Patents

Literature

47 results about "Flash reactor" patented technology

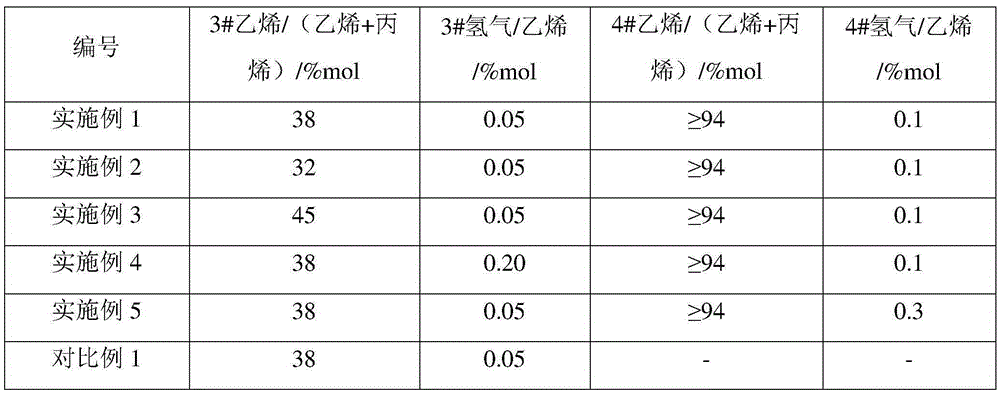

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

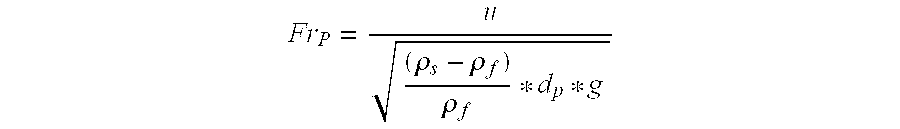

As an extension of the fluidized bed family of separation processes, the flash reactor (FR) (or transport reactor) employs turbulent fluid introduced at high velocities to encourage chemical reactions with feeds and subsequently achieve separation through the chemical conversion of desired substances to different phases and streams. A flash reactor consists of a main reaction chamber and an outlet for separated products to enter downstream processes.

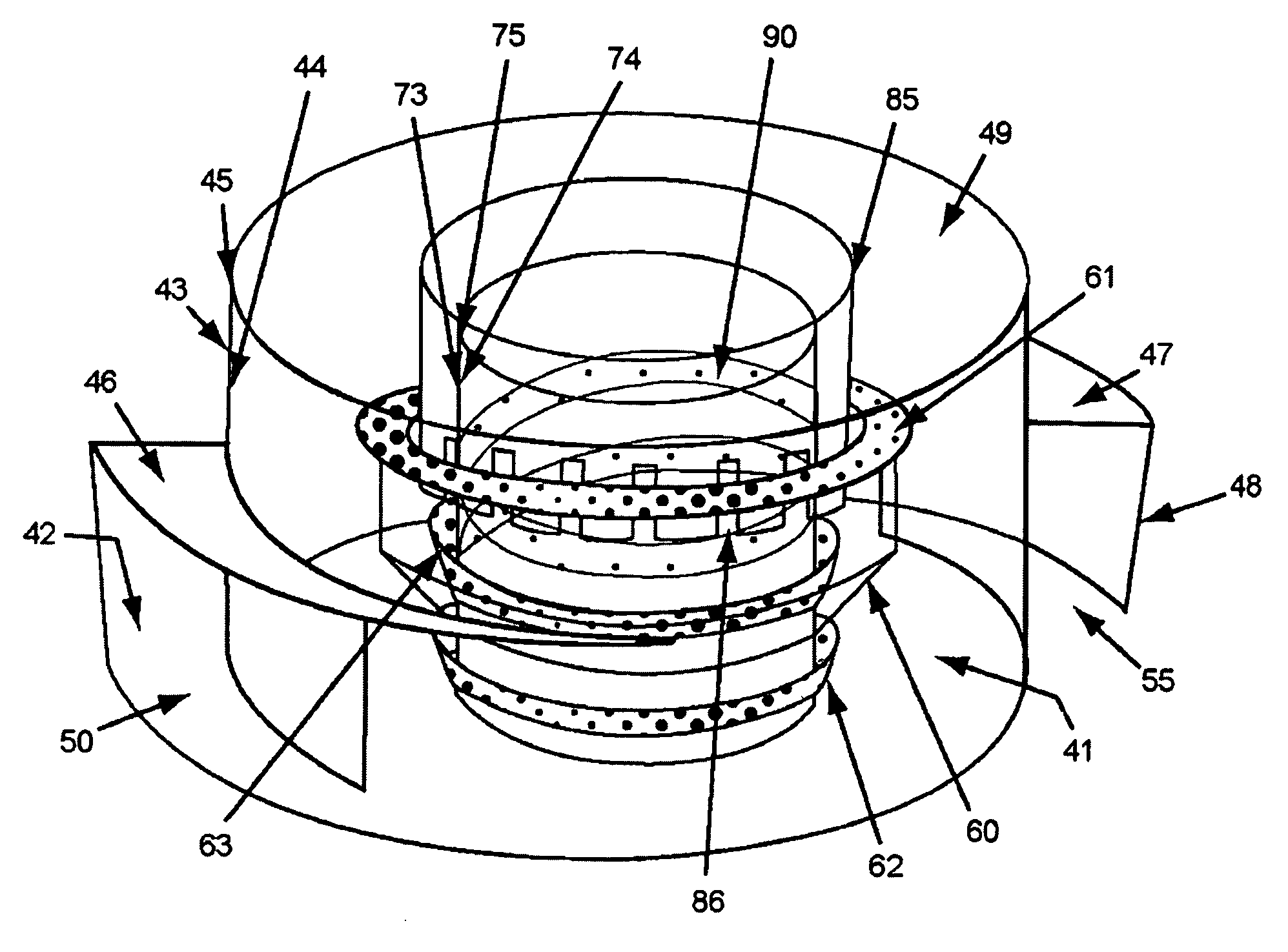

Mixing device for a down-flow reactor

ActiveUS8017095B2Improve efficiencySmall sizePhysical/chemical process catalystsFlow mixersGas phaseProcess engineering

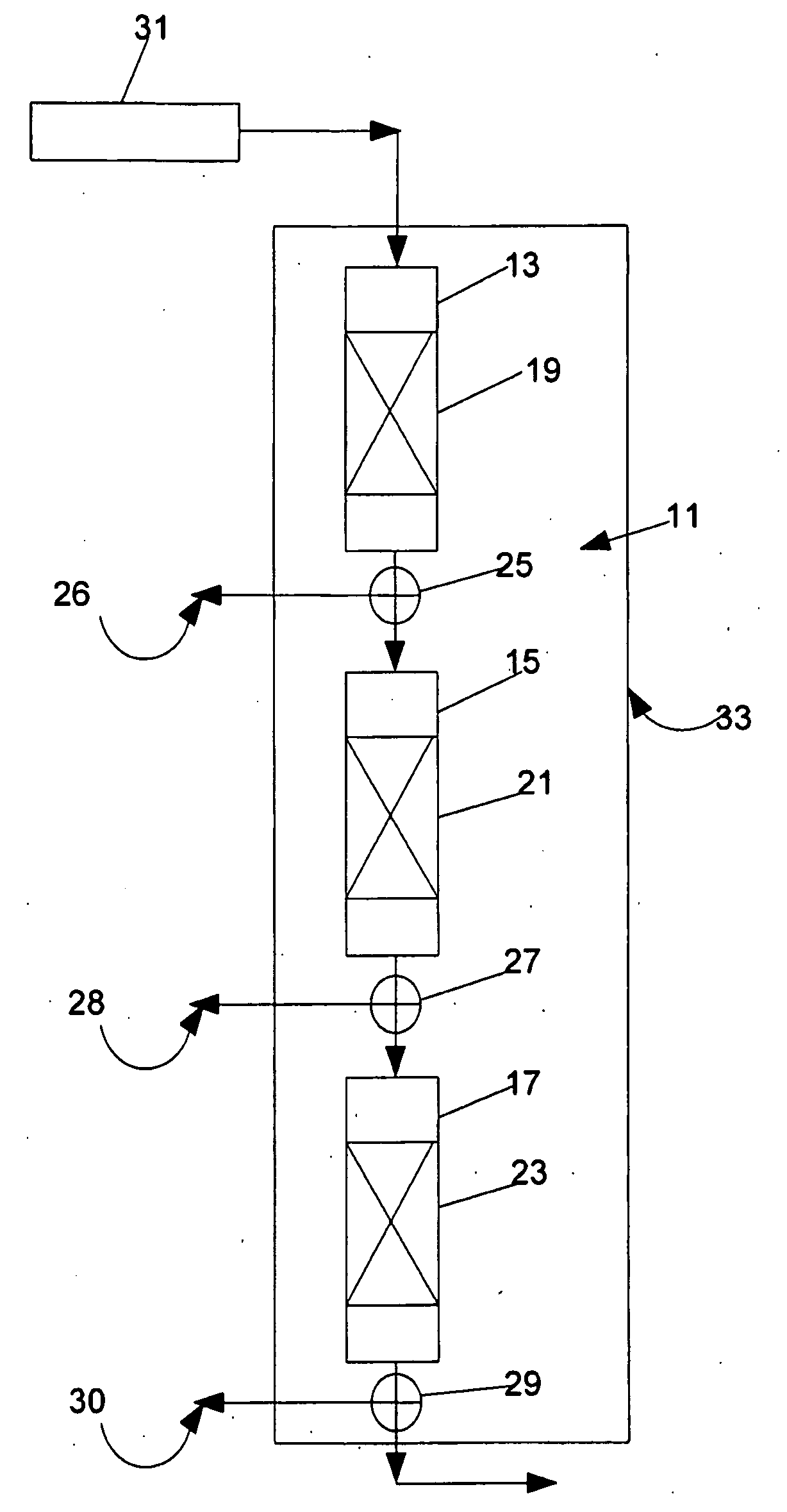

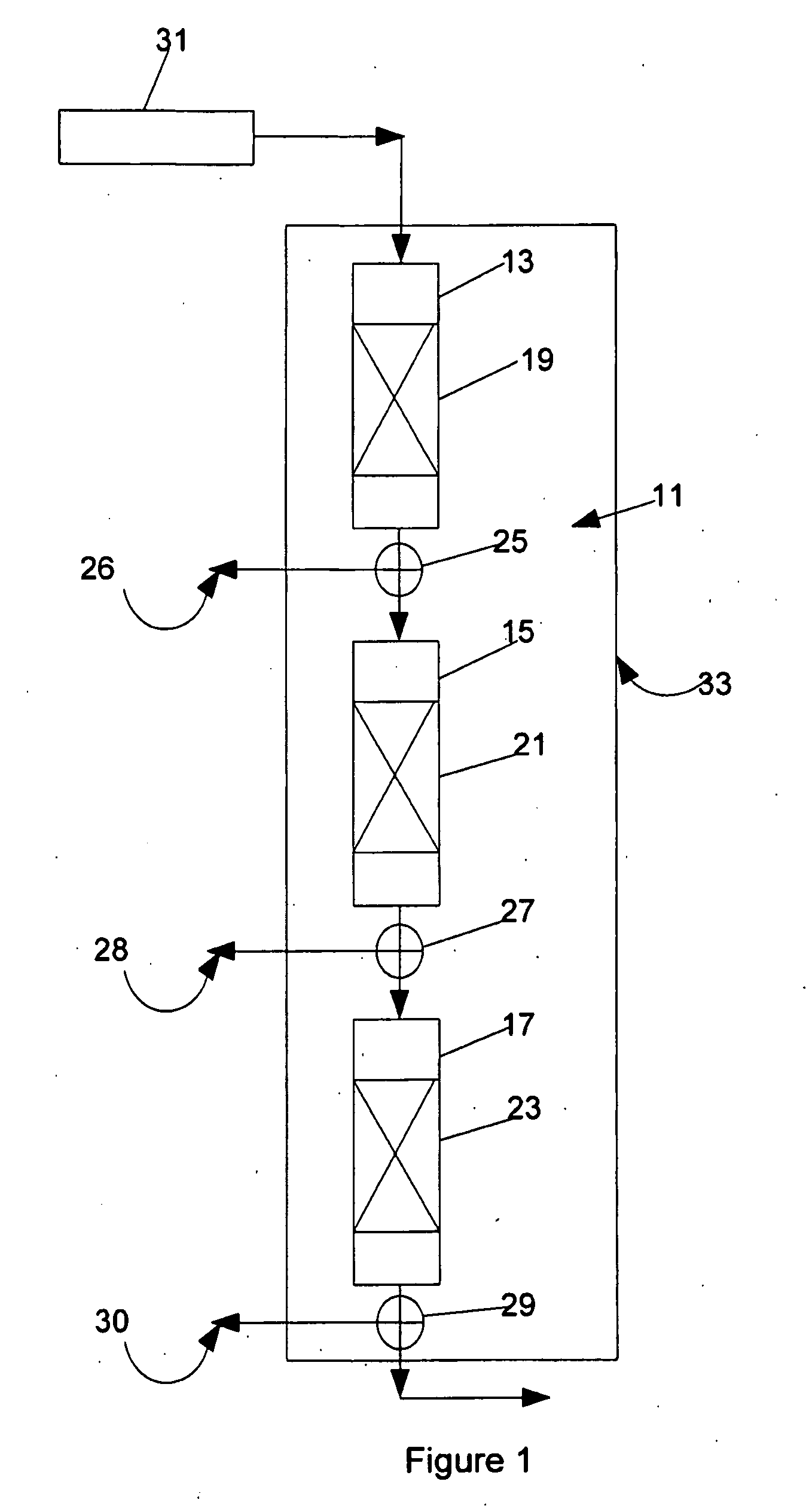

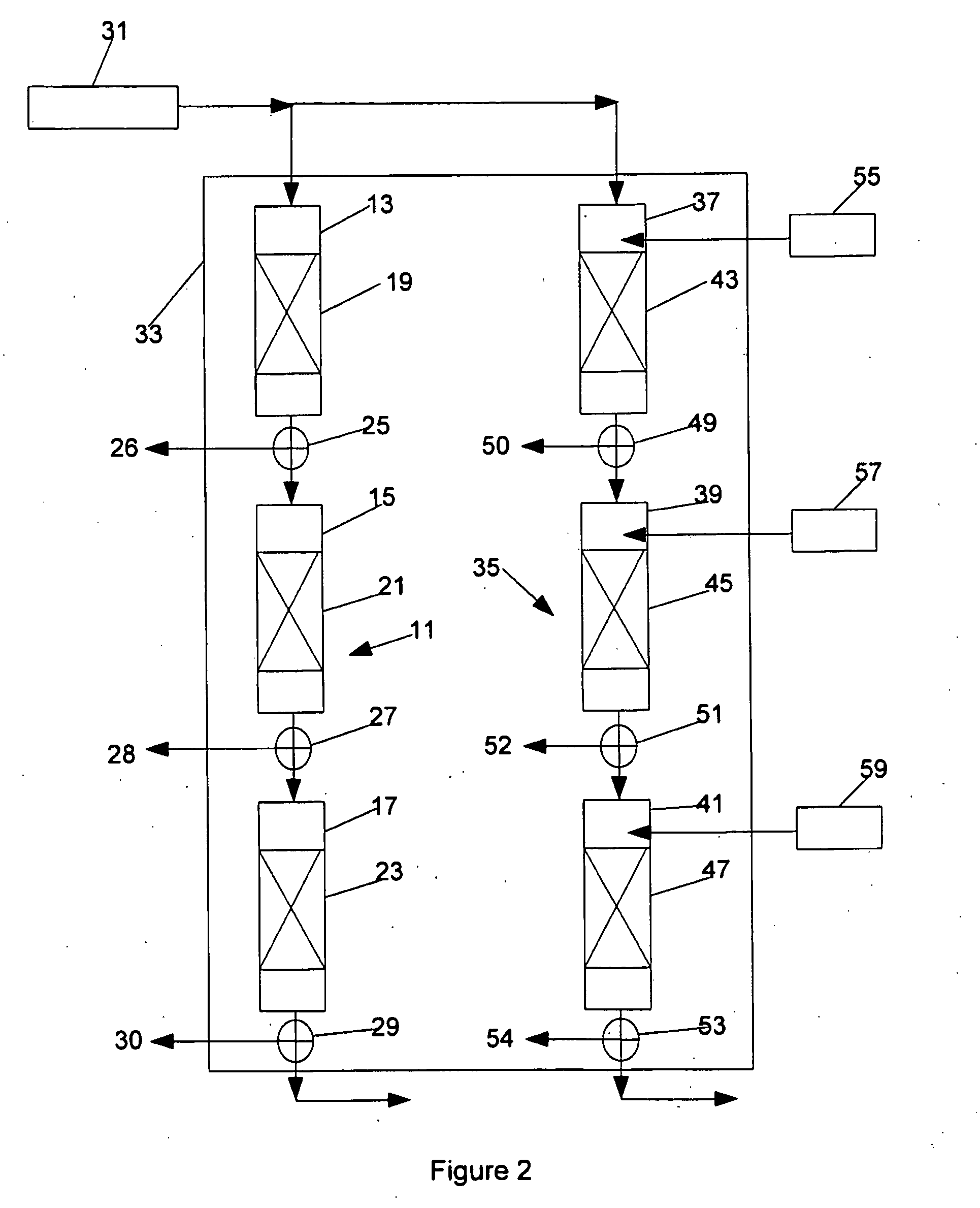

The present invention provides a novel means to provide more effective mixing of gas and fluids in a height constrained interbed space of a catalytic reactor without increasing pressure drop. In particular, the device improves the effectiveness of an existing mixing volume in mixing the gas phase and liquid phase of two-phase systems. According to the present invention, the mixing device helps create a highly arcuate flow to incoming effluents and a high degree of mixing within a constrained interbed space of a catalytic reactor.

Owner:CHEVROU USA INC

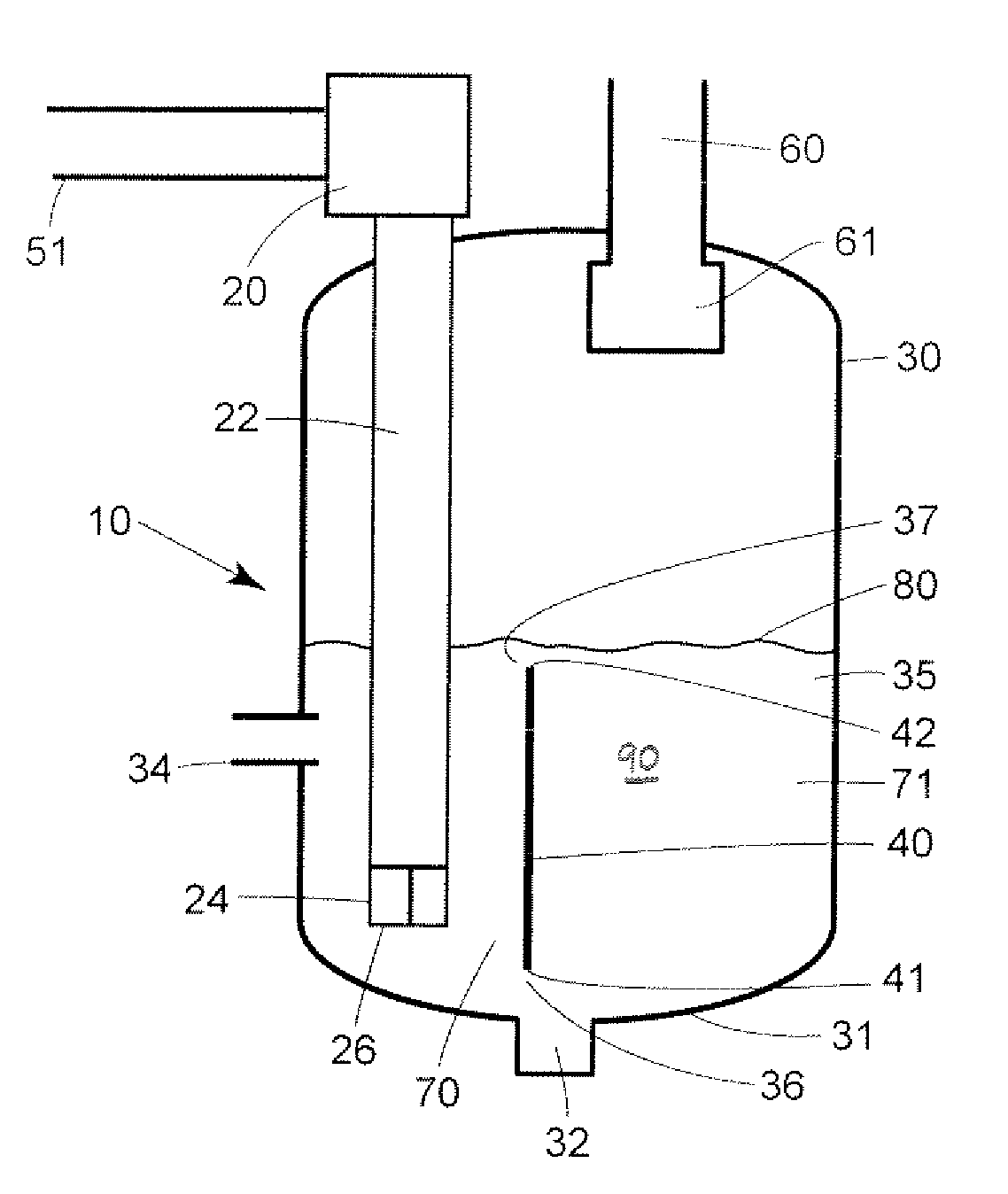

Air stripper

ActiveUS20080174033A1Increased turbulenceEnhanced mixing processMixing methodsUsing liquid separation agentChemical reactionHigh rate

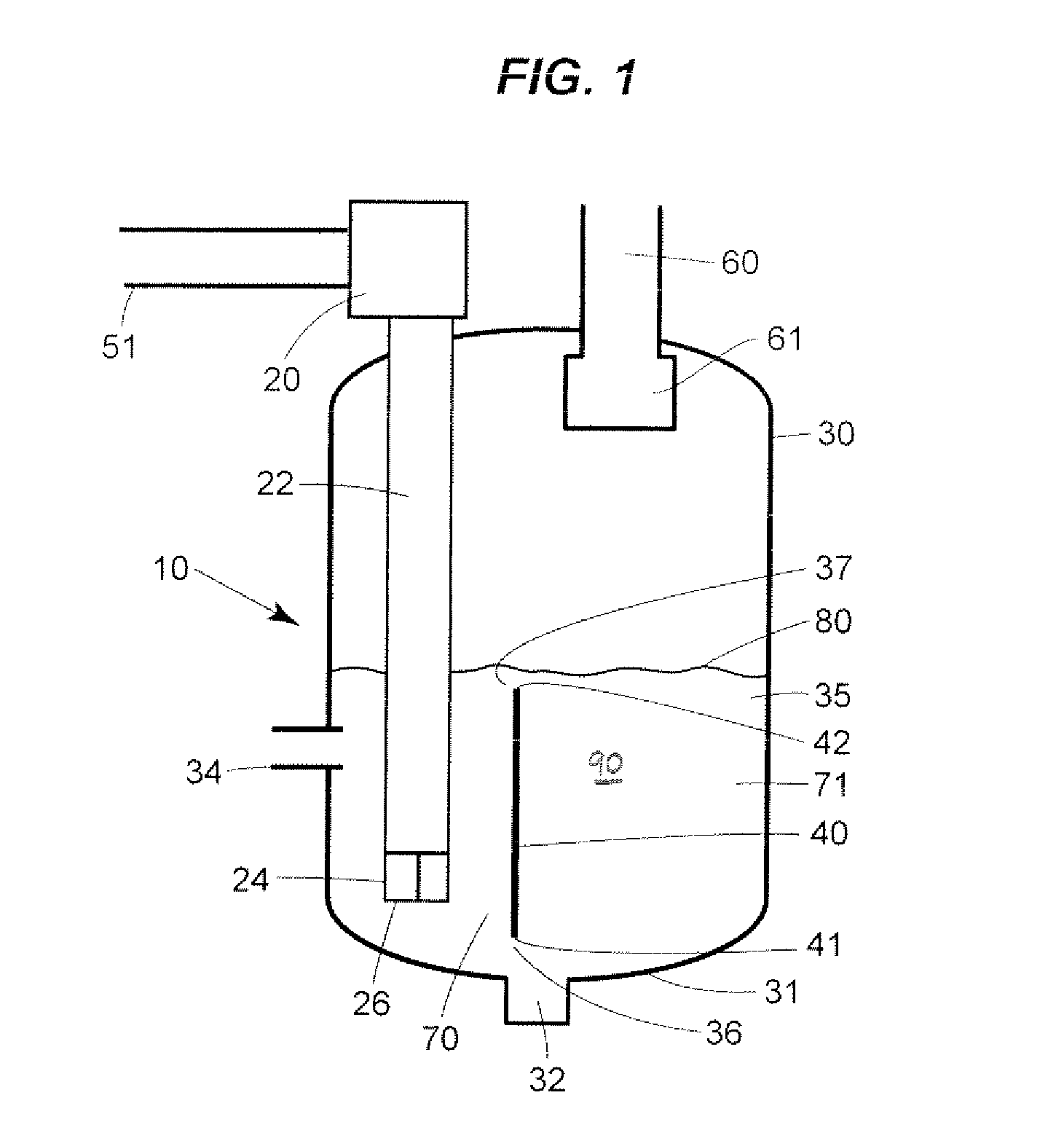

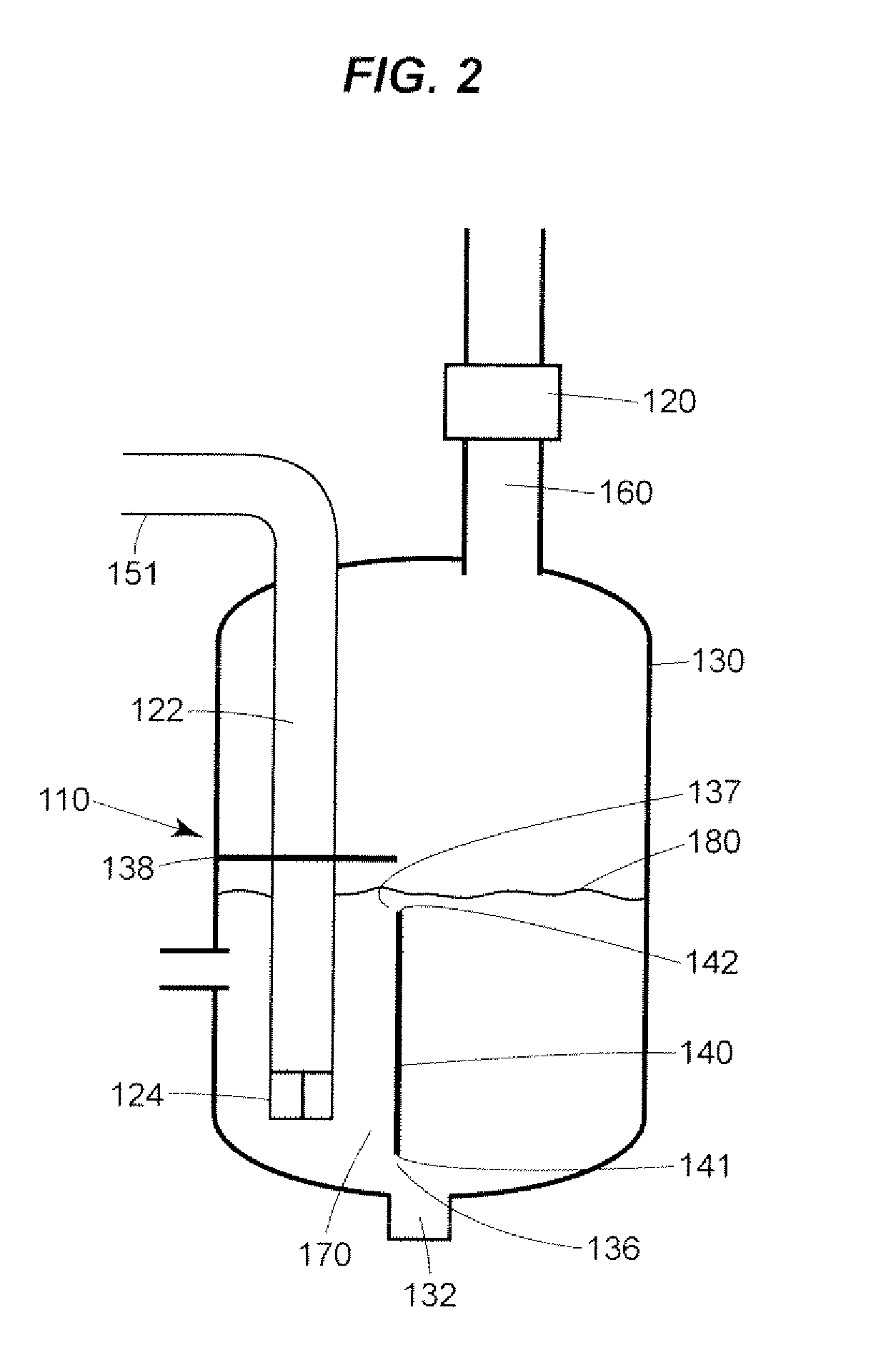

An air stripper in the form of an submerged gas evaporator or a submerged gas reactor that includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a contaminated liquid inlet that provides a contaminated liquid to the vessel at a rate sufficient to maintain a controlled constant level of process fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:HEARTLAND WATER TECH INC

