Patents

Literature

37results about How to "Reduce stirring power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

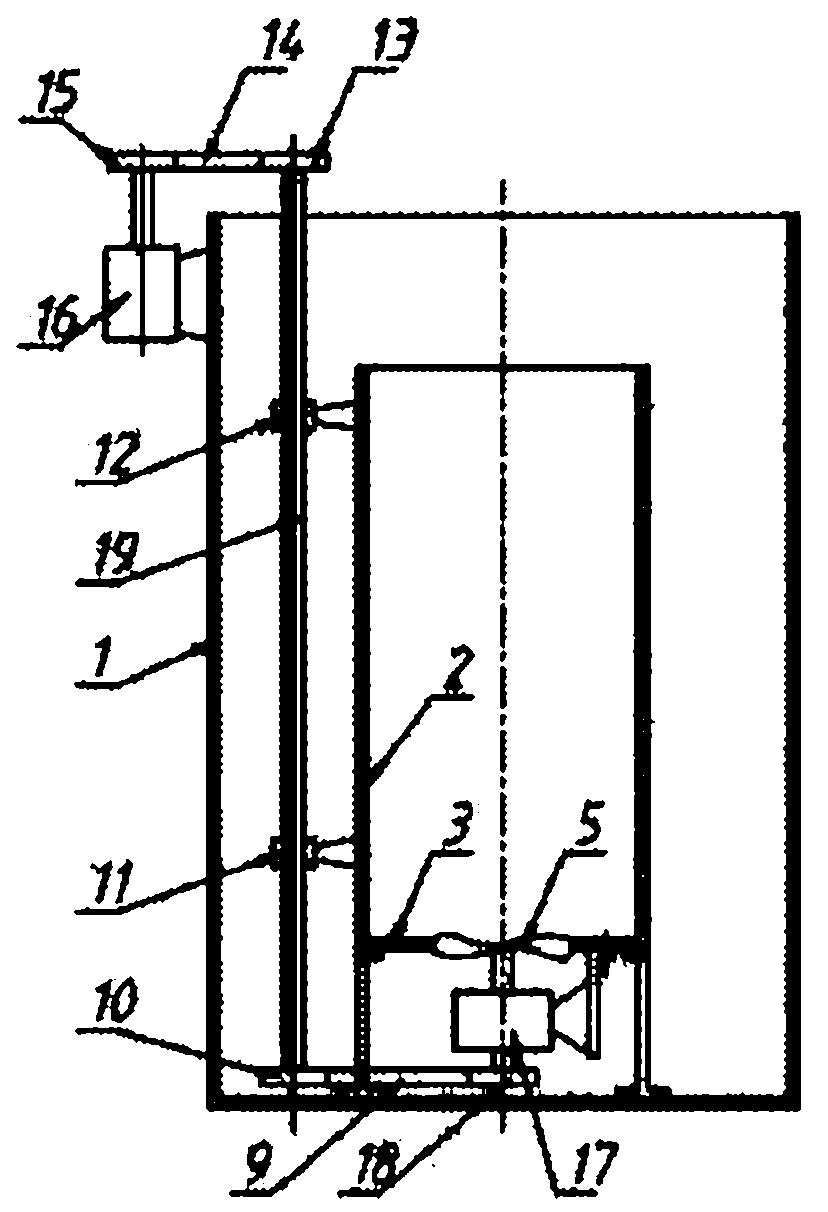

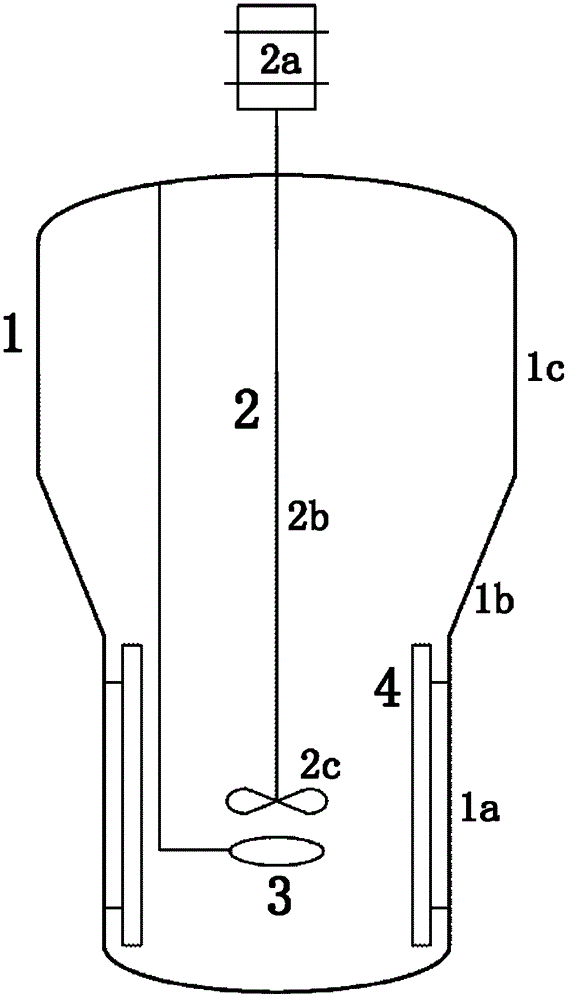

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

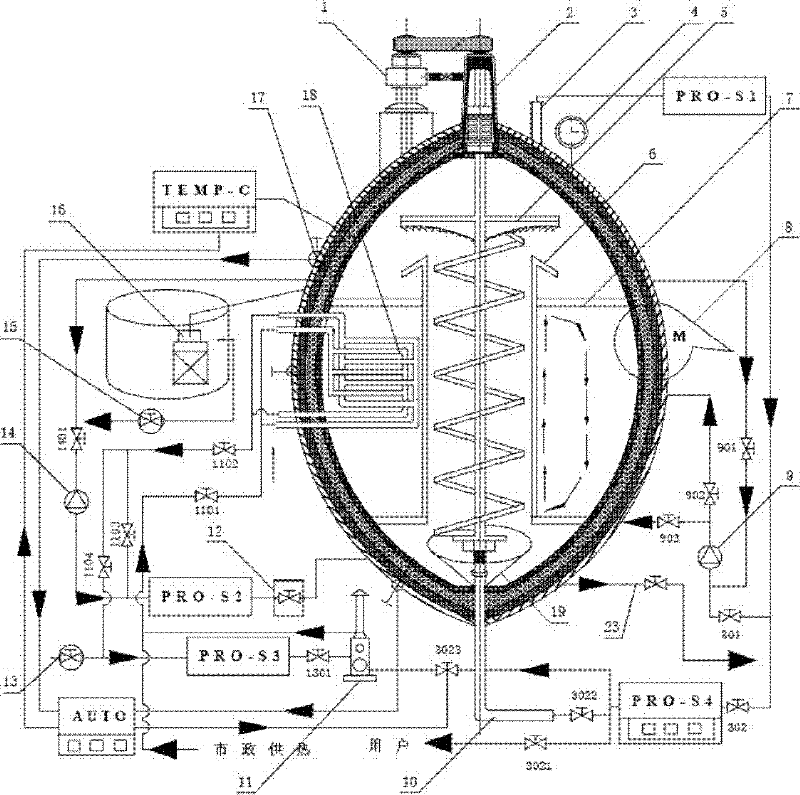

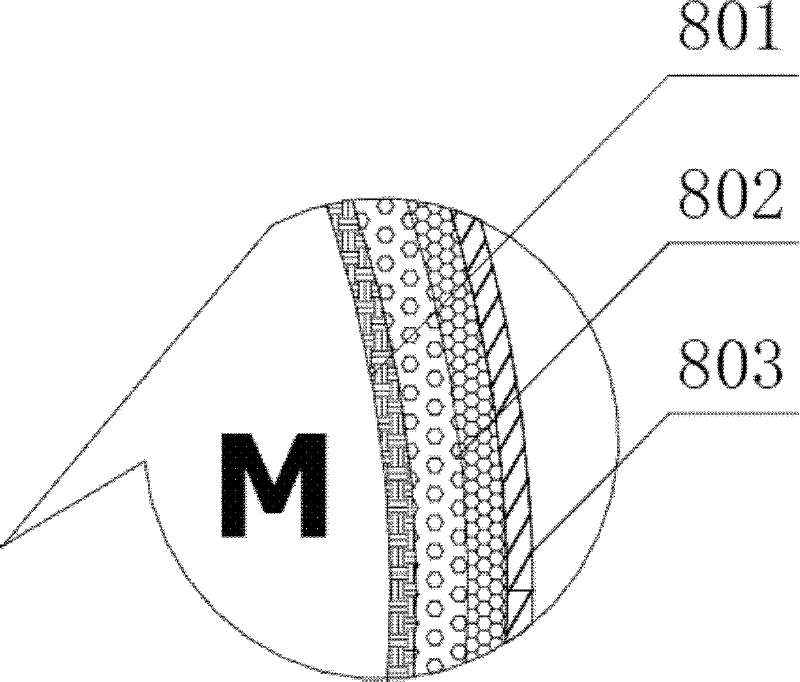

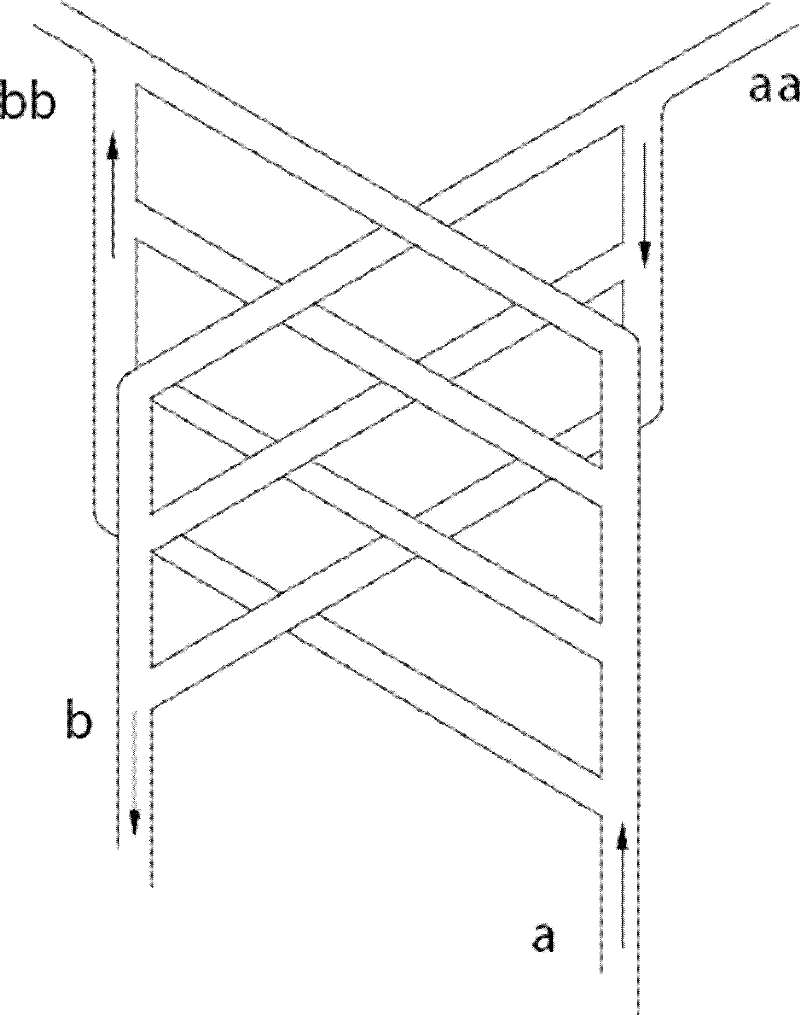

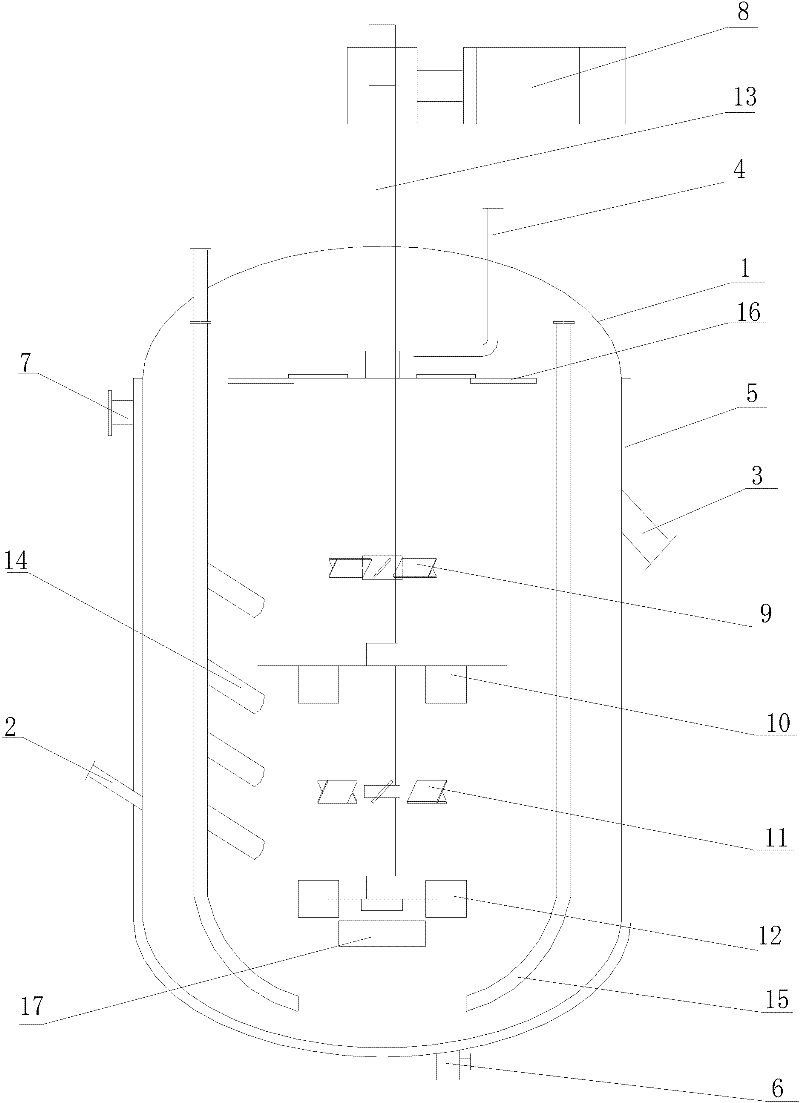

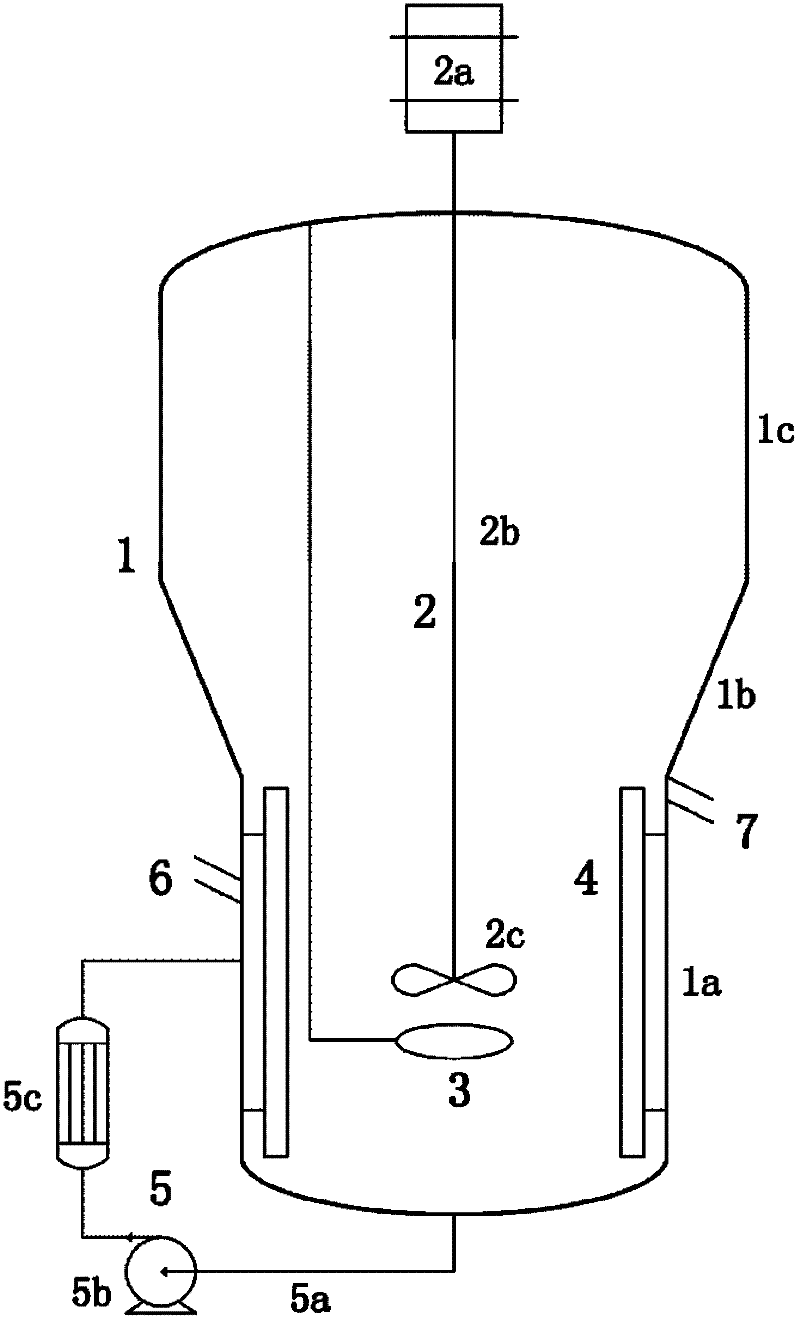

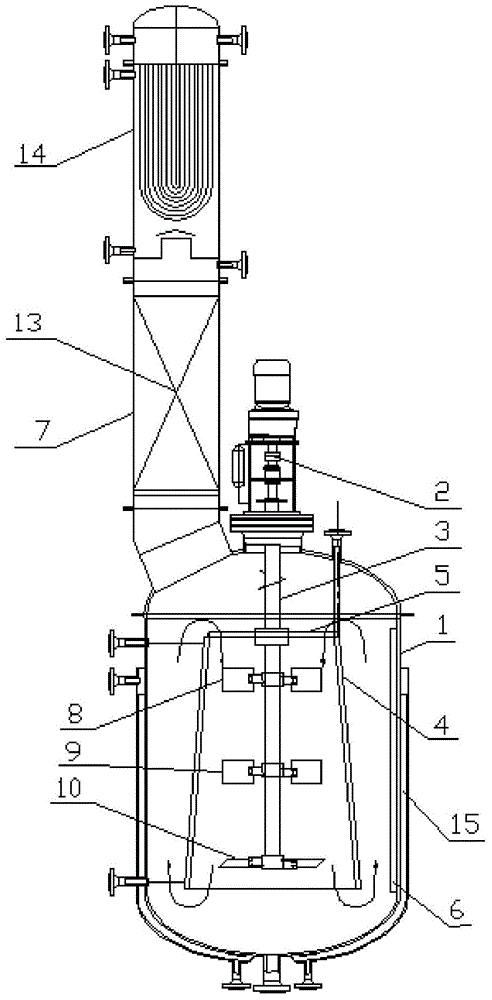

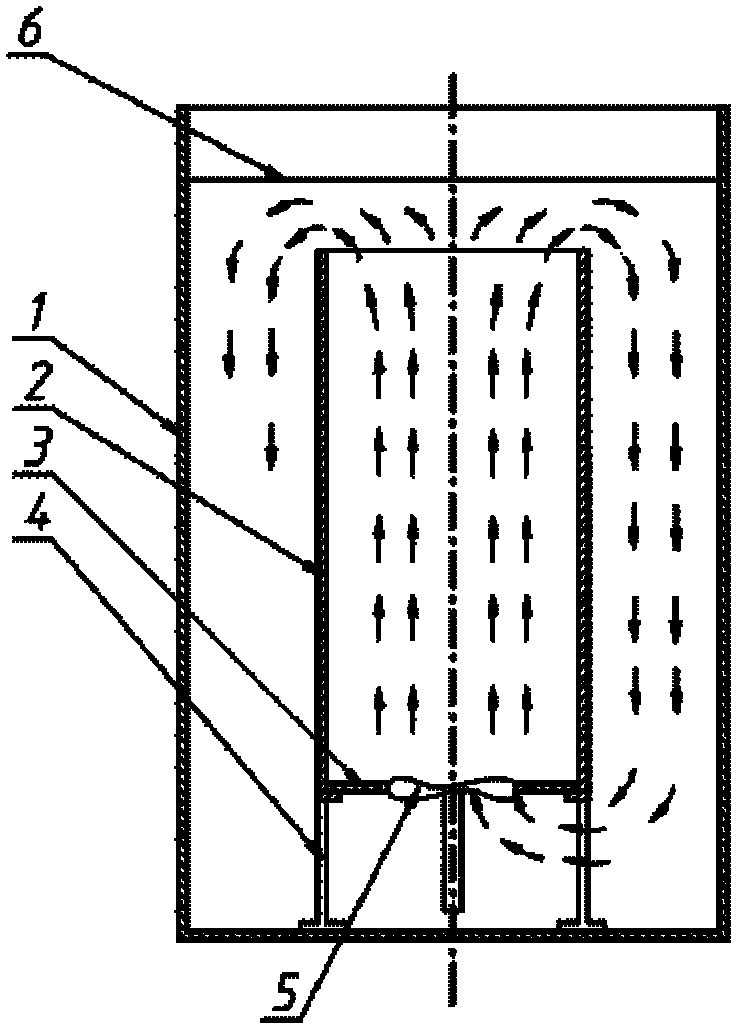

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

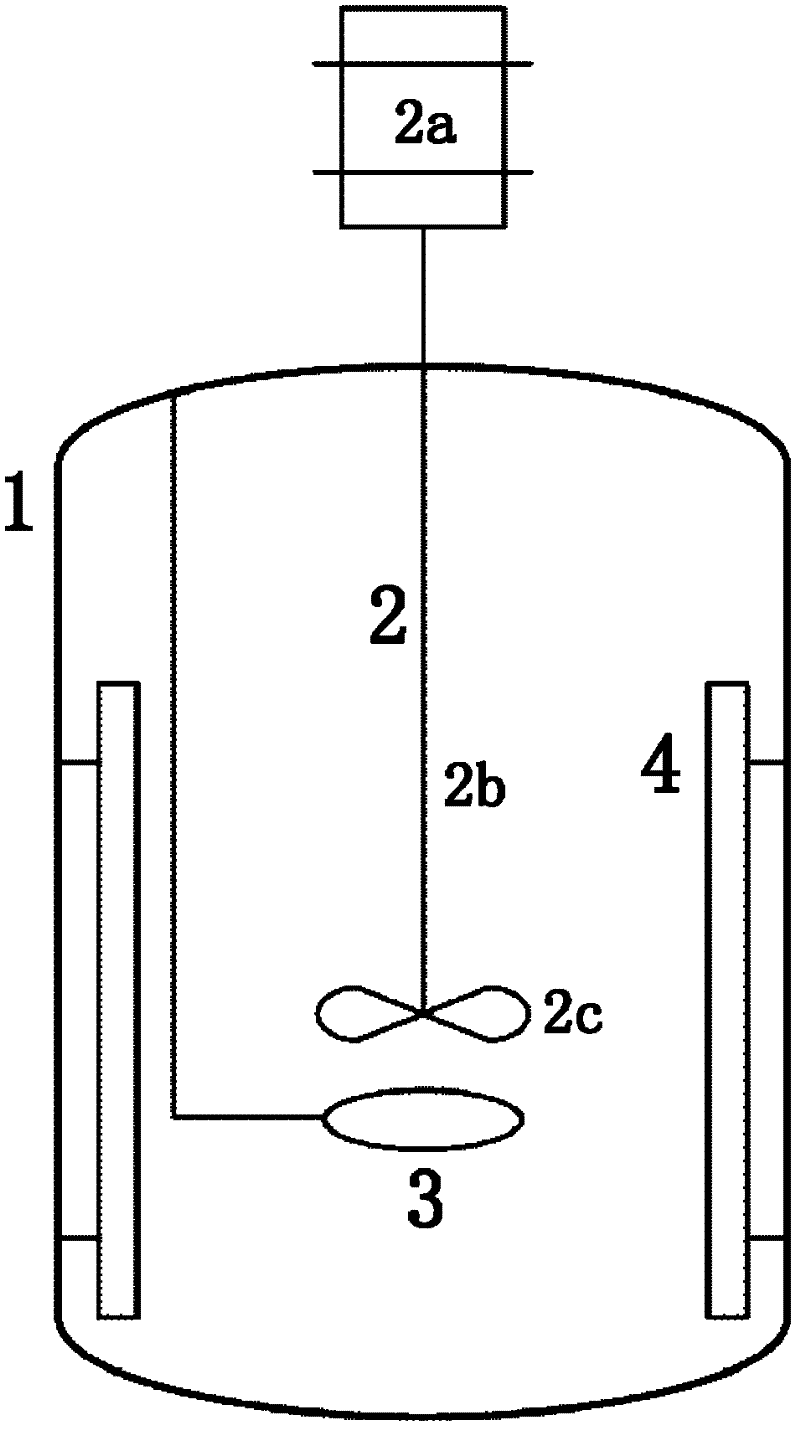

Stirred tank reactor

InactiveCN102358760ALarge circulationShort mixing timeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsSizingProcess engineering

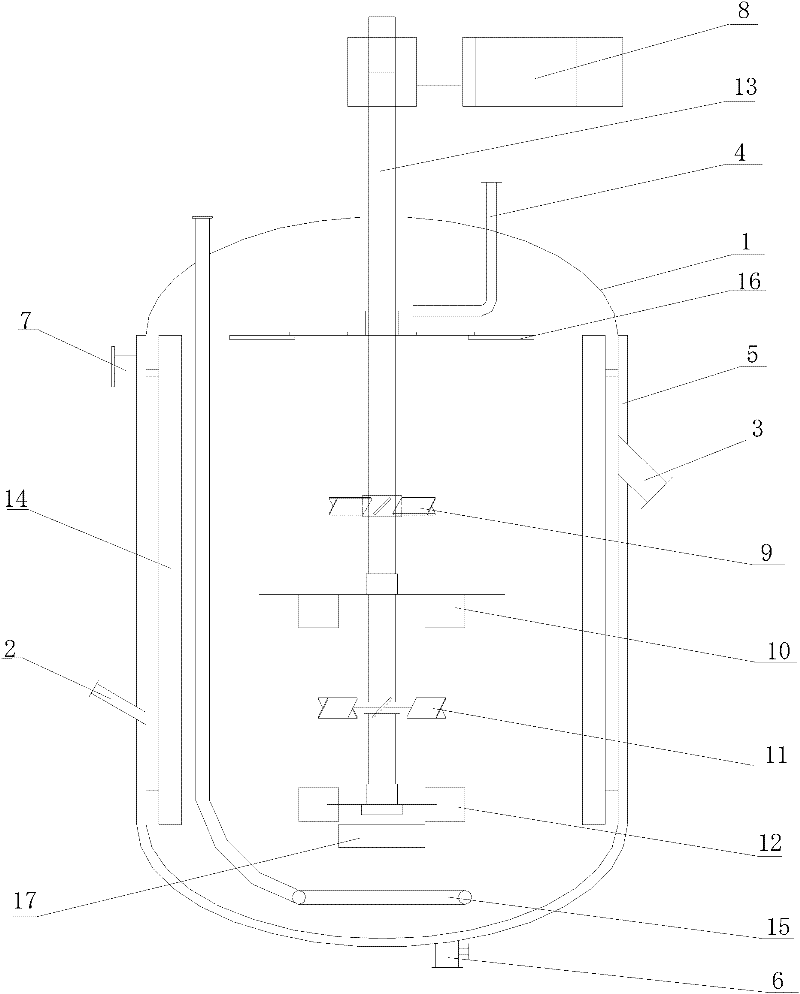

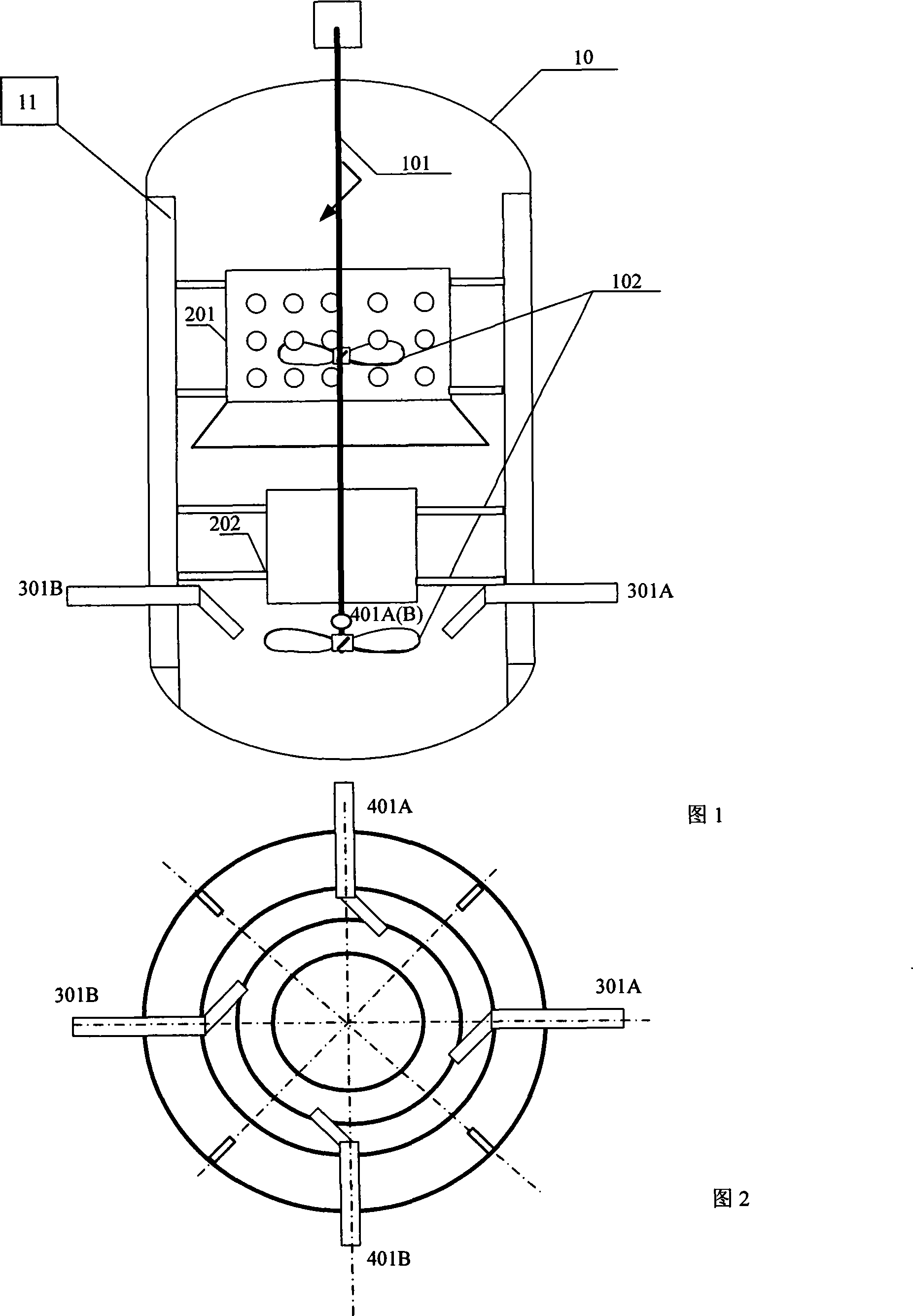

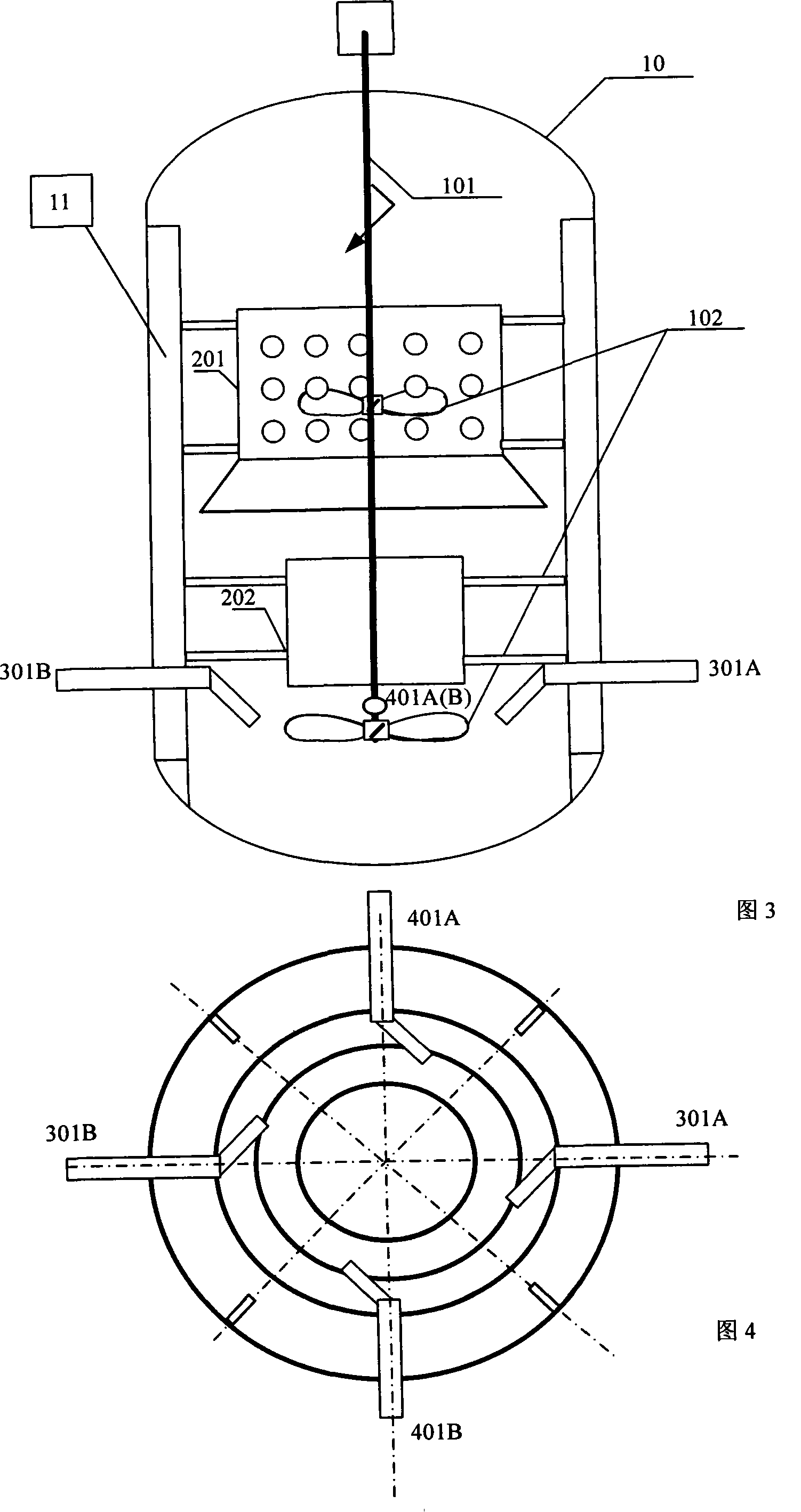

The invention discloses a stirred tank reactor and aims at improving a stirring turbine in the stirred tank reactor by using a four-layer combination stirring turbine. The stirring turbine comprises a first layer turbine, a second layer turbine, a third layer turbine and a fourth layer turbine which are arranged from the middle to the bottom of a stirring shaft sequentially. The first layer turbine is an upward axial flow turbine, the second layer turbine is a disk type turbine, the third layer turbine is an upward axial flow turbine, and the fourth layer turbine is a radial flow turbine. Radial circulation close to a liquid level, radial circulation close to a middle area of a stirred tank and radial circulation in a bottom area of the stirred tank are formed, so that circulation quantity inside the stirred tank is big and mixing time is short. Poor mixing area does not exist, and solid containing rate and gas containing rate are evenly distributed. A mass transfer condition of air and liquid is good, and single transfer efficiency is high. Entrainment quantity of sizing is greatly reduced, fouling of a heat exchanger is reduced, and service life is long. Operation cost is lowered, and production cost is saved.

