Innocent treatment method for sulfuryl fluoride gas

A harmless treatment, sulfuryl fluoride technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as polluting the environment, endangering the health of surrounding residents, increasing greenhouse gas emissions, and achieving removal High efficiency, improved energy utilization efficiency, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

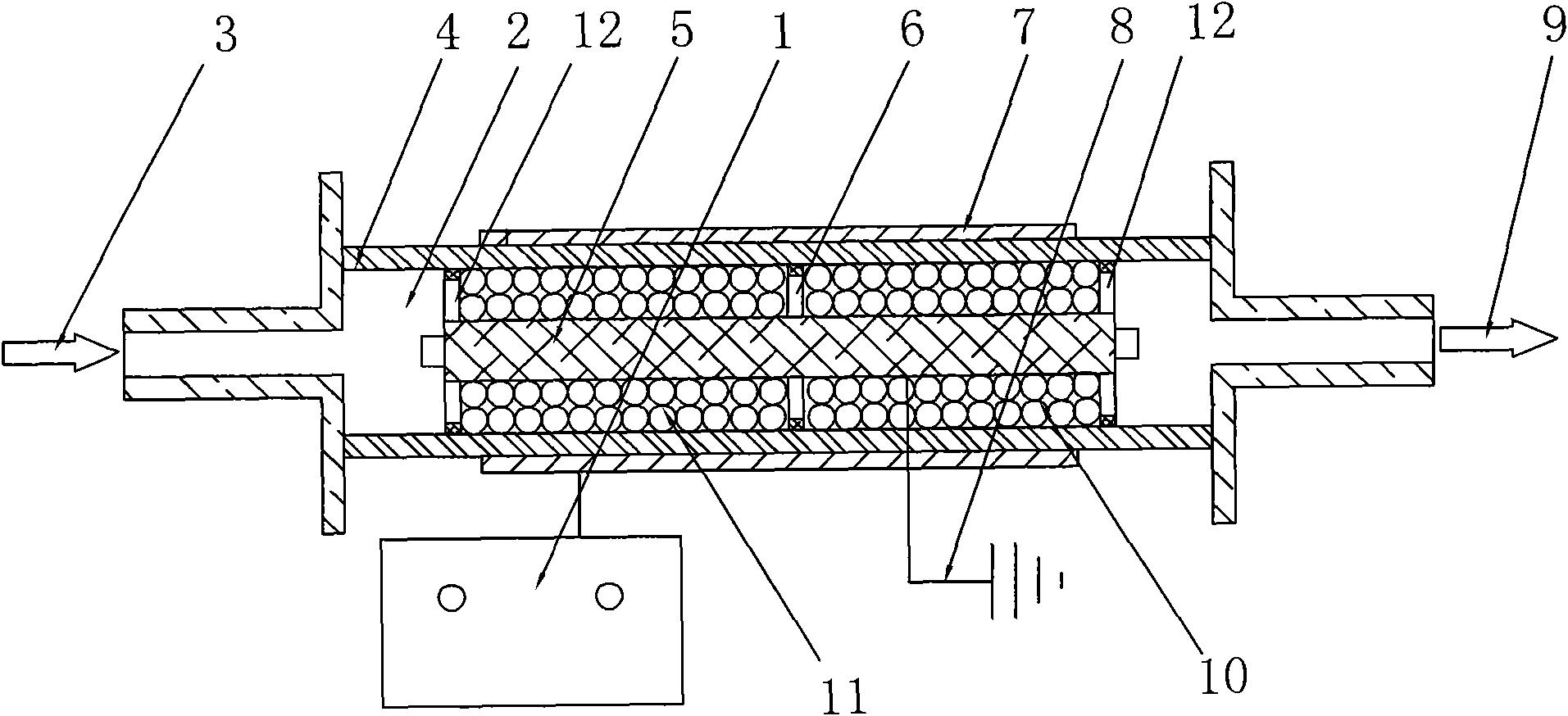

Method used

Image

Examples

example 1

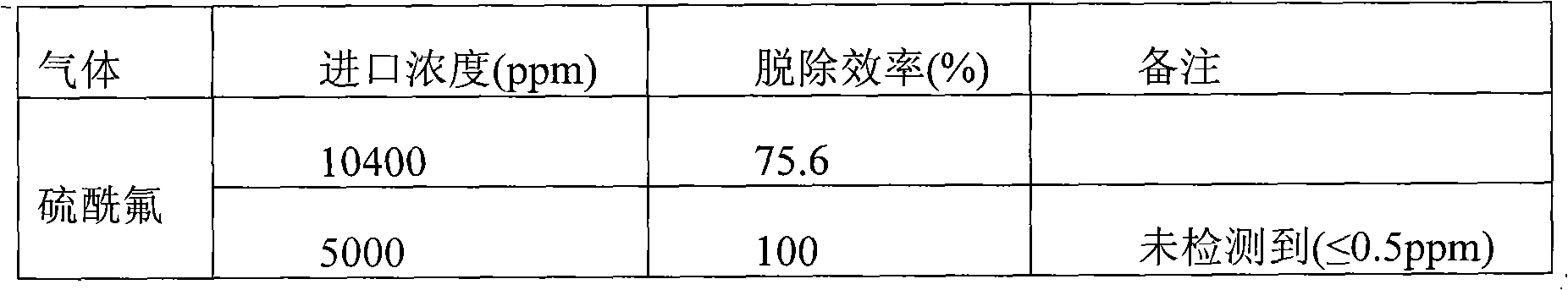

[0016] The conditions of Example 1 are: power supply peak voltage 12kV, power supply discharge frequency 7.5kHz; gas flow rate 200ml / min, gas temperature: room temperature.

[0017] Example 1 processing results are shown in Table 1:

[0018] Table 1

[0019]

[0020] It can be seen from Table 1 that the removal efficiency of sulfuryl fluoride decreases with the increase of the inlet concentration. When the inlet concentration of sulfuryl fluoride is lower than 5000ppm, this method can completely remove sulfuryl fluoride gas.

example 2

[0021] Example 2, change the input voltage of the power supply, investigate the impact of injected energy density on the removal effect of sulfuryl fluoride, other conditions are as in Example 1, and the results are shown in Table 2:

[0022] Table 2

[0023] Import concentration (ppm)

[0024] It can be seen from Table 2 that the removal efficiency of sulfuryl fluoride increases with the increase of injected energy density. When the energy density is 1300J / L, the removal efficiency can reach 100%.

example 3

[0025] Example 3, change the discharge frequency, investigate the influence of the power supply frequency on the sulfuryl fluoride removal effect, other conditions are as in Example 1, and the results are as shown in Table 3:

[0026] table 3

[0027] Import concentration (ppm)

[0028] It can be seen from Table 3 that the removal efficiency of sulfuryl fluoride has an optimal value for the discharge frequency. When the discharge frequency is 8kHz, the removal efficiency can reach 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com