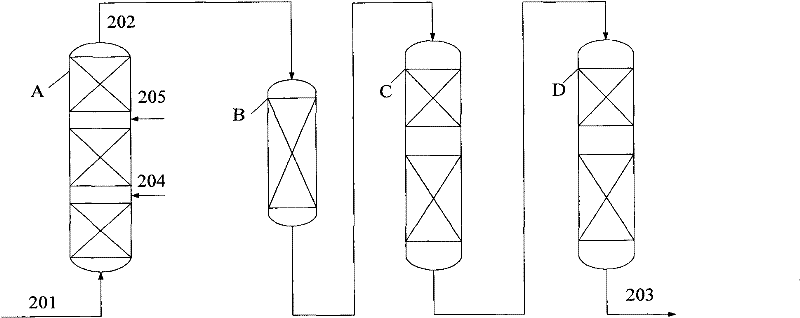

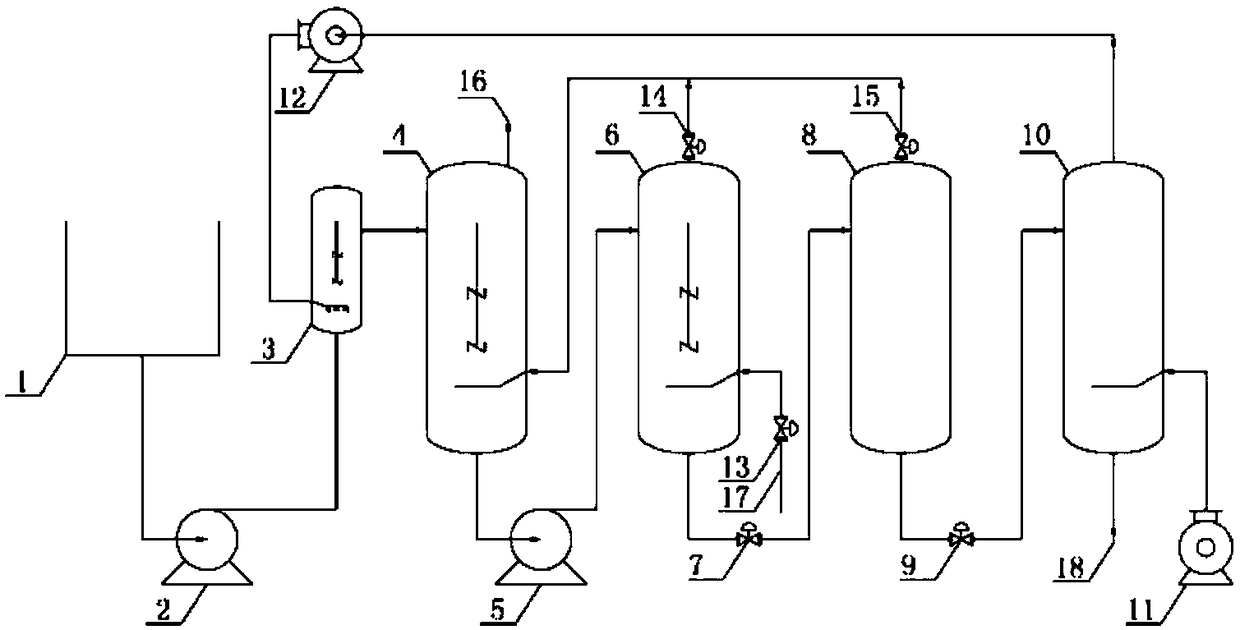

Method for processing heavy material by using up-flow reactor system

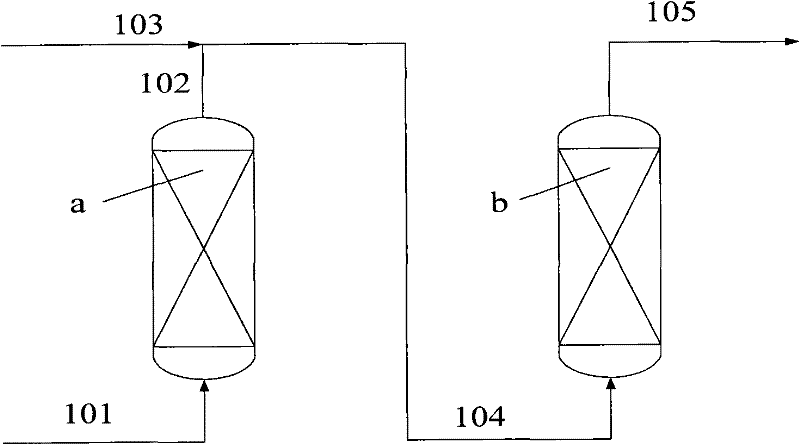

The invention discloses a method for processing a heavy material by using an up-flow reactor system. At least two serially connected single-catalyst bed up-flow reactors are arranged; according to the flowing direction of a reaction material flow, the hydrogenation activity of a catalyst in a first reactor bed is lower than that of a catalyst in a second reactor bed; and the bottom of each reactor is provided with fluid distribution equipment for controlling to uniformly distribute fluid flowing through catalyst layers. The invention provides a method for processing heavy oil by using an up-flow reactor system in which fluids in the reactors is uniformly distributed and components in the reactors are easy to design and manufacture. An optimized catalyst grading method is adopted, and the metal removal rate for the heavy material in the up-flow reactor system is over 50 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

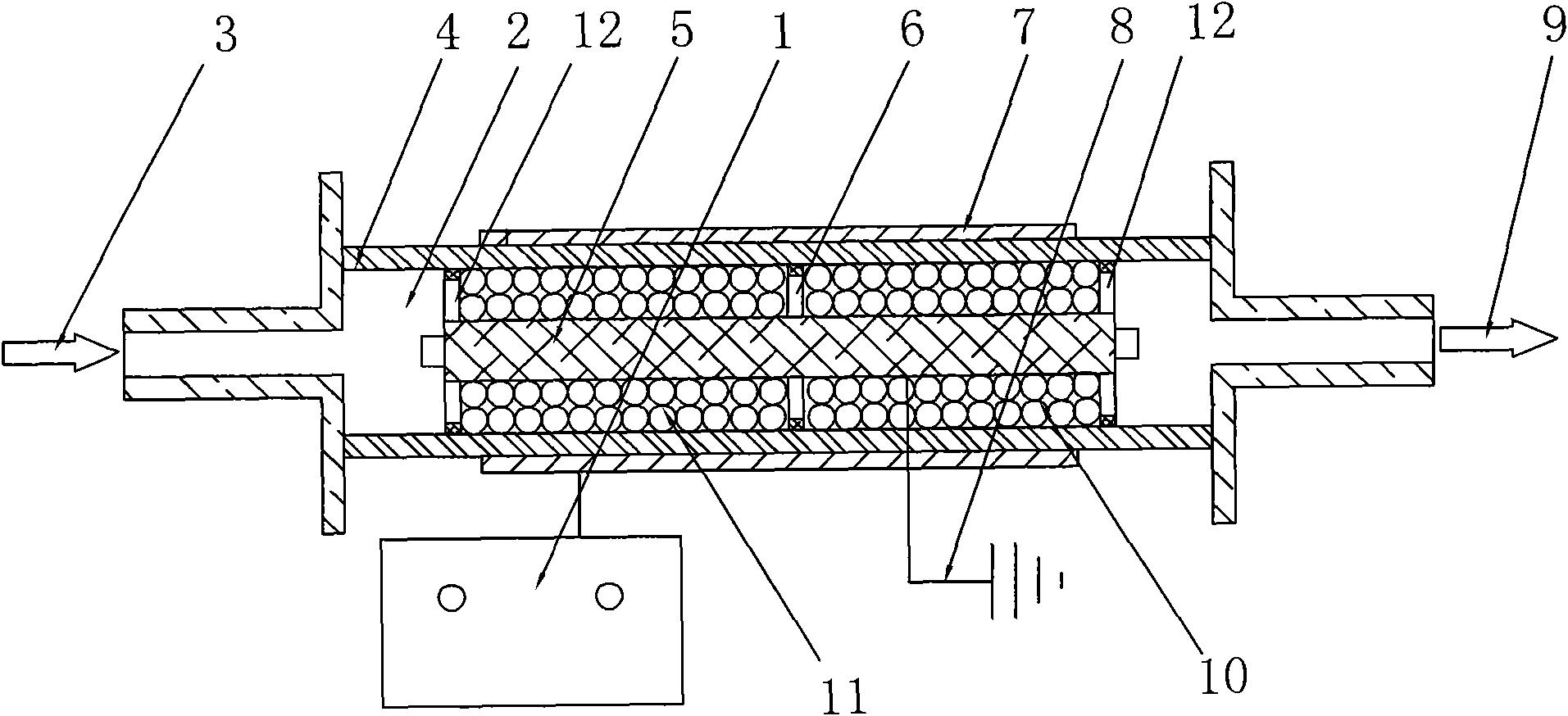

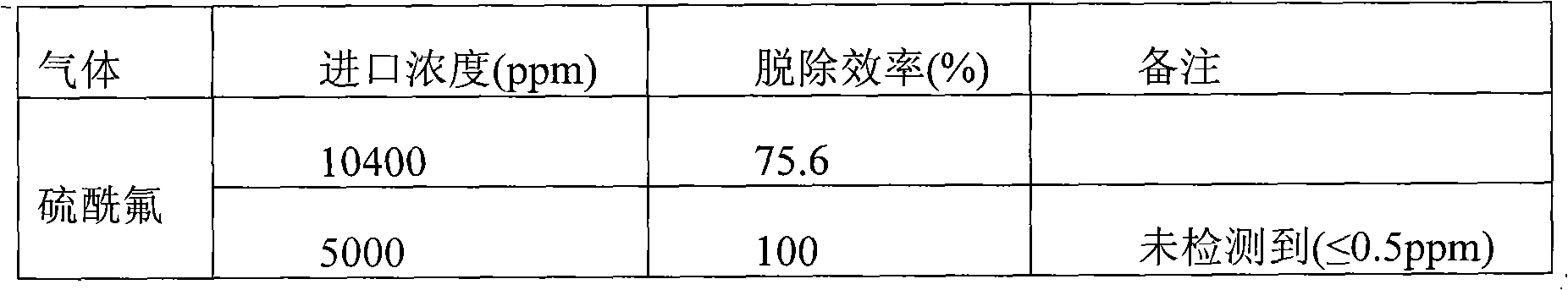

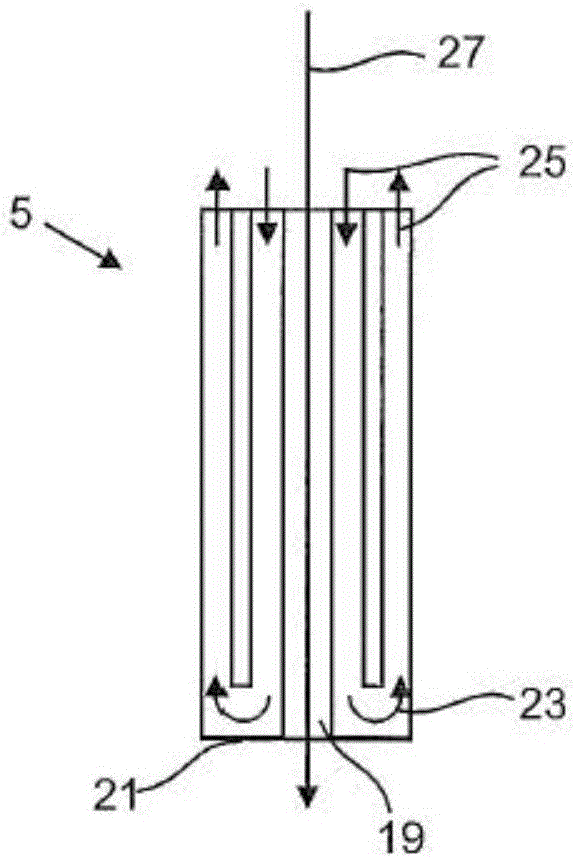

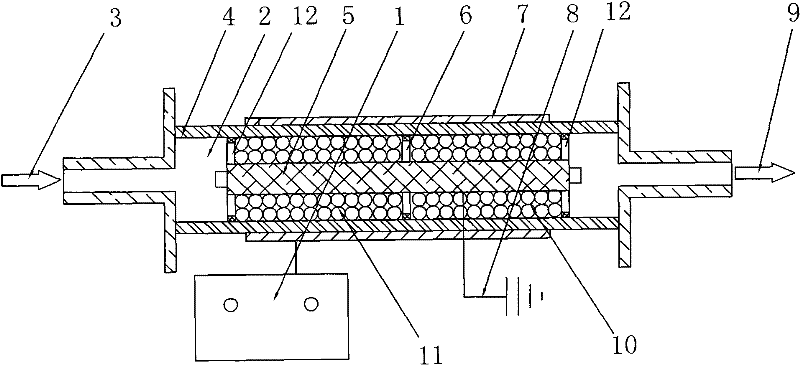

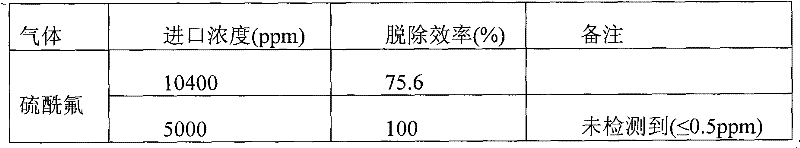

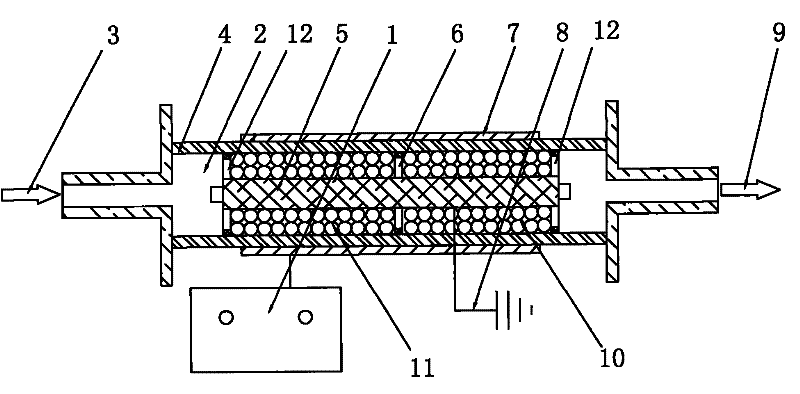

Innocent treatment method for sulfuryl fluoride gas

ActiveCN101972587AImprove removal efficiencyImprove utilization efficiencyDispersed particle separationElectric dischargeHigh energy

The invention belongs to the technical field of gas pollutant treatment, in particular relates to an innocent treatment method for sulfuryl fluoride gas. The method comprises the following steps of: dividing a plasma reactor serving as a reactor into two stuffing cavities between two electrodes by gas distribution baffles at both ends and a porous baffle in the middle; and introducing sulfuryl fluorid-containing gas into the plasma reactor from a gas inlet, performing oxidization reaction and degradation reaction on the sulfuryl fluorid-containing gas and high-energy electrons and active particles which are generated by electric discharge and reacting with secondary stuffing in the plasma reactor and absorbing under the action of nonequilibrium plasma to generate non-toxic and innocent gas without greenhouse effect and discharging from a gas outlet. The method has the advantages that the sulfuryl fluoride is oxidized and degraded under the action of the nonequilibrium plasma by adopting a mode that the discharge plasma and the stuffing are in the same electric field simultaneously, and reacts with the stuffing loaded in the reactor simultaneously to be absorbed so as to promote the reaction to perform towards the innocent direction, and improve the desorption efficiency, and thus the utilization ratio of energy is improved.