Owner:ZHEJIANG UNIV

Oxidation reactor for producing polybasic carboxylic acid

ActiveCN101172939AImprove distributionEvenly distributedOrganic compound preparationChemical/physical/physico-chemical stationary reactorsEngineeringCarboxylic acid

The invention relates to an oxidating reactor for producing polybasic carboxylic acids. A flow gudie cylinder is arranged in a cylindrical stand pressure container, and two layers of mixing devices are axially arranged. The pressure container is internally provided with a baffle and liquid and air inlet nozzles, wherein, the flow guide cylinder has an upper layer and a lower layer. The surface of the upper layer cylinder is provided with holes with certain shape, and the lower end surface has a tapered expansion. The invention adopts the optimized and combined dual-layer flow guide cylinder mixing devices. Under the co-action of a mixing impeller and the flow guide cylinder, the materials of the oxidation reaction disperse rapidly to distribute the methyl aromatic hydrocarbon entering the container evenly in the solvent, and quickly react with the oxygen, and then the heat is rapidly transmitted out through even mixing and dispersing, so as to make the internal temperature of the container even, satisfy the technical requirements of oxidation and reduce the possibility of aggravated side reaction caused by partial high temperature.

Owner:SINOPEC YANGZI PETROCHEM

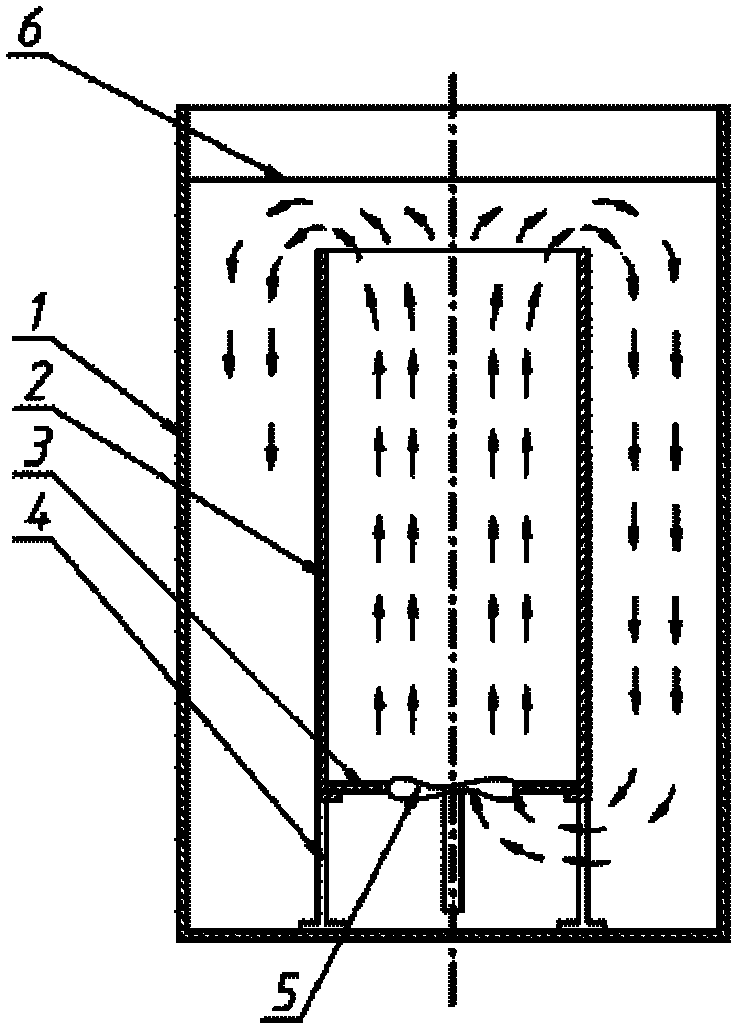

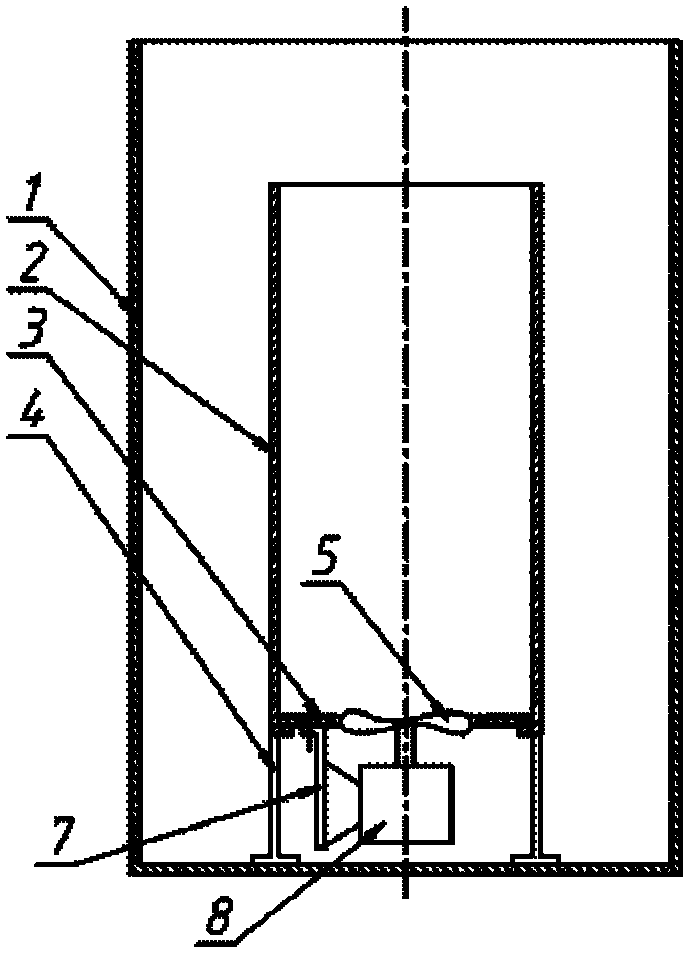

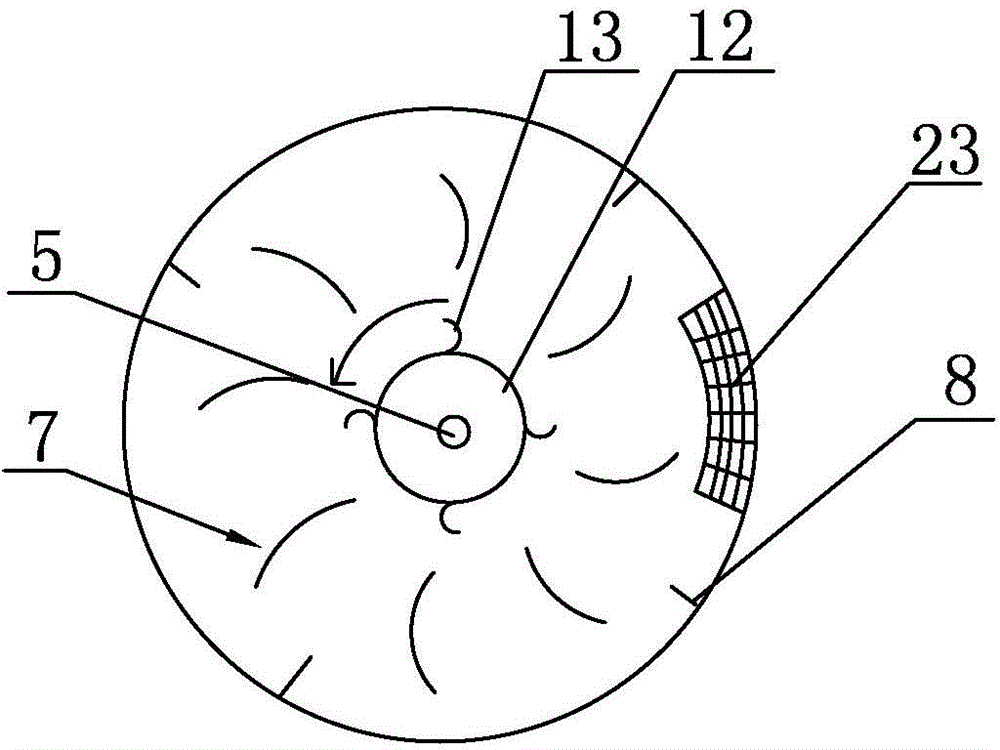

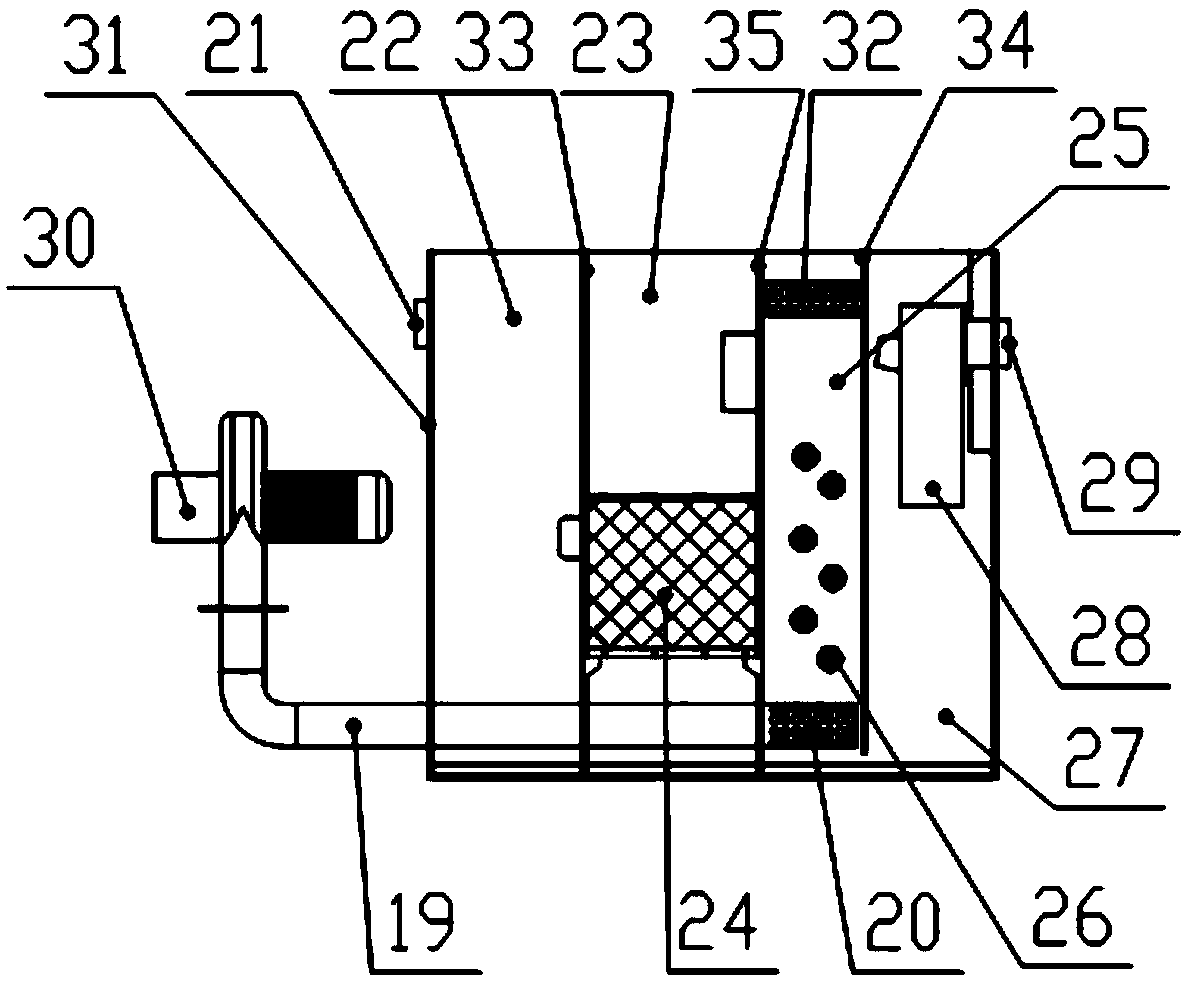

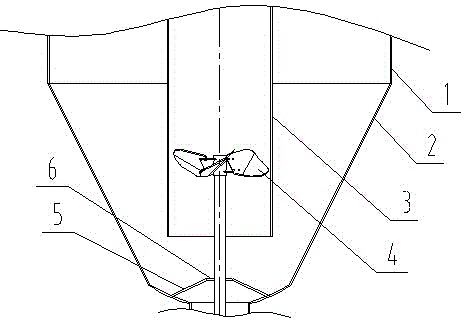

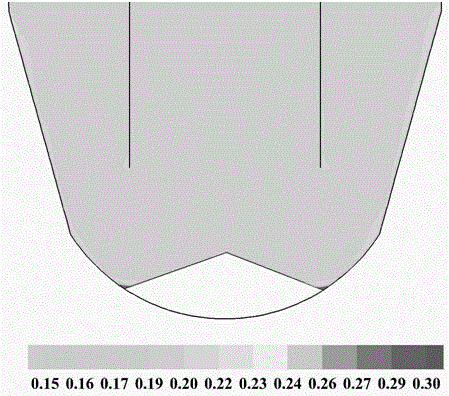

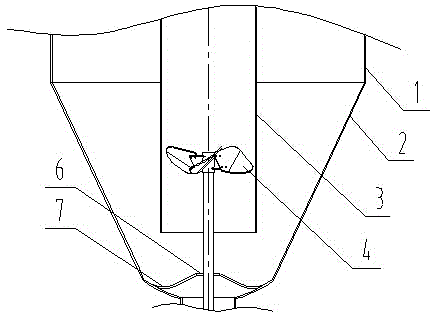

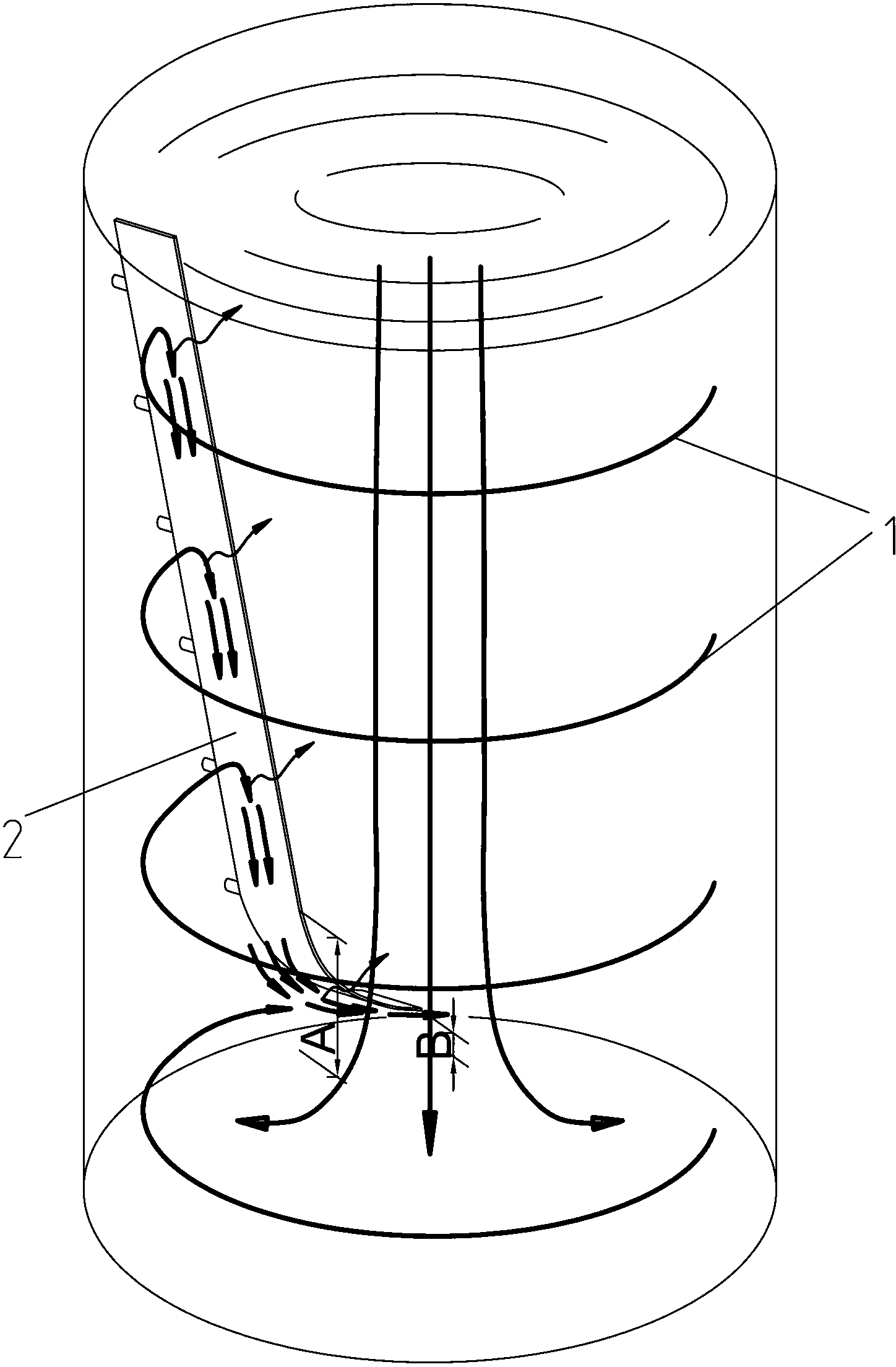

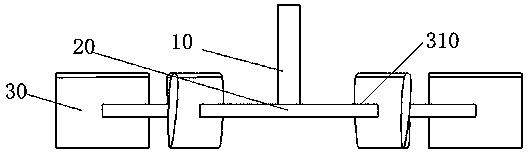

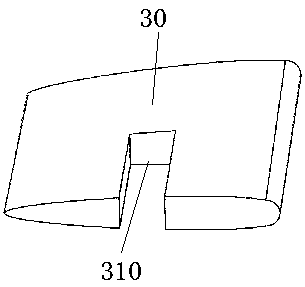

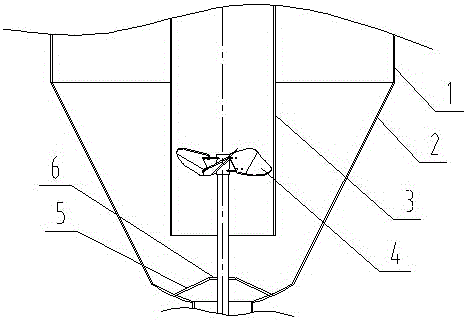

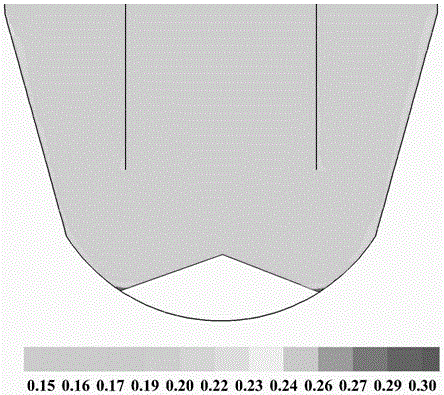

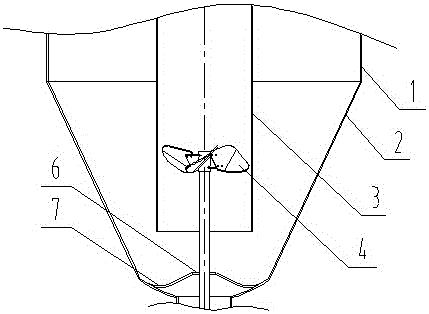

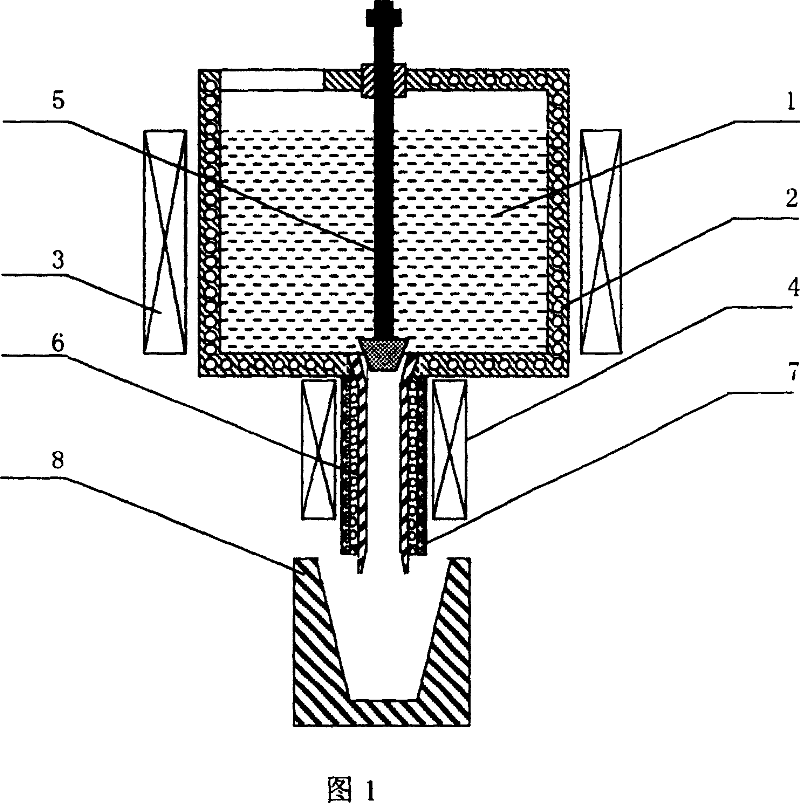

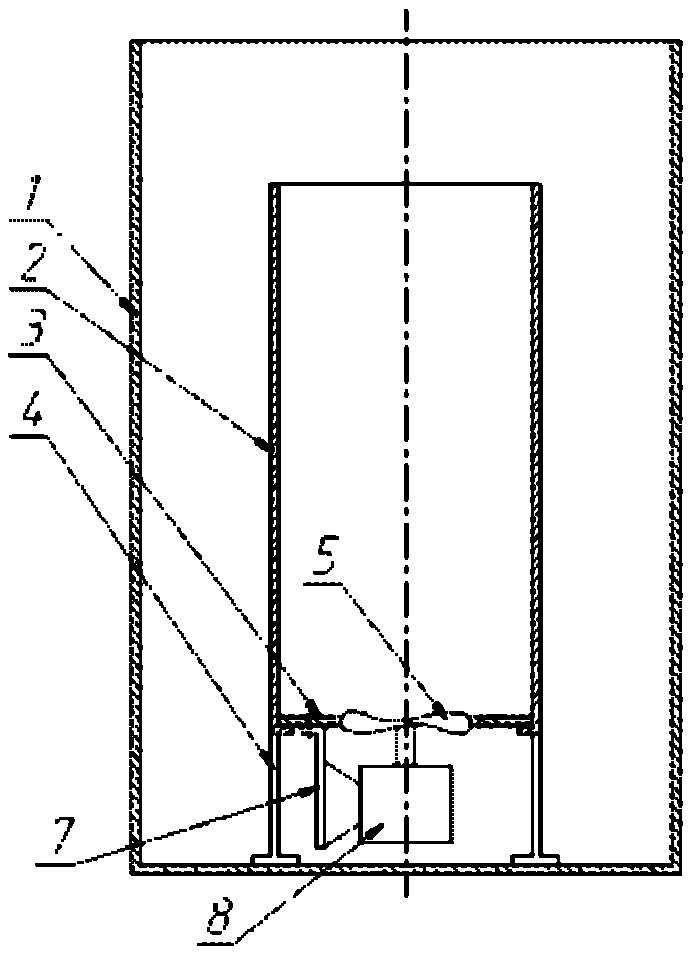

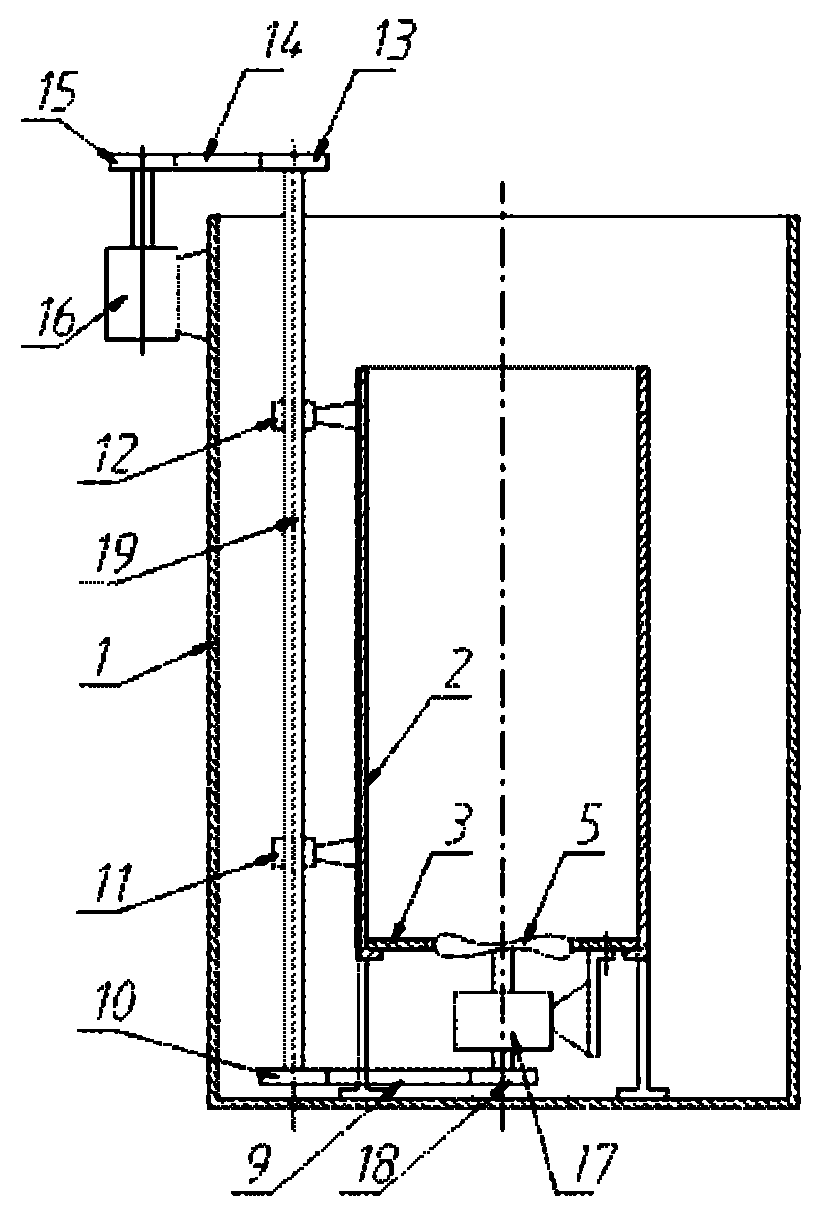

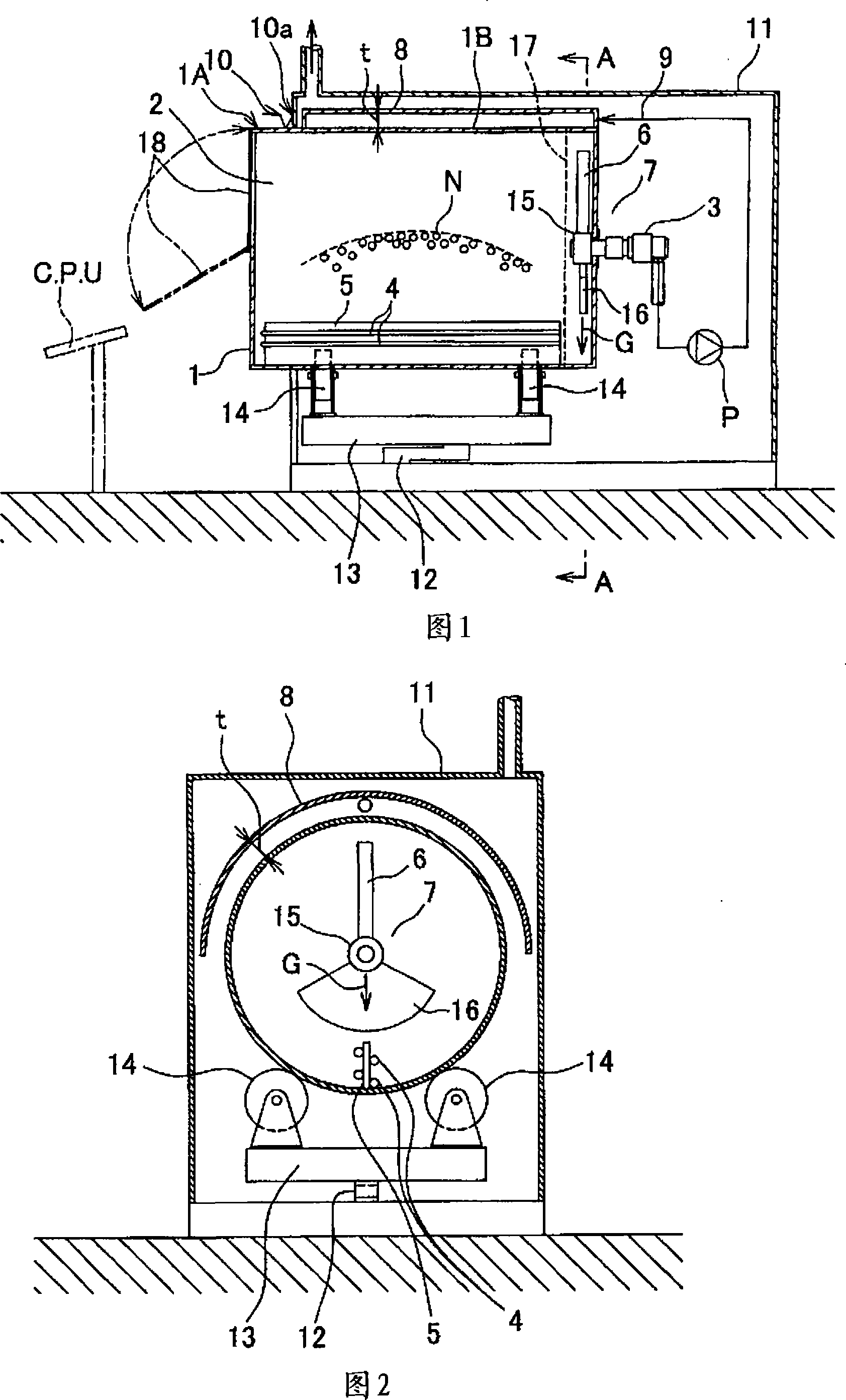

