Thermal-energy recycling system in spandex-spinning production process

A technology of production process and heat recovery, applied in the manufacture of textile/flexible products, complete sets of equipment for the production of artificial threads, dry spinning, etc., can solve the problems that the temperature cannot be further lowered and the temperature of the gas on the cold side cannot be further increased, etc. To achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

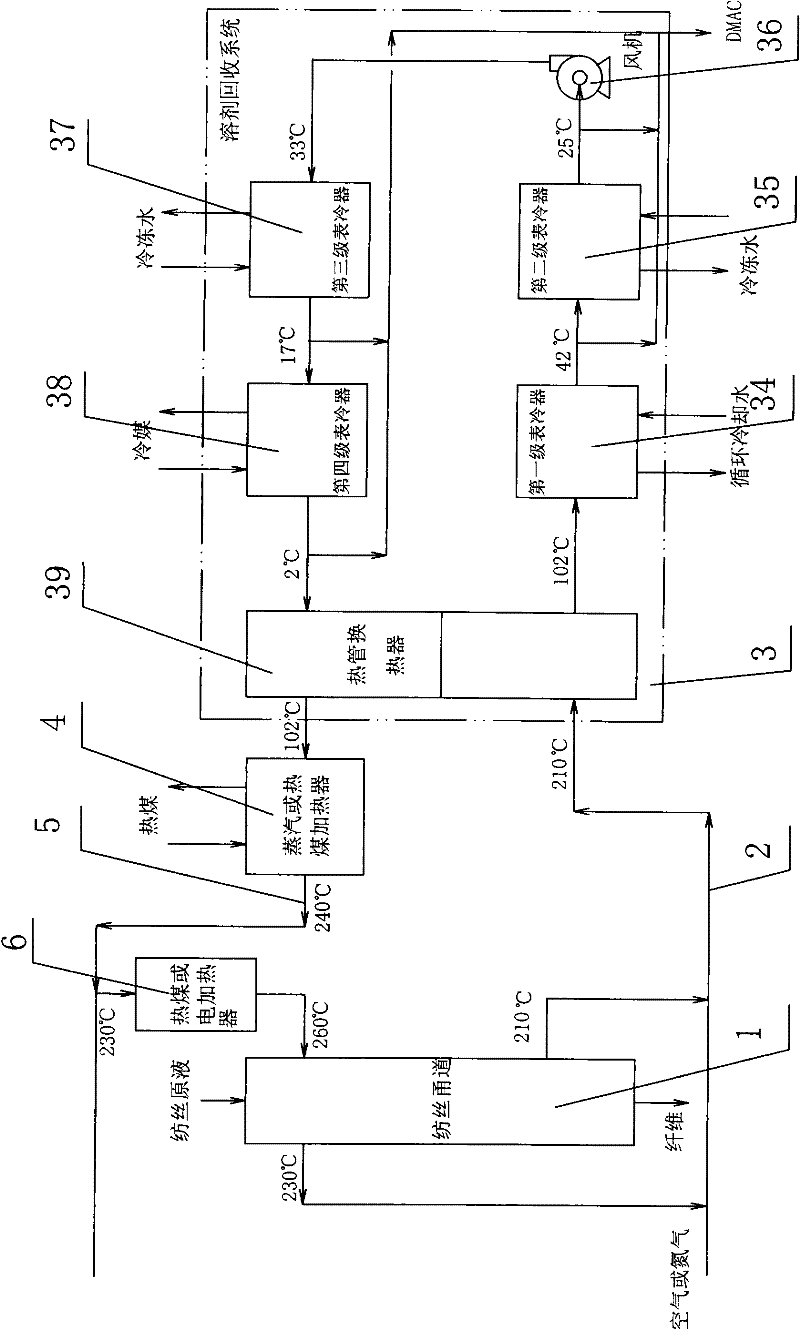

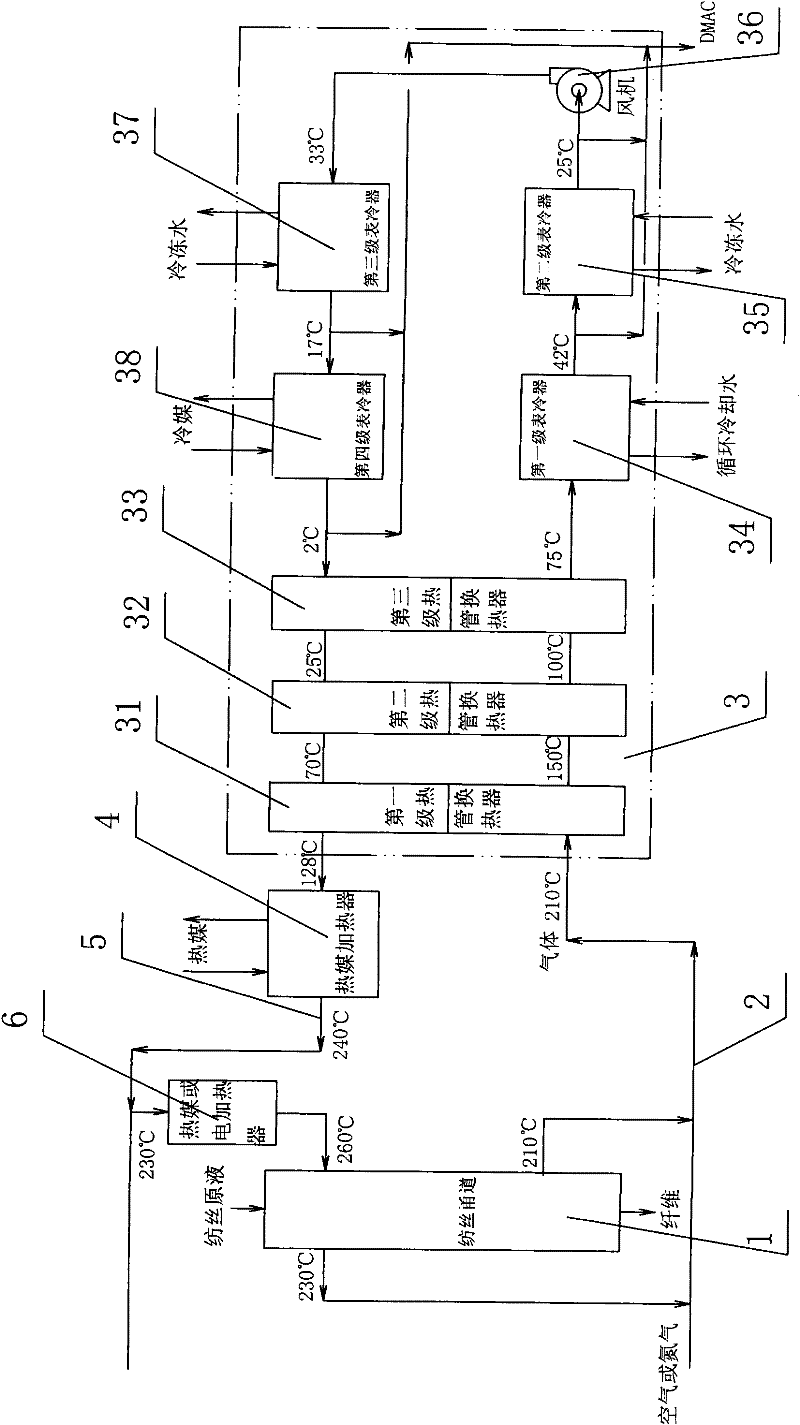

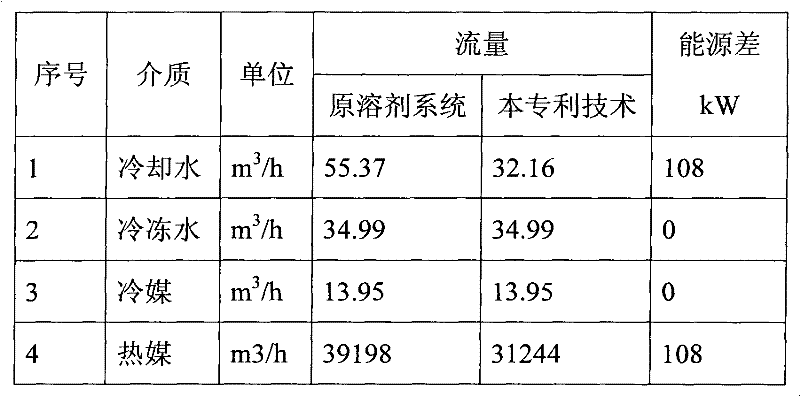

[0021] see figure 2 , figure 2 It is a schematic flow chart of the spandex spinning solvent recovery system of the present invention. Depend on figure 2 It can be seen that the spandex spinning solvent recovery system of the present invention comprises a spinning shaft 1, a first air pipe 2, a solvent recovery system 3, a heat medium heater 4, a second air pipe 5 and a heat medium or an electric heater 6, There are multiple spinning shafts 1, and the hot air containing solvent DMAC from multiple spinning shafts 1 is connected to the first air duct 2, and the first air duct 2 is connected to the solvent recovery system 3, and the solvent recovery system 3 includes Heat pipe heat exchanger, fan 36 and surface cooler, the heat pipe heat exchanger includes two or more stages, figure 2 There are three stages in the middle, namely the first stage heat pipe heat exchanger 31, the second stage heat pipe heat exchanger 32 and the third stage heat pipe heat exchanger 33, the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com