Owner:ZHEJIANG UNIV OF TECH +1

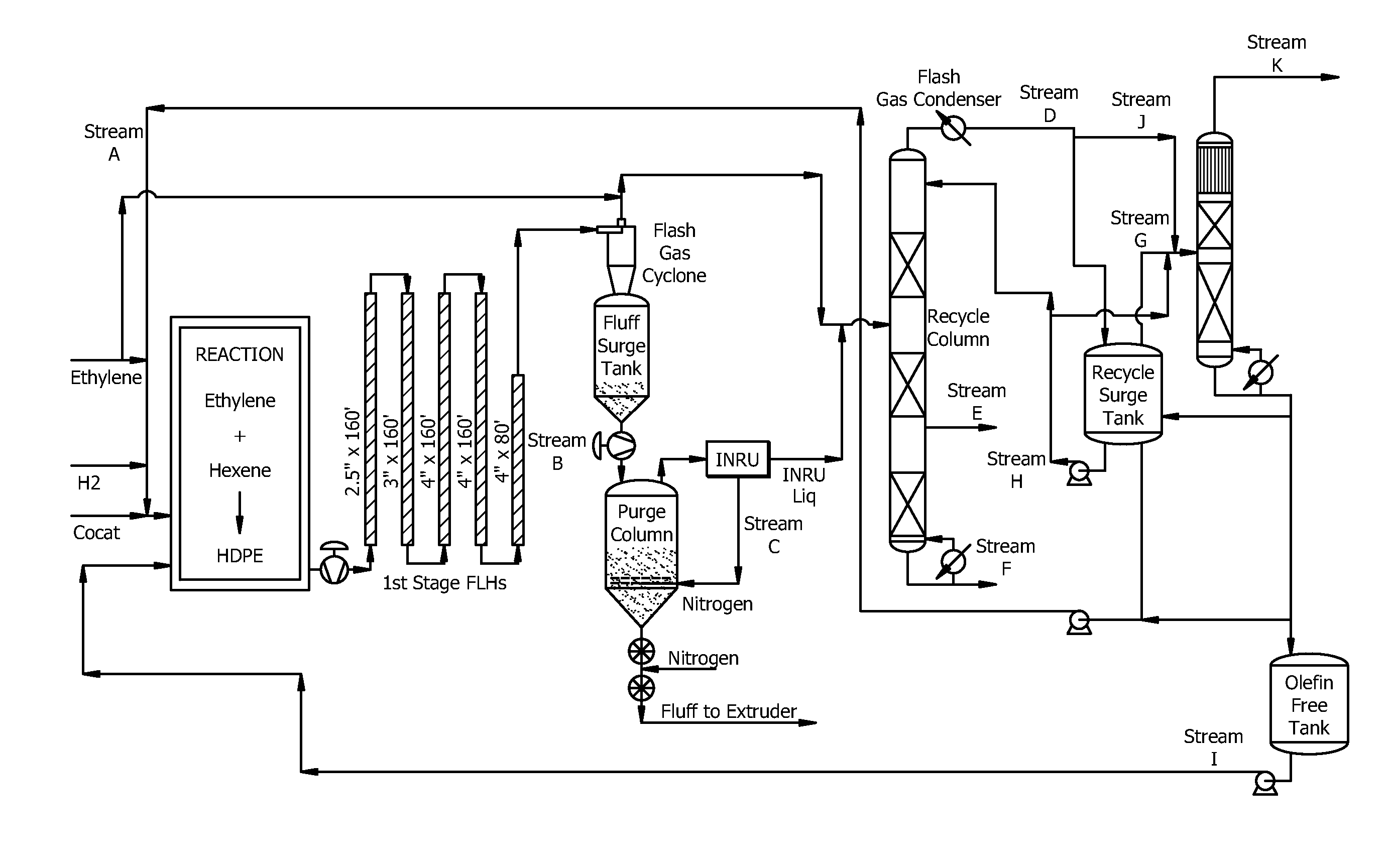

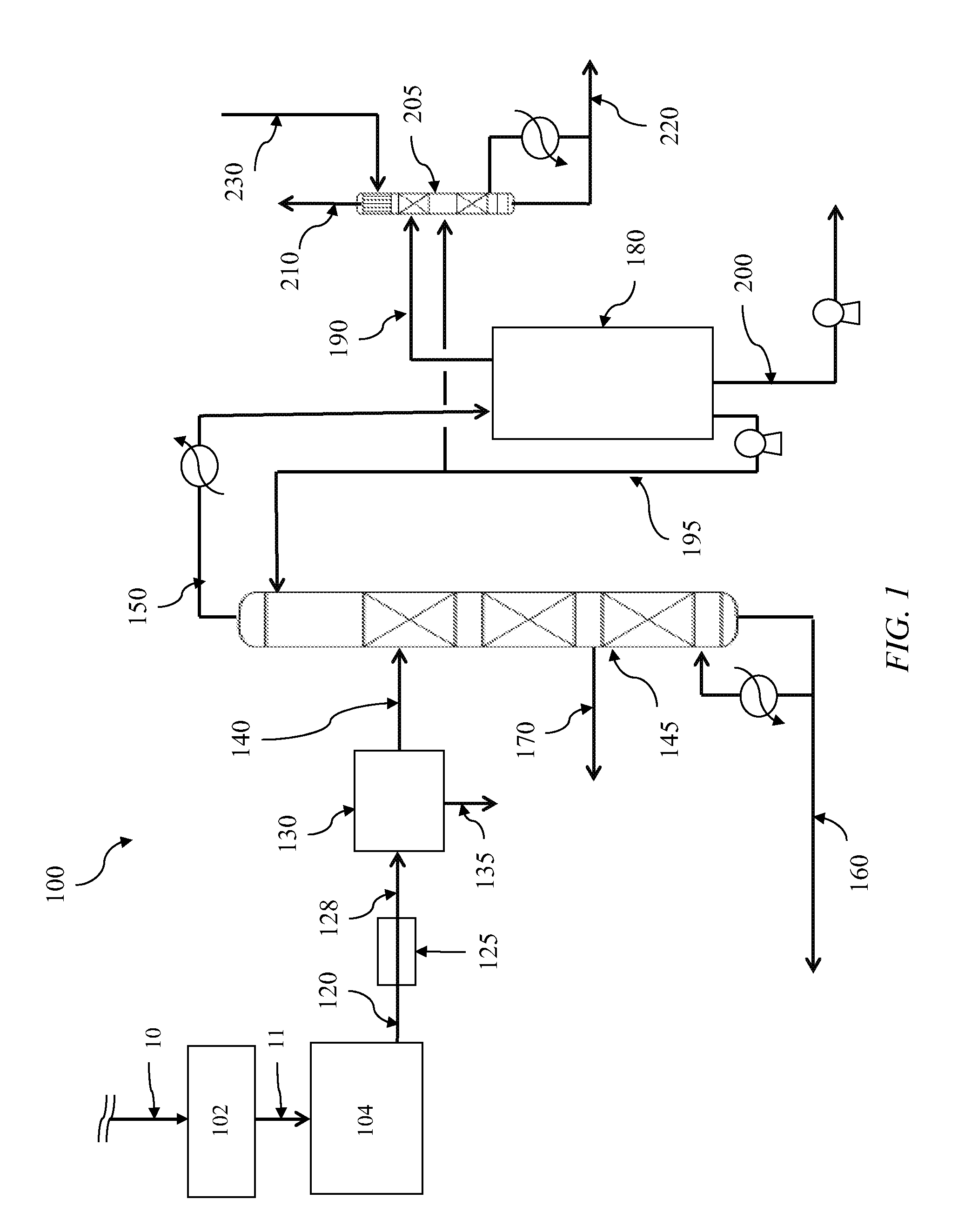

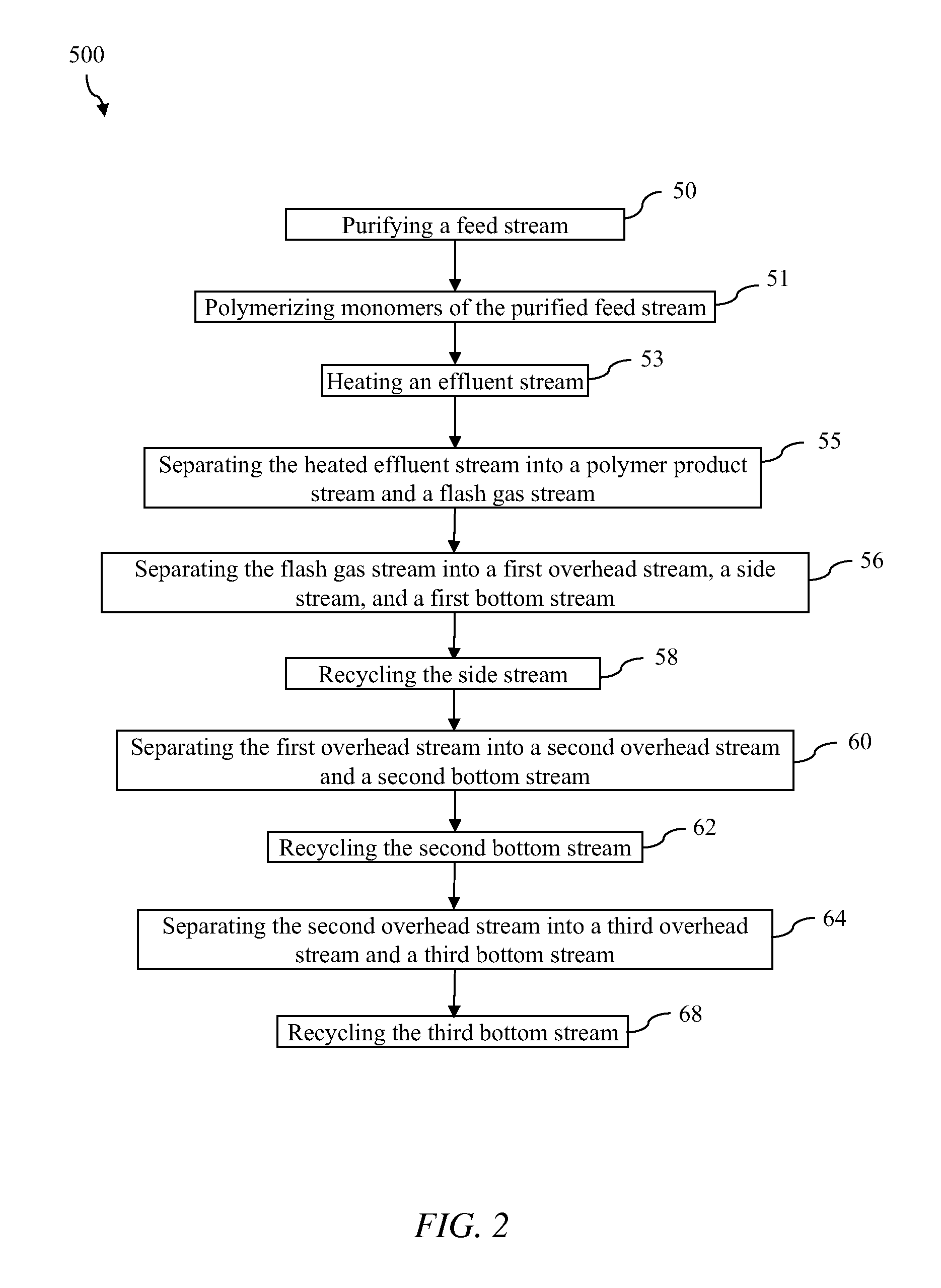

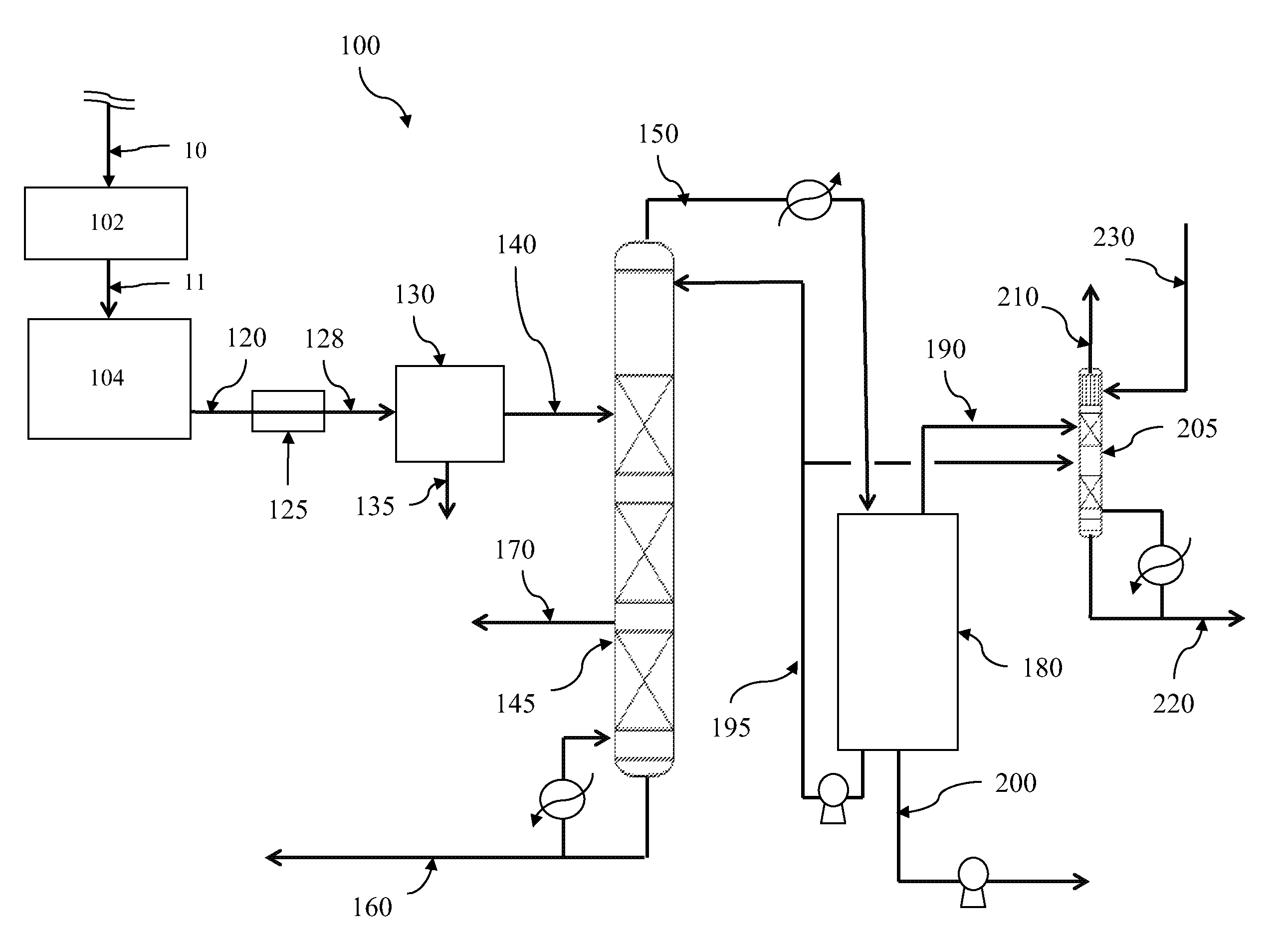

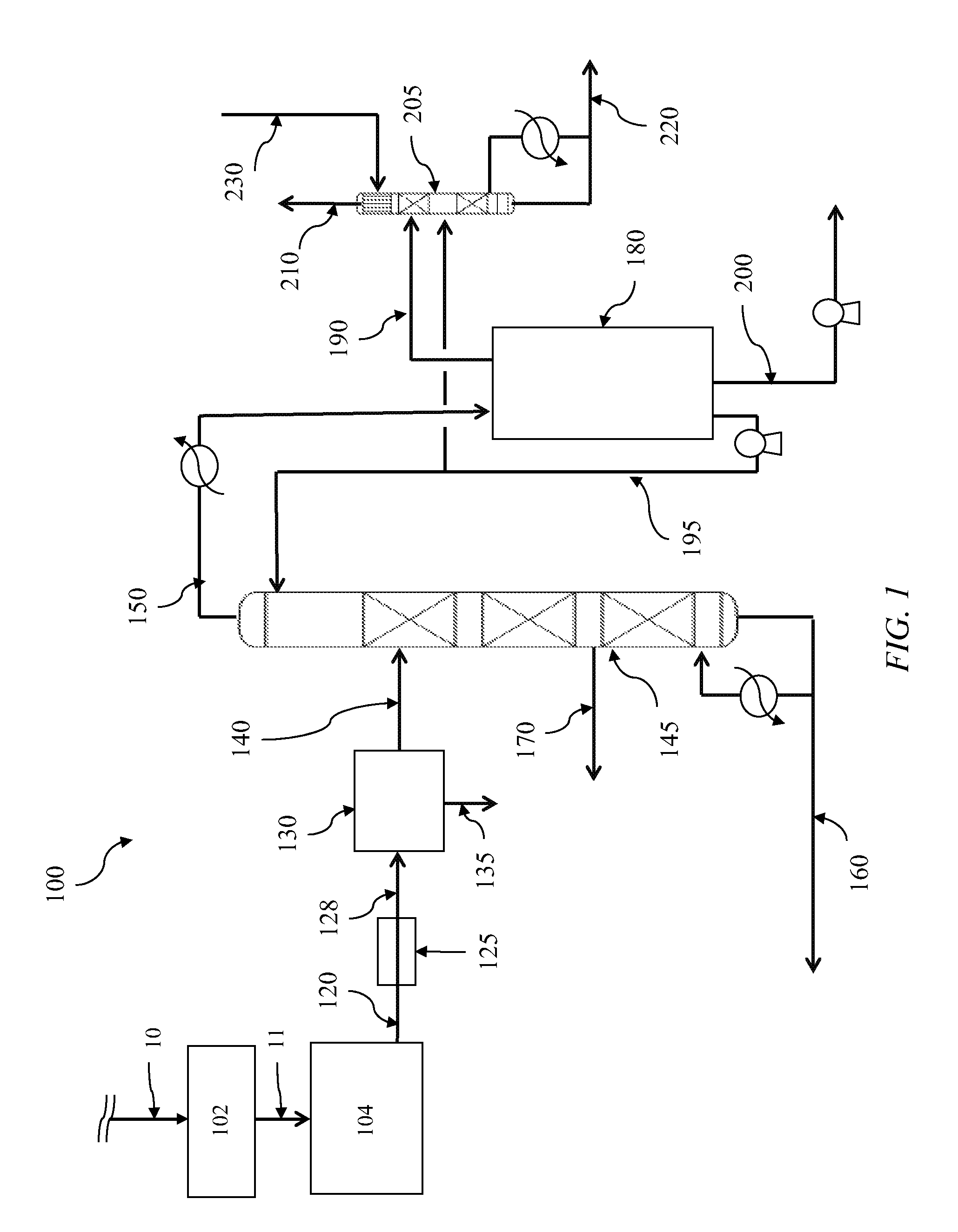

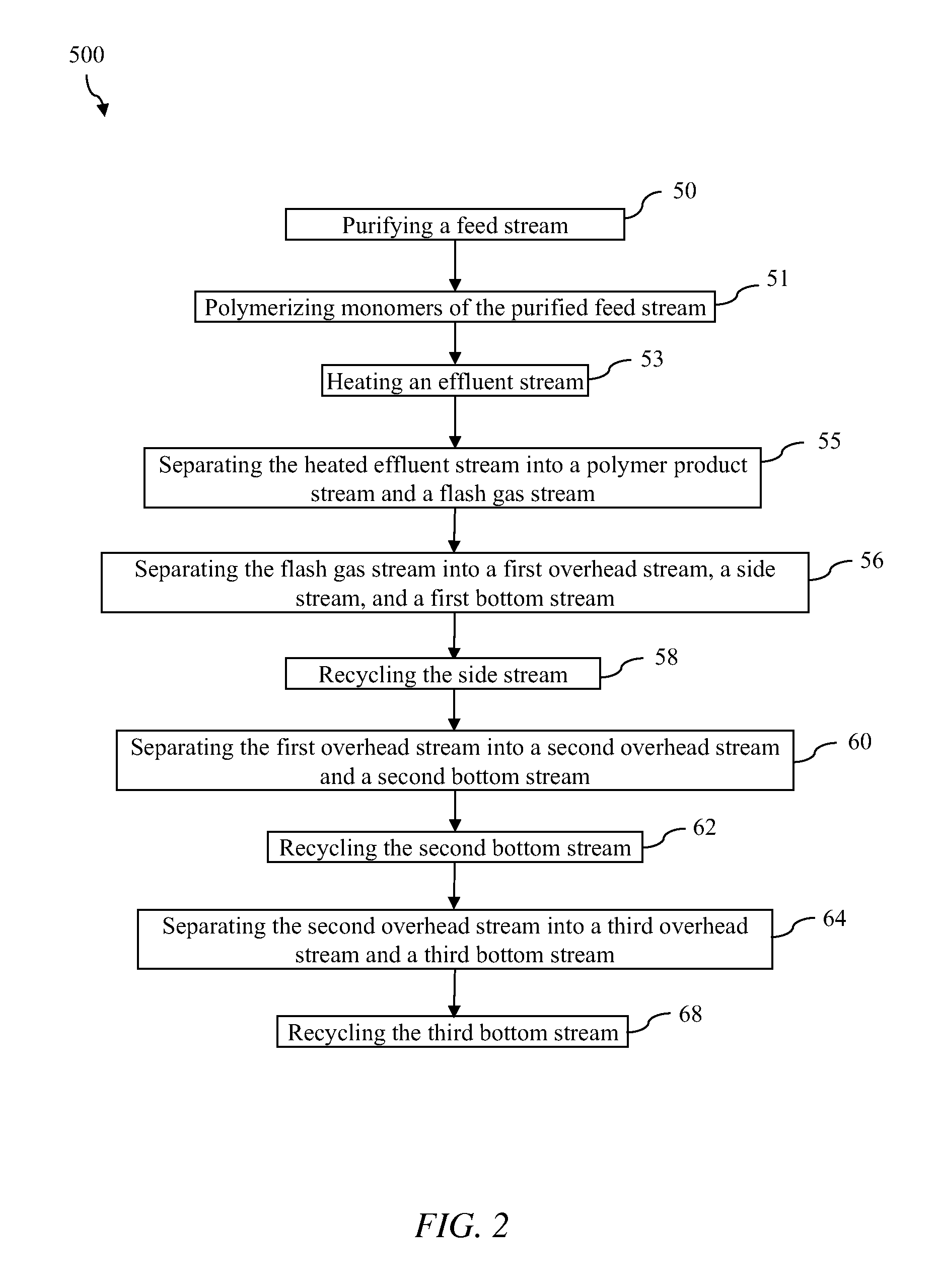

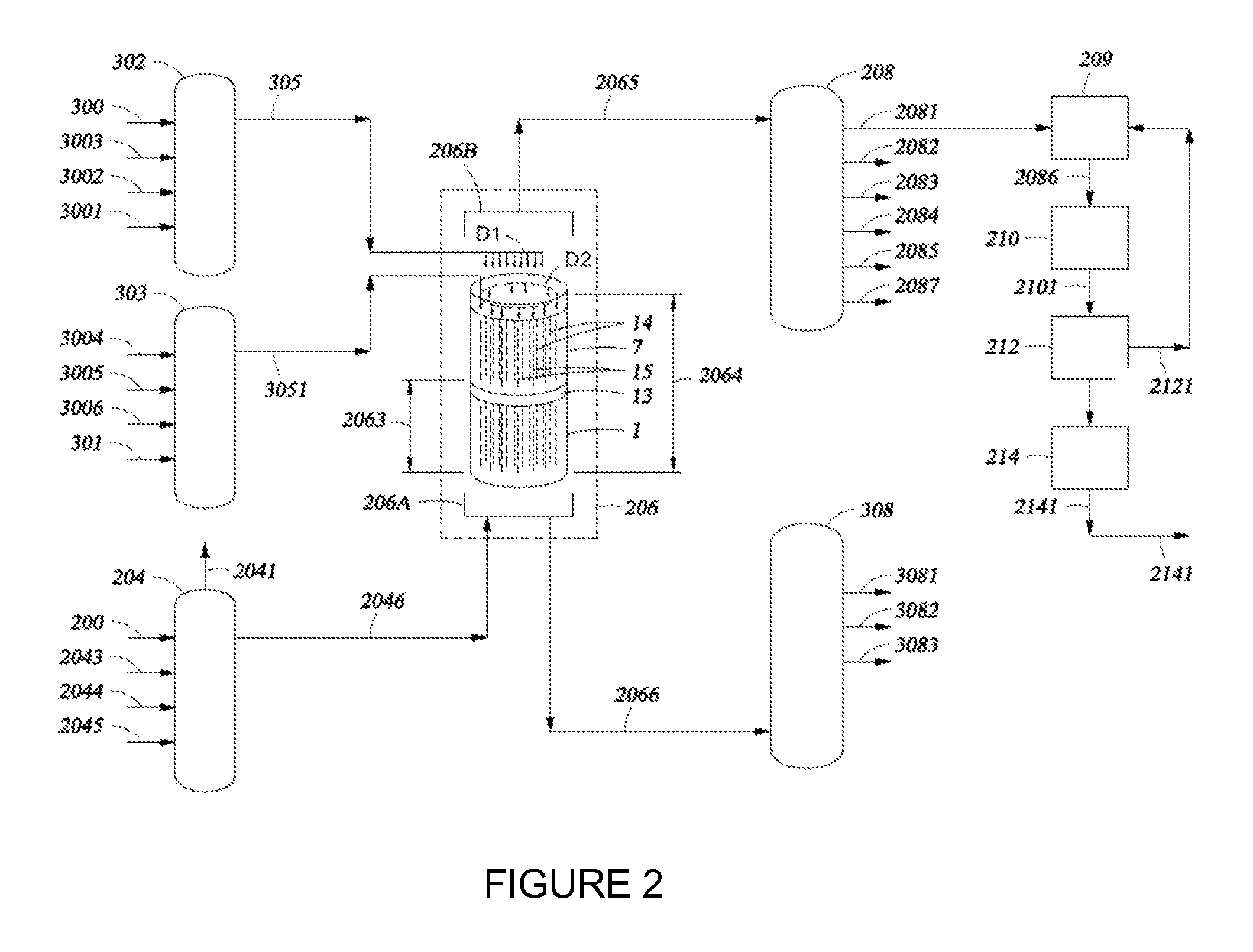

System and Method for Processing Reactor Polymerization Effluent

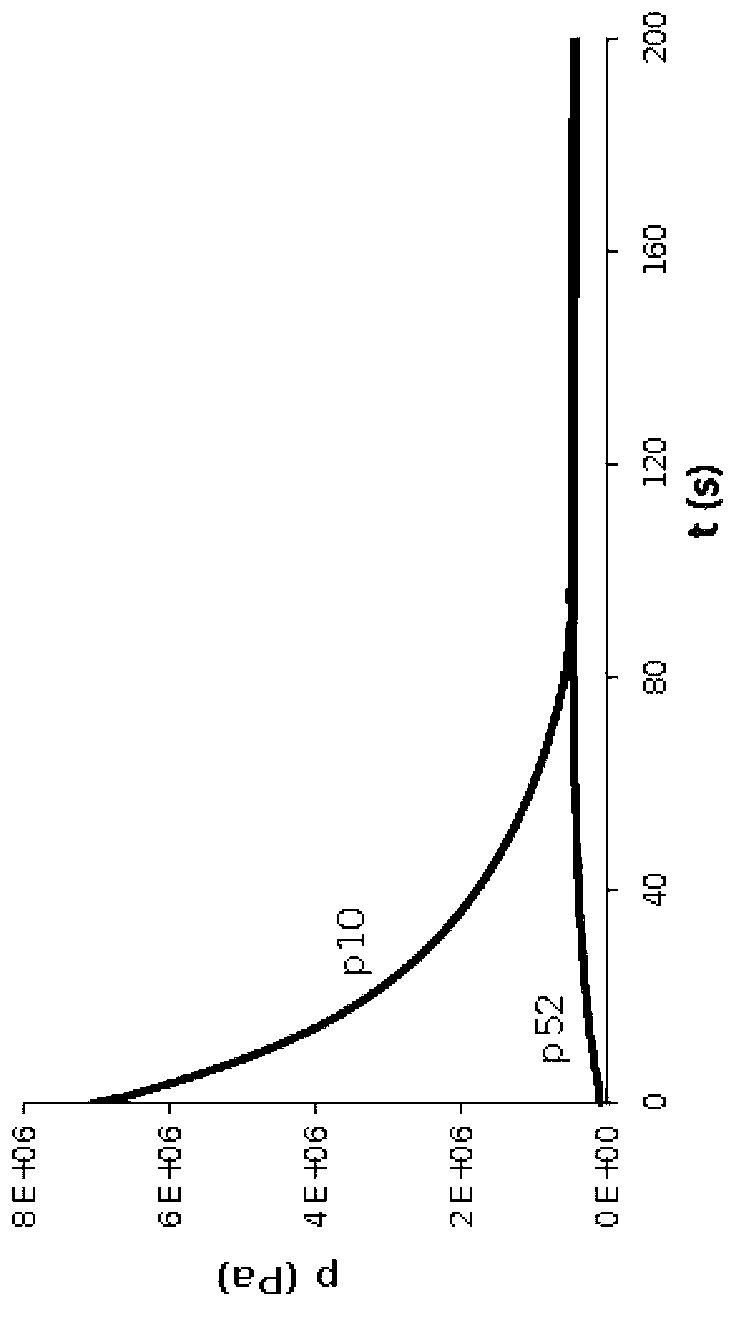

A method of treating a polymerization reactor effluent stream comprising recovering the reactor effluent stream from the polymerization reactor, flashing the reactor effluent stream to form a flash gas stream, separating the flash gas stream into a first top stream, a first bottom stream, and a side stream, wherein the side stream substantially comprises hexane, separating the first top stream into a second top stream and a second bottom stream, wherein the second bottom stream substantially comprises isobutene, and separating the second top stream into a third top stream and a third bottom stream; wherein the third top stream substantially comprises ethylene, and wherein the third bottom stream is substantially free of olefins.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

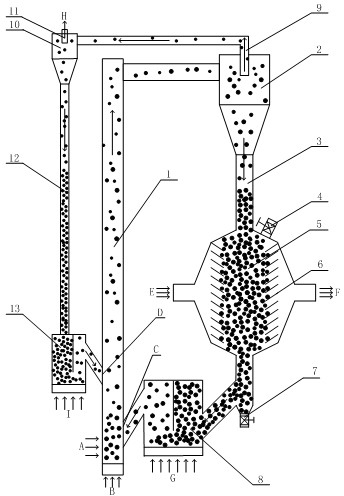

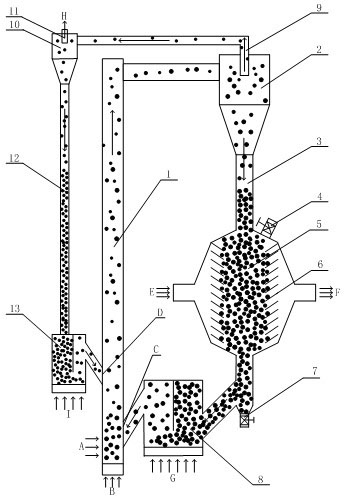

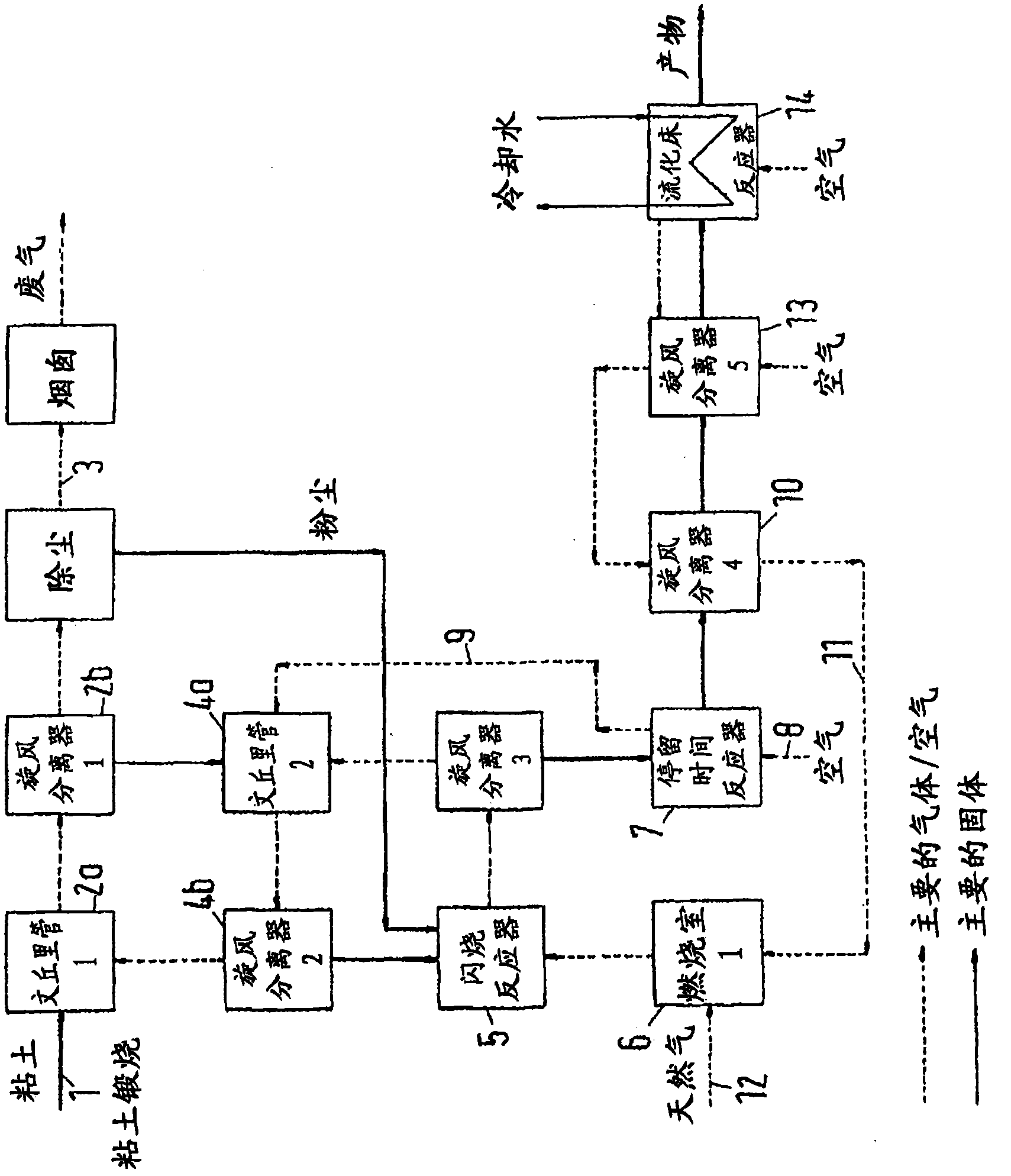

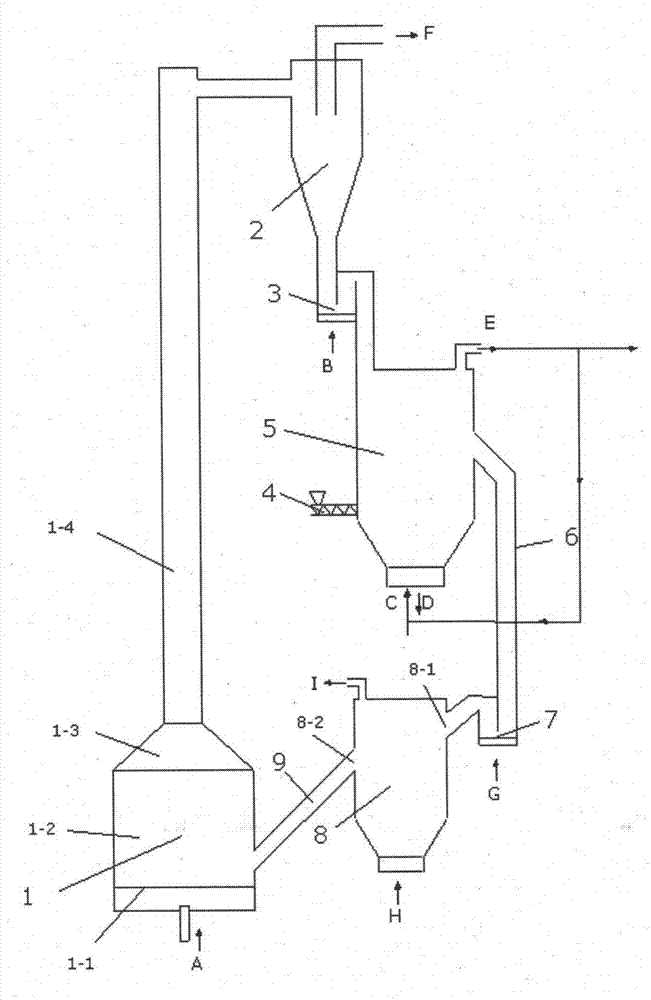

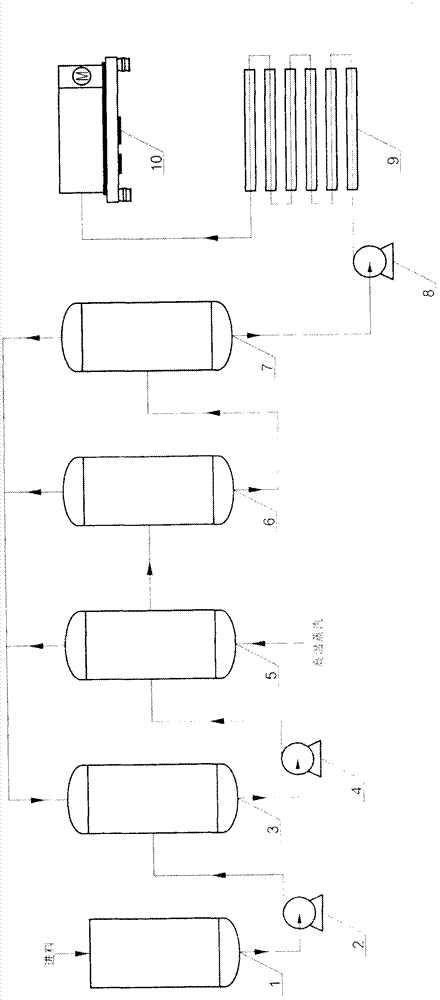

Method for separating CO2 through chemical looping combustion in coal pressure high-density circulating fluidized bed

ActiveCN102183014AIncrease the combustion reaction rateSolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationCycloneHigh density

The invention provides a method for separating CO2 through chemical looping combustion in a coal pressure high-density circulating fluidized bed, which comprises the following steps: coal particles and a gasifying agent are subjected to gasification reaction in a fuel reactor 1 of the coal pressure high-density circulating fluidized bed, and gasified products and oxygen carriers which return to the fuel reactor are subjected to combustion reaction to produce CO2 and H2O; smoke which is produced during the reaction and carries oxygen-lost oxygen carriers and carbon-containing coal ash enters a primary cyclone separator 2 for separation, and separated oxygen-lost oxygen carriers are in contact with transversely passing air for reaction in an air reactor 5 of a cross flow moving bed to be regenerated and are turned to the combustion reactor through a primary material returning device 8 to continuously participate in the combustion reaction; and separated smoke in the primary cyclone separator 2 further enters a secondary cyclone separator 10 for separation, solid particles secondarily separated are returned to the fuel reactor 1 through a secondary material returning device 13 to continuously participate in the combustion reaction, and H2O is removed from the separated gases through condensation to obtain high-purity CO2.

Owner:SOUTHEAST UNIV

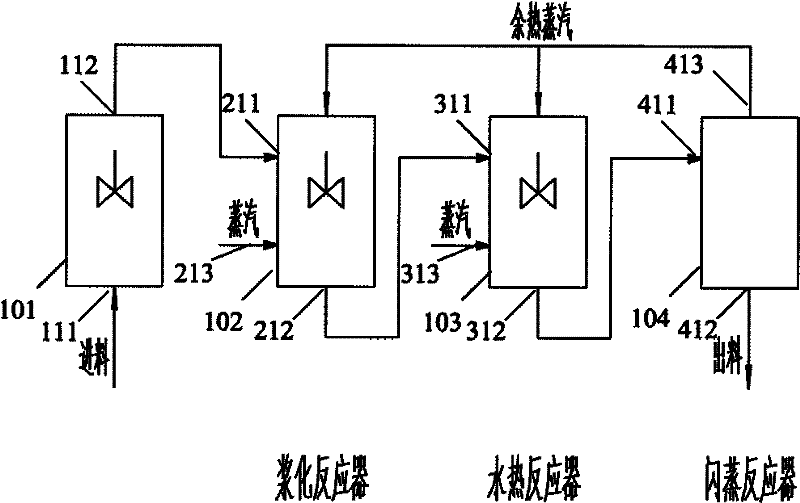

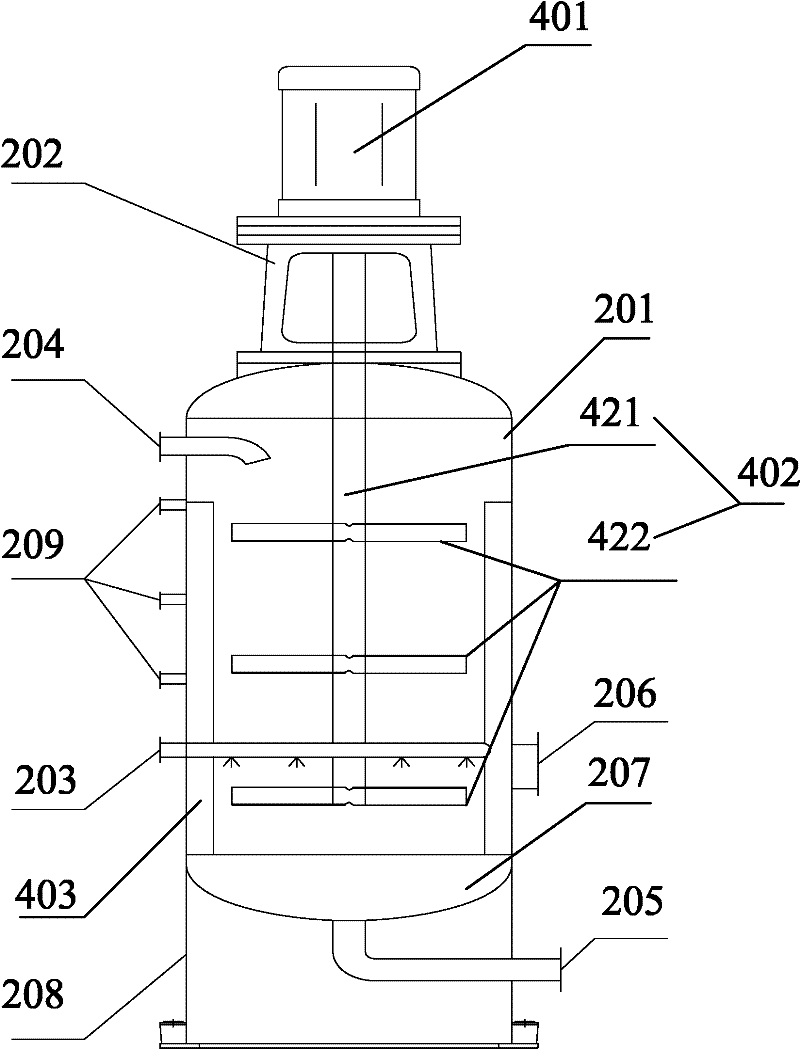

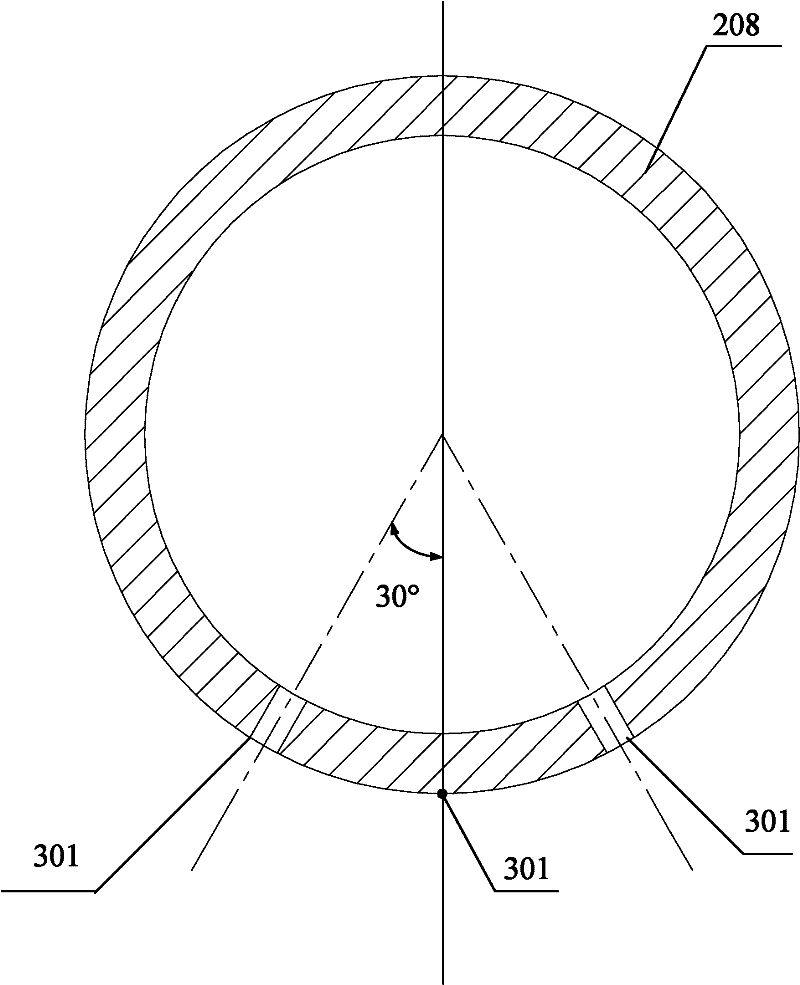

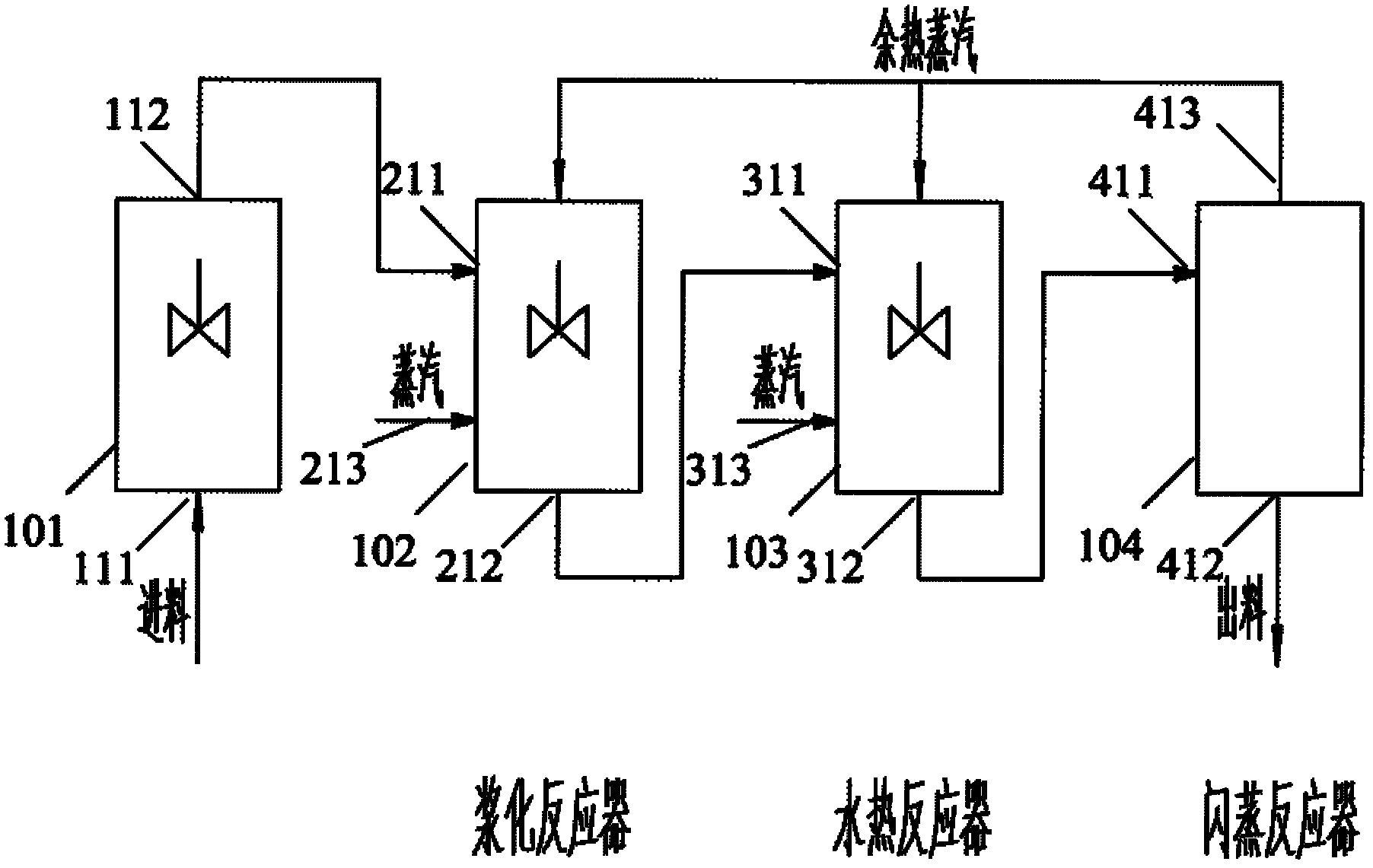

Sludge hydrothermal drying treating device and hydrothermal reactor thereof

InactiveCN102531315AEasy to separateSmooth handlingSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeColloid

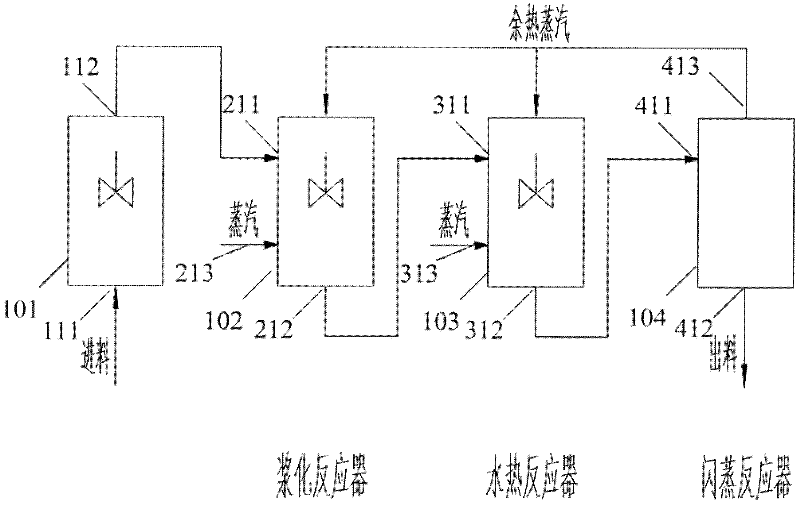

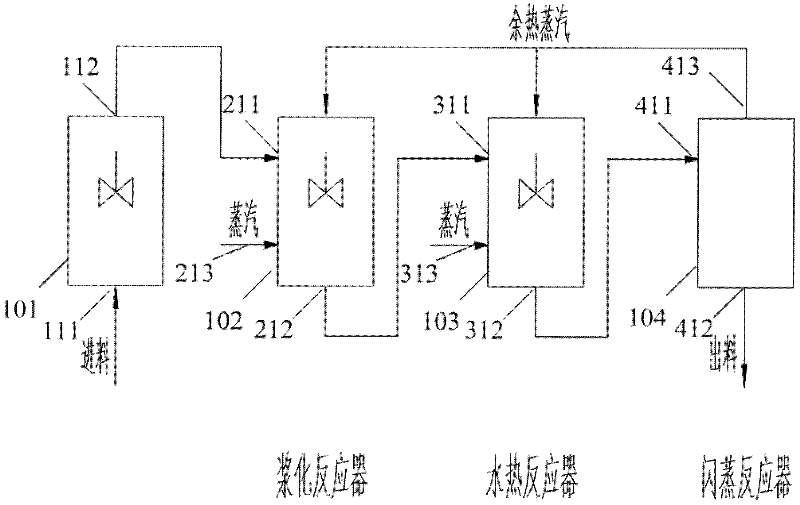

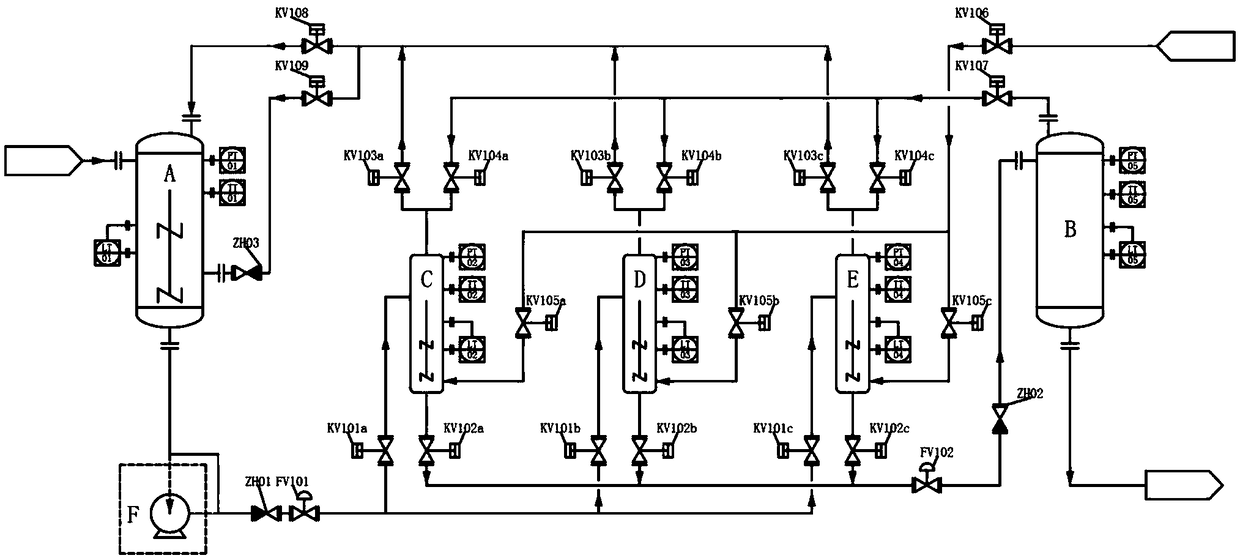

The invention provides a sludge hydrothermal drying treating device and a hydrothermal reactor thereof, wherein the sludge hydrothermal drying treating device comprises a homogenous reactor, a slurrying reactor, the hydrothermal reactor and a flash evaporation reactor which are sequentially connected. The homogeneous reactor is used for smashing and stirring materials which are conveyed to the slurrying reactor to perform even preheating, the preheated materials are performed with a hydrothermal reaction in the hydrothermal reactor and then are stored in the flash evaporation reactor, and steam recovered by the flash evaporation reactor can be led in the slurrying reactor and / or the hydrothermal reactor. The sludge hydrothermal drying treating device hydrolyzes sticky organics in sludge at certain temperature and pressure, breaks the colloid structure of the sludge and promotes separation of bound water and solid particles. The hydrothermal reactor can evenly heat sludge materials and improve pressure, leads the sludge materials to be performed with the hydrothermal reaction evenly enough, and accordingly the aim of dehydration can be achieved.

Owner:北京科力丹迪技术开发有限责任公司

High throughput propylene from methanol catalytic process development method

InactiveUS20100174129A1Low costHigh propylene productivitySequential/parallel process reactionsMolecular sieve catalystsProcess developmentLaboratory scale

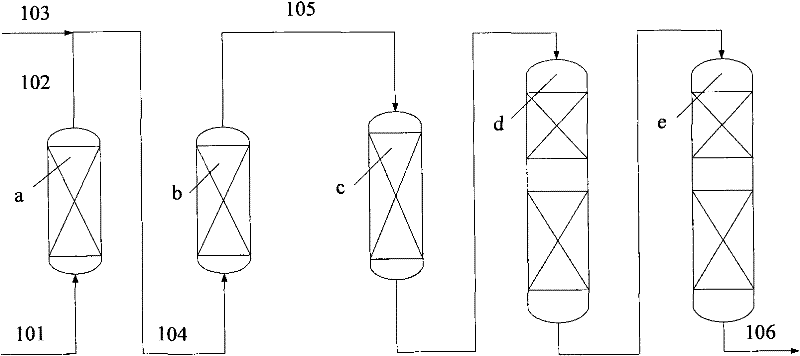

A catalytic process development apparatus and method for simulating a commercial scale methanol and / or DME to propylene catalytic conversion system that includes a plurality of series-connected plug-flow reactors. The method involves simulating the operation of the series-connected plug-flow reactors by operating a series of multistage series-connected laboratory scale plug-flow reactors, the stages of which each containing a zeolite catalyst bed, each of the laboratory scale reactors corresponding to a separate one of the commercial scale series-connected reactors. Fresh feed, including methanol and / or DME, is supplied to the first of the laboratory scale reactor stages, and selected ones of steam, methanol and / or DME, contaminants and reaction products are supplied to selected ones of the laboratory scale reactor stages. The simulation is repeated at different sets of operating conditions and catalyst characteristics.

Owner:BAUMAN RICHARD F +1

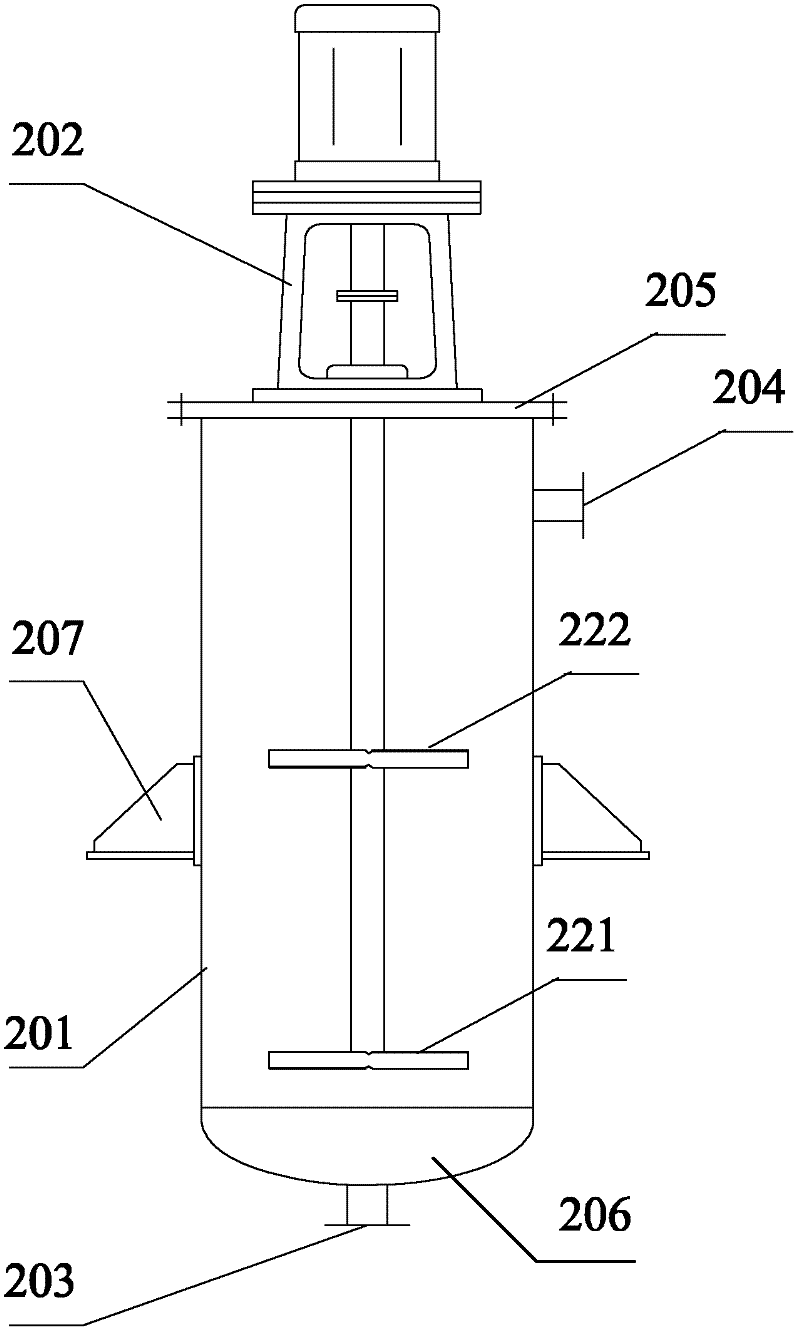

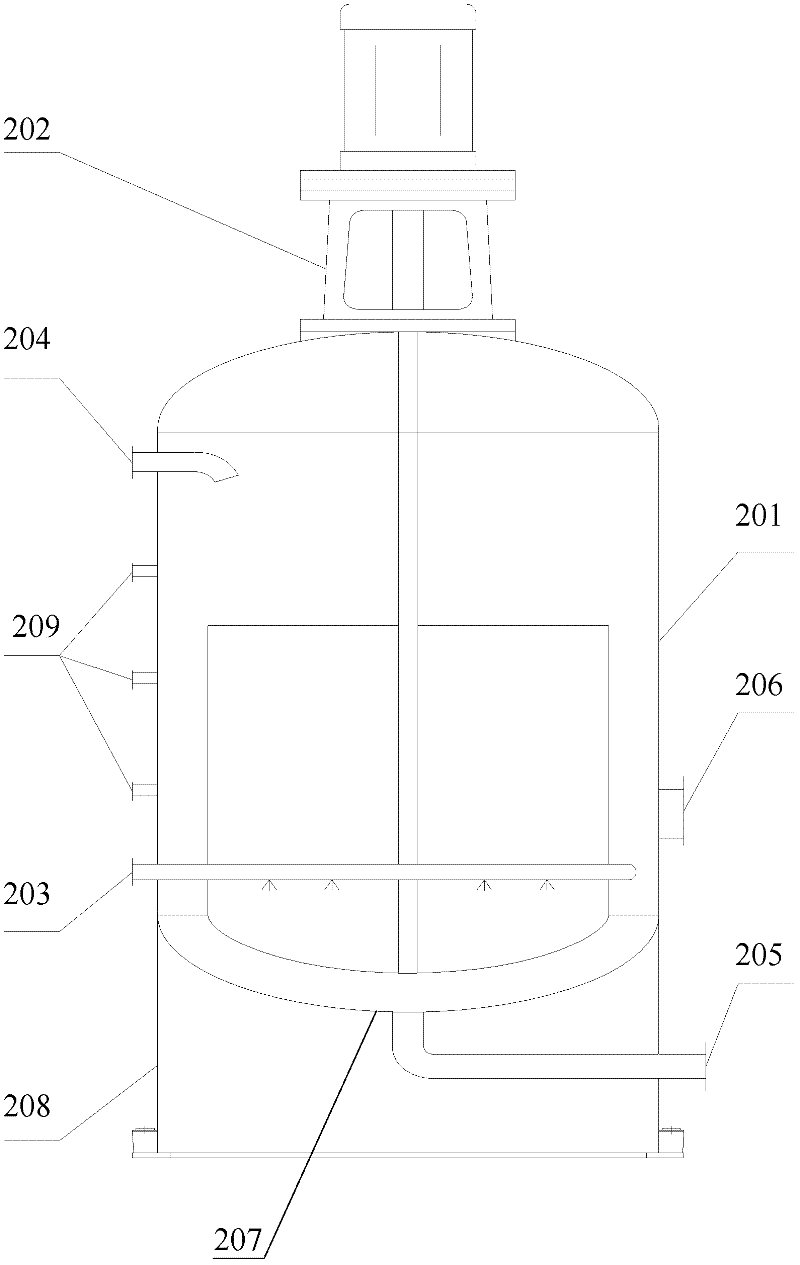

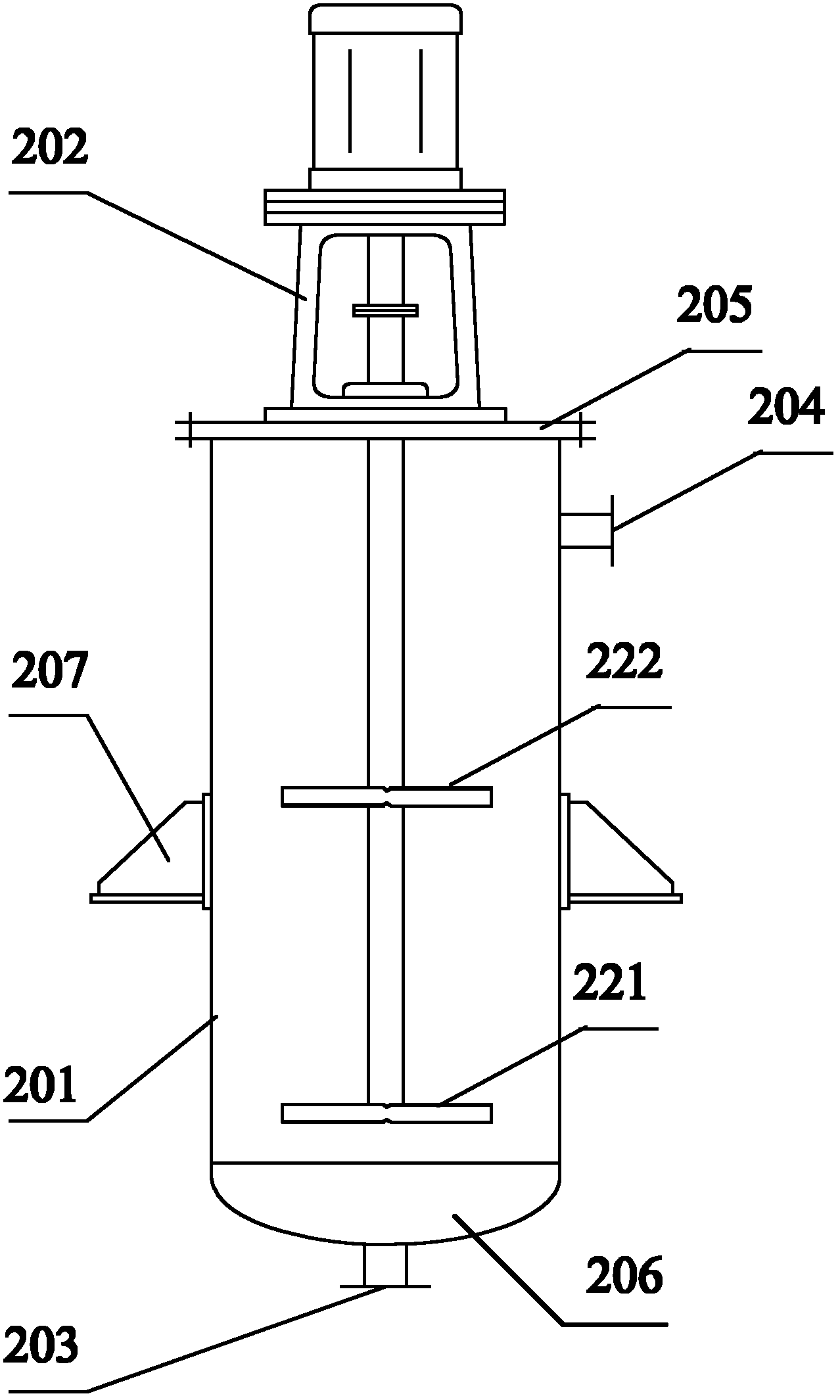

Sludge water heat drying treatment device and homogeneous reactor thereof

InactiveCN102531321AEasy to separateSmooth handlingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSlurry reactorSludge

The invention provides a sludge water heat drying treatment device and a homogeneous reactor thereof. The sludge water heat drying treatment device comprises the homogeneous reactor, the slurry reactor, a hydrothermal reactor and a flashing reactor which are sequentially connected. The homogeneous reactor is used for chopping and agitating materials, then the materials are delivered to the slurry reactor for even preheating, hydrothermal reaction is conducted to the preheated materials in the hydrothermal reactor, the materials are stored in the flashing reactor and the recovered steam of the flashing reactor can be fed into the slurry reactor and / or the hydrothermal reactor. When the sludge water heat drying treatment device is under certain temperature and pressure, viscous organic matters in sludge are hydrolyzed, the colloid structure of the sludge is destructed and bond water is facilitated to be separated from solid particles. The homogeneous reactor can chop and evenly agitate the materials and can ensure sludge water heat drying treatment to be uninterruptedly conducted.

Owner:北京科力丹迪技术开发有限责任公司

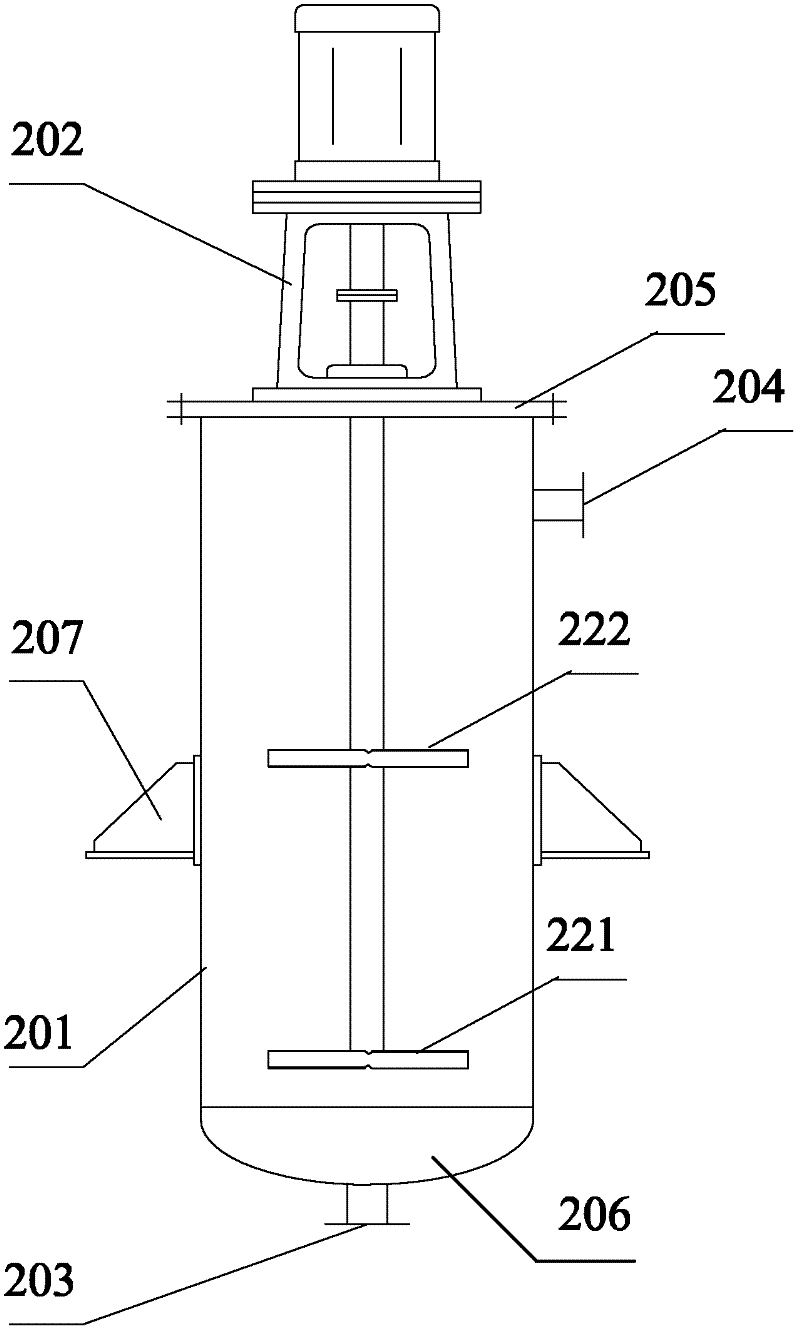

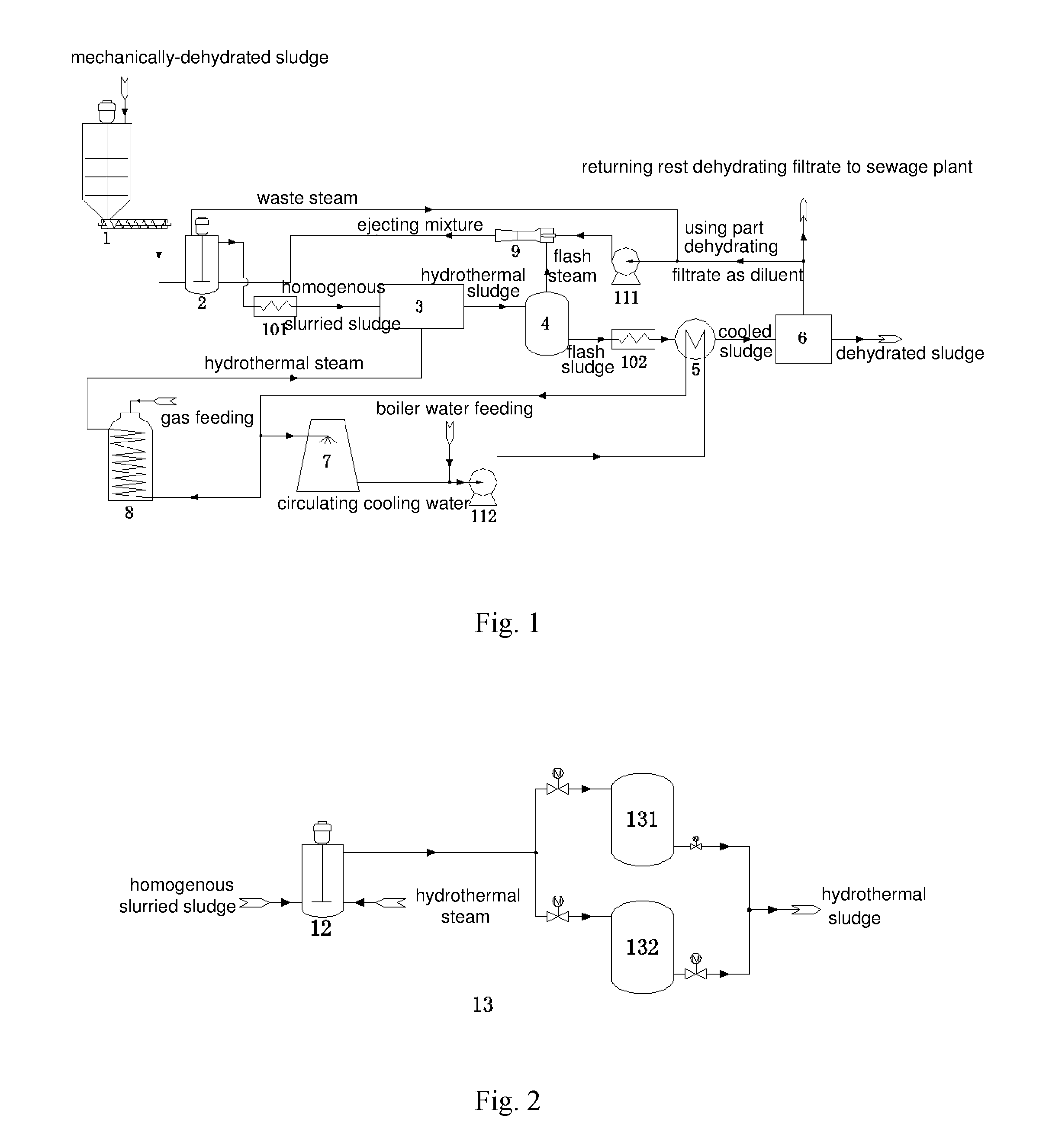

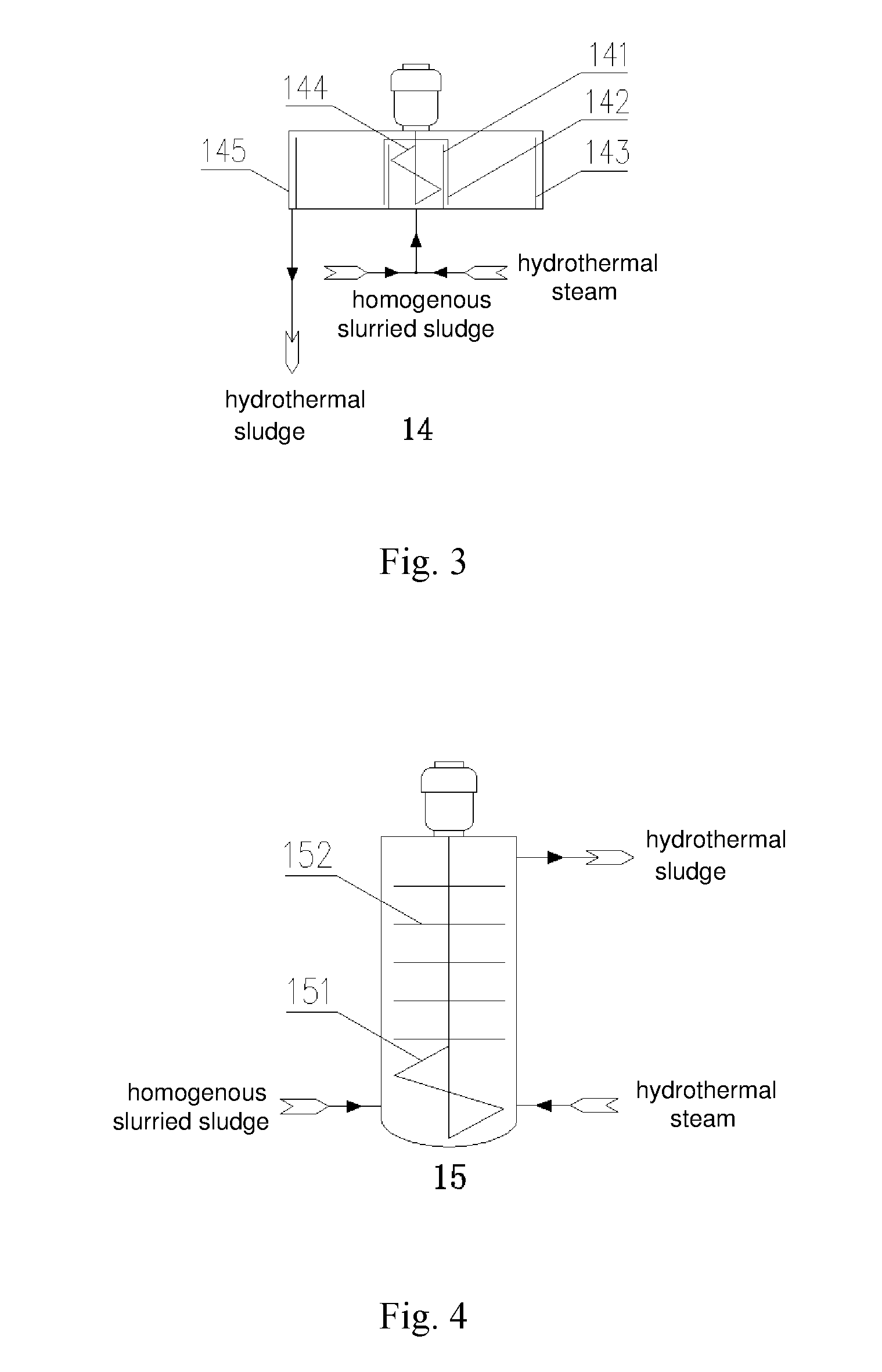

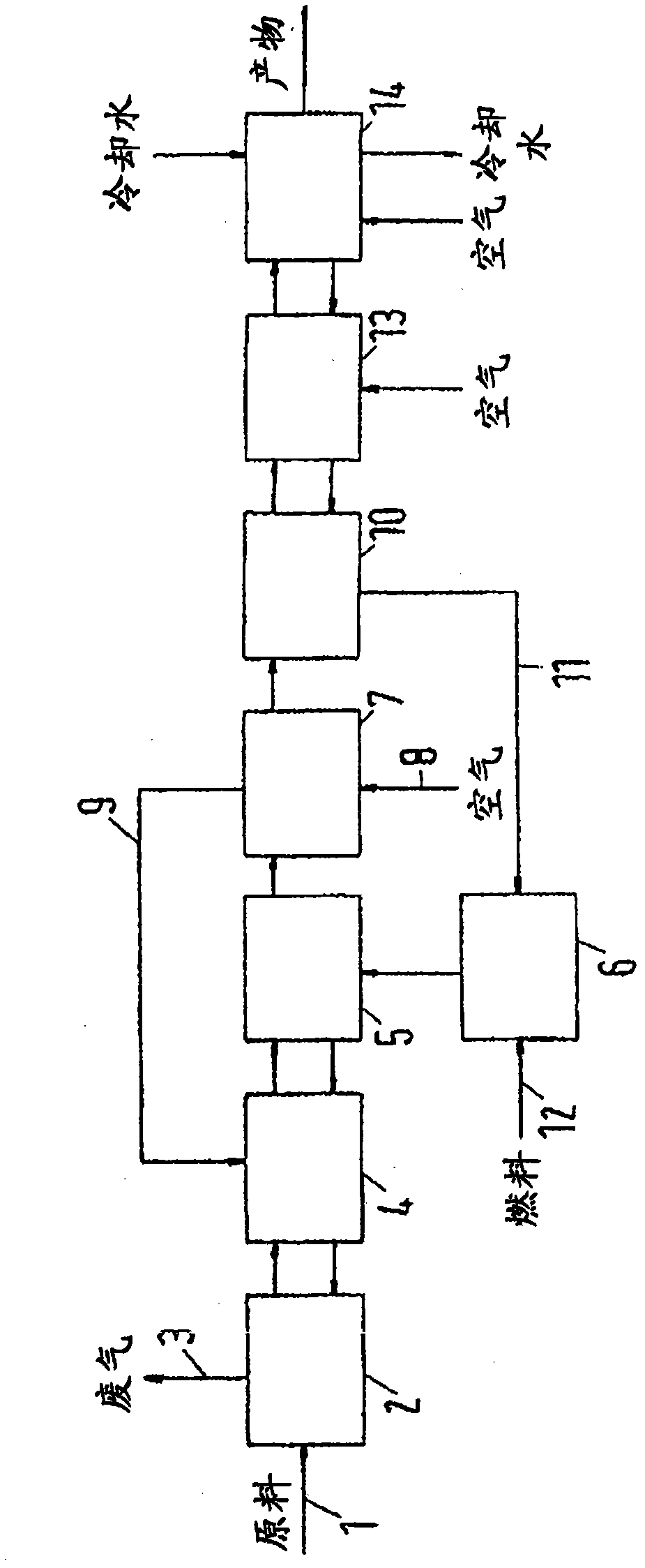

Sludge dehydrating system and method thereof based on thermal hydrolysis technology