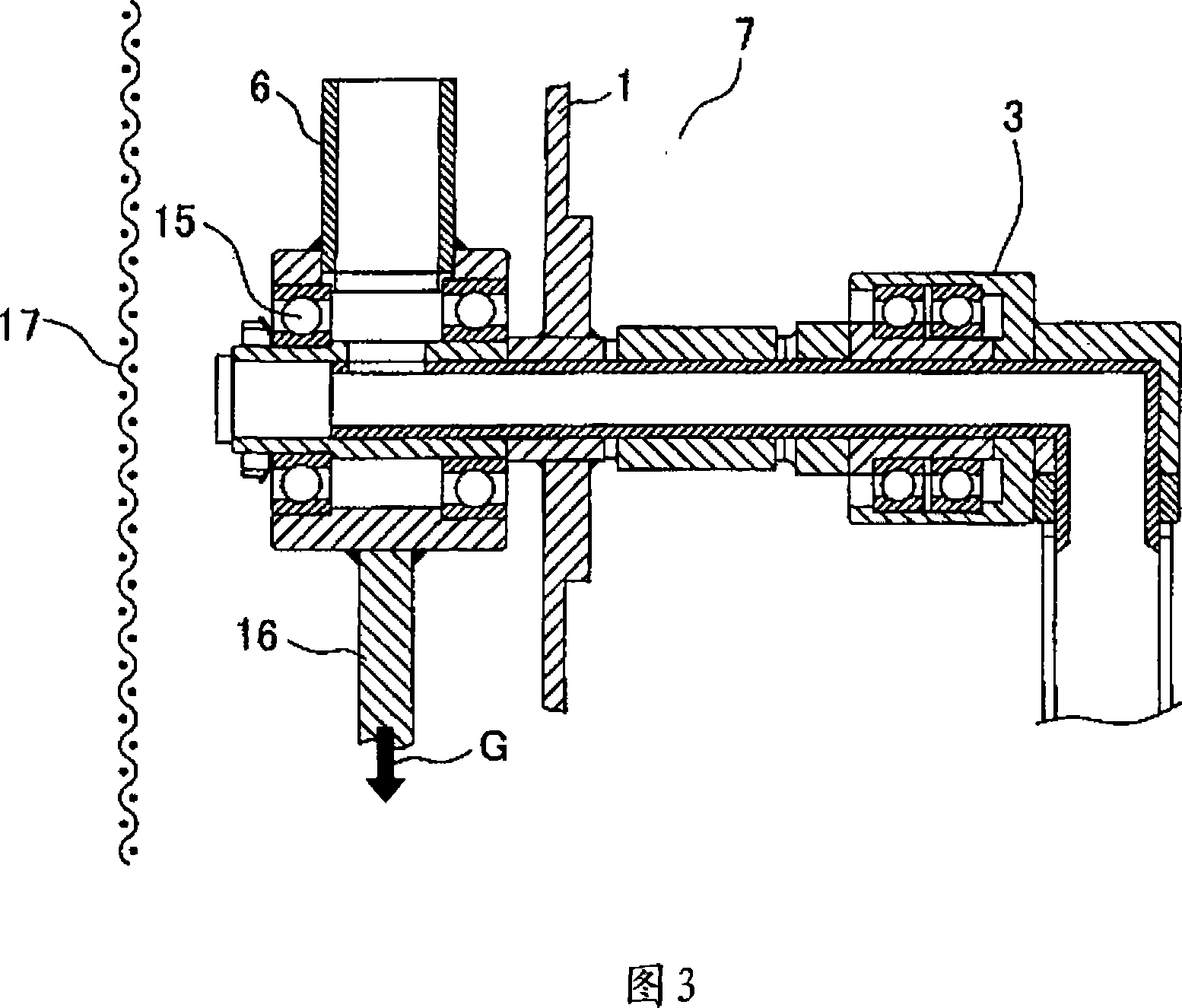

Combined quenching tank provided with inner tank with bottom inserted propeller

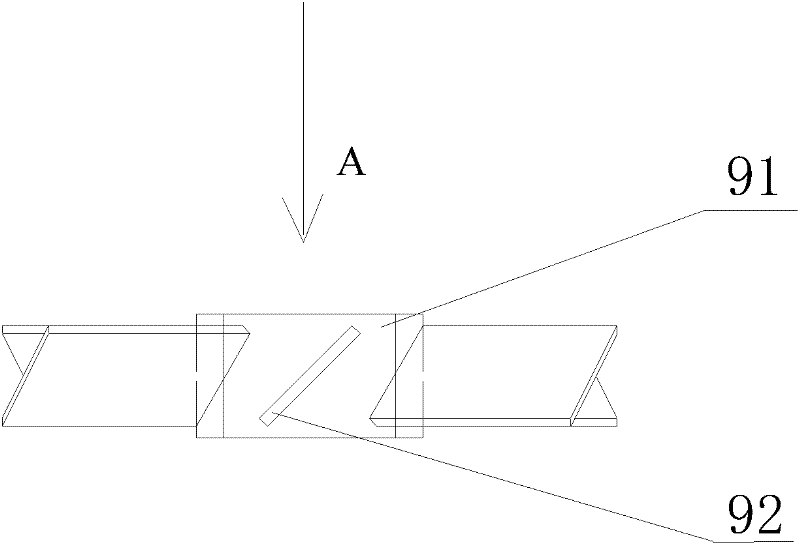

ActiveCN102352428AReduce stirring powerImprove flow uniformityQuenching devicesMetallic materialsPropeller

The invention discloses a combined quenching tank provided with an inner tank with a bottom inserted propeller, and belongs to the technical field of metal material heat treatment. The combined quenching tank comprises an outer tank, a support, at least one inner tank and corresponding bottom plate, and at least one stirring mechanism, wherein the outer tank and the inner tank form a structure which can be separated or combined relatively, the inner tank, the bottom plate and the support are arranged in the outer tank from top to bottom, the stirring mechanism is arranged in a corresponding water inlet on the bottom plate, the liquid at the bottom of the outer tank is delivered into the inner tank under the drive of the stirring mechanism, and the liquid moves in the inner tank from bottom to top, overflows from an upper opening of the inner tank to a gap between the outer tank and the inner tank and flows down and back to the bottom of the outer tank. By adopting the combined quenching tank provided with the inner tank with the bottom inserted propeller, higher stirring capability, uniform and oriented flow field and good cooling capability can be obtained. Meanwhile, the combined quenching tank structure can be combined flexibly according to the size of the workpiece and can also facilitate the installation, repair and cleaning of the equipment.

Owner:SHANGHAI JIAO TONG UNIV

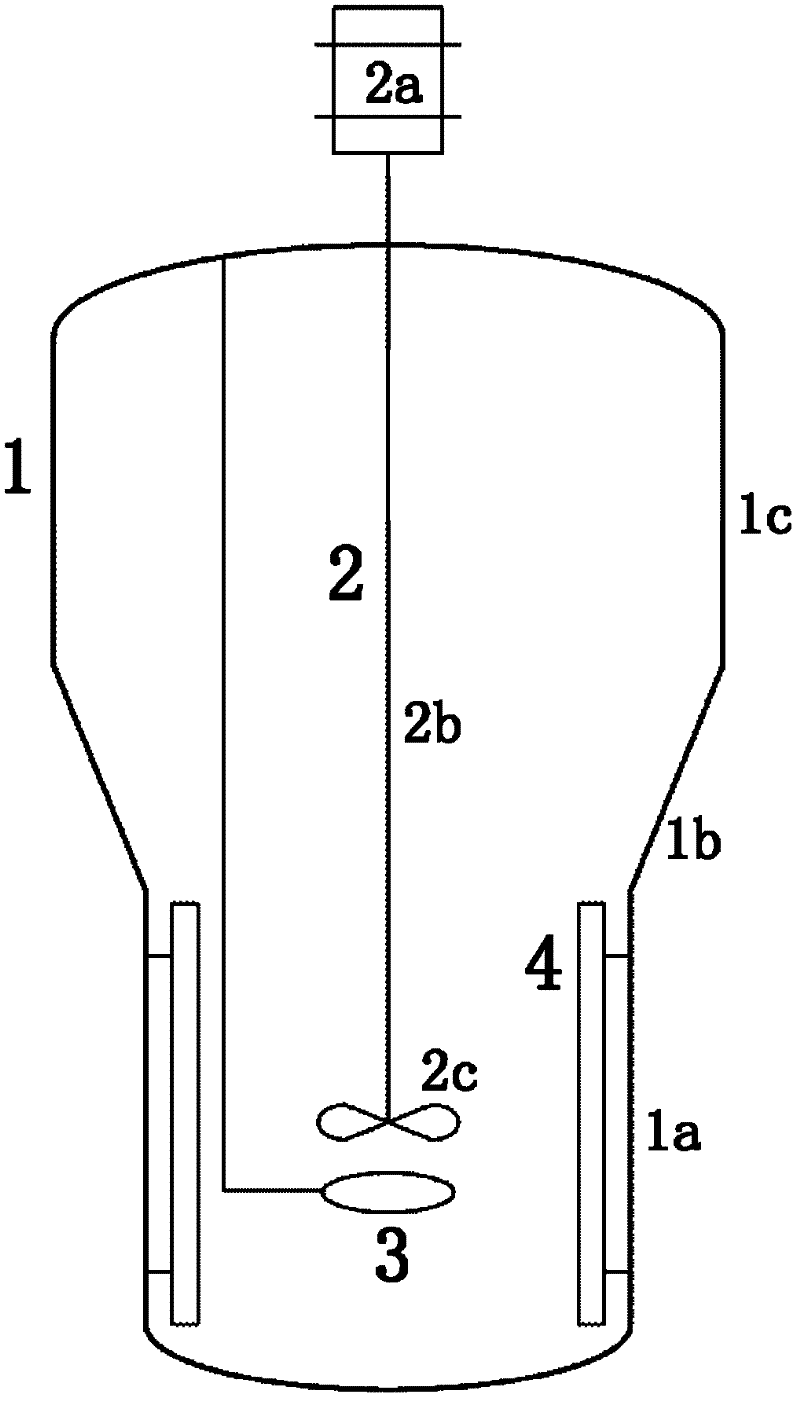

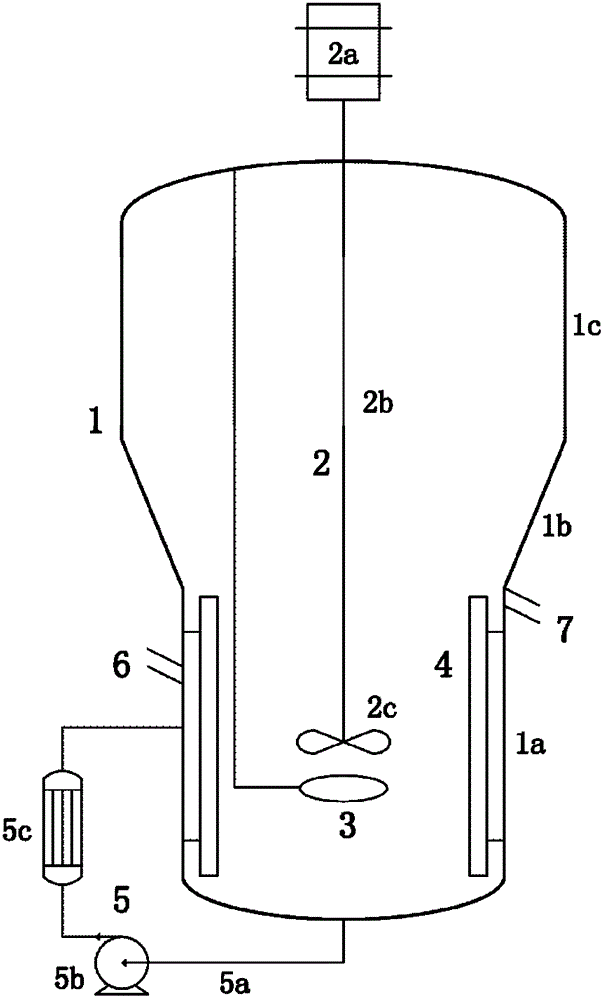

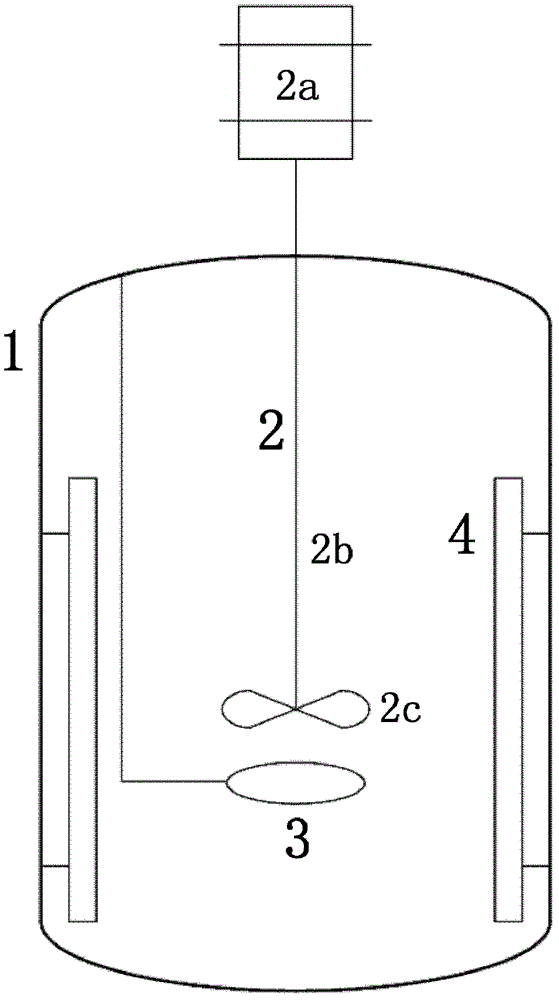

Olefin polymerization reactor

The invention discloses an olefin polymerization reactor. The reactor comprises a polymerization kettle body, a stirring device, a feeding port and an overflowing port, wherein the polymerization kettle body is composed of a reaction segment, an enlargement segment, and a connection segment located between the reaction segment and