Reaction system for preparing stress whitening resistant polypropylene and method for preparing polypropylene in system

A reaction system and polypropylene technology, applied in the field of polymer chemical industry, can solve the problems of product rigidity reduction, achieve the effect of increasing polymerization time, high catalytic activity, and reducing the occurrence of stress lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

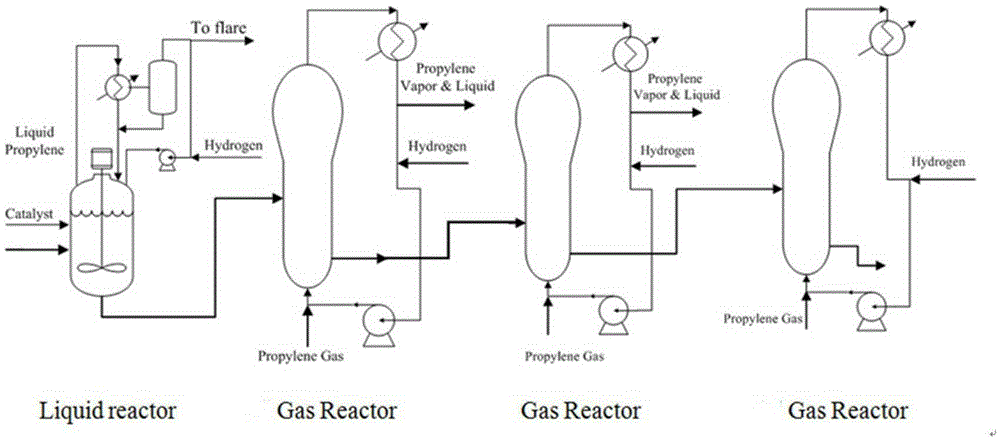

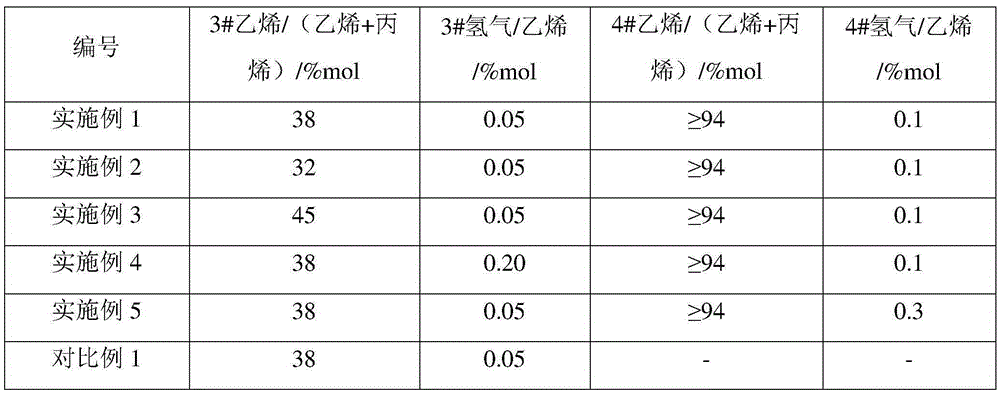

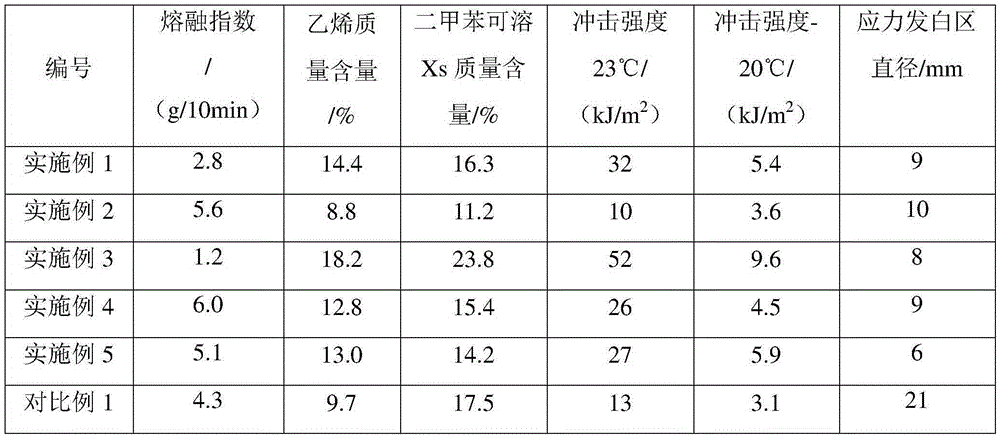

[0042] Liquid phase stirred reactor + gas phase fluidized bed flash reactor + gas phase fluidized bed reactor + gas phase fluidized bed reactor, connected in series, the volumes are 0.175 cubic meters, 1 cubic meter, 1.1 cubic meters, 1.1 cubic meters, The reaction temperatures are 70°C, 80°C, 70°C, 70°C respectively, the average residence time is about 0.6 hour, 0.8 hour, 1.0 hour, 1.0 hour respectively, the total polymerization amount is 25-30kg / h, continuous polymerization. Among them, the first two reactors are for homopolymerization of propylene, the third reactor is for ethylene propylene copolymerization, the fourth reactor is for ethylene self-polymerization, and a gas-solid separation facility is added between the third and fourth reactors to ensure The powder particles that enter the fourth reactor do not carry propylene monomer as much as possible to ensure that what is carried out in the fourth reactor is ethylene self-polymerization, the third reactor ethylene / (eth...

Embodiment 2

[0044] Repeat Example 1, but the third reactor ethylene / (ethylene+propylene)=32% mol, hydrogen / ethylene=0.05% mol, the fourth reactor ethylene / (ethylene+propylene)≥94% mol (considering particle interior part of propylene that is difficult to replace), hydrogen / ethylene = 0.1% mol.

Embodiment 3

[0046] Repeat Example 1, but the third reactor ethylene / (ethylene+propylene)=45% mol, hydrogen / ethylene=0.05% mol, the fourth reactor ethylene / (ethylene+propylene)≥94% mol (considering particle interior part of propylene that is difficult to replace), hydrogen / ethylene = 0.1% mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com