Multi-stage flashing sludge continuous hydrothermal treatment device

A technology of hydrothermal treatment and heat exchange device, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. It can solve the problems of insufficient sludge treatment efficiency and treatment quality, and achieve increased steam Effect of absorption efficiency, reduction of steam usage, process profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

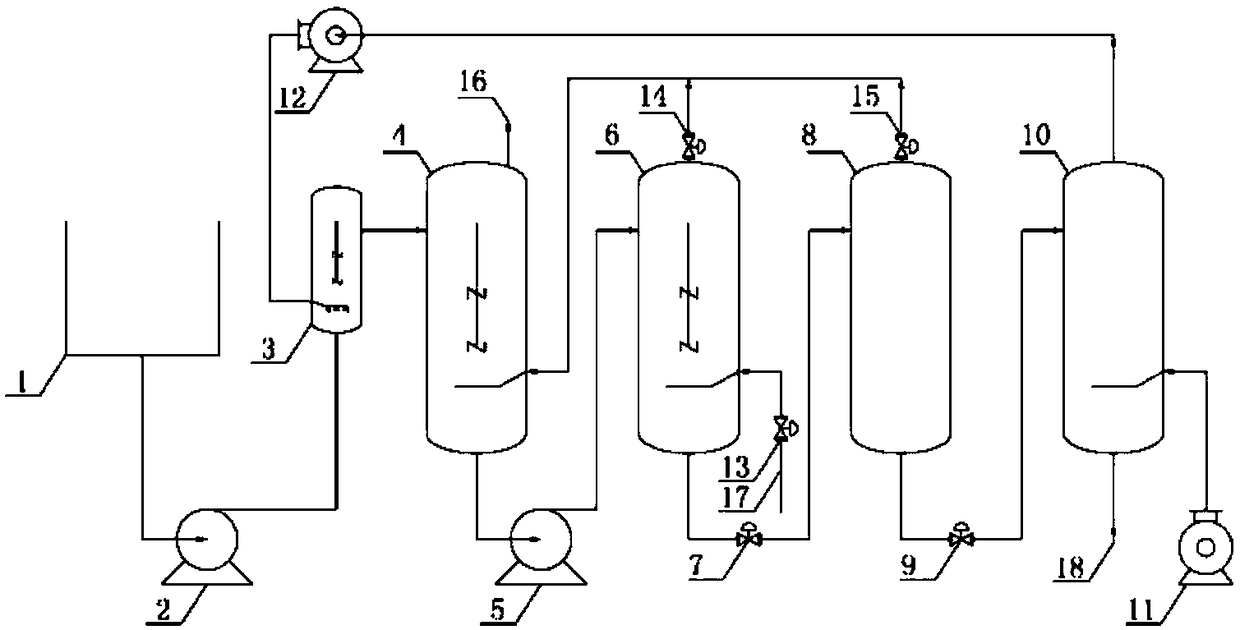

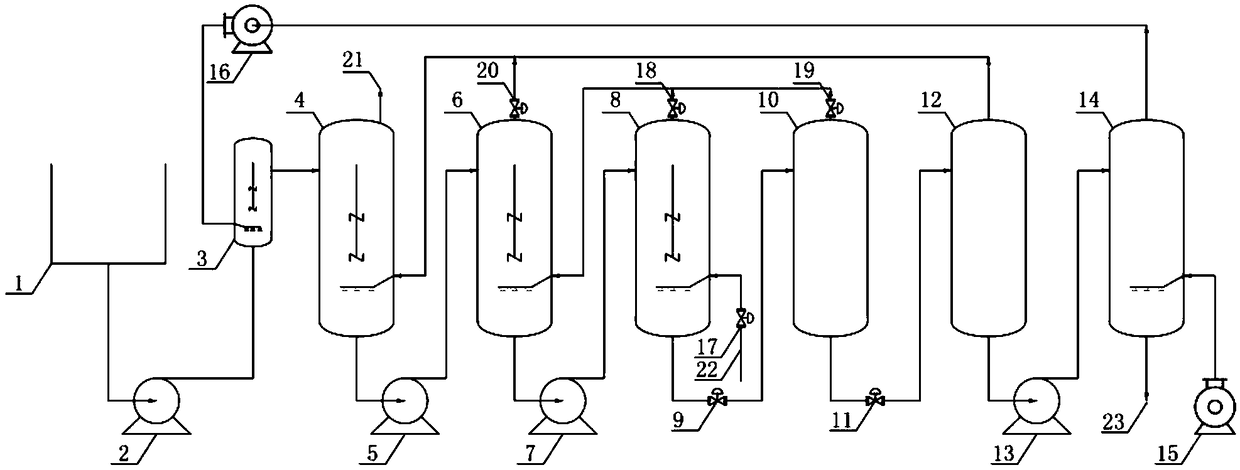

[0023] Such as figure 1 As shown, a multi-stage flash sludge continuous hydrothermal treatment device disclosed in the embodiment of the present invention includes: raw mud buffer bin 1, homogeneous reactor 3, slurry reactor 4, hydrothermal reaction Device 6, flash reactor (8,10), described slurry reactor 4 is provided with at least one, and described flash reactor is provided with at least two, for convenience of description, in the present embodiment, slurry reactor only There is only one flash reactor, and there are only two flash reactors, and each slurry reactor and each flash reactor are sequentially connected in series, wherein, the homogeneous reactor 3, slurry reactor 3, and slurry reactor arranged from front to back The reactor 4 is also connected with each of the flash reactors (8, 10) arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com