the enlargement segment; the stirring device is arranged at the center inside the polymerization kettle body, is used for stirring raw materials in the kettle, and is composed of a transmission device, a stirring shaft and a stirring turbine which are sequentially connected; the feeding port is arranged on the side wall of the reaction segment of the polymerization kettle body and is used for adding solvent, catalyst and the like; and the overflowing port is used for discharging the slurry and controlling the liquid level in the kettle. By using the reactor, the entrainment can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle

ActiveCN104128133AIncrease contact timeIncrease contact areaHydrocarbon by hydrogenationChemical industryLiquid jetTemperature control

The invention discloses a swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle. The reaction kettle comprises a cylindrical kettle body which is arranged vertically. A discharge port, a liquid feeding port, and a gas feeding port are sequentially arranged from top to bottom on the side wall of the kettle body. A central shaft connected with an outside motor is arranged vertically in the kettle body. The reaction kettle is characterized in that three layers of vertically arranged swept-back half-pipe turbo agitators are arranged on the central shaft. 6-10 high-efficiency heat-exchange diversion rectification devices are horizontally uniformly distributed between the outer end of the swept-back half-pipe turbo agitators and the inner wall of the kettle body. 4-6 sheets of side wall diversion full baffles are uniformly distributed on the inner wall of the kettle body. A liquid jet distributor connected with the liquid feeding port and a gas jet distributor connected with the gas feeding port are arranged on the bottom of the kettle body. An overflow zone is arranged in the kettle body. Reaction products pass through the overflow zone and is collected from the discharge port. The swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle has the advantages of good multiphase system mixing effect, large heat-exchange area, and precise temperature control.