InactiveUS20160194231A1Effectively water contentMeet the requirementsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWaste heat recovery unitDiluent

A sludge dehydrating system and a method thereof based on a thermal hydrolysis technology include: a homogeneous slurry unit, a hydrothermal unit, a flash reactor, a waste heat recovery unit, and a dehydrator; wherein a viscosity of sludge is lowered by homogenously slurrying before entering a pump, which is conducive to transportation; a sludge tank firstly crashes and then quantitatively transports for improving a homogenizing efficiency; a diluent is sludge dehydrated filtrate which is mixed with flash steam in an ejector, wherein an mixing efficiency is high; during homogenously slurrying, waste steam generated is added into a sludge diluent pipe for being absorbed; a hydrothermal unit include a variety of forms such as an intermittent form and a continuous form, in such a manner that reaction parameters, especially reaction time are effectively guaranteed; the flash steam enters the homogeneous slurry unit for heating the sludge.

Owner:XI AN JIAOTONG UNIV +1

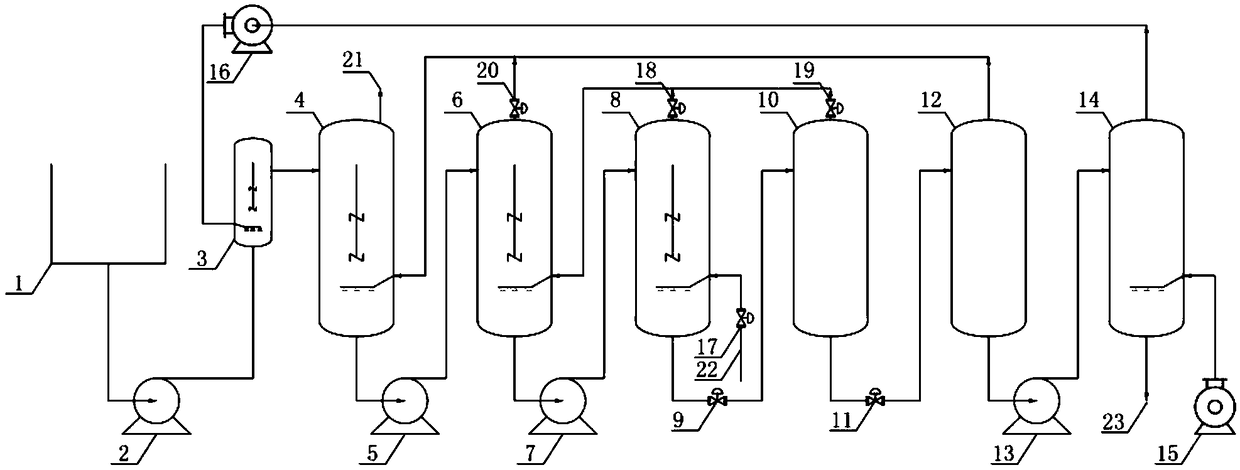

Multi-stage flashing sludge continuous hydrothermal treatment device

InactiveCN109020113AProcess introductionReduce usageSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeMulti-stage flash distillation

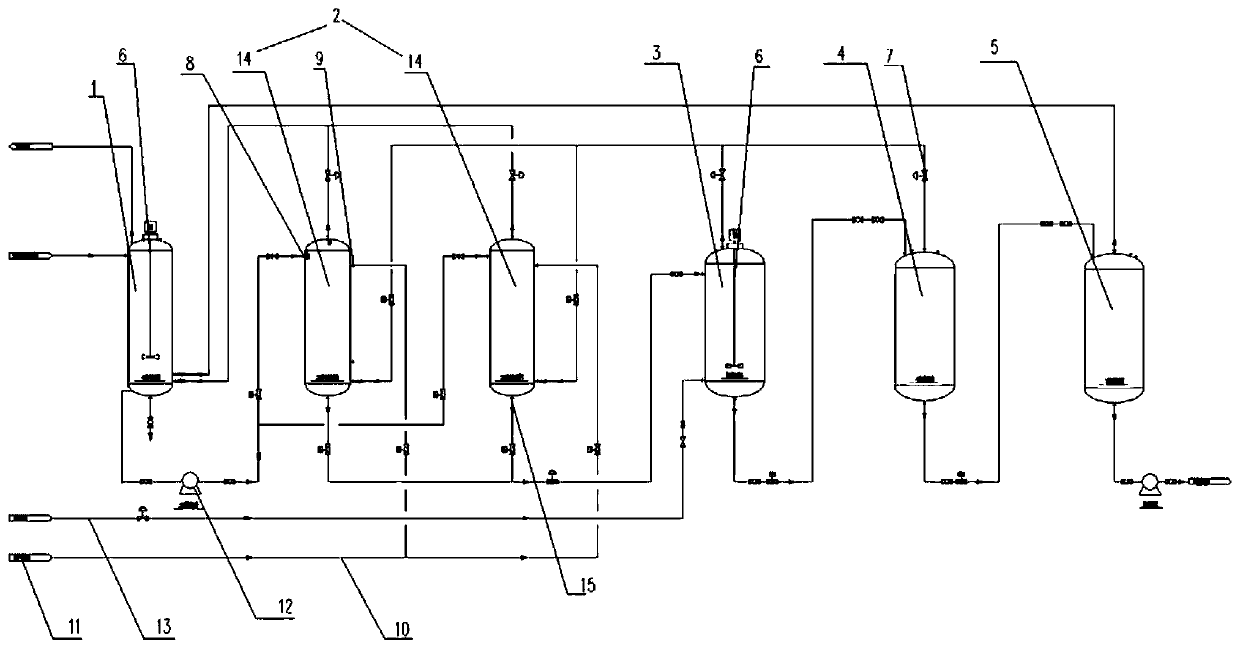

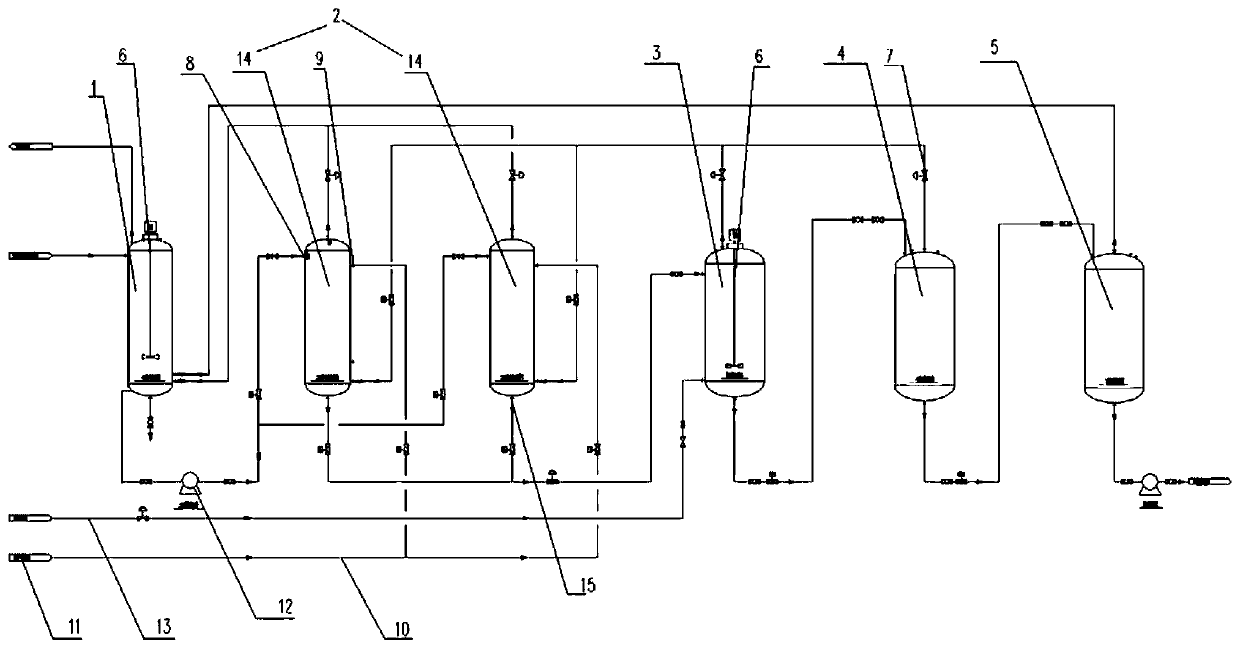

The invention discloses a multi-stage flashing sludge continuous hydrothermal treatment device, and the multi-stage flashing sludge continuous hydrothermal treatment device comprises a raw mud buffertank, a homogenization reactor, slurrying reactors, a hydrothermal reactor and flashing reactors which are sequentially connected. The number of the slurrying reactors is at least one, and the numberof the flashing reactors is at least two, the slurrying reactors are sequentially connected in series and the flashing reactors are sequentially connected in series. The homogenization reactor and theslurrying reactors arranged from front to back are also in one-to-one correspondence connection with the flashing reactors which are arranged from the back to the front. The multi-stage flashing sludge continuous hydrothermal treatment device is simple in equipment and process, the sludge treatment efficiency is high, and the energy consumption is effectively reduced.

Owner:四川深蓝环保科技有限公司

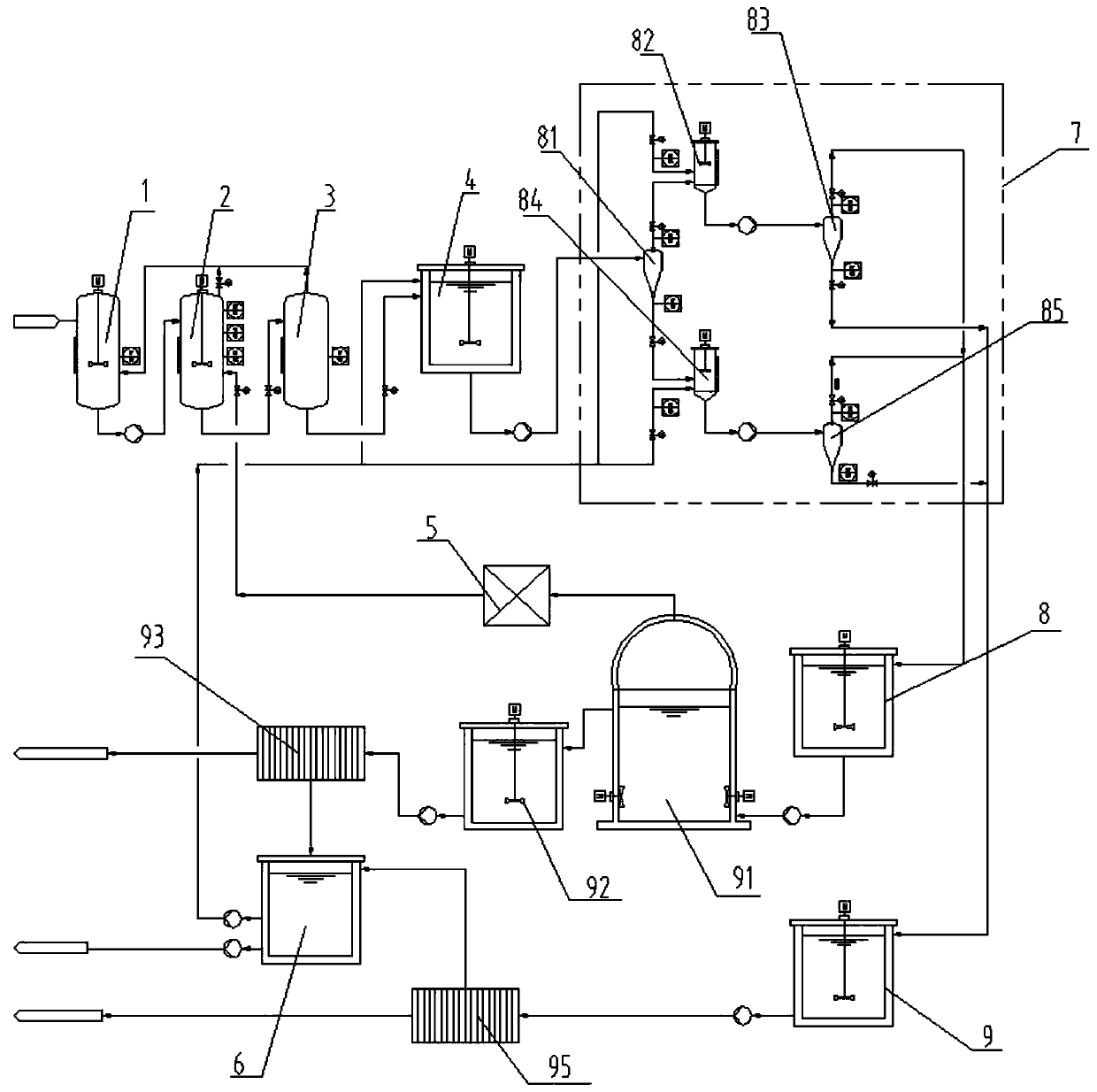

Biomass quality-based utilization system and method based on hydrothermal technology

InactiveCN111423097AIncrease solid contentEasy to dehydrateSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludge cakeBiogas production

The invention discloses a biomass quality-divided utilization system based on a hydrothermal technology. The biomass quality-divided utilization system comprises a pretreatment tank, a hydrothermal reactor, a flash evaporation reactor, a hydrothermal sludge buffer pool and a multi-stage cyclone separation system, wherein the pretreatment tank, the hydrothermal reactor, the flash evaporation reactor, the hydrothermal sludge buffer pool and the multi-stage cyclone separation system are communicated with one another through pumps; according to the invention, after organic matters and inorganic matters in the sludge are effectively separated by the system and the method, the resource utilization value of the sludge can be improved. Organic sludge is easier to perform anaerobic biogas production; inorganic sludge is excellent in dehydration performance, and a sludge cake with high solid content can be obtained, so that subsequent building materials can be conveniently utilized, or the sludge cake can be used as landfill covering soil; and the scheme is combined with an anaerobic digestion process. Due to the fact that inorganic components in the sludge are separated, sand in the sludgecan be prevented from being deposited and caked in the digestion tank, and the problems that the effective tank capacity of the digestion tank is reduced, and a pipeline is blocked can be solved.

Owner:四川深蓝环保科技有限公司

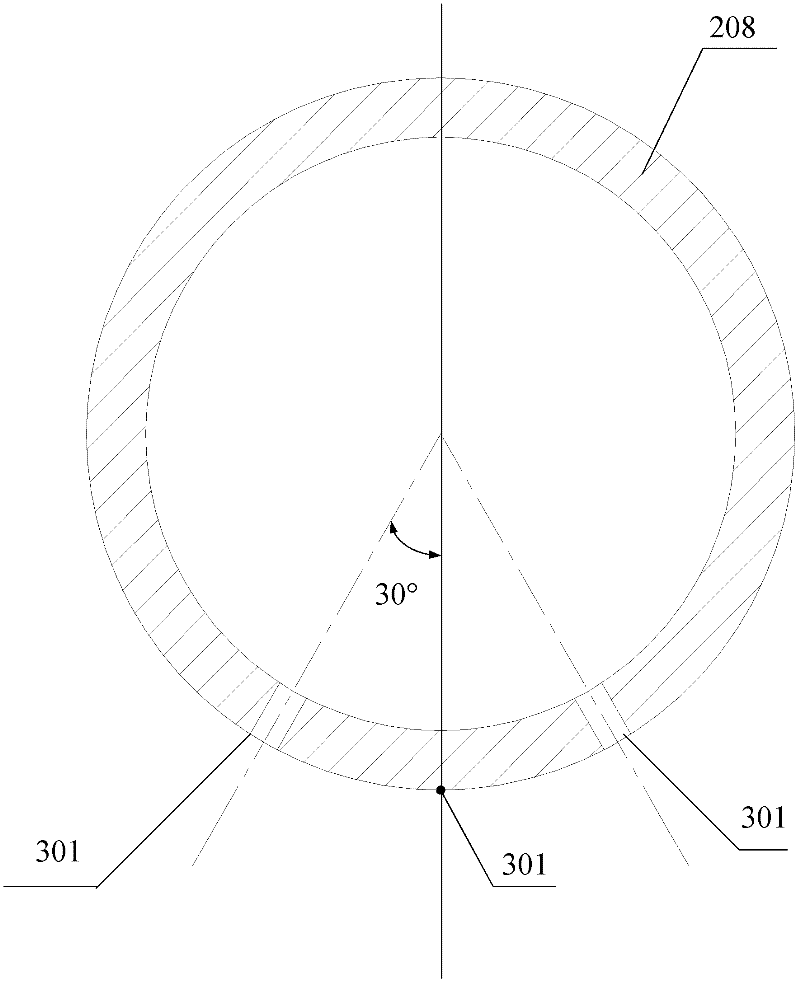

Sludge hydrothermal drying treatment device and slurry reactor thereof

InactiveCN102557384AEasy to separateSmooth handlingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSlurry reactorSludge

The invention provides a sludge hydrothermal drying treatment device and a slurry reactor of the device. The sludge hydrothermal drying treatment device comprises a homogeneous reactor, a slurry reactor, a hydrothermal reactor and a flash evaporation reactor which are connected sequentially. The homogeneous reactor cuts up and mixes materials, then inputs materials into the slurry reactor to pre-heat uniformly, the pre-heated materials are subjected to hydrothermal reaction in the hydrothermal reactor and are stored in the flash evaporation reactor; and the steam recovered by the flash evaporation reactor can be introduced into the slurry reactor and / or the hydrothermal reactor. The sludge hydrothermal drying treatment device of the invention can hydrolyze the viscous organic materials in the sludge under certain pressure and temperature, destroy the colloidal structure of the sludge, and drive the bound water and the solid grains to separate. The slurry reactor of the invention can uniformly mix and pre-heat the materials, so as to ensure the uninterrupted running of the sludge hydrothermal drying treatment.

Owner:北京科力丹迪技术开发有限责任公司

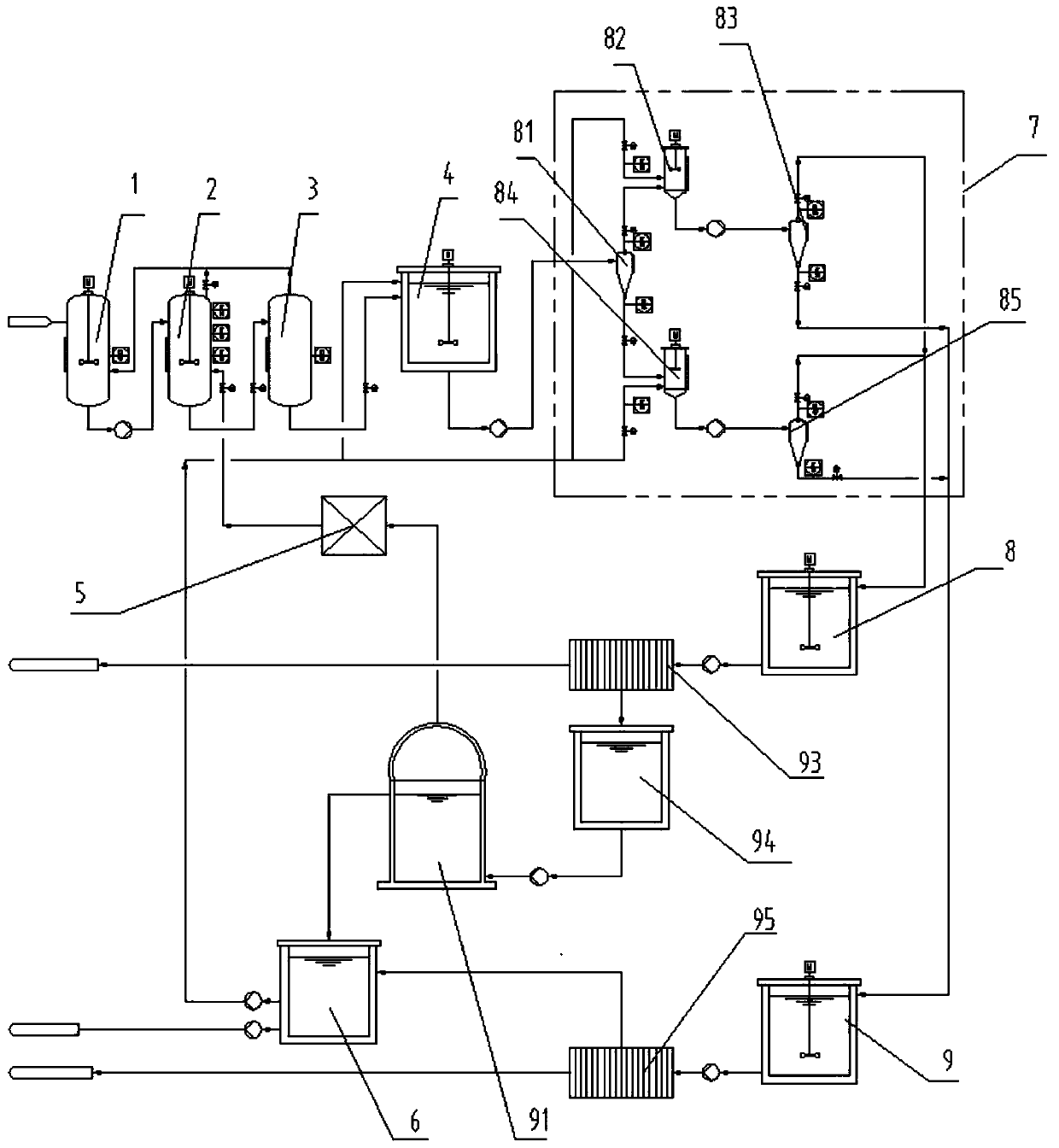

Continuous organic solid waste thermal hydrolysis treatment system and method

InactiveCN111013517AImprove absorption efficiencyPromote absorptionProcess control/regulationSequential/parallel process reactionsProcess engineeringEnvironmental engineering

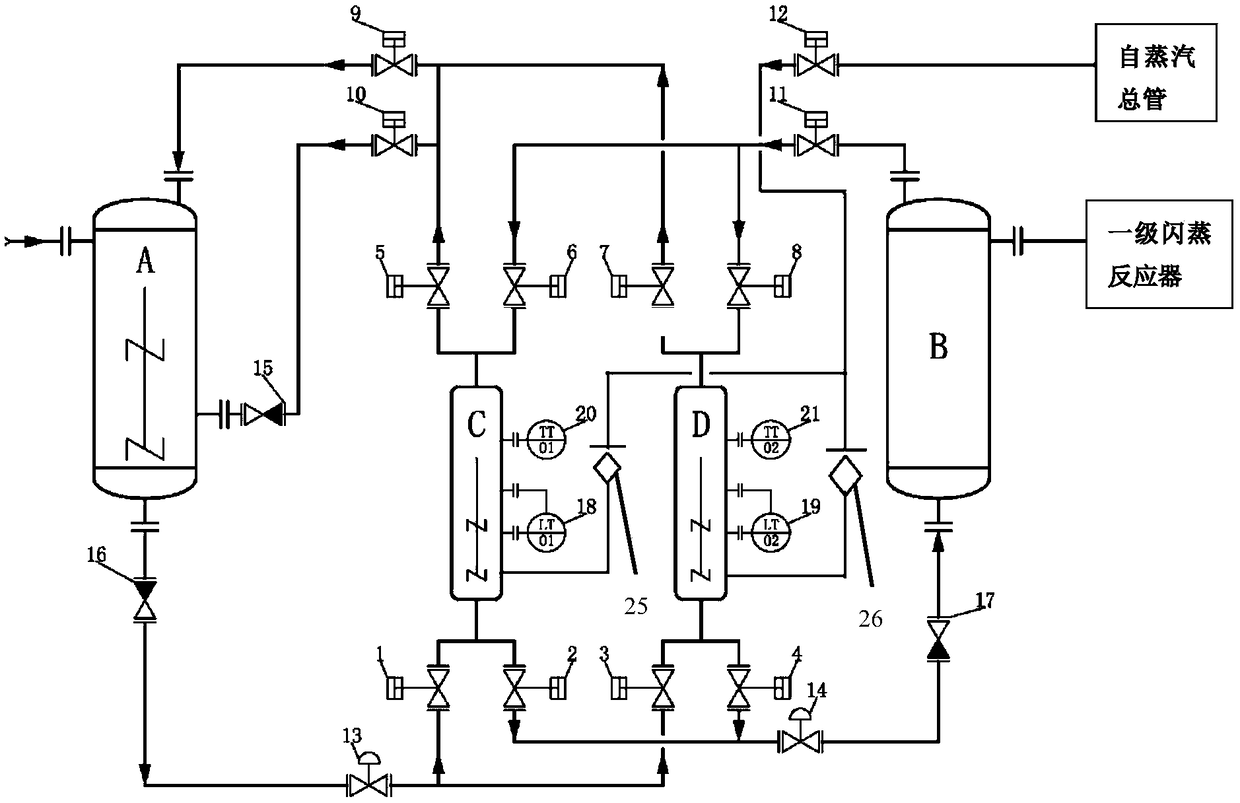

The invention discloses a continuous organic solid waste pyrohydrolysis treatment system and method. The continuous organic solid waste pyrohydrolysis treatment system comprises a primary slurrying reactor, a secondary slurrying reactor group, a pyrohydrolysis reactor, a primary flash evaporation reactor and a secondary flash evaporation reactor; a discharge port of the primary slurrying reactor is connected with feed ports of the secondary slurrying reactors in the secondary slurrying reactor group through a material conveying pump; at least two secondary slurrying reactors are arranged in the secondary slurrying reactor group, discharge ports of the secondary slurrying reactors are connected in parallel and then connected with a feed port of the pyrohydrolysis reactor, and the pyrohydrolysis reactor is sequentially connected with the subsequent flash evaporation reactors in series. According to the invention, the treatment efficiency and the system treatment capacity are greatly improved, and the construction cost of the unit treatment capacity is reduced, that is, under the condition of the same volume of the reactors, the scale of the continuous pyrohydrolysis system is improved by 60%-100% compared with that of a sequencing batch treatment system. The temperature and pressure fluctuation range in the pyrohydrolysis reactor is small, and the steam consumption is reduced.

