Two-stage sludge hydrothermal reaction device

A technology of sludge water and heat reaction, applied in the direction of controlling sludge treatment through temperature, can solve the problems of high cost, bulky, complex structure, etc., and achieve the effect of reducing installed power, improving stirring intensity and reducing stirring power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

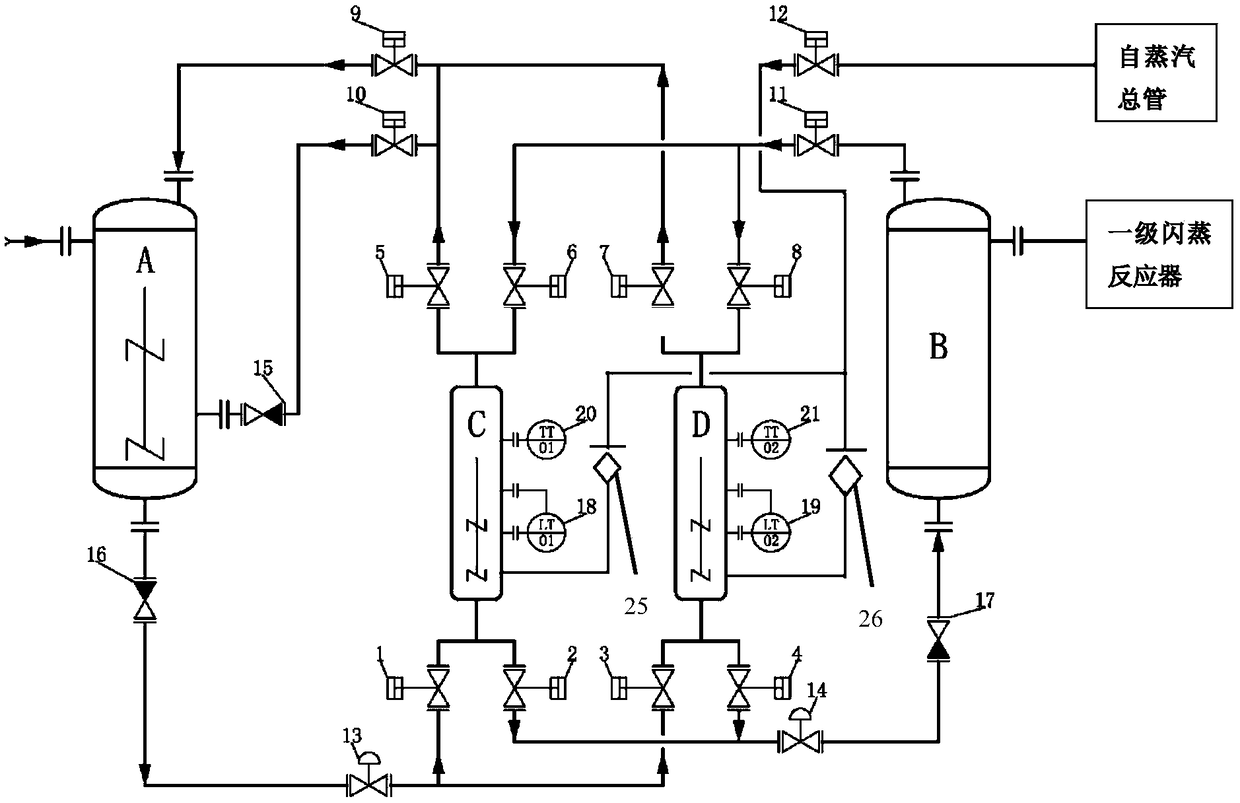

[0027] like figure 1As shown, in a preferred embodiment of the present invention, there are two hydrothermal heating reactors of the two-stage sludge hydrothermal reaction device, and they are arranged in parallel. Of course, those skilled in the art should understand that the There can be 3 or more hydrothermal heating reactors, among which 2 or 3 are the best, and multiple feeders, outlets or other related components can be shared between multiple reactors. Stable continuous use of incoming and outgoing materials and air sources to reduce system fluctuations. Specifically, the device includes: the slurry reactor A arranged last is arranged horizontally with the hydrothermal heating reactor C and the hydrothermal heating reactor D, and the hydrothermal heating reactor C and the hydrothermal heating reactor D are arranged in parallel , the automatic switching is used alternately, so that the discharge of the slurry reactor A and the feed of the hydrothermal retention reactor ...

Embodiment 2

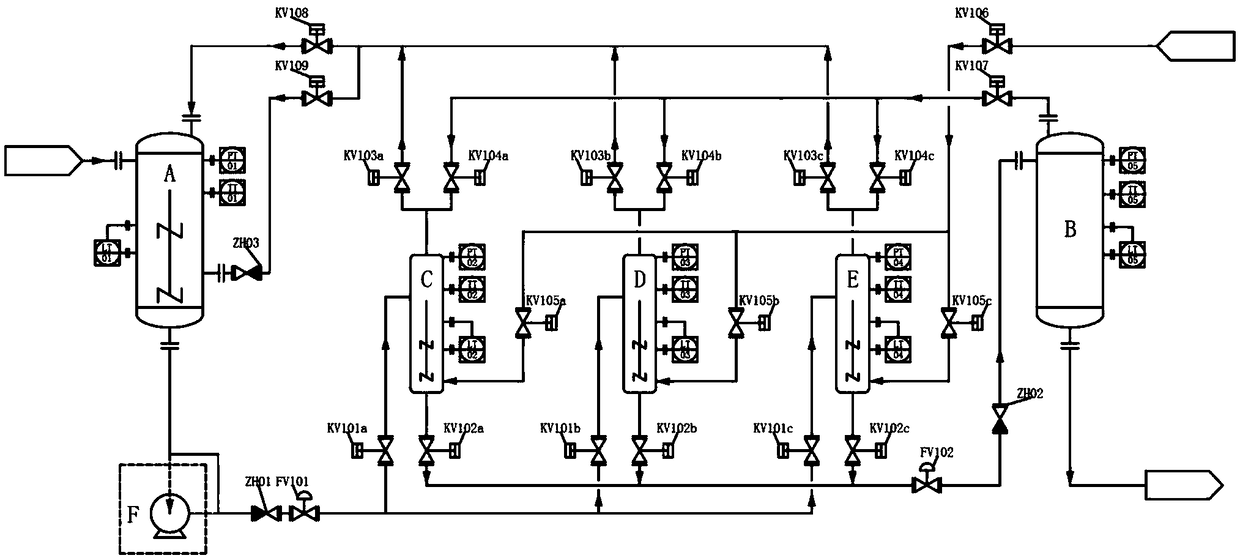

[0048] like figure 2 As shown, in this embodiment, the hydrothermal heating reactor is provided with three (C / D / E), arranged in parallel, the connection relationship between the three heating and conveying, and their connection with the final slurry reactor and The connection relationship between the hydrothermal retention reactors is basically the same as the connection relationship between the two units in Embodiment 1, and will not be repeated here.

[0049] Different from Embodiment 1, in this embodiment, not only temperature and liquid level monitoring, but also pressure monitoring and pressure transmitters are installed for each hydrothermal heating reactor (C / D / E) , in addition, three transmitters of temperature TT, liquid level LT and pressure PT are also set up for the slurry reactor A and the hydrothermal retention reactor B for monitoring, among which, the hydrothermal heating reactor (C / D / E ) to the hydrothermal stagnation reactor B, it is necessary to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com