Owner:SEDIN NINGBO ENG

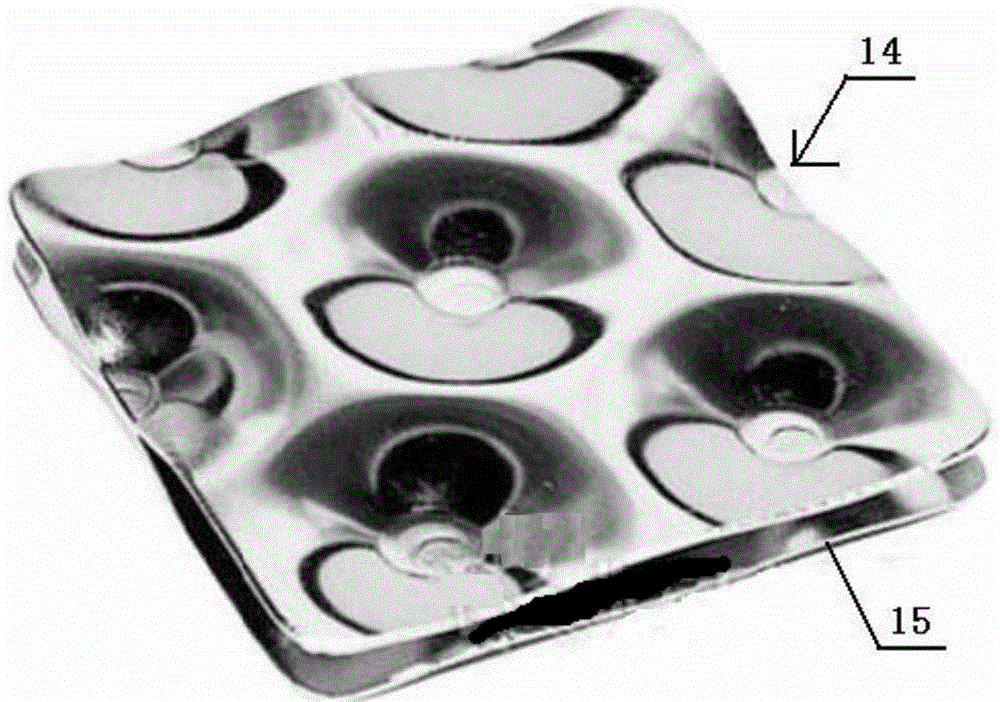

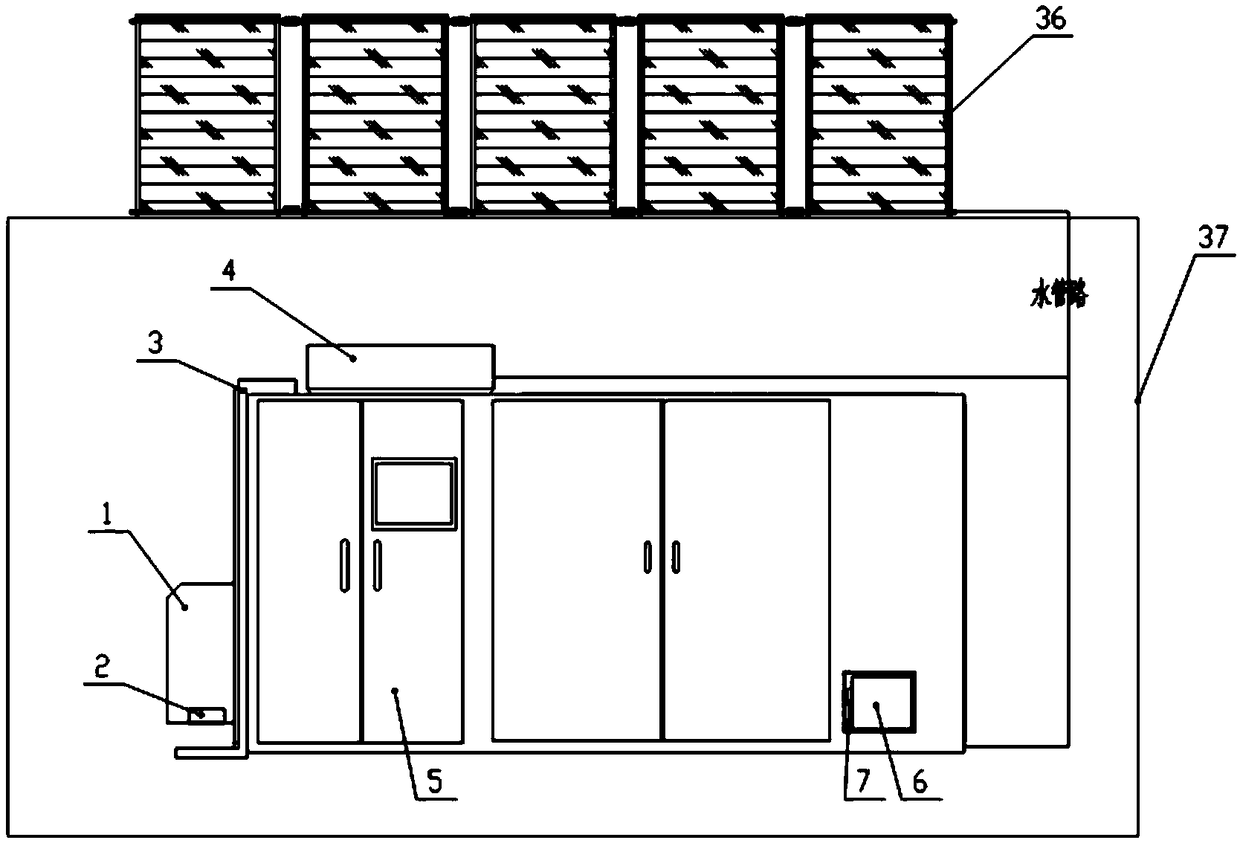

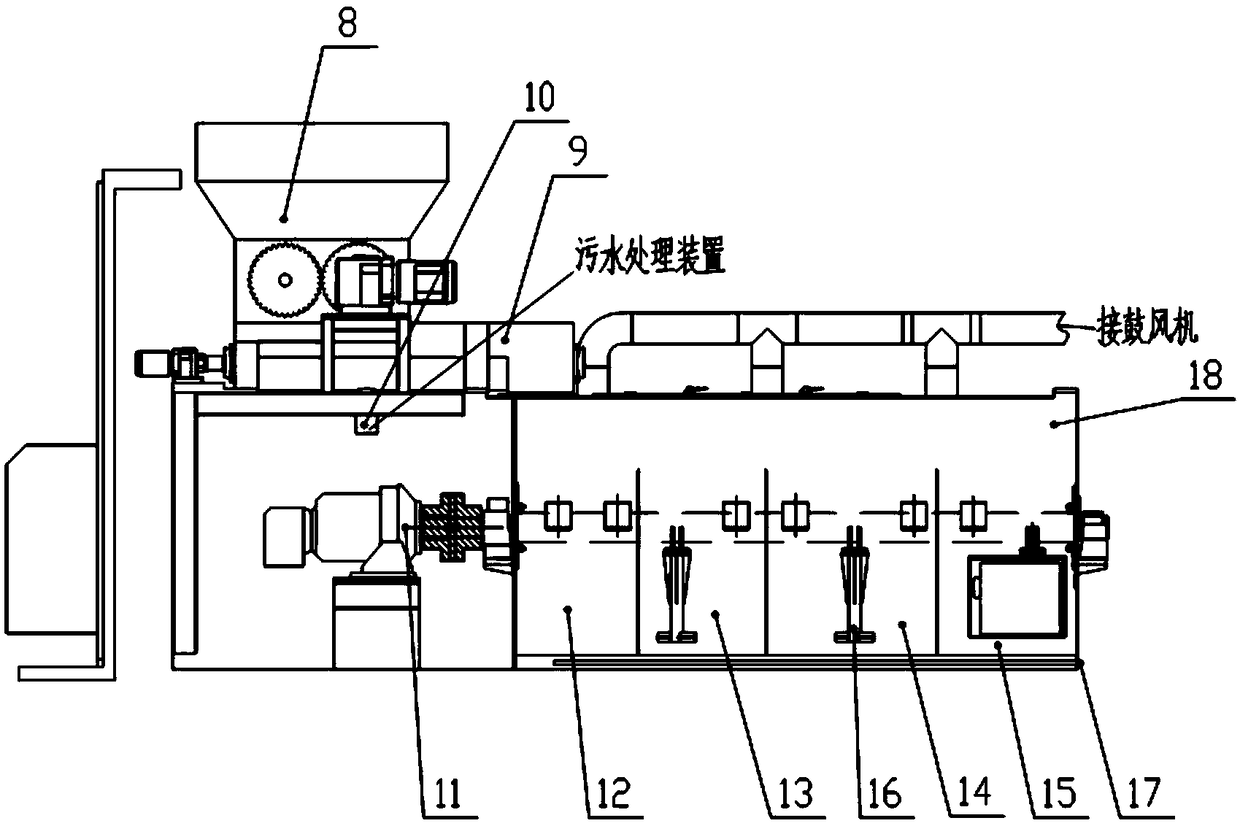

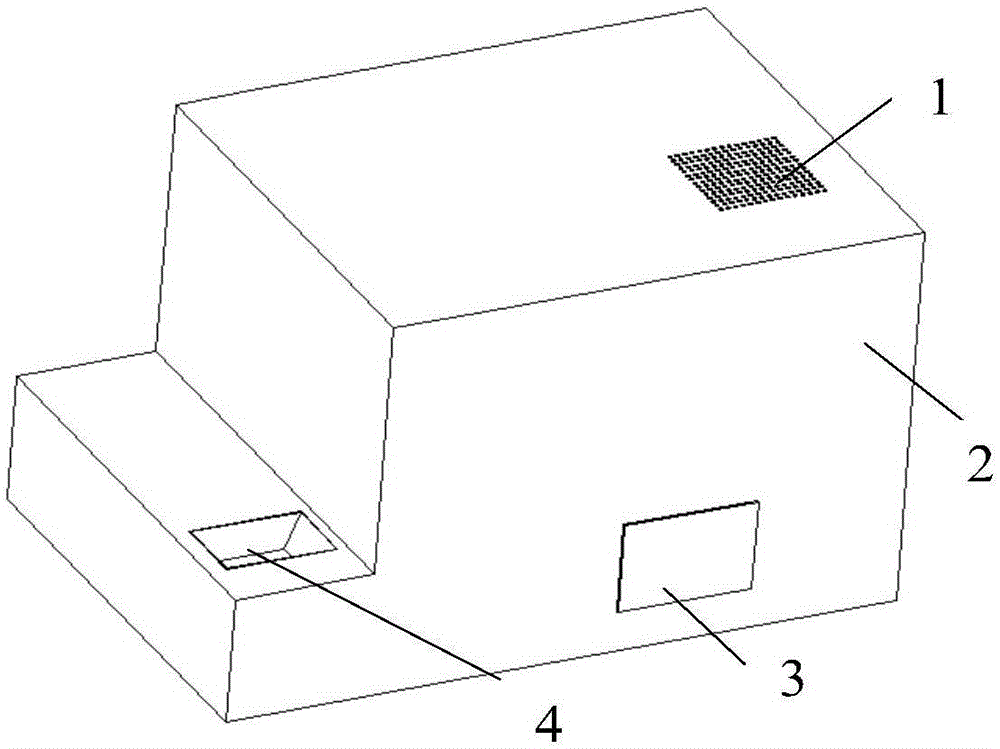

Organic rubbish resourceful treatment equipment

PendingCN108840725AReduce pollutionGuaranteed to be environmentally friendlySolar heating energyGas treatmentControl systemSmall footprint

The invention discloses organic rubbish resourceful treatment equipment. The organic rubbish resourceful treatment equipment comprises an automatic feeding device, a crushing device, a dewatering device, a fermentation device, a sewage treatment device, a tail gas treatment device, an automatic discharging device and a long-distance control system, wherein the automatic feeding device, the crushing device, the dewatering device, the fermentation device, the sewage treatment device, the tail gas treatment device and the automatic discharging device are sequentially arranged; the long-distance control system can monitor the operation state of the equipment, and can set operation parameters of the equipment in a long-distance manner to control the equipment to operate. The organic rubbish resourceful treatment equipment disclosed by the invention has the characteristics of being small in floor space, low in heating energy consumption, low in stirring power, good in fermentation effect andthe like; integration treatment can be realized; and harmless, reducing and resourceful treatment of organic rubbish is realized.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

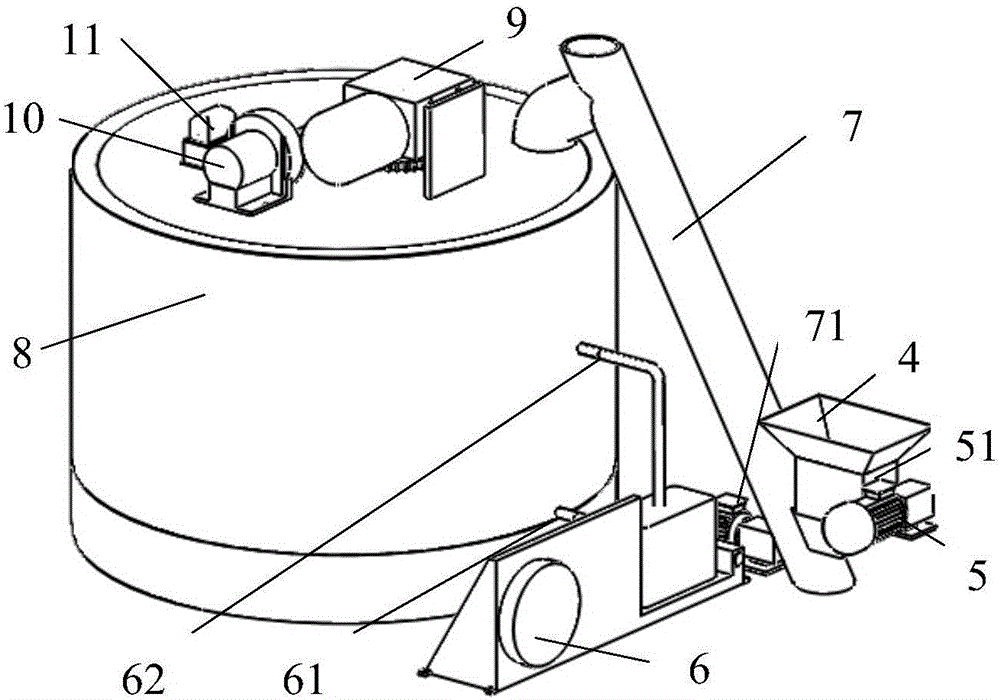

Equipment and method for disposing kitchen waste based on high-temperature aerobic fermentation technology

InactiveCN106495748AThe position of the discharge port is lowManual pouring is convenientClimate change adaptationEnergy inputFilter effectFermentation

The invention discloses equipment and a method for disposing kitchen waste based on a high-temperature aerobic fermentation technology. The equipment comprises a shell, a waste conveyor and a waste fermentation tank, wherein a pouring opening through which the waste is poured is formed in the shell, the shell is step-shaped, and the pouring opening is formed in the shell at the position of the lowest step, so that the waste is convenient to pour; the waste conveyor is arranged slantly, and the inlet end of the waste conveyor is arranged at the bottom of the pouring opening; and the outlet end of the waste conveyor communicates with the waste fermentation tank, a heating source is arranged on the periphery of the waste fermentation tank so as to heat the waste in the waste fermentation tank, the waste fermentation tank is internally provided with at least one hollow shaft, a plurality of through holes are formed in the circumferential direction of the hollow shaft, and a filter layer is arranged at the bottom of the waste fermentation tank so as to discharge liquid generated through waste fermentation. Meanwhile, the requirement for the stirring effect of stirring paddles is reduced, and the stirring power is low. The filter structure is simple and reliable. The filter layer is arranged at the bottom of the fermentation tank, and liquid in the material is filtered by adopting fine sand, so that the equipment is simple in structure and good in filter effect.

Owner:SHANDONG CRRC HUATENG ENVIRONMENT CO LTD

Drum mixer

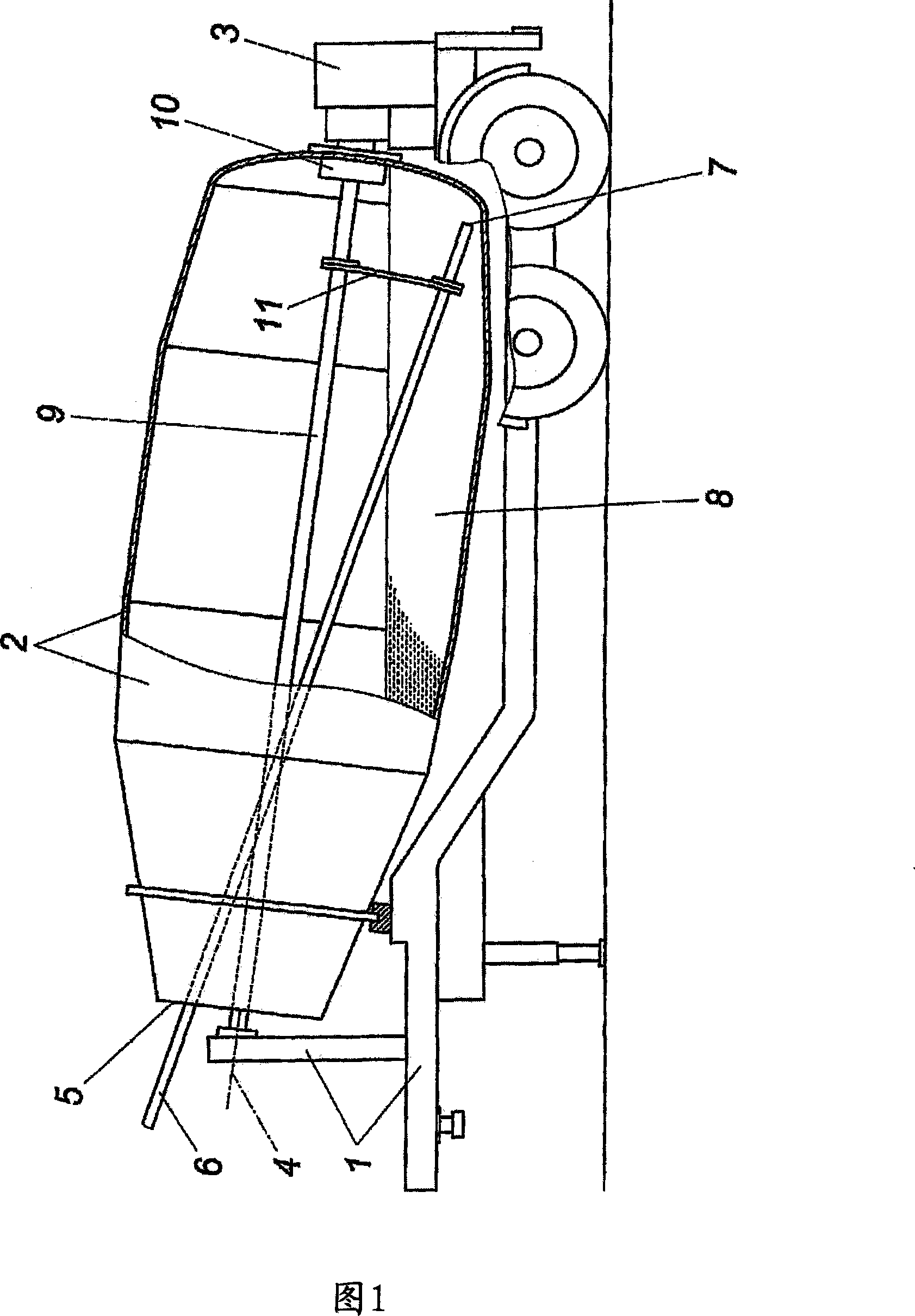

InactiveCN101237920ALow costSimple structureRotating receptacle mixersConcrete transportationMechanical engineeringEngineering

The invention relates to a drum mixer with a drum (2) of mixing material (8) rotatably supported on a support (1) and a drum (2) for rotating the drum (2) around its axis of rotation (4). The transmission device (3) has a feeding pipe (6) which receives the mixing material (8) of the drum (2) from the feeding port (5) on the end surface of the drum (2) by its feeding port (7). In order to produce an advantageous structure, it is proposed to have a support (9) connected to the support (1), which is connected in the drum (2) with the feed pipe (6) extending into the mixing material (8) of the drum (2). ) at least the partitions are force-reduced, especially rigidly connected.

Owner:库尔特·希姆尔弗洛恩德波茵特纳

Crystallizer with rectifying hood

ActiveCN104826357APromote growthStable flow patternSolution crystallizationEngineeringMechanical engineering

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Stirred tank with baffle plates capable of reducing accumulating materials at tank bottom

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Novel car paint stirring paddle

InactiveCN110141984ASpeed up the flowPromotes convective circulationRotary stirring mixersTransportation and packagingCircular discConvective diffusion

The invention provides a novel car paint stirring paddle, which comprises a middle stirring shaft. The stirring shaft is coaxially and fixedly connected to a round disc. Blades are uniformly and fixedly arranged along the periphery of the round disc. The vertical cross section of each blade is in a leaf shape. The periphery of each blade is a curved surface. The middle of each blade is provided with a socket. Through the sockets, the blades and the round disc are fixedly connected. The flat blades are converted into cured blades. The result of a flow field simulation test shows that compared with original blades, the energy consumption is reduced, and a large shearing speed and a strong body convective diffusion performance are obtained.