Owner:四川深蓝环保科技有限公司

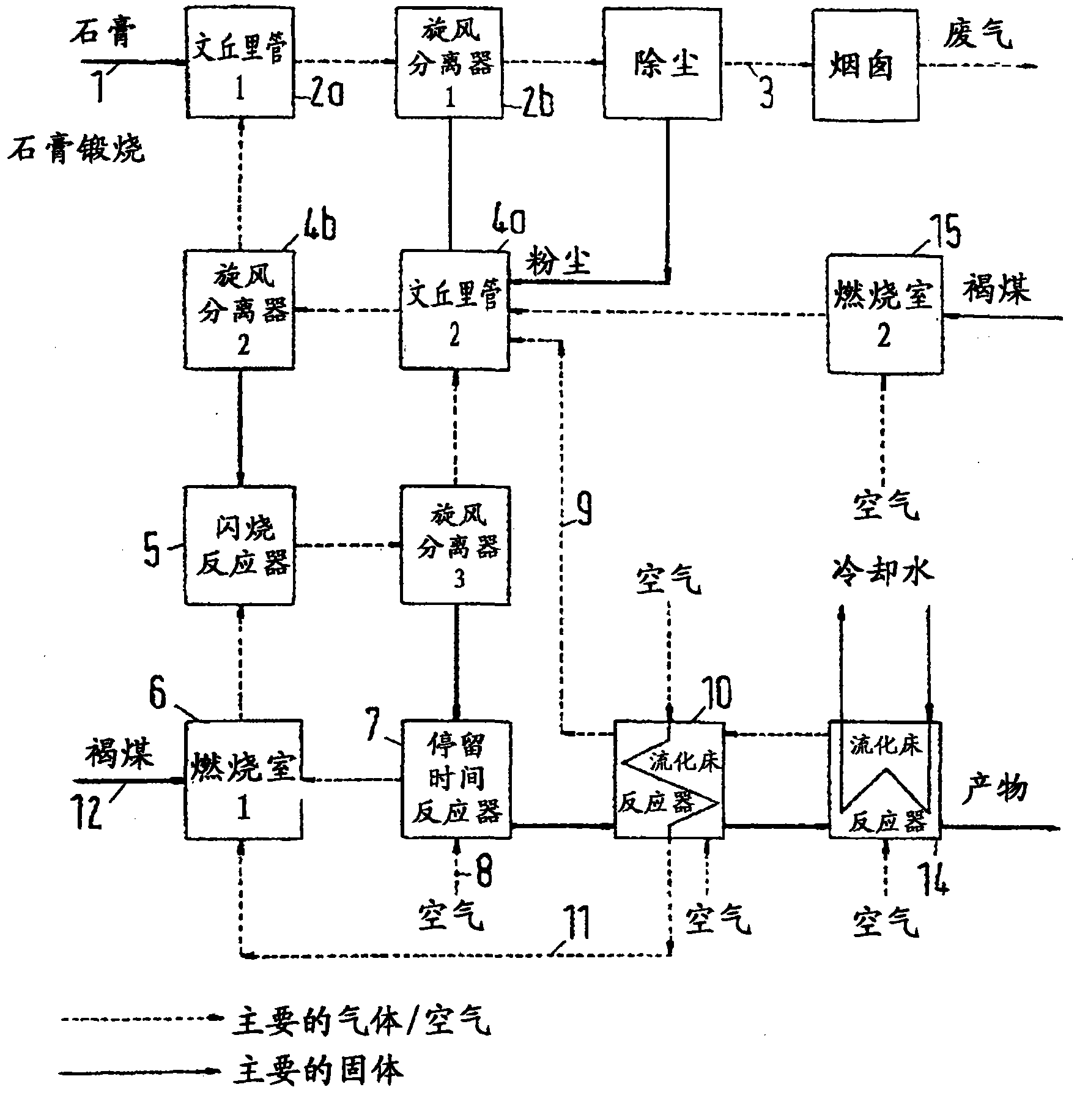

Process and plant for the heat treatment of fine-grained mineral solids

In the heat treatment of fine-grained mineral solids, in particular for calcining clay or gypsum, the solids are passed through a flash reactor (5), in which they are contacted with hot gases at a temperature of 450 to 1500 DEG C, and subsequently they are passed through a residence time reactor (7) at a temperature of 550 to 800 DEG C, from which they are withdrawn after a residence time of 1 to 600 minutes and possibly supplied to a further treatment stage.

Owner:OUTOTEC OYJ

Chemical chain combustion device and method for three-reactor structure

InactiveCN103486576AImprove capture efficiencyTo achieve the purpose of purificationFluidized bed combustionIndirect carbon-dioxide mitigationWater vaporFluidized bed

The invention discloses a chemical chain combustion device and method for a three-reactor structure. The chemical chain combustion device comprises an air reactor fluidized bed, wherein the air reactor fluidized bed is connected with a cyclone separator through a lifting pipe; the bottom of the cyclone separator is connected with a fuel reactor; a spiral feeder is arranged on the fuel reactor. The chemical chain combustion device is characterized in that the fuel reactor is connected with a material inlet of a purification reactor through a down pipe; a material outlet of the purification reactor is connected with a reaction chamber of the air reactor fluidized bed through a return pipe. The structure of the device is especially suitable for chemical chain combustion reaction of solid fuel; materials are fluidized and purified by water vapor in the added purification reactor; the purposes of cleaning oxygen carriers and carrying fine particles out of the purification reactor can be achieved while carbon particles remained in the oxygen carriers are removed through a gasification reaction by adjusting the flow quantity of the fluidizing vapor.

Owner:SHANGHAI BOILER WORKS

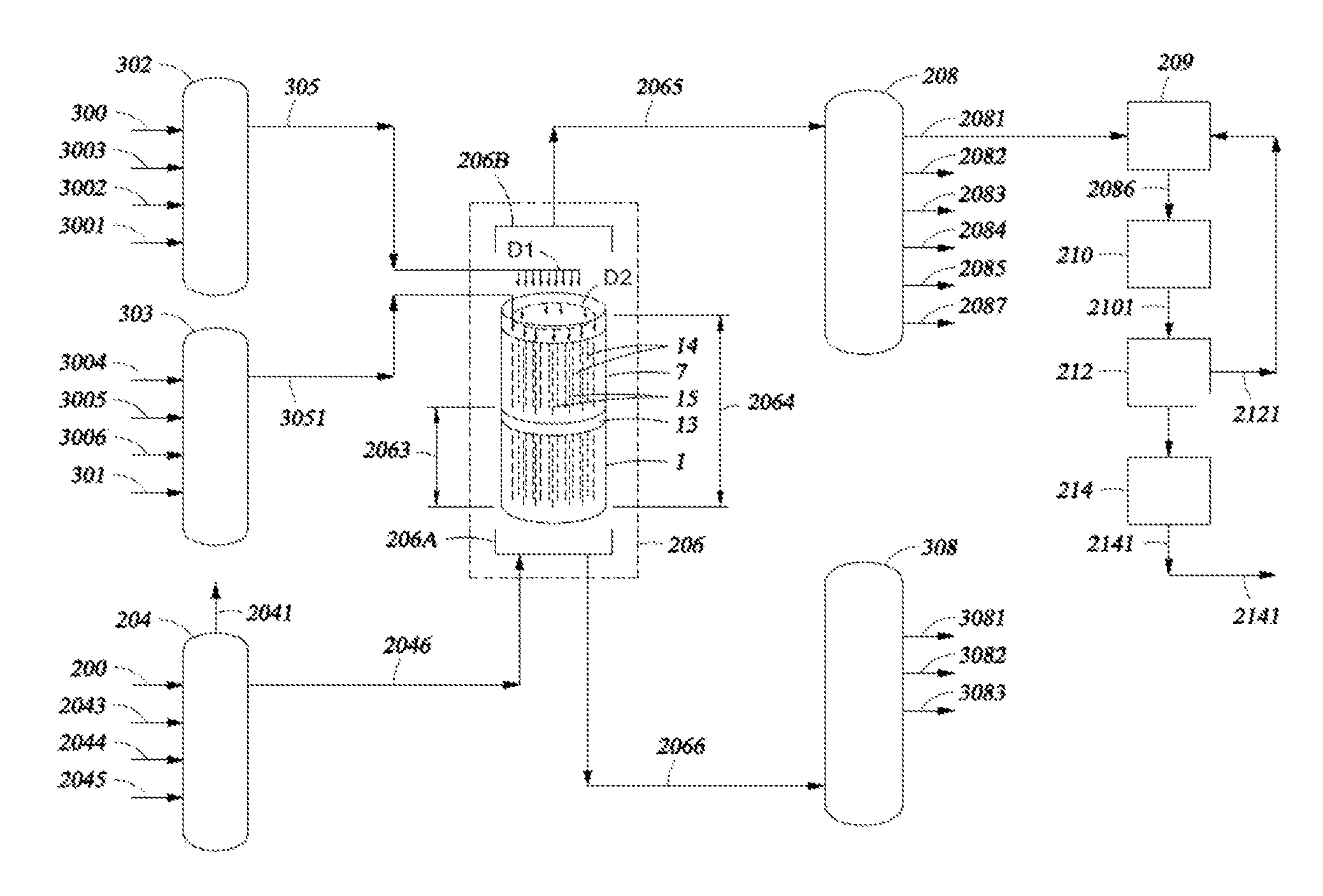

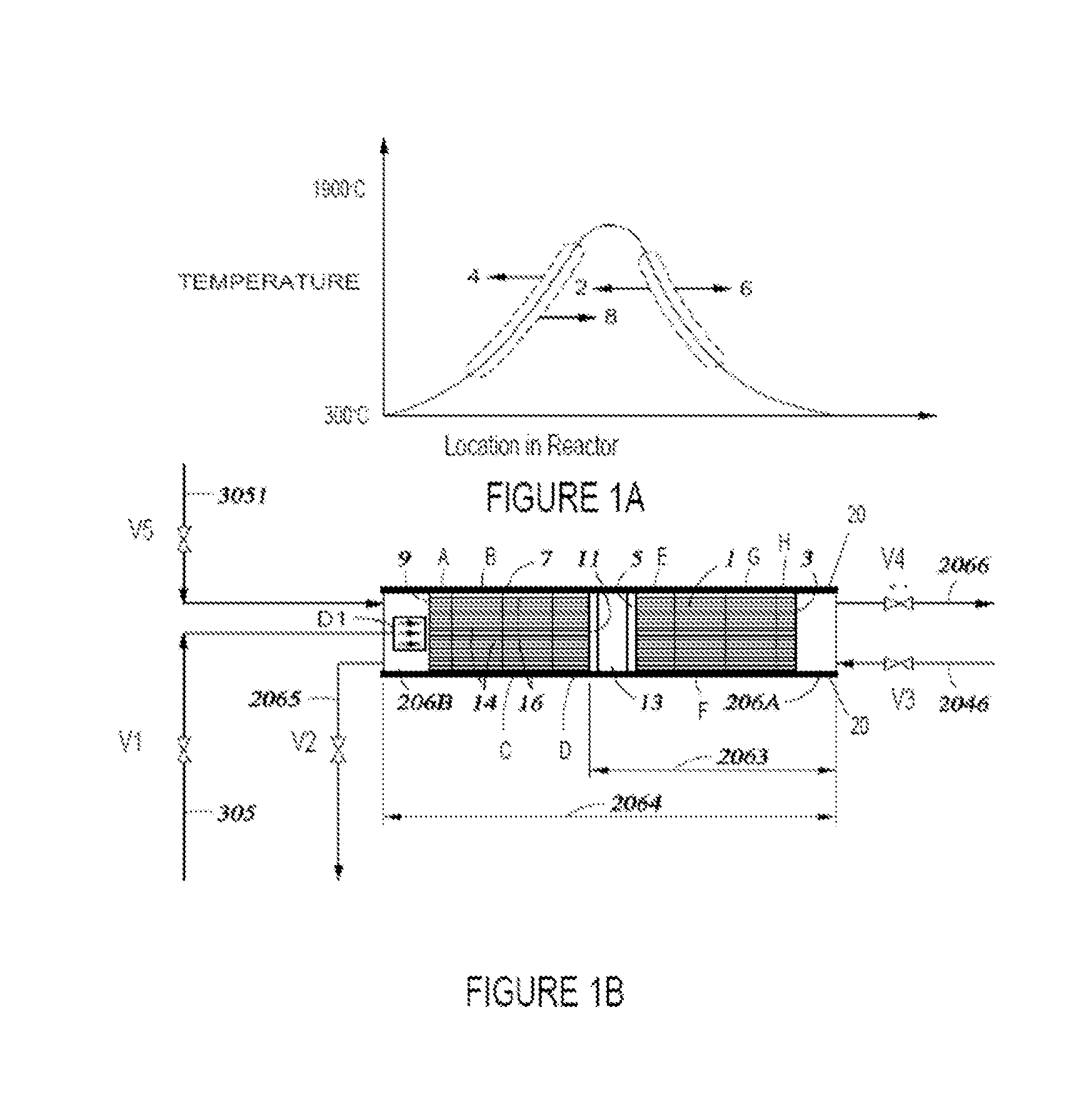

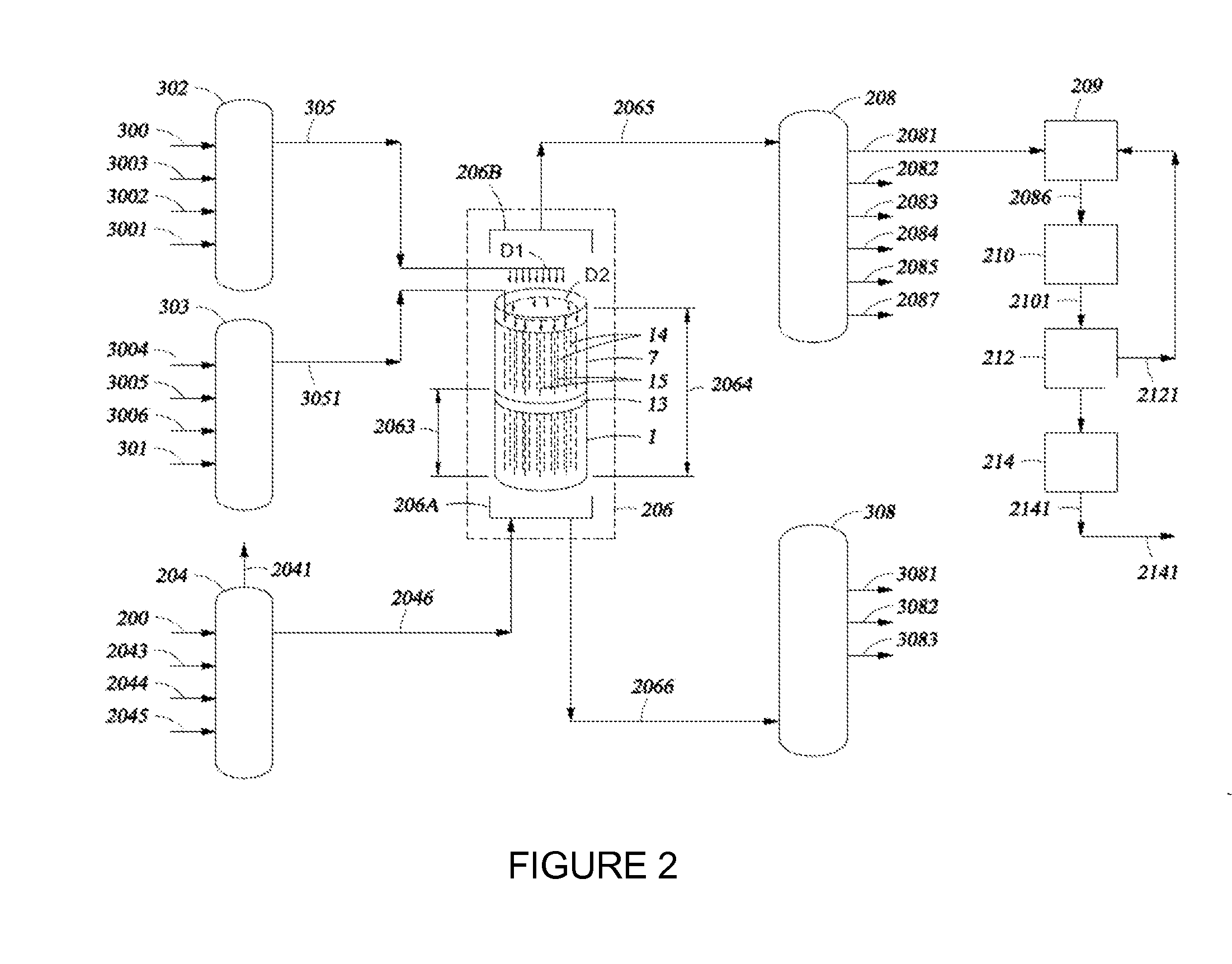

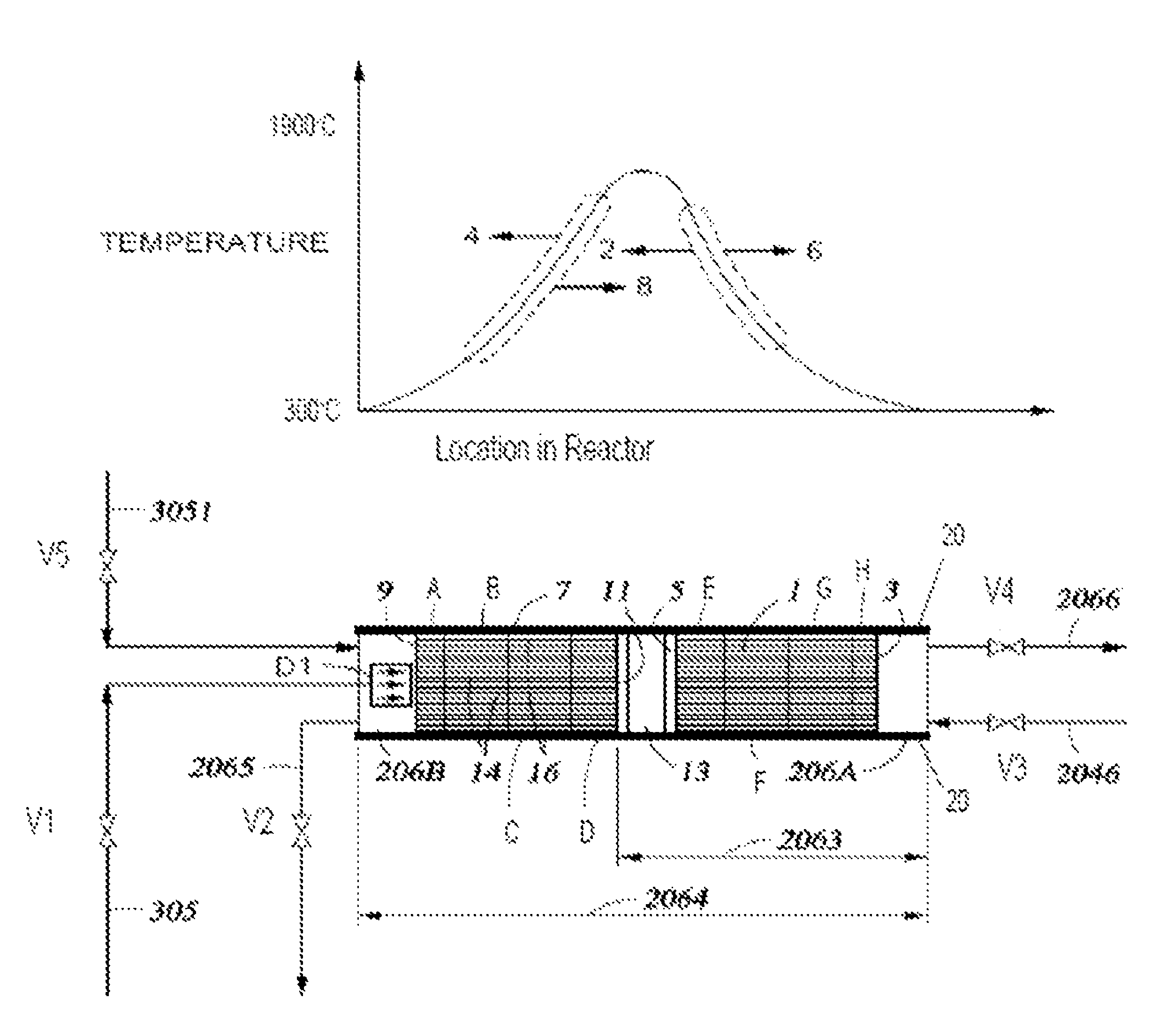

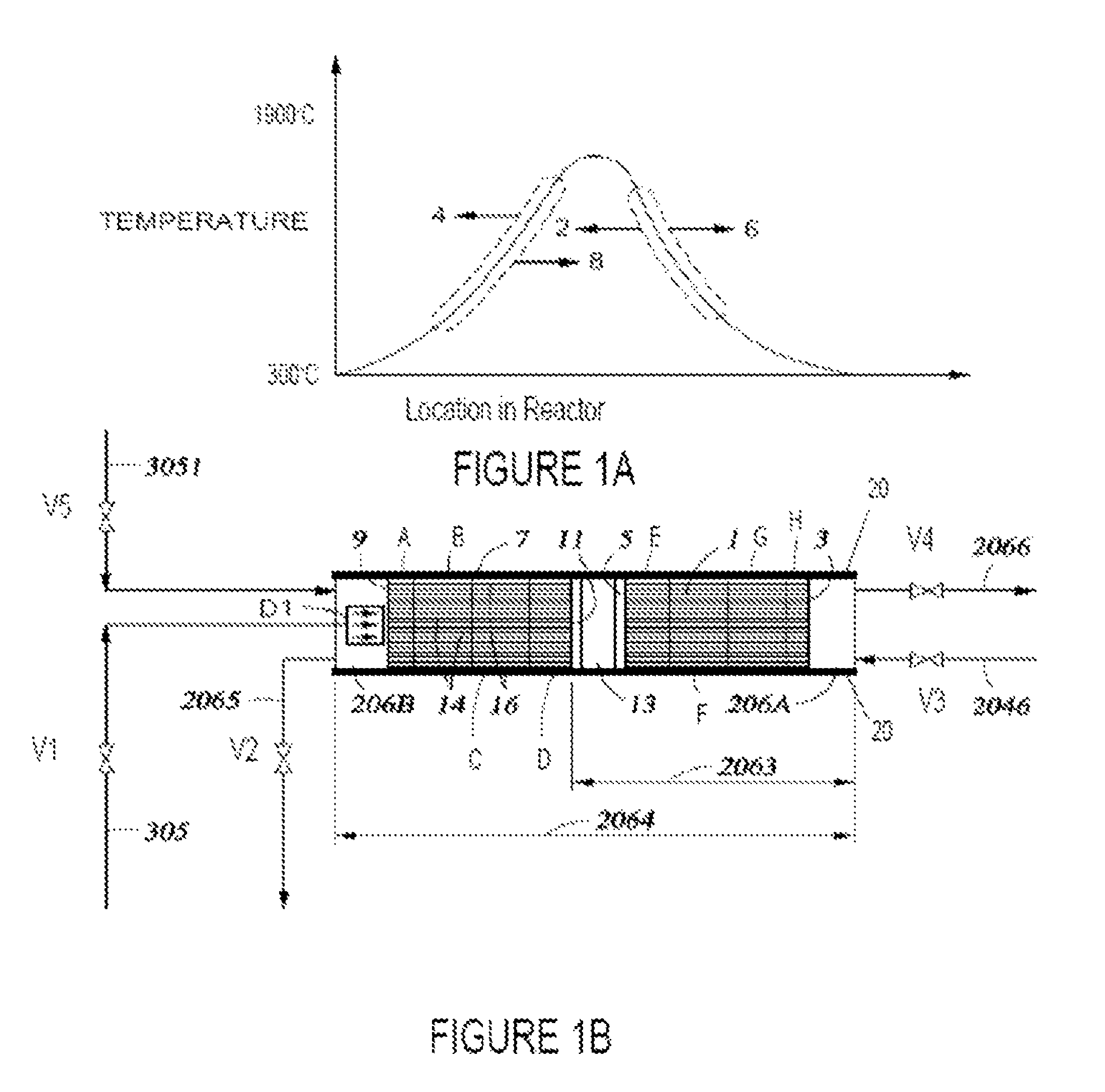

Reactor Components

ActiveUS20130150644A1Easy to operateIncrease temperatureThermal non-catalytic crackingCombustion processNuclear engineeringFlash reactor

The present disclosure relates to reactor components and their use, e.g., in regenerative reactors. A process and apparatus for utilizing different wetted areas along the flow path of a fluid in a pyrolysis reactor, e.g., a thermally regenerating reactor, such as a regenerative, reverse-flow reactor, is described.

Owner:EXXONMOBIL CHEM PAT INC

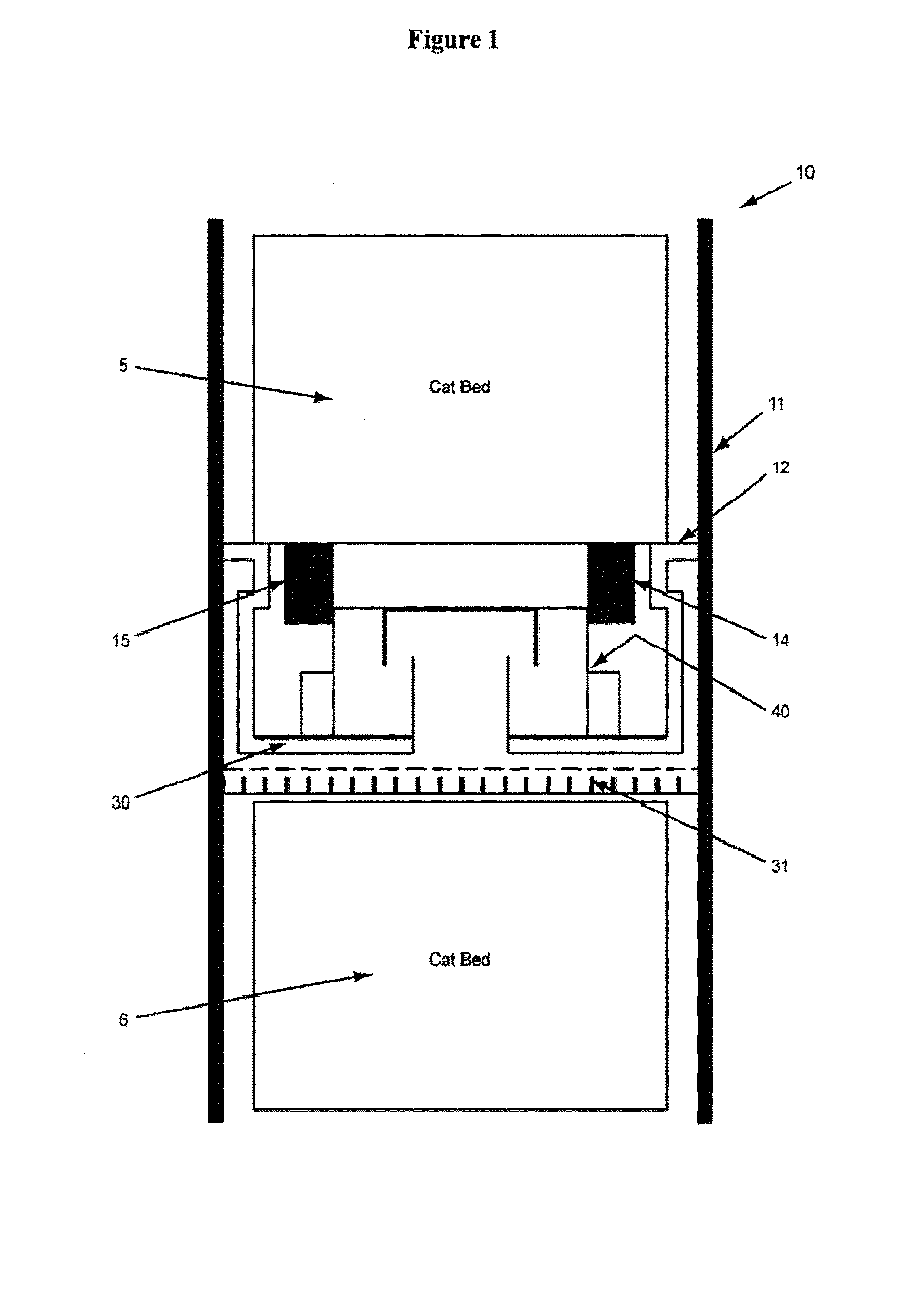

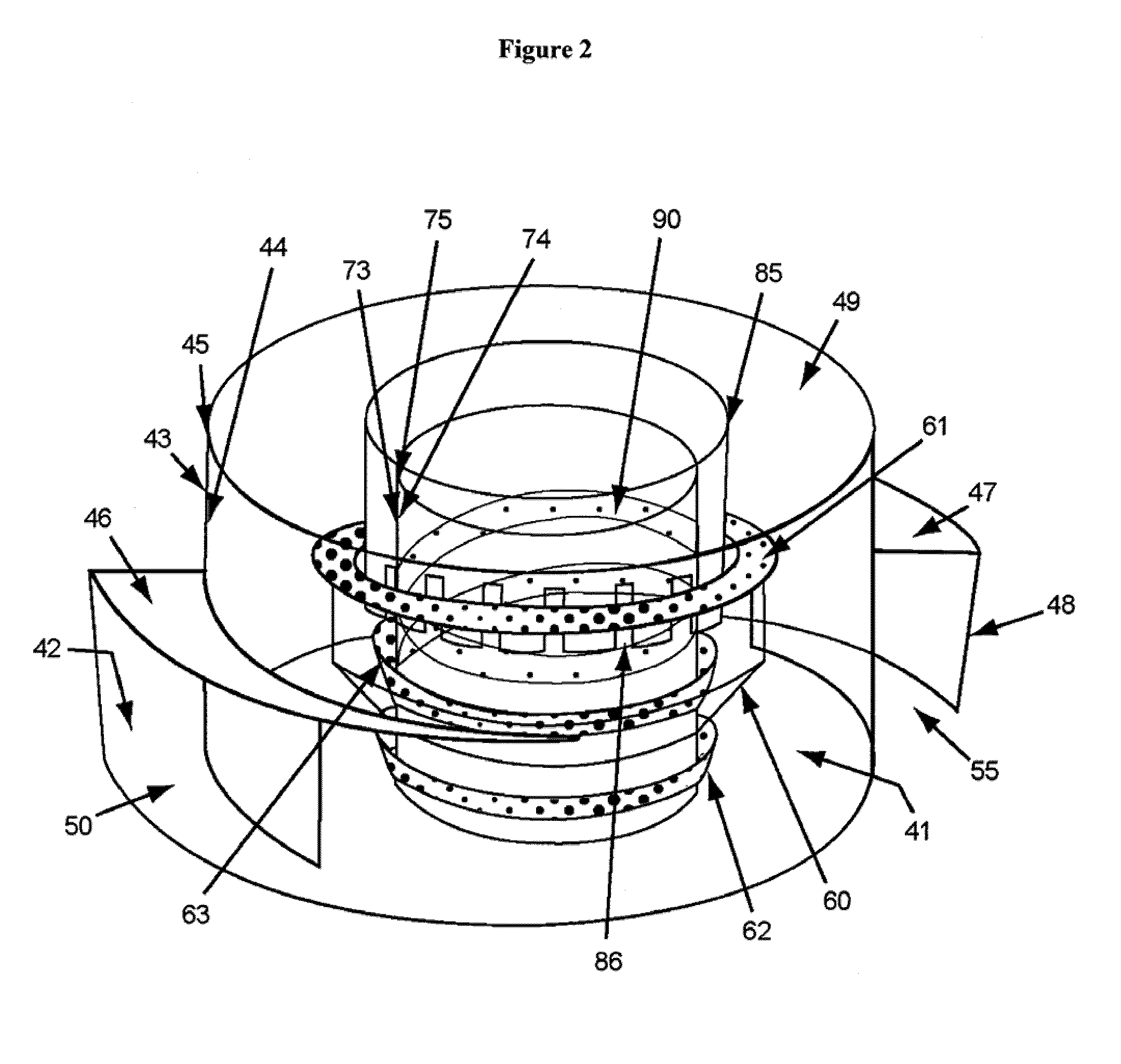

Continuous modular reactor

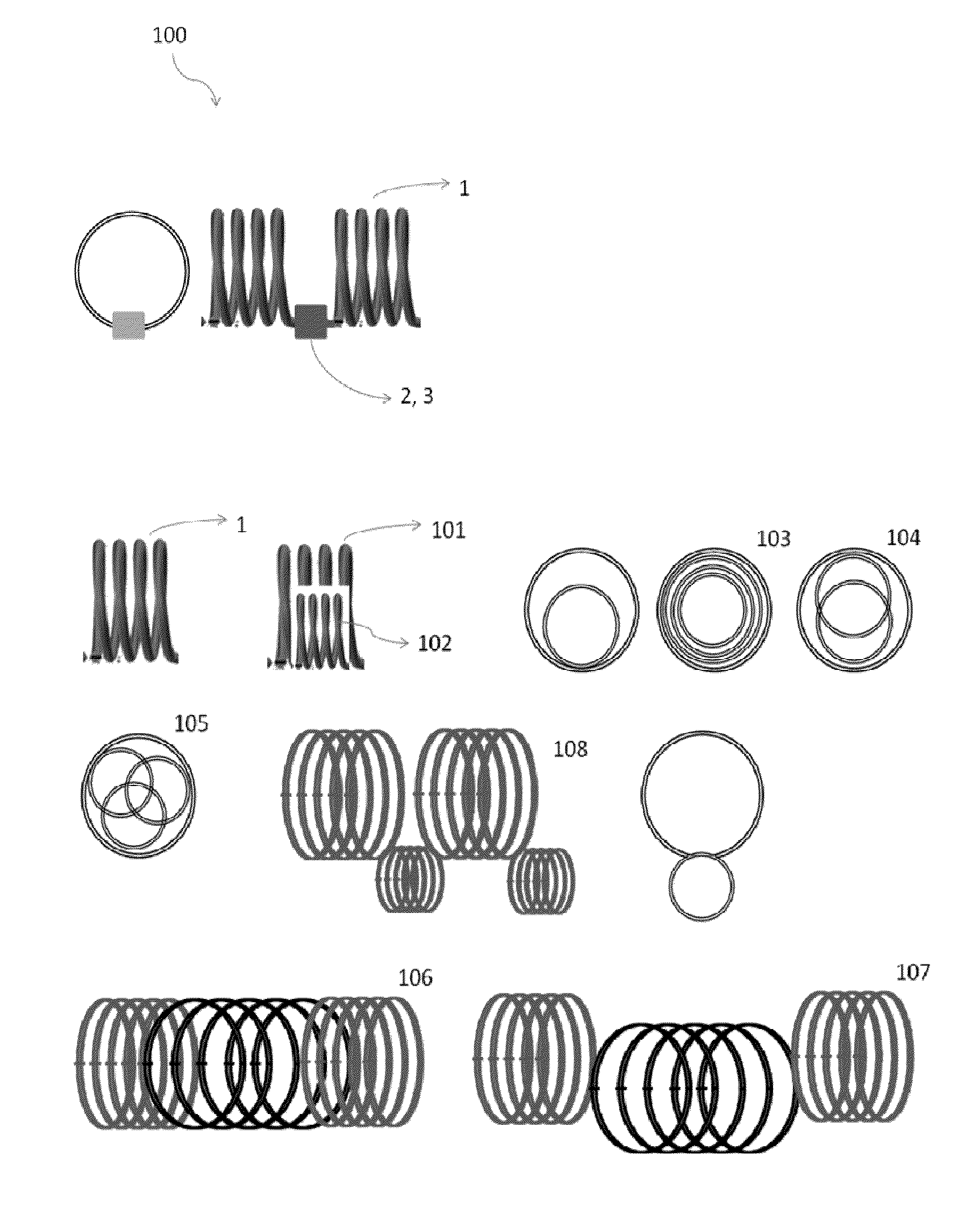

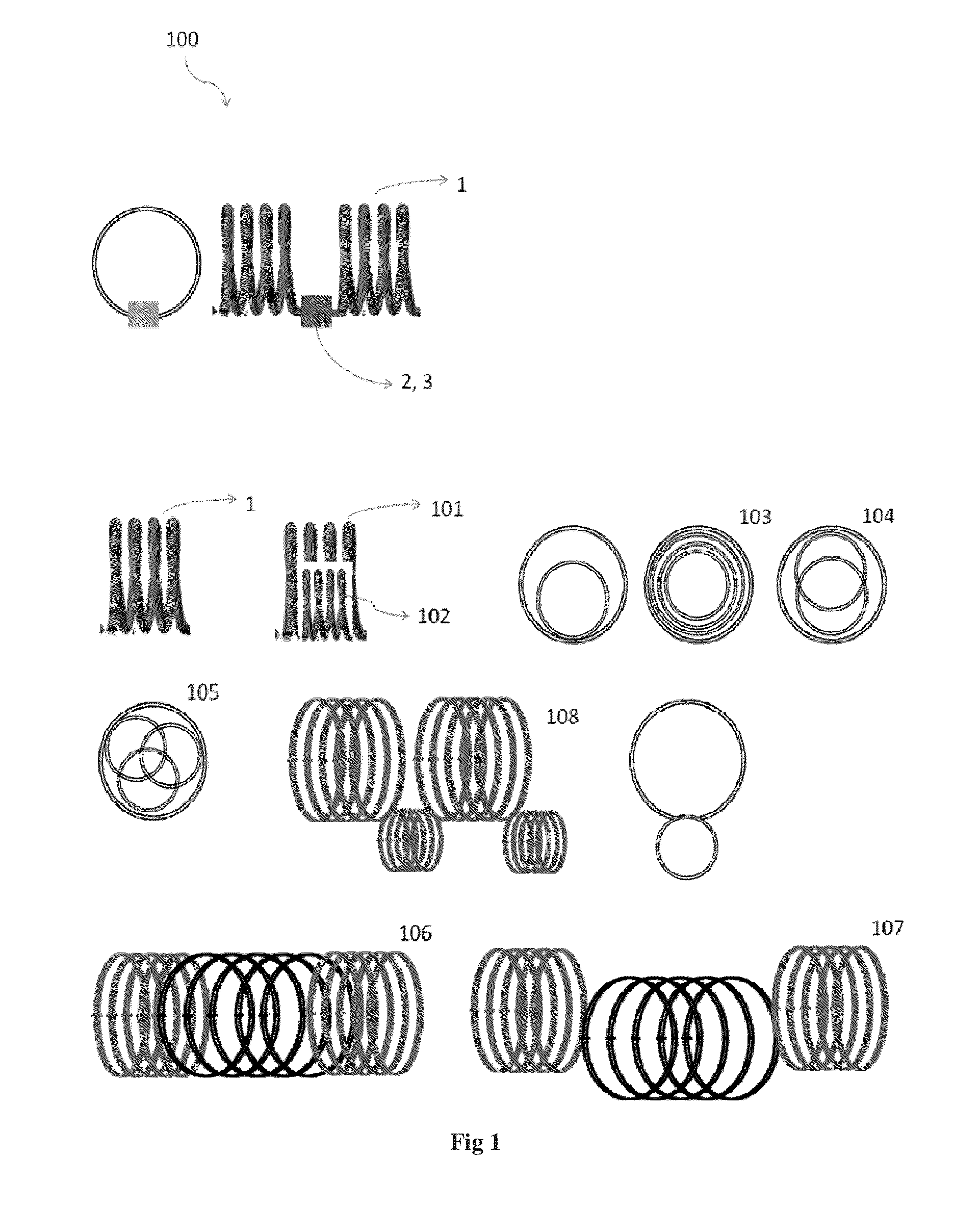

ActiveUS9446375B2The process is simple and fastRetain agility and re-configurability of the continuous processesChemical/physical/physico-chemical stationary reactorsContinuous reactorModularity

The present invention discloses a flow reactor composed of plurality of modular / fluidic components that helps retain agility and re-configurability of the continuous chemical processes with improved processing ability. More specifically, disclosed herein is a continuous flow reactor composed of varied permutations and combinations of a plurality of modular / fluidic components for chemical processing. The components are connected to each other using connectors that facilitate the connection of either with two or more, similar or different components.

Owner:COUNCIL OF SCI & IND RES

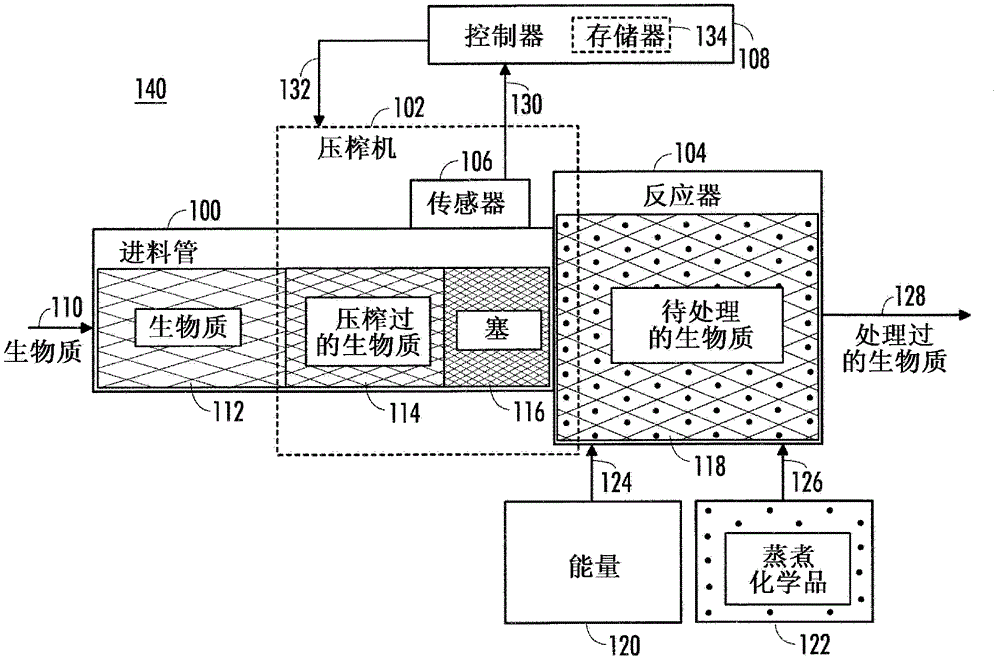

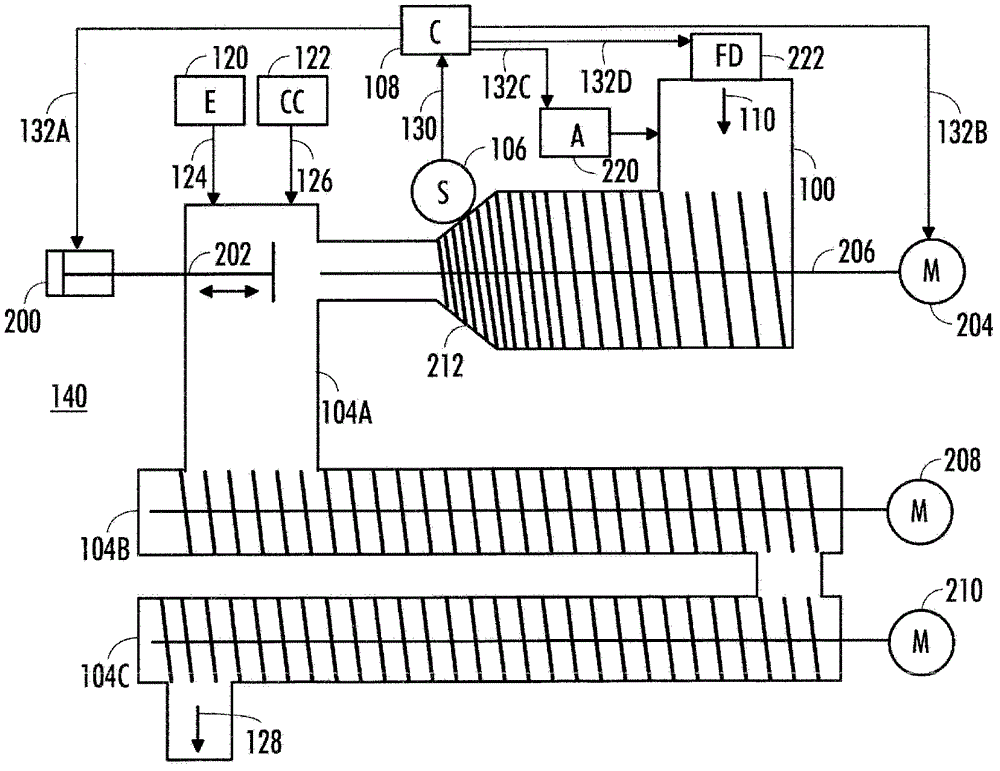

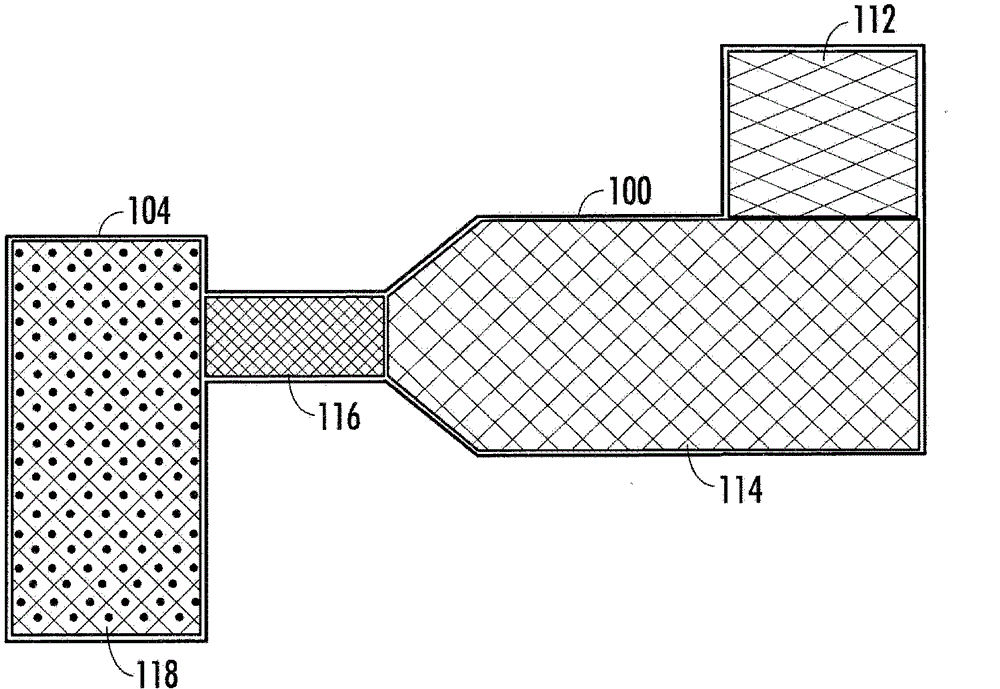

Device and method for controlling flow reactor used for processing lignocellulose biomass

The present invention relates to a device and a method for controlling a flow reactor used for processing lignocellulose biomass. The present invention describes control to the flow reactor used for processing lignocellulose biomass with a device and a method. The device (140) comprises the flow reactor (104) used for processing the lignocellulose biomass, a feed pipe (100) used for feeding the lignocellulose biomass into the reactor, and a presser (102) used for pressing the lignocellulose biomass in the feed pipe. In addition, the device (140) comprises a sensor (106) used for measuring parameters related to the pressed lignocellulose biomass in the feed pipe, and a controller (108) used for controlling the presser based on the measured parameters, so as to continuously maintain compactness of a plug formed by the pressed lignocellulose biomass in the feed pipe, therefore, the plug can prevent the lignocellulose biomass in the reactor having a higher pressure than the lignocellulose biomass in the feed pipe from being discharged back into the feed pipe.

Owner:CHEMPOLIS OY

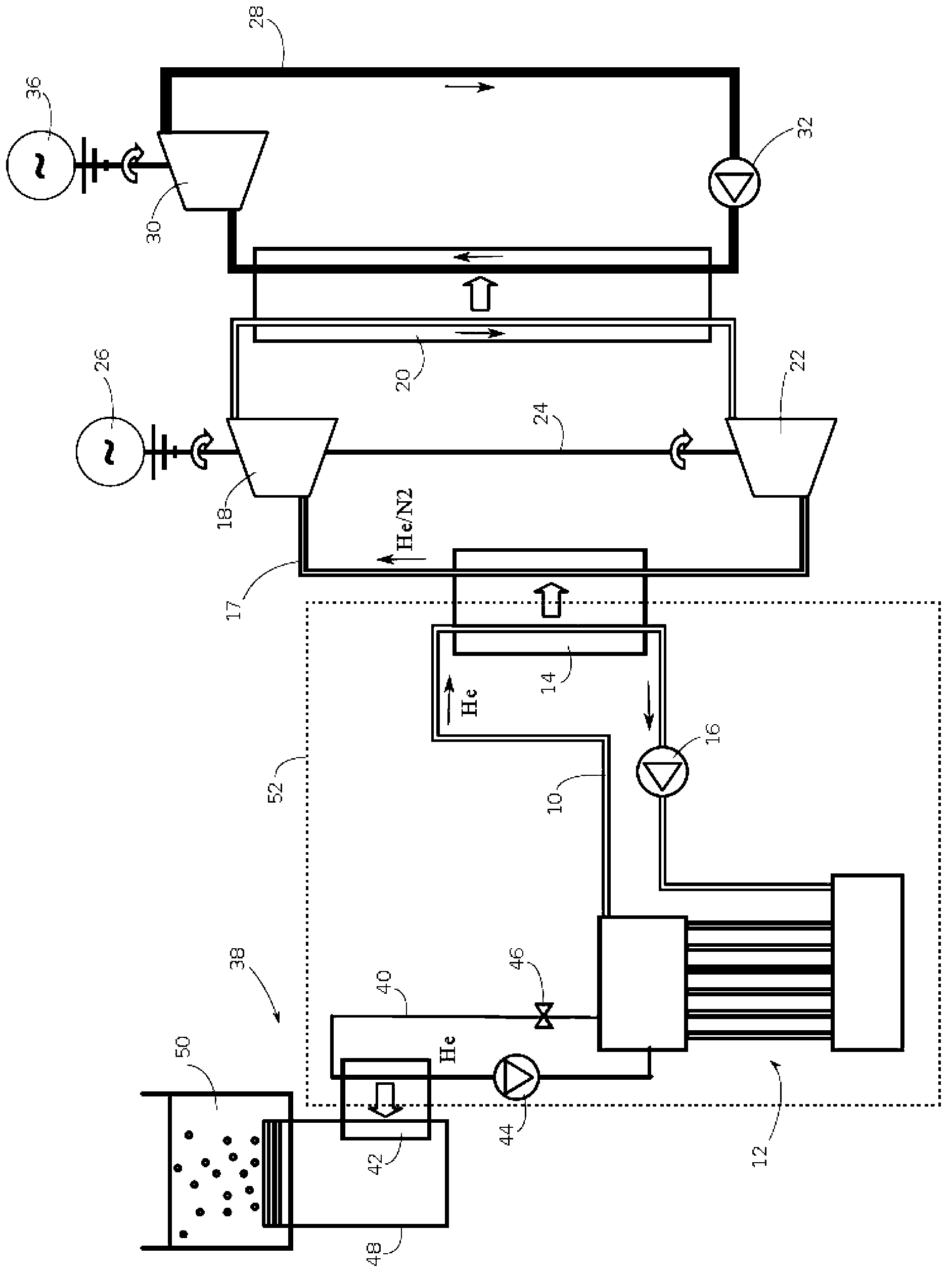

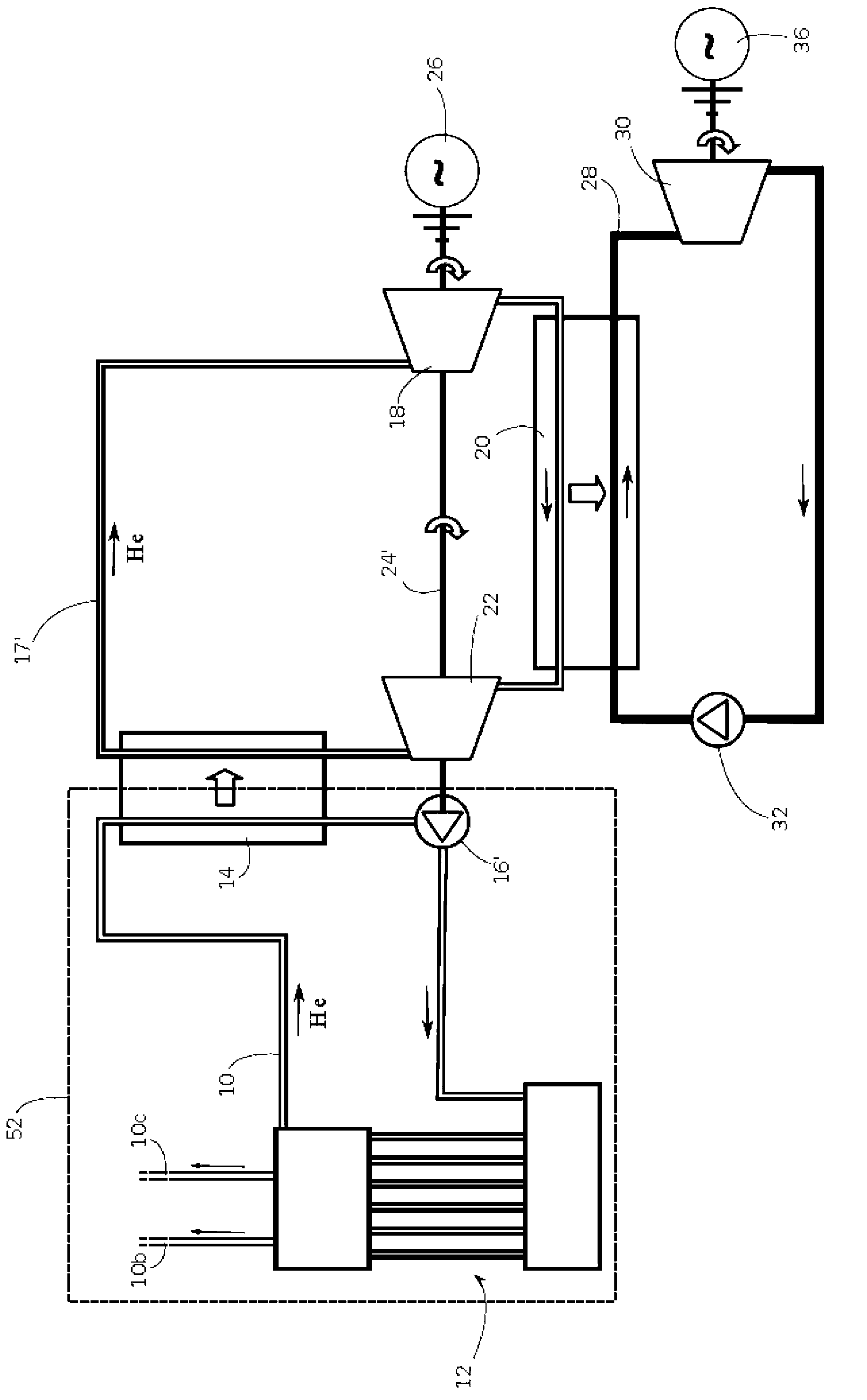

Facility for producing energy using a gas-cooled fast reactor

InactiveCN102870165APower plant safety arrangementNuclear energy generationNuclear reactorGas-cooled fast reactor

The present invention relates to a facility for producing energy comprising a gas primary circuit (10) passing through a nuclear reactor (12), through a first heat exchanger (14), and through a fan (16'). An incondensable-gas secondary circuit (17') passes through the first exchanger (14), and through a turbine (18) and a compressor (22) which are mounted on one and the same shaft (24'). The fan is driven by the shaft. The gases in the primary and secondary circuits are of the same kind, and the pressure in the secondary circuit is slaved to the pressure in the primary circuit.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

System and method for processing reactor polymerization effluent

A method of treating a polymerization reactor effluent stream comprising recovering the reactor effluent stream from the polymerization reactor, flashing the reactor effluent stream to form a flash gas stream, separating the flash gas stream into a first top stream, a first bottom stream, and a side stream, wherein the side stream substantially comprises hexane, separating the first top stream into a second top stream and a second bottom stream, wherein the second bottom stream substantially comprises isobutane, and separating the second top stream into a third top stream and a third bottom stream; wherein the third top stream substantially comprises ethylene, and wherein the third bottom stream is substantially free of olefins.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

