactor (1) is Φ400×18000mm, and the size of the adiabatic reactor (3) is Φ350×18000mm. Both reactors adopt the operation mode of bottom in and top out. First fill up the ethylene carbonate containing 38kg composite ionic liquid catalyst in the straight tube reactor (1), start to feed the raw materials ethylene oxide and carbon dioxide after the temperature rises and boost the pressure, the feed rate of ethylene oxide is 400kg / h, The feed rate of carbon dioxide is 440kg / h, the top discharge of the straight tube reactor (1) enters the tube side of the evaporative cooler (2), and 1960kg / h of liquid phase methanol is pumped into the shell side, and the methanol is vaporized Then enter the lower part of the reactive distillation tower (8), the reaction temperature of the straight tube reactor (1) is controlled at 125~135°C, and the reaction pressure is controlled at 4.3MPa; the reaction material enters the flash reactor (3) after passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com