Owner:FUZHOU UNIV

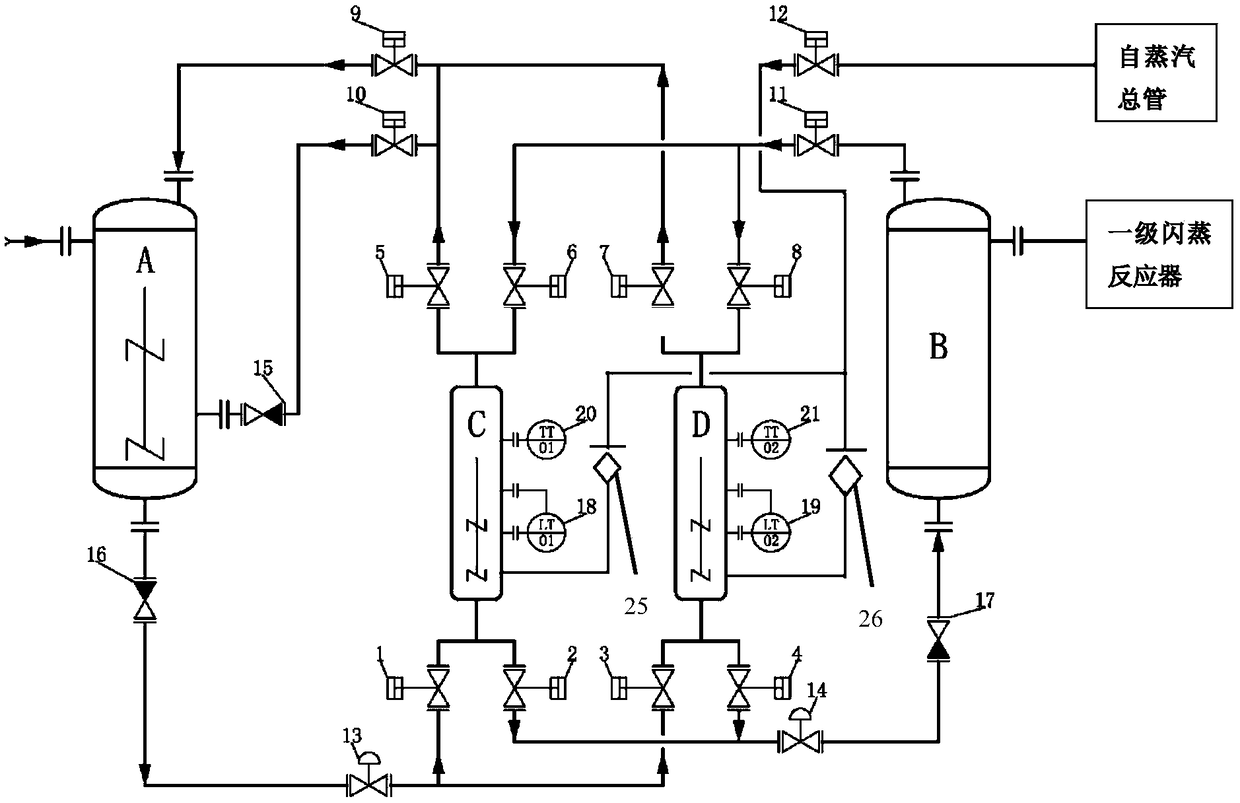

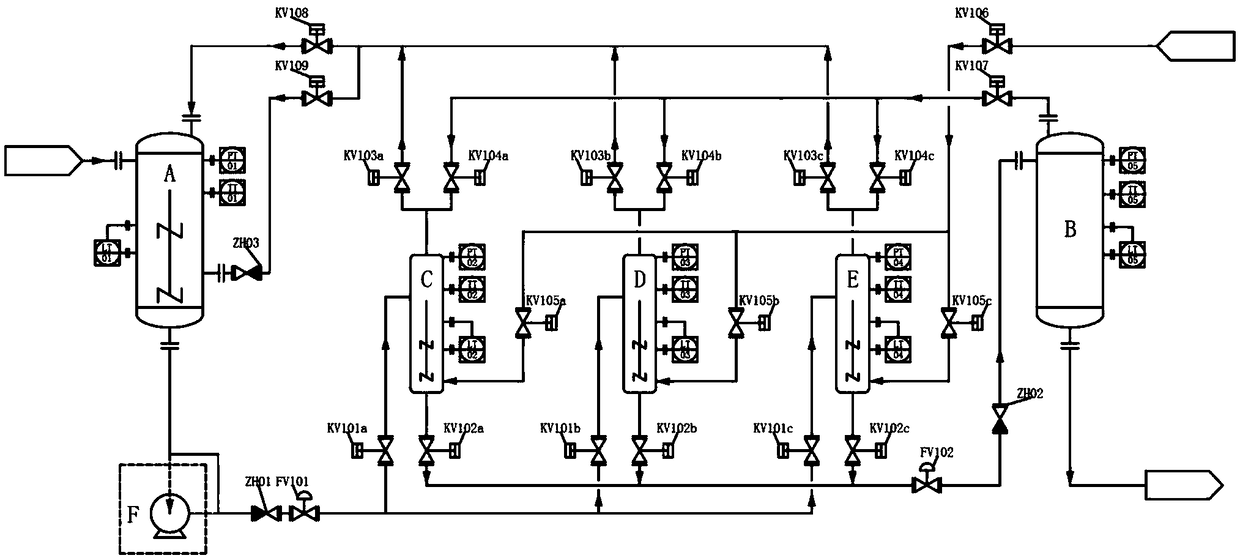

Two-stage sludge hydrothermal reaction device

InactiveCN108911478AReduce volumeLower the volumeSludge treatment by thermal conditioningResidenceSludge

The invention discloses a two-stage sludge hydrothermal reaction device. The device comprises: a plurality of slurrying reactors which are serially connected from front to back, a hydrothermal residence reactor and a plurality of flash evaporation reactors which are serially connected from front to back, and the hydrothermal residence reactor is arranged between the backmost slurrying reactor andthe headmost flash evaporation reactor, wherein at least one hydrothermal temperature reactor is also mounted between the hydrothermal residence reactor and the backmost slurrying reactor, every hydrothermal heating reactor is provided with a gas inlet tube, a gas outlet tube, a steam tube, a feed tube and a discharging tube which are connected with the corresponding hydrothermal heating reactor,a plurality of the hydrothermal heating reactors alternately run, and arrangement according to a preset timing sequence makes the discharging of the final-stage slurrying reactor and the feeding of the hydrothermal residence reactor continuously performed. The two-stage sludge hydrothermal reaction device disclosed in the invention simplifies the heating function of the hydrothermal reactor, and realizes good stirring performance, energy saving and high sludge treatment efficiency of the hydrothermal reactor.

Owner:四川深蓝环保科技有限公司

Method of preparing syndiotectic polystyrene

A process for preparing the syndiotactic polystyrene from stylene features that the metallocene compound, triisobutyl aluminium and alkyl aluminium are used as catalyst, the inertial solvent is used as medium and reaction temp is 10-100 deg.C.

Owner:CHINA PETROLEUM & CHEM CORP +2

A crystallizer with fairing

ActiveCN104826357BPromote growthStable flow patternSolution crystallizationEngineeringMechanical engineering

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

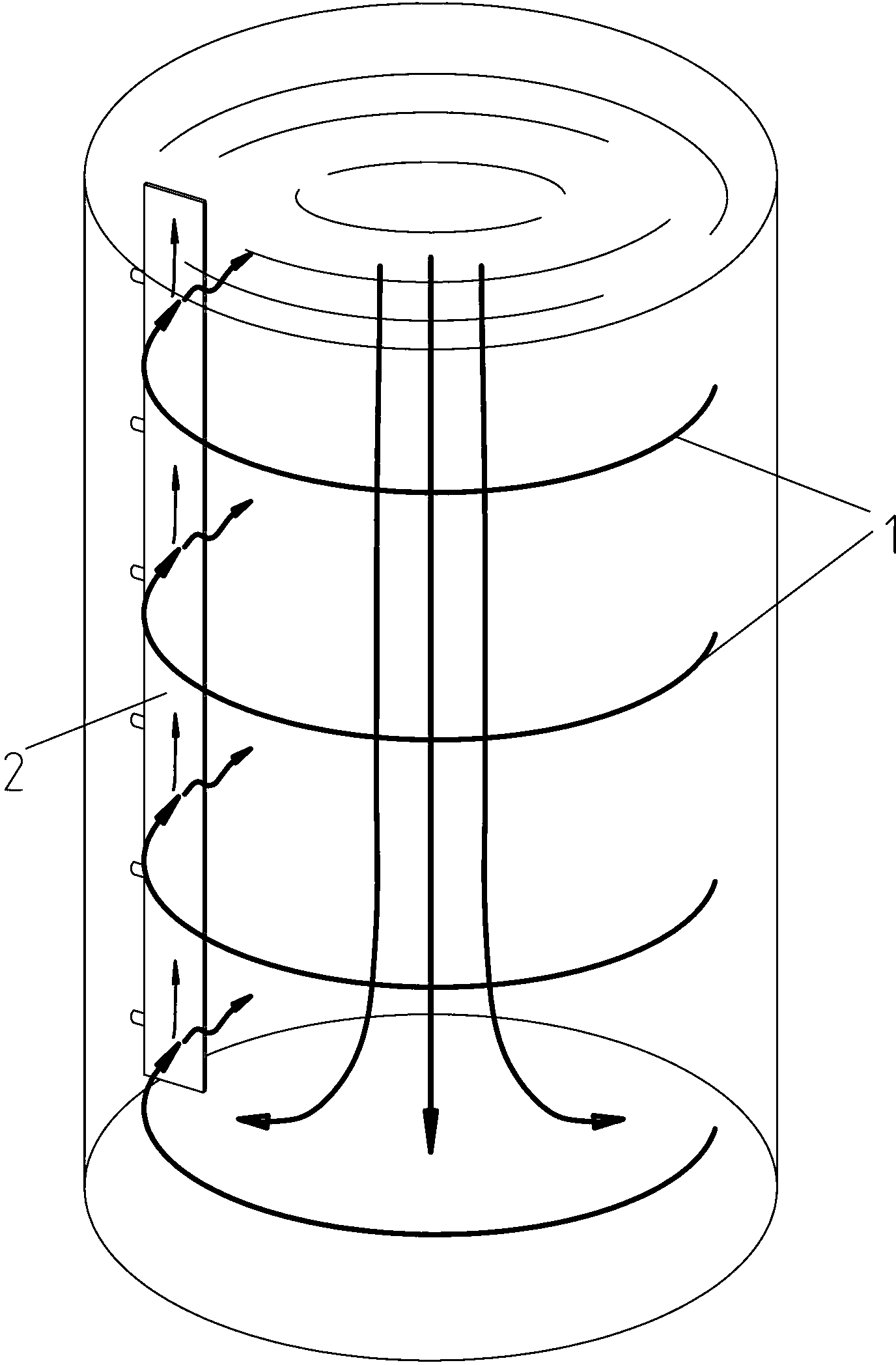

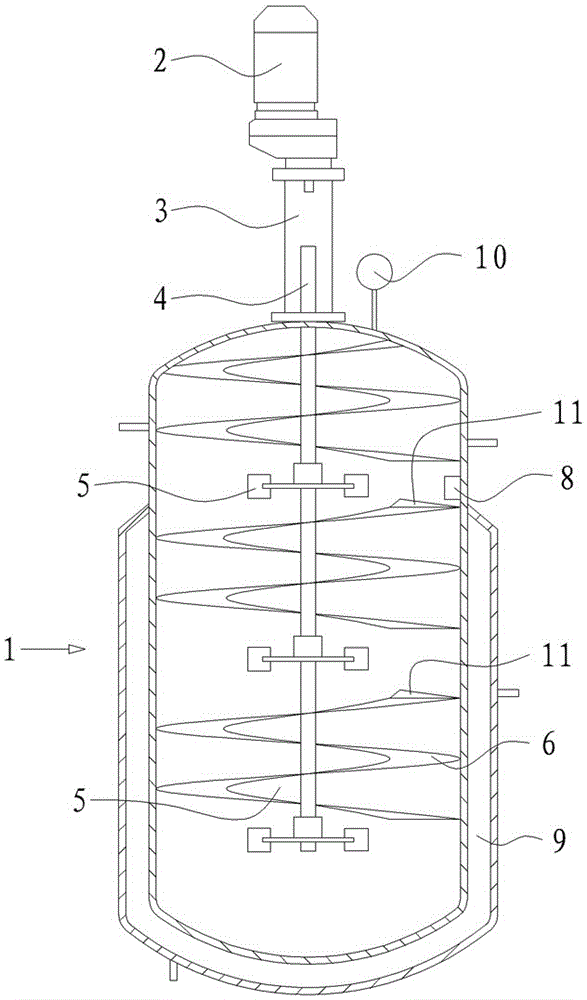

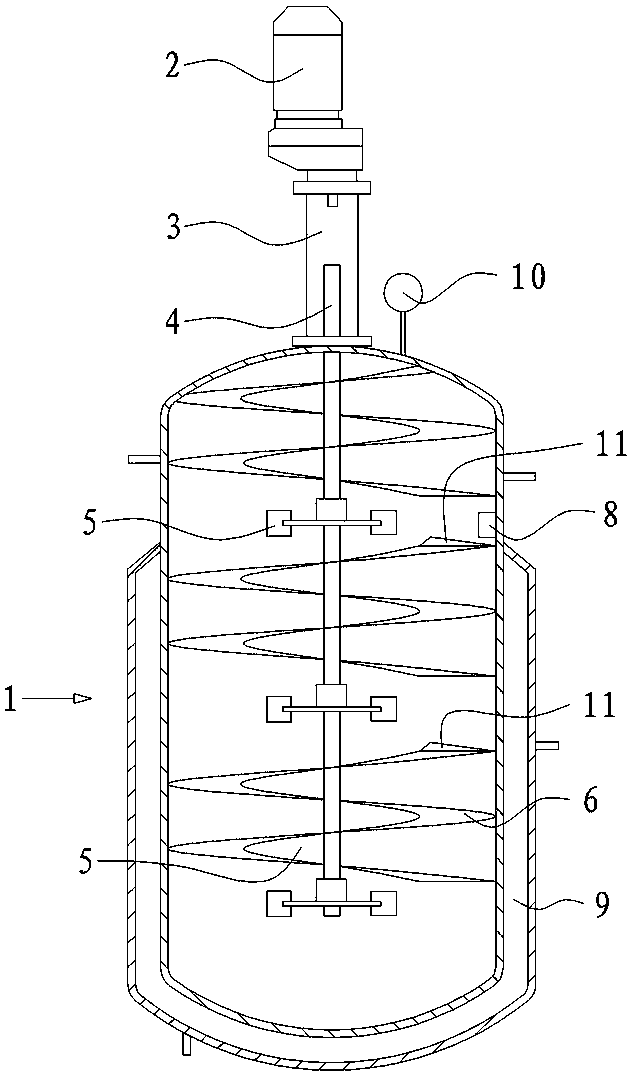

Efficient and vertical fermentation tank

ActiveCN106281979APromote growthReduce metabolic damageBioreactor/fermenter combinationsBiological substance pretreatmentsHelical bladeEngineering

The invention relates to an efficient and vertical fermentation tank and belongs to the technical field of fermentation devices. The fermentation tank comprises a vertical tank body, a motor, a speed reducer driven by the motor and a stirring shaft, wherein the lower end of the stirring shaft penetrates into the tank body, multiple stirring blades are arranged at the lower end of the stirring shaft at intervals, multiple helical channels sequentially are formed in the inner wall of the tank body from top to bottom, each helical channel is formed by splicing multiple helical blades fixed to the inner wall of the tank body along the central axis of the tank body in a surrounding mode and is provided with a through channel for containing the corresponding stirring blades, one stirring blade is located at the lower end of the corresponding helical channel and is same as the corresponding helical channel in helix angle, a zooming plate inclining towards the stirring shaft is arranged at the upper end of the helical channel, and the surfaces of the helical blades and the zooming plates are coated with continuous polytetrafluoroethylene coatings. The fermentation tank has the advantages that the structure is simple, and the oxygen dissolution rate can be remarkably improved without increase of stirrer diameter and rotation speed.

Owner:扬中市威柯特生物工程设备有限公司

High-efficiency vertical fermentation tank

ActiveCN106281979BPromote growthReduce harmBioreactor/fermenter combinationsBiological substance pretreatmentsHelical scanHelical blade

The invention relates to an efficient and vertical fermentation tank and belongs to the technical field of fermentation devices. The fermentation tank comprises a vertical tank body, a motor, a speed reducer driven by the motor and a stirring shaft, wherein the lower end of the stirring shaft penetrates into the tank body, multiple stirring blades are arranged at the lower end of the stirring shaft at intervals, multiple helical channels sequentially are formed in the inner wall of the tank body from top to bottom, each helical channel is formed by splicing multiple helical blades fixed to the inner wall of the tank body along the central axis of the tank body in a surrounding mode and is provided with a through channel for containing the corresponding stirring blades, one stirring blade is located at the lower end of the corresponding helical channel and is same as the corresponding helical channel in helix angle, a zooming plate inclining towards the stirring shaft is arranged at the upper end of the helical channel, and the surfaces of the helical blades and the zooming plates are coated with continuous polytetrafluoroethylene coatings. The fermentation tank has the advantages that the structure is simple, and the oxygen dissolution rate can be remarkably improved without increase of stirrer diameter and rotation speed.

Owner:扬中市威柯特生物工程设备有限公司

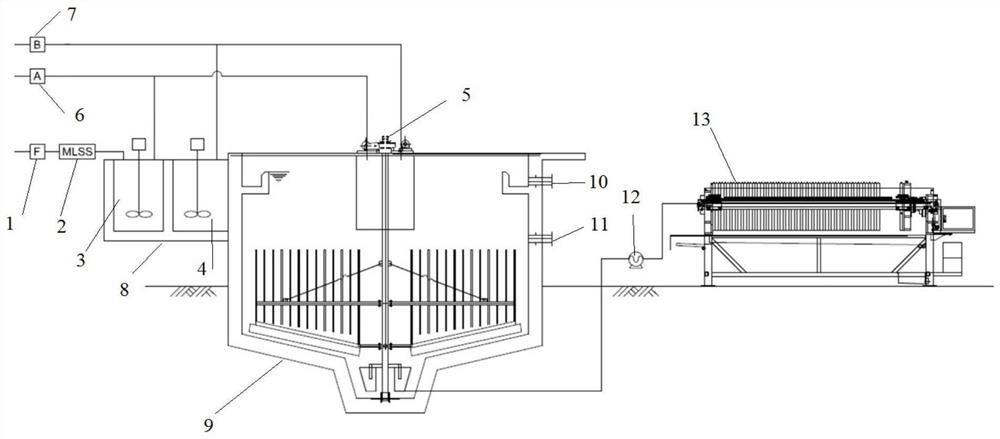

Online sludge conditioning and concentrating system and process

The invention relates to online sludge conditioning and concentrating system and process. The system comprises a sludge conditioning tank (8), a sludge concentration tank (9) and a plate-and-frame filter press (13) which are sequentially connected through sludge pipelines in the sludge feeding direction, wherein the sludge conditioning tank (8) is divided into a coagulation tank (3) and a flocculation tank (4) in the sludge feeding direction, and the coagulation tank (3) is connected with a coagulant adding device (6); the flocculating tank (4) is connected with a flocculating agent adding device (7), and a sludge thickener (5) is arranged in the sludge thickening tank (9). Compared with the prior art, the sludge mixing and conditioning device has the advantages that the sludge mixing and conditioning can be accurately realized on line, the sludge conditioning power and the volume of the gravity concentration tank are greatly reduced, and the water content of the concentrated sludge is improved; therefore, the current situation that a sludge thickening tank and a conditioning tank with large volumes, a high-power stirrer and plate-and-frame filter pressing equipment with a large filtering area need to be adopted for sludge conditioning is solved, so that the investment of subsequent dehydration equipment is reduced.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

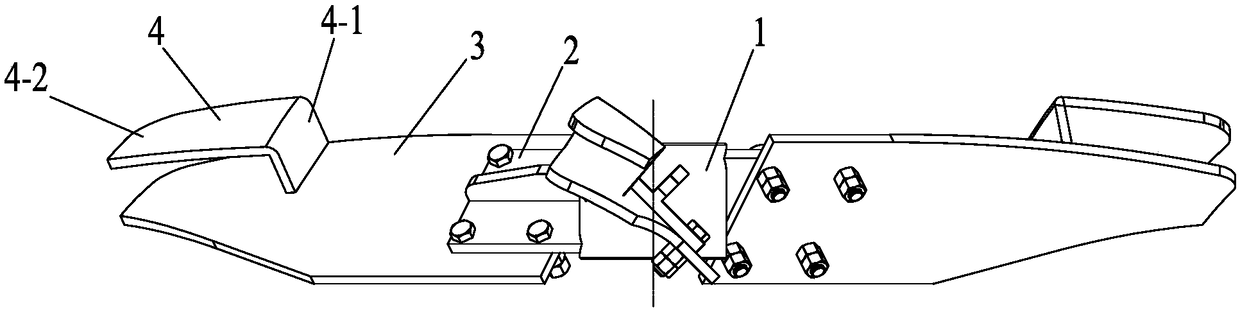

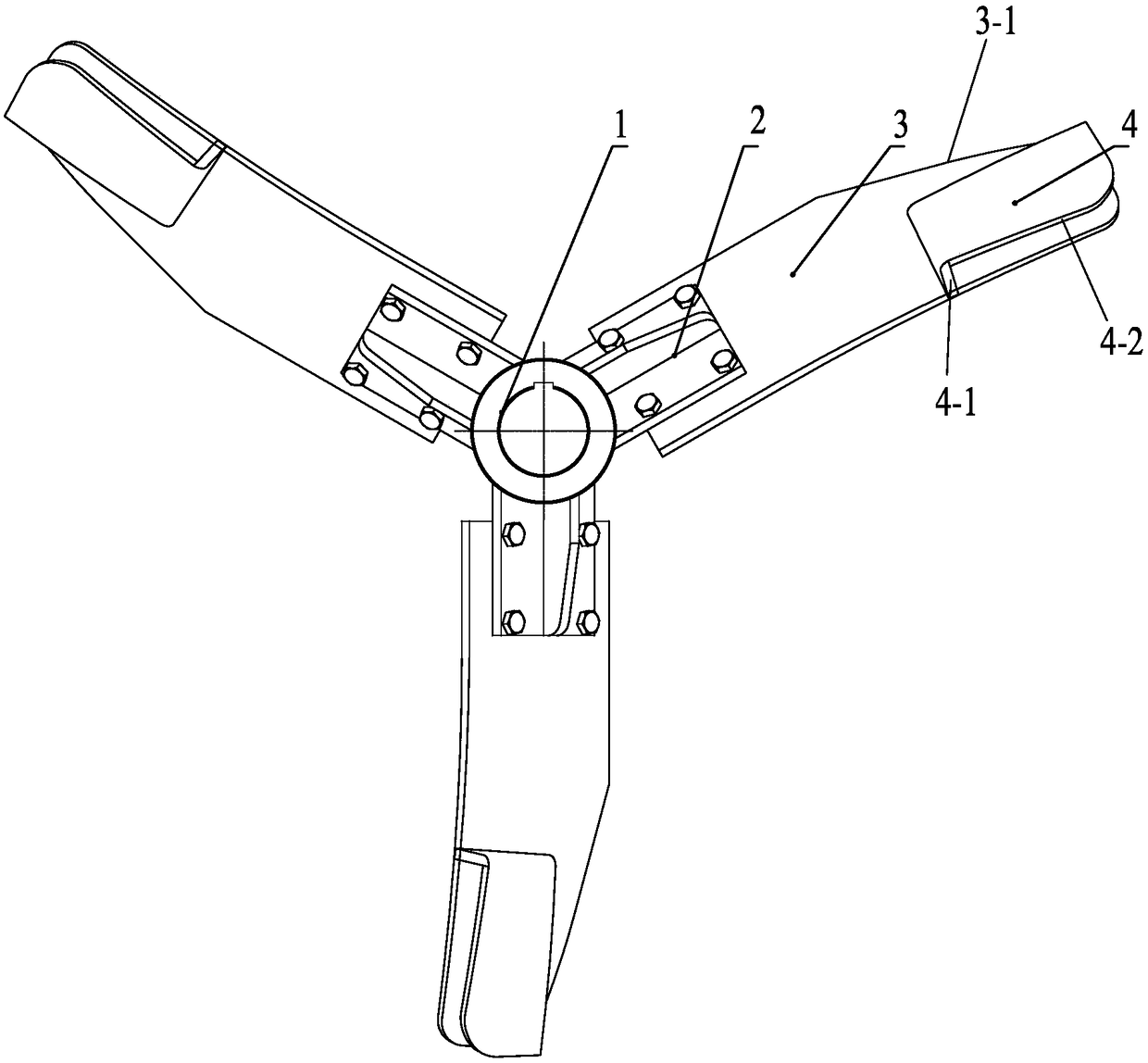

Agitator paddle

PendingCN108355514AEliminate flow peelingPass awayTransportation and packagingRotary stirring mixersImpellerHeat transmission

The invention belongs to the technical field of agitating devices, and relates to an agitator paddle. The agitator paddle comprises a wheel hub, wherein at least two groups of paddle connection blocksare uniformly distributed on the circumferential surface of the wheel hub, each paddle connection block is fixedly connected with a main paddle, a upstream face is formed on outer end side part of the main paddle, the upstream face is of a chamfered surface structure, and a secondary paddle is arranged at the side, far from the upstream face, of the outer end surface of the main paddle. Due to the paddle, flows caused by the paddle and a paddle system can be turbulent flow and transition flow state, so that the paddle is very suitable for mixing, solid-liquid suspending, dissolving, heat transmission, reacting and crystalizing of medium and low viscosity liquid. Compared with a traditional impeller of open turbine, the agitator paddle improves the efficiency by 50%, or lowers the energy consumption by 40% under the same agitation effect.

Owner:JIANGSU HAOTELONG MIX EQUIP

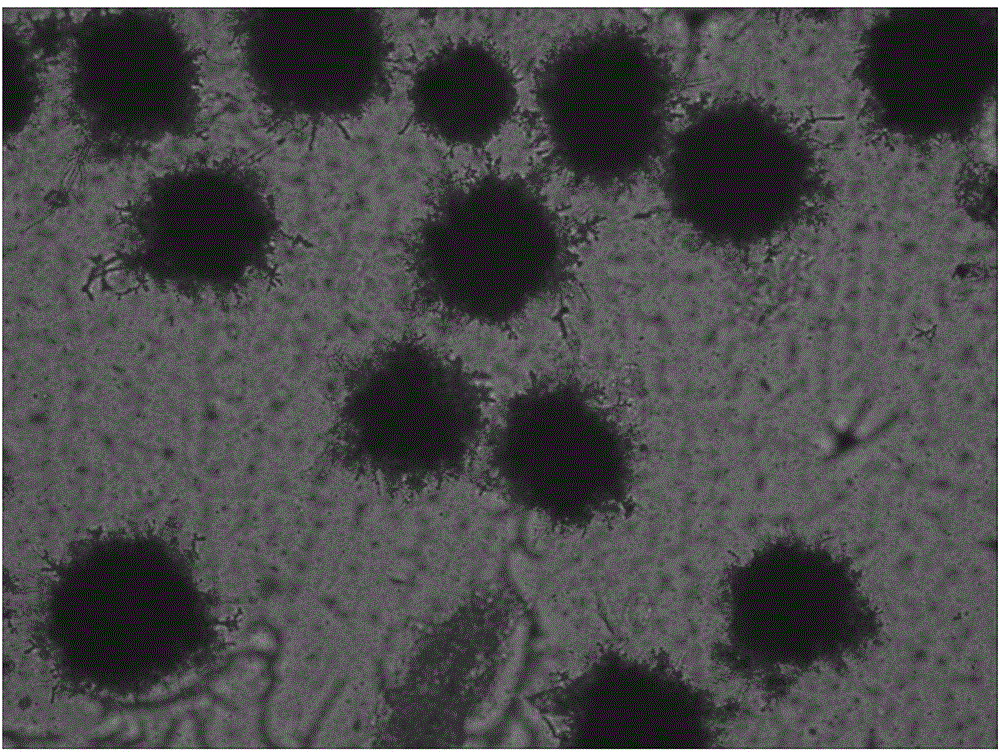

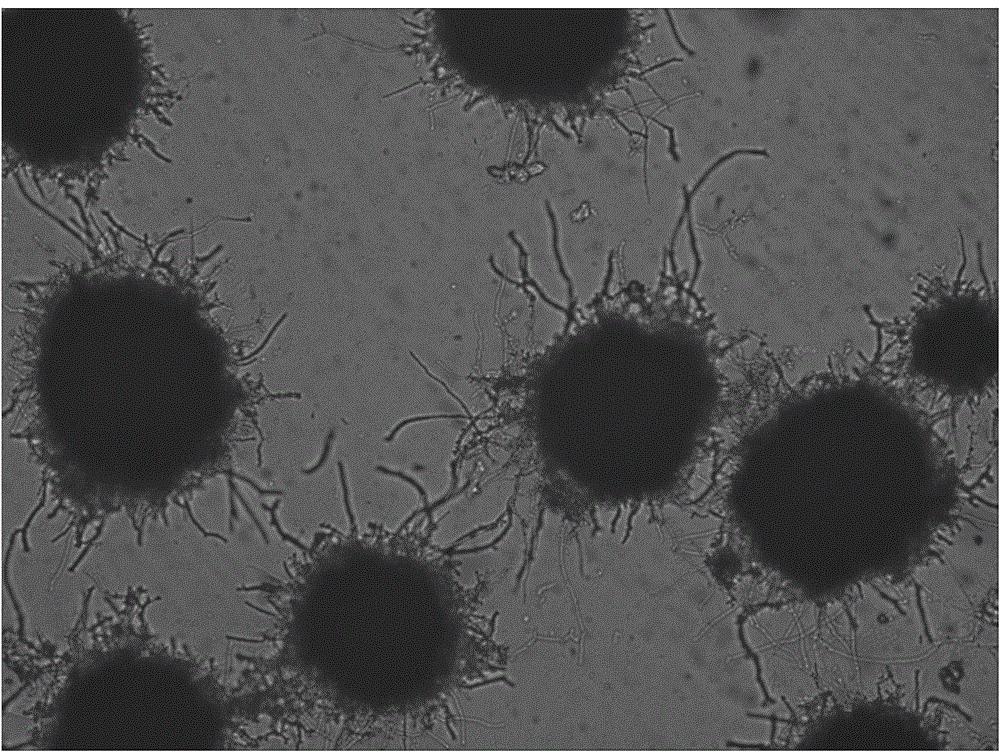

Method for preparing citric acid by fermentation

ActiveCN103497977BInhibition of excessive growthGuaranteed dissolved oxygenMicroorganism based processesFermentationMyceliumHypha

The invention discloses a method for preparing citric acid by fermentation. The method comprises the following steps: under conditions that the citric acid can be produced, inoculating Aspergillus niger in a fermentation medium for fermentation, and adding an inhibitor in the fermentation medium when the content of the Aspergillus niger in the fermentation medium achieves 1-1.7wt%, wherein the appropriate addition of the inhibitor can increase the content of the Aspergillus niger, but the increment of the Aspergillus niger does not exceed 0.2wt% per hour. In the fermentation of the citric acid by the technical scheme, the excessively fast growth of fermentative strains is effective inhibited, and fermentative bacterium and nutrient substances are all developed to a trend beneficial to production of the citric acid, so that the fermentation level is enhanced. Meanwhile, the balls of the fermentative strains are small and compact, and the mycelium is short, so that on the premise of guaranteeing the required amount of dissolved oxygen for fermentation, the stirring power is lowered, and consequently, the method is easy to operate and the production cost is lowered.

Owner:COFCO BIOTECHNOLOGY CO LTD

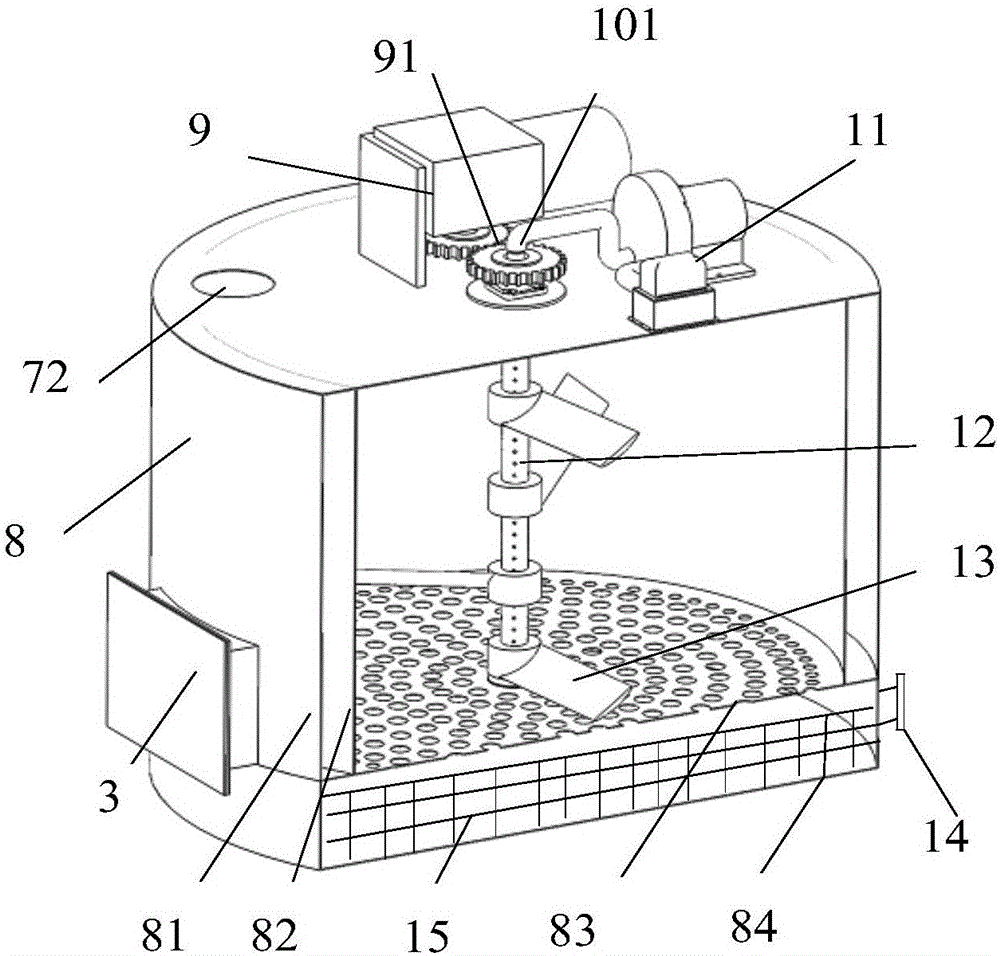