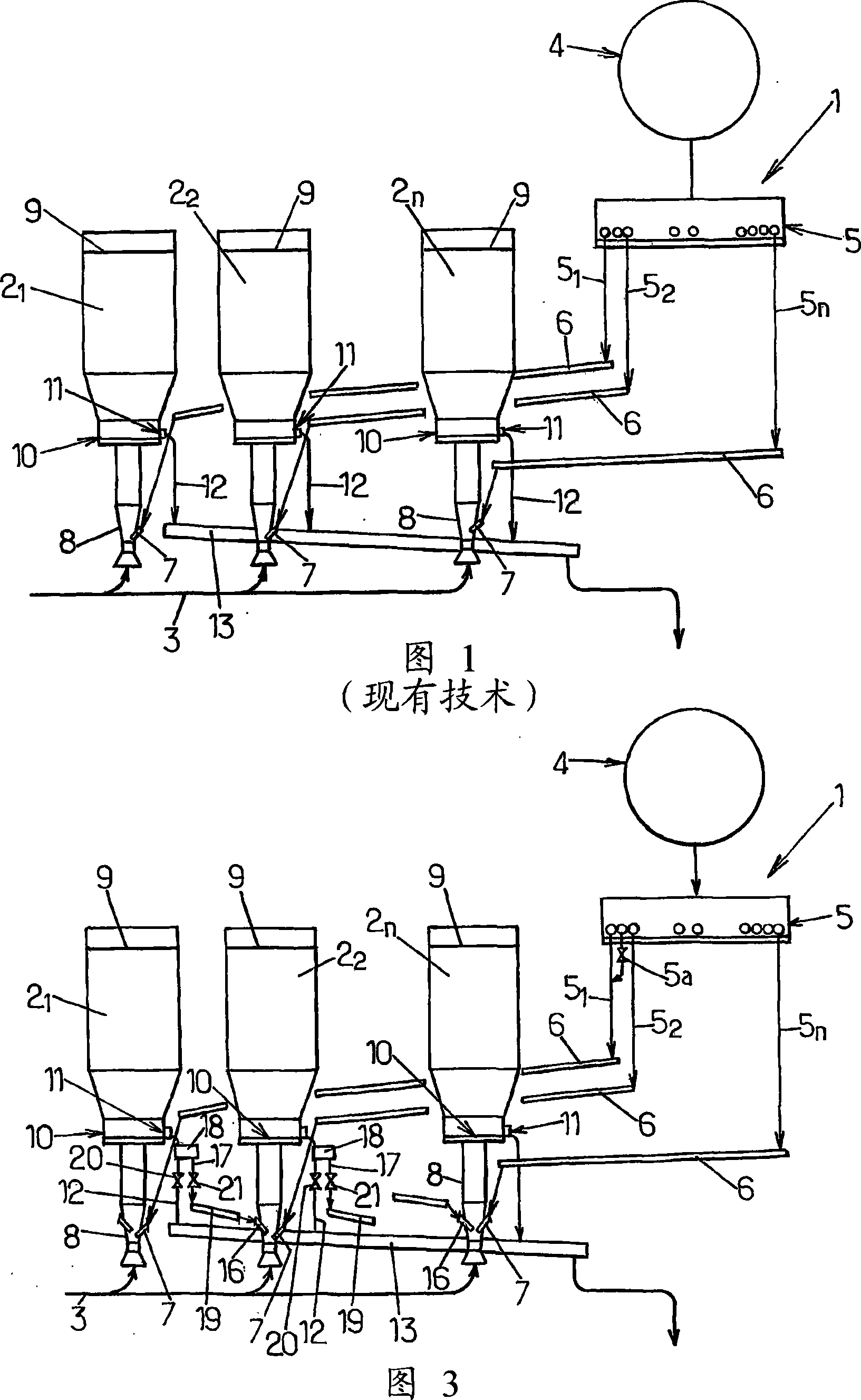

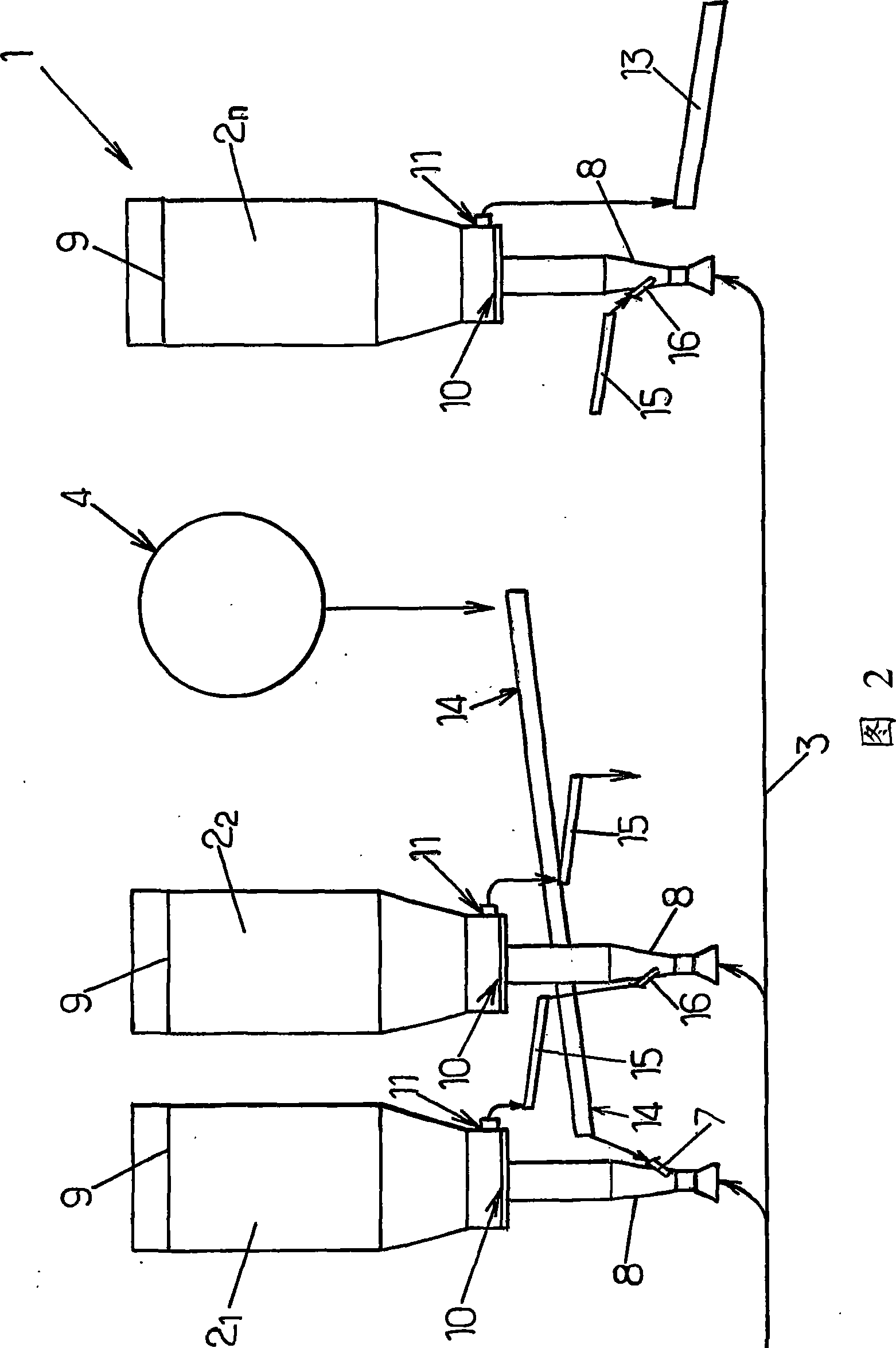

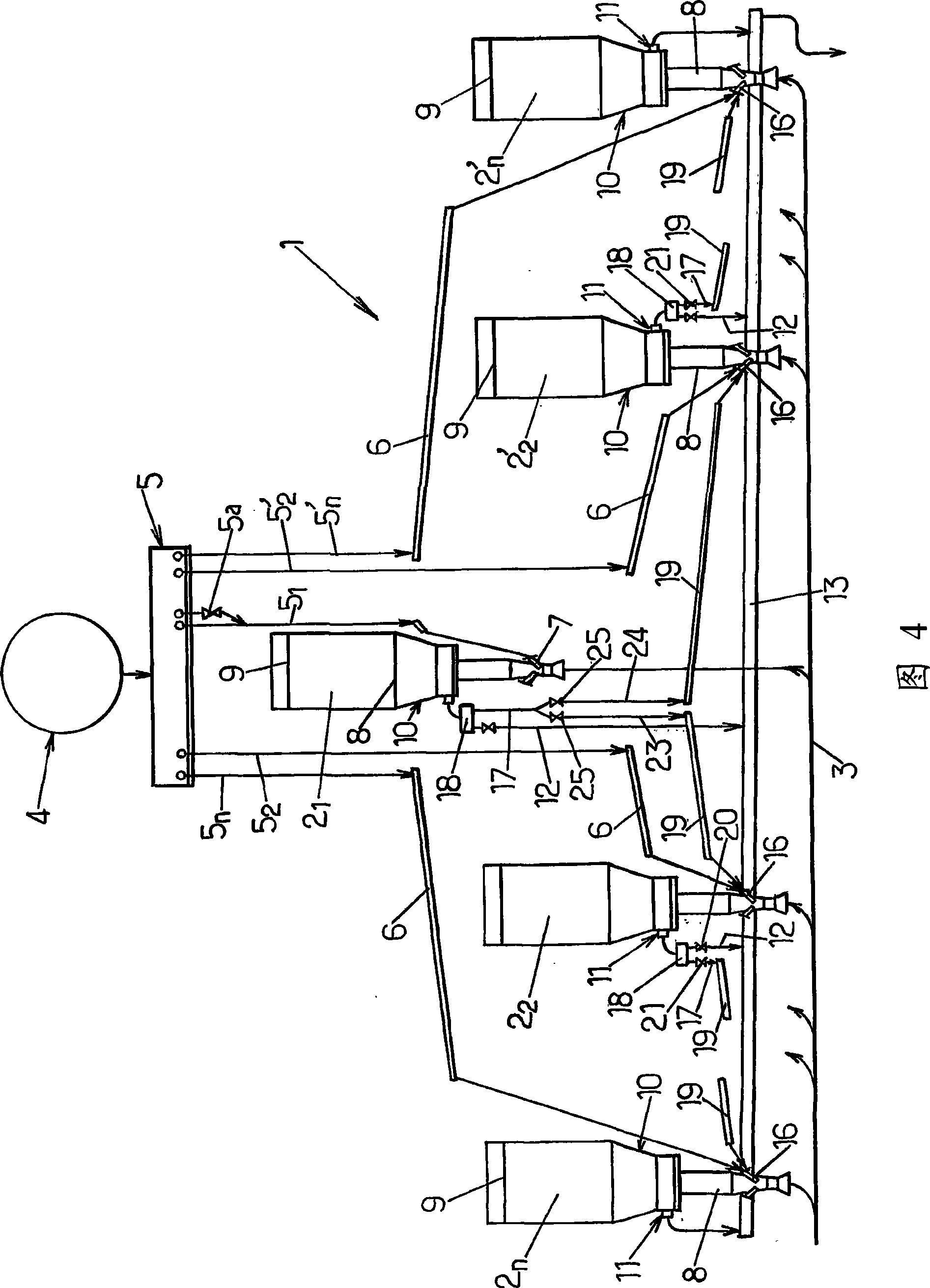

Group of at least two gas-flow reactors supplied with chemical neutralization and/or sorption agent

ActiveCN101389396AImprove purification effectDispersed particle separationChemical/physical processesMaterial typeSorbent

The present invention relates to a group of at least two gas-flow reactors (21, 22, 2'2, ..., 2n, 2'n) preferably with an ascending gas flow (3), which are supplied on the one hand, in parallel, with gas and on the other hand with a chemical neutralization and / or sorption agent of the pulverulent material type that is capable of adsorbing effluents present in said gas flow (3) by bringing said chemical neutralization and / or sorption agent in contact with said gas flow (3), said at least two reactors (21, 22, 2'2, ..., 2n, 2'n) having means (10) for collecting said chemical neutralization and / or sorption agent after it has been brought into contact with said gas flow (3), characterized in that at least one of said two reactors (2l, 22, 2'2, ..., 2n, 2'n) has means (11) for discharging said chemical neutralization and / or or sorption agent, after having been brought into contact with said gas flow (3), said means (11) being connected to said collecting means (10), and means (7, 16) for injecting the chemical neutralization and / or sorption agent into at least one other of said at least two reactors (2l, 22, 2'2, ..., 2n, 2'n).

Owner:SOLIOS ENVIRONNEMENT

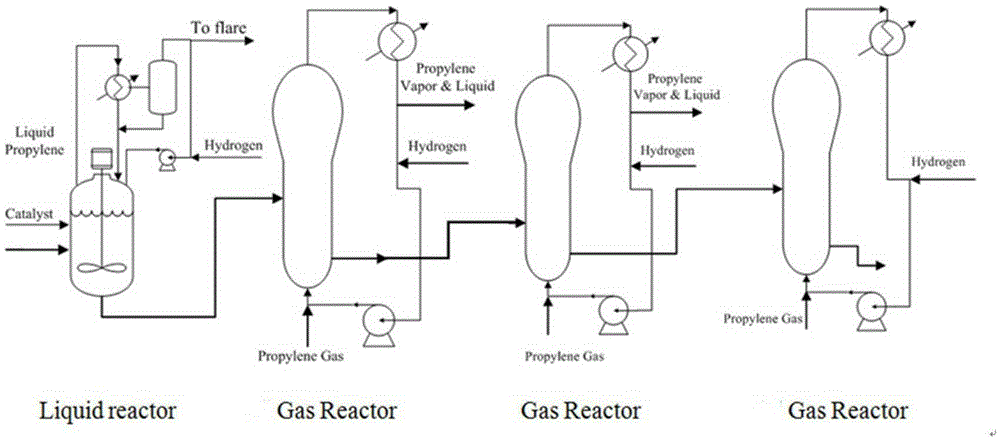

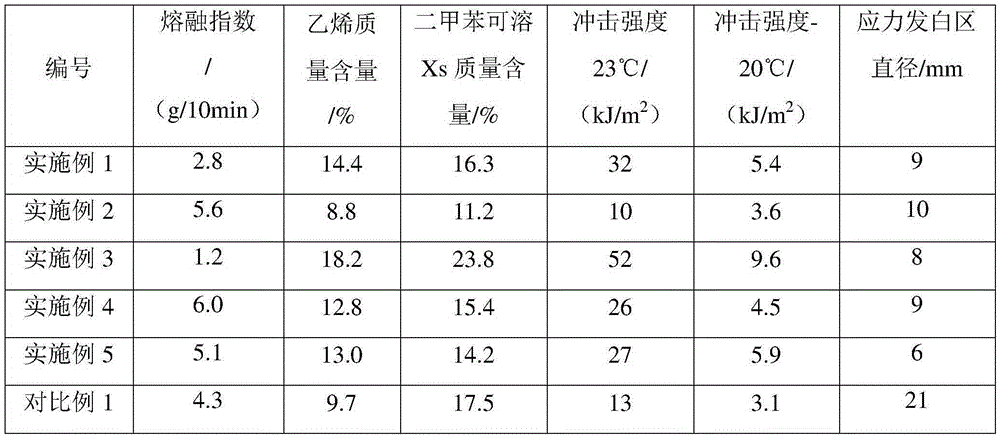

Reaction system for preparing stress whitening resistant polypropylene and method for preparing polypropylene in system

The invention discloses a reaction system for preparing stress whitening resistant polypropylene and a method for preparing polypropylene by employing the system. A liquid-phase stirring reactor is sequentially connected with a gas-phase fluidized bed flashing reactor and at least two gas-phase fluidized bed reactors which are connected in series. According to the method, polypropylene granules are sequentially subjected to propylene liquid-phase homopolymerization, propylene gas-phase homopolymerization, propylene ethylene gas-phase copolymerization and ethylene gas-phase spontaneous polymerization through the reaction system and a Ziegler-Natta catalytic system, and pass a gas-solid drying and separating system and are discharged, so that the stress whitening resistant polypropylene is obtained. The system has the advantages that a copolymerization reactor is additionally arranged at the stage of gas-phase polymerization, a flow of propylene liquid-phase homopolymerization, propylene gas-phase homopolymerization, propylene ethylene gas-phase copolymerization and ethylene gas-phase spontaneous polymerization is formed, a notable characteristic is reflected in the stage of gas-phase polymerization, polymer granules are subjected to three polymerization stages including propylene homopolymerization, propylene ethylene copolymerization and ethylene spontaneous polymerization, and the interface integration of different structural molecules is properly improved, so that the stress whitening resistant polypropylene has relatively good mechanical property and processing property, and the reaction system further has outstanding characteristics that the occurrence probability of stress cracking is reduced, and the stress whitening phenomenon of products is obviously improved.

Owner:SINOPEC YANGZI PETROCHEM +1

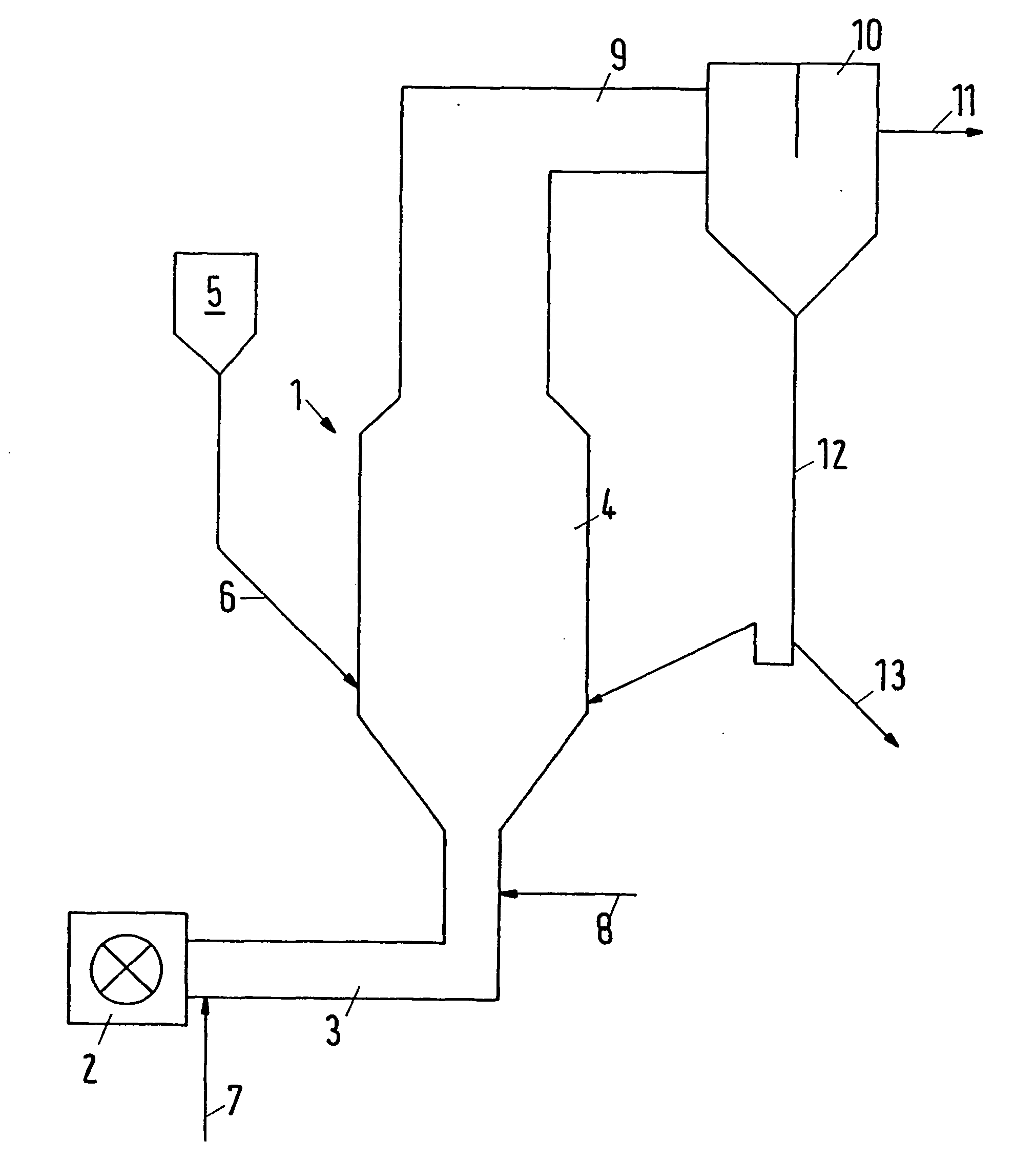

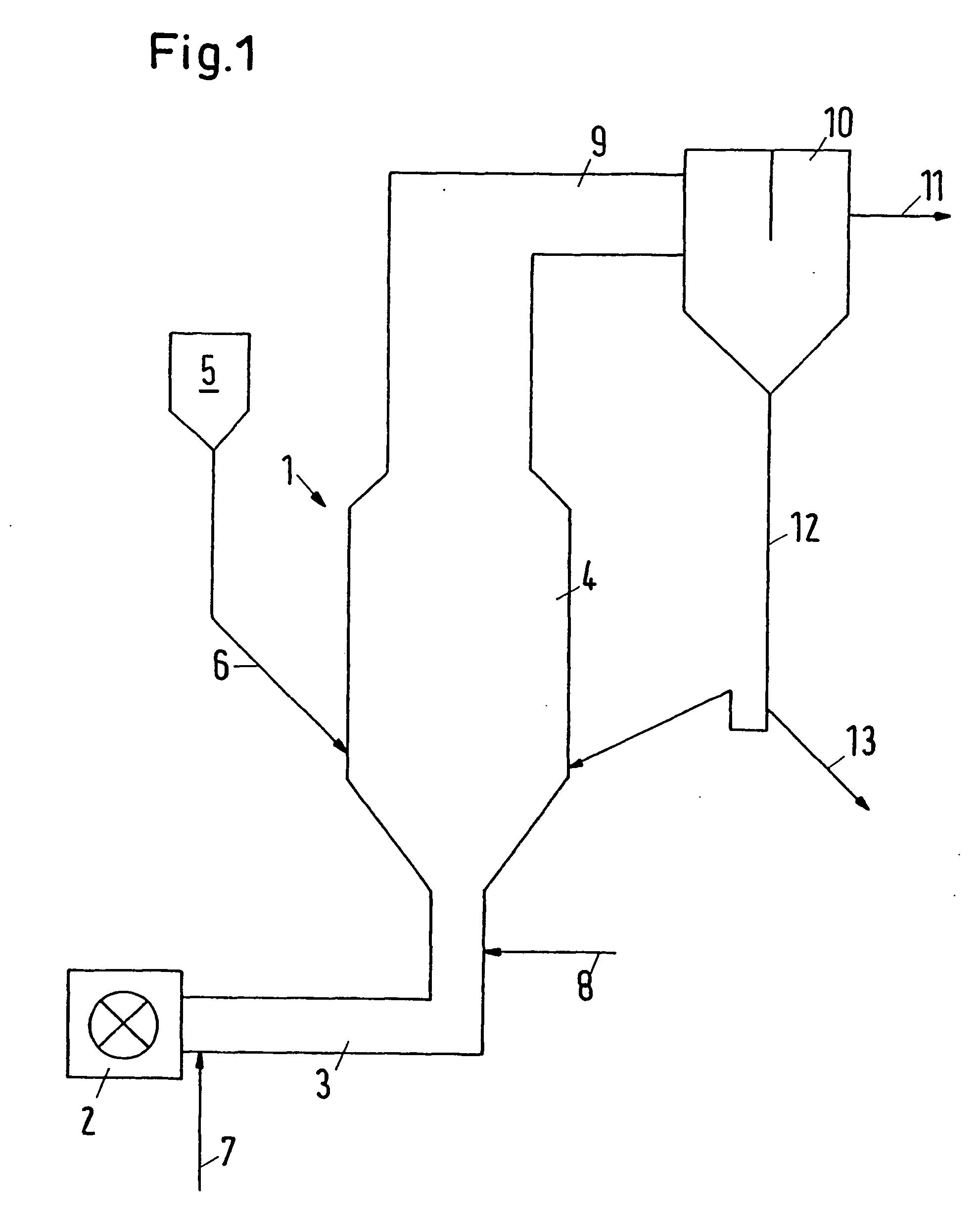

Method and plant for the thermal treatment of granular solids

InactiveUS20070007282A1Efficient feedingSimple structureMicrowave heatingEnergy based chemical/physical/physico-chemical processesProcess engineeringThermal treatment

This invention relates to a method for the thermal treatment of granular solids in a reactor (1) with swirl chamber (4), which in particular constitutes an flash reactor or suspension reactor, wherein the microwave radiation from a microwave source (2) is fed into the reactor (1) through a wave guide, and to a corresponding plant. To avoid deposits in the wave guide, the same constitutes a gas supply tube (3), a gas stream being additionally fed through the gas supply tube (3) into the swirl chamber (4).

Owner:STRODER MICHAEL +3

Two-stage sludge hydrothermal reaction device

InactiveCN108911478AReduce volumeLower the volumeSludge treatment by thermal conditioningResidenceSludge

The invention discloses a two-stage sludge hydrothermal reaction device. The device comprises: a plurality of slurrying reactors which are serially connected from front to back, a hydrothermal residence reactor and a plurality of flash evaporation reactors which are serially connected from front to back, and the hydrothermal residence reactor is arranged between the backmost slurrying reactor andthe headmost flash evaporation reactor, wherein at least one hydrothermal temperature reactor is also mounted between the hydrothermal residence reactor and the backmost slurrying reactor, every hydrothermal heating reactor is provided with a gas inlet tube, a gas outlet tube, a steam tube, a feed tube and a discharging tube which are connected with the corresponding hydrothermal heating reactor,a plurality of the hydrothermal heating reactors alternately run, and arrangement according to a preset timing sequence makes the discharging of the final-stage slurrying reactor and the feeding of the hydrothermal residence reactor continuously performed. The two-stage sludge hydrothermal reaction device disclosed in the invention simplifies the heating function of the hydrothermal reactor, and realizes good stirring performance, energy saving and high sludge treatment efficiency of the hydrothermal reactor.

Owner:四川深蓝环保科技有限公司

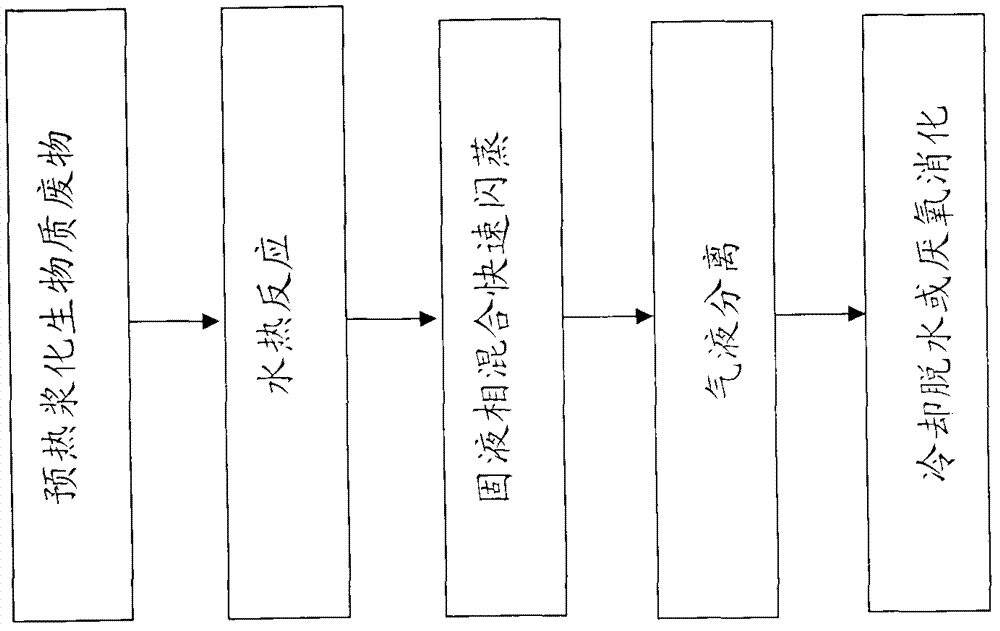

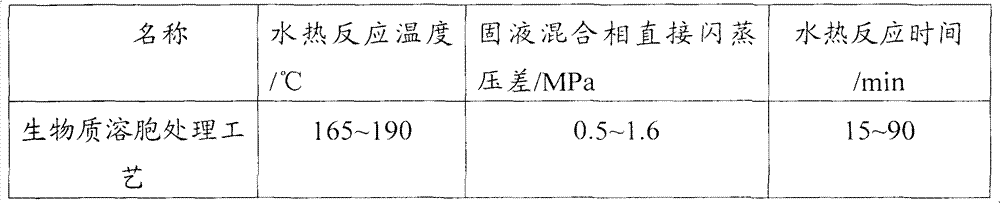

Biomass cell dissolving treatment process of solid-liquid mixed phase by quick flash evaporation

InactiveCN103357645AEnhanced Anaerobic DigestionImprove dehydration effectSolid waste disposalGas phaseReaction temperature

The invention discloses a cell breaking process and system of a solid-liquid mixed phase by direct quick flash evaporation. The method comprises the following steps of: feeding biomass waste to a pulpifying reactor for heating and preheating; then, pumping into a hydrothermal reactor, and heating to reaction temperature; after hydrothermal reaction, performing direct depressurization and flash evaporation on a high-temperature high-pressure solid-liquid phase mixed material, wherein the material expands and is gasified severely, and the pressure is reduced quickly, and then, entering into a flash reactor; separating the depressurized material in the flash reactor from steam and entering into a cooling system for cooling; and directly dehydrating the cooled material or entering into an anaerobic digestion system for subsequent treatment. According to the invention, the mode of direct flash evaporation of the solid-liquid mixed phase rather than depressurized flash evaporation to the gas phase of the high temperature and high pressure reactor is adopted. The flash evaporation process of the process directly acts on the solid phase, so that the cell structure is more efficiently damaged, and intracellular matters are accelerated to be dissolved out.

Owner:北京健坤伟华新能源科技有限公司

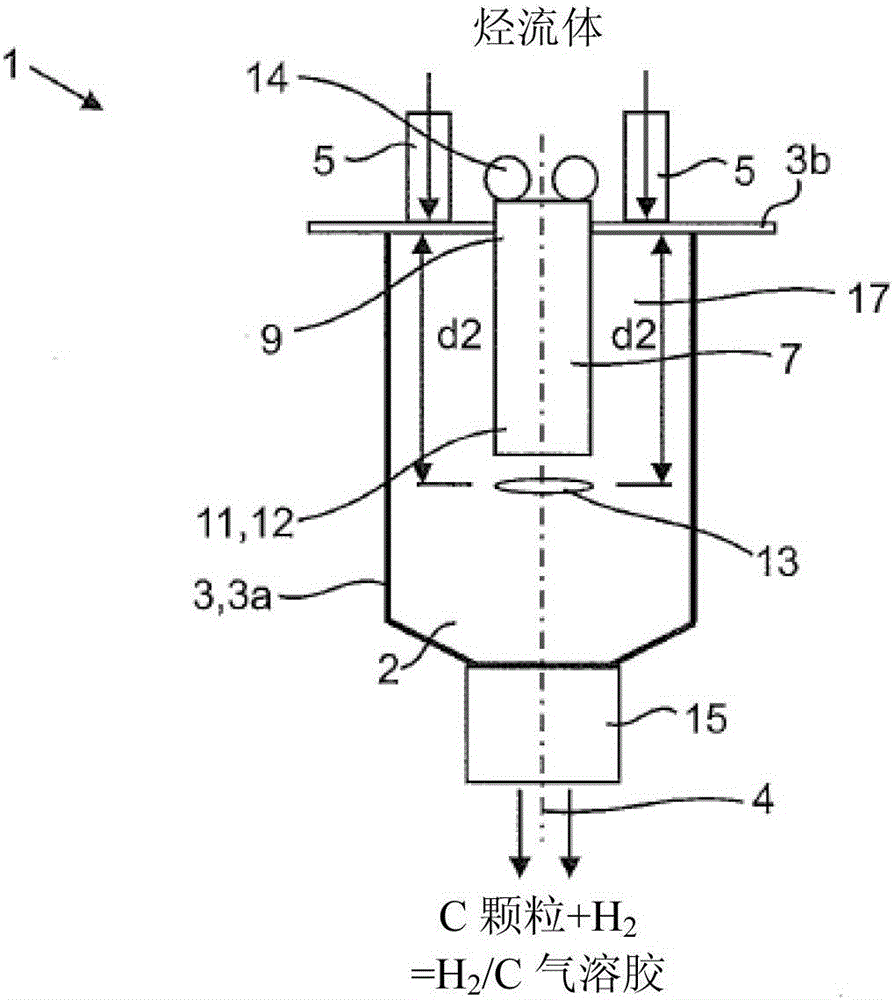

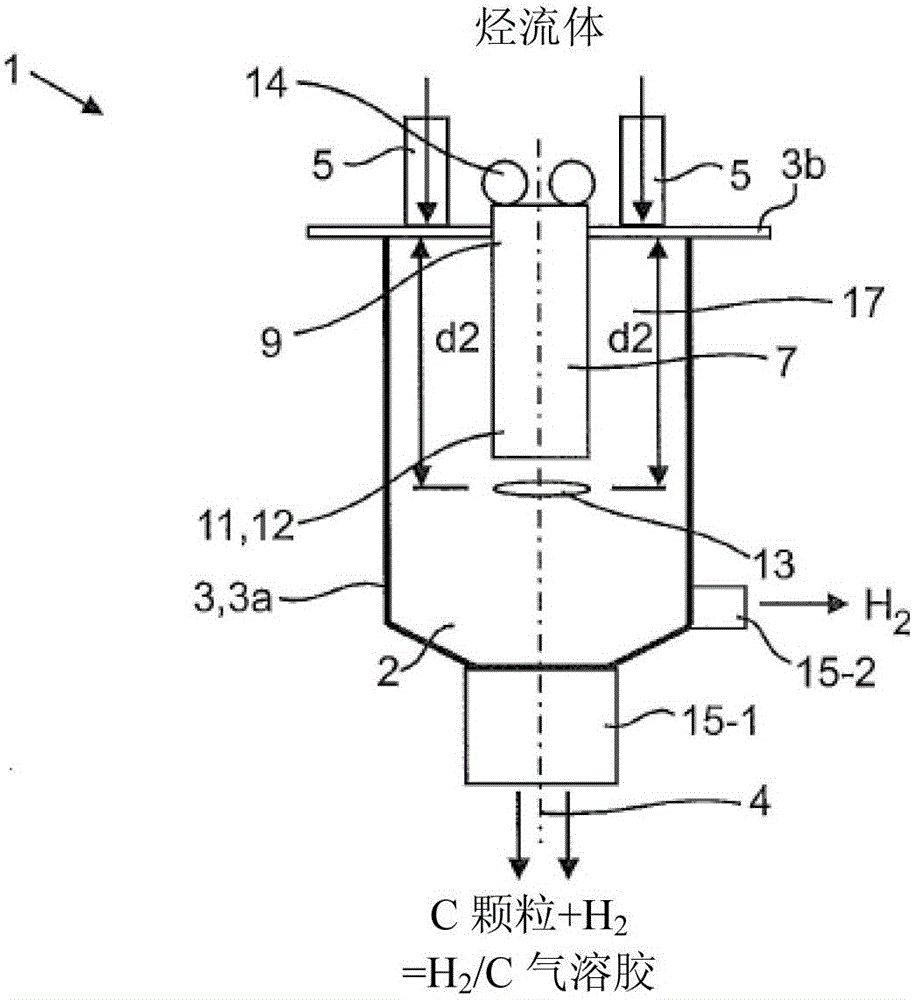

Plasma reactor and method for decomposing a hydrocarbon fluid

InactiveCN105934273AIncrease flow rateAvoid accumulationGaseous chemical processesHydrogen productionCombustorPlasma reactor

In a plasma reactor (1) for decomposing a hydrocarbon fluid, the deposition of C particles is to be reduced or completely prevented. In order to achieve this object, there is described a plasma reactor (1) for decomposing a hydrocarbon fluid which comprises a reactor chamber (2) enclosed by a reactor wall (3, 3a) and having at least one hydrocarbon fluid inlet (5) and at least one outlet (15), and in addition it comprises a plasma burner (7) having at least two elongated electrodes which each have a base part (9) that is fixed to the reactor wall (3b) and a burner part (11) which projects into the reactor chamber (2) and has a free end. The hydrocarbon fluid inlet (5) opens out into the reactor chamber (2) in such a manner that a hydrocarbon fluid flowing out therefrom flows in a space between the reactor wall and the electrodes along at least one electrode to the free end (12) thereof. A high flow rate of the fluid is thereby achieved and the direction of flow of the incoming fluid is directed away from the hydrocarbon fluid inlet (5).

Owner:CCP TECH GMBH

Innocent treatment method for sulfuryl fluoride gas

ActiveCN101972587BImprove removal efficiencyImprove utilization efficiencyDispersed particle separationElectric dischargeHigh energy

Owner:ZHEJIANG UNIV OF TECH +1

Sludge water heat drying treatment device and homogeneous reactor thereof

InactiveCN102531321BEasy to separateSmooth handlingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSlurry reactorSludge

Owner:北京科力丹迪技术开发有限责任公司

Reactor components

ActiveUS9315430B2Easy to operateDoubles the overall heat transfer coefficientThermal non-catalytic crackingCombustion processNuclear engineeringFlash reactor

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com