Extraction method for reducing vanadium in sulfuric acid leaching solution by using waste vanadium-poor catalyst

An extraction method and catalyst technology, which are applied in the field of vanadium extraction from waste-lean vanadium catalyst reduction sulfuric acid leaching solution, can solve the problems of low recovery rate of waste-lean vanadium catalyst, increase processing cost, waste of vanadium resources, etc., and achieve the recovery rate High, simple operation, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

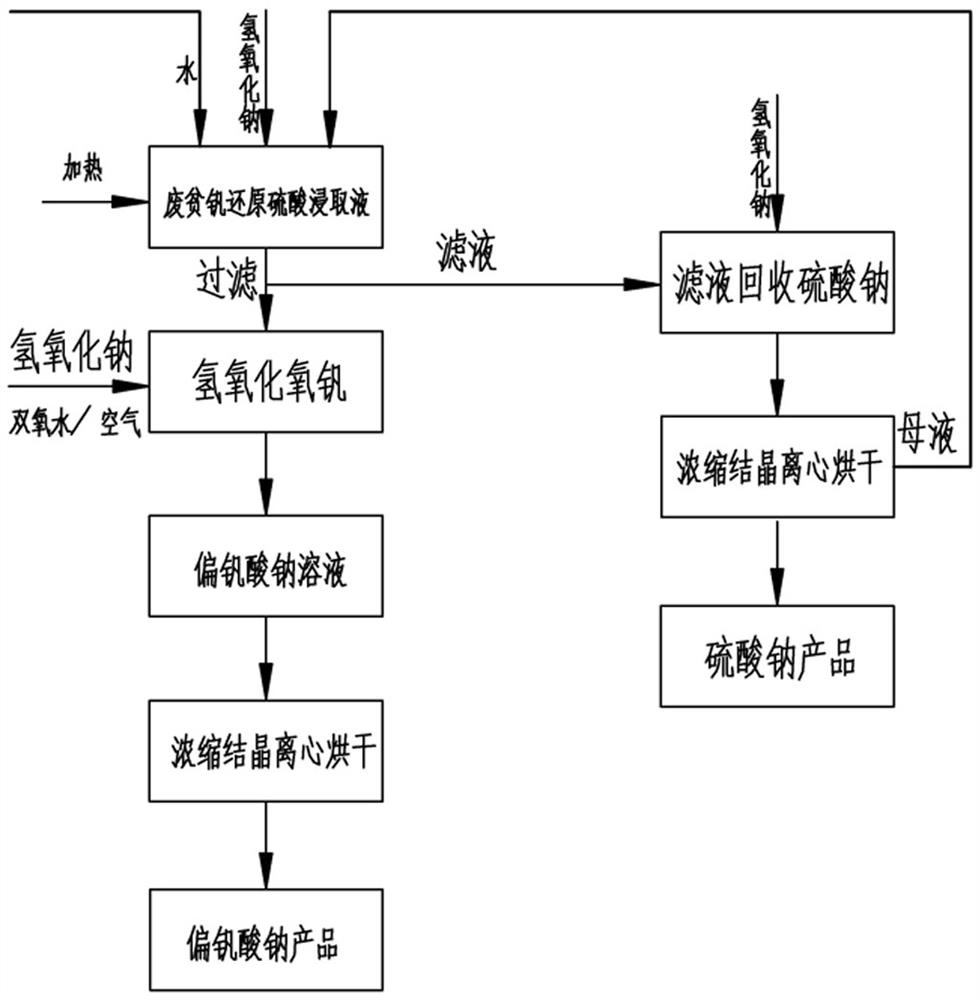

[0017] see figure 1 , a method for extracting vanadium in the sulfuric acid leaching solution reduced by spent vanadium-poor catalysts, comprising the following steps: adding 1000 g of 3.1% vanadium-poor catalyst-reduced sulfuric acid leaching solutions into a container, heating to 70° C. , add sodium hydroxide to it to adjust the pH of the solution to 7.5, continue to stir and react for 1 hour, the vanadyl sulfate in the solution is neutralized to form a vanadyl hydroxide precipitate, filter and wash, and add 10% sodium hydroxide to the filter residue In the solution, add hydrogen peroxide until the solution is light yellow and the pH value reaches 11, and continue to stir for 30 minutes to convert the vanadium hydroxide into sodium metavanadate into the solution, filter and wash to remove insoluble matter (the filter residue is iron oxide, discarded) , the filtrate was concentrated, crystallized, centrifuged, and dried to obtain 74.2g of sodium metavanadate product, and the ...

Embodiment 2

[0021] A method for extracting vanadium in the leach solution of sulfuric acid reduced by spent vanadium-poor catalyst, comprising the following steps: adding 1000 g of leach solution of sulfuric acid reduced by spent vanadium-poor catalyst with a vanadium mass fraction of 3.12% into a container, heating to 75° C. Add sodium hydroxide therein to adjust the pH of the solution to 7, continue to stir and react for 1.5 hours, the vanadyl sulfate in the solution is neutralized to form a vanadyl hydroxide precipitate, filter and wash, and add a mass fraction of 8% sodium hydroxide solution to the filter residue , add hydrogen peroxide until the solution is light yellow, and the pH value reaches 12, continue to stir for 30 minutes, so that the vanadium hydroxide is converted into sodium metavanadate into the solution, filter and wash to remove insoluble matter (the filter residue is iron oxide, discarded), The filtrate was concentrated, crystallized, centrifuged, and dried to obtain 7...

Embodiment 3

[0025] A method for extracting vanadium in a leach solution for reducing sulfuric acid by a spent vanadium-poor catalyst, comprising the following steps: adding 1000 g of a leach solution for reducing sulfuric acid by a spent vanadium-poor catalyst with a mass fraction of 3.09% into a container, heating to 80° C. Add sodium hydroxide therein to adjust the pH of the solution to 8, continue to stir and react for 2 hours, the vanadyl sulfate in the solution is neutralized to form a vanadyl hydroxide precipitate, filter and wash, and add a mass fraction of 12% sodium hydroxide solution to the filter residue , add hydrogen peroxide until the solution is pale yellow, and the pH value reaches 10, continue to stir for 30 minutes, so that the vanadium hydroxide is converted into sodium metavanadate into the solution, filter and wash to remove insoluble matter (the filter residue is iron oxide, discarded), The filtrate was concentrated, crystallized, centrifuged, and dried to obtain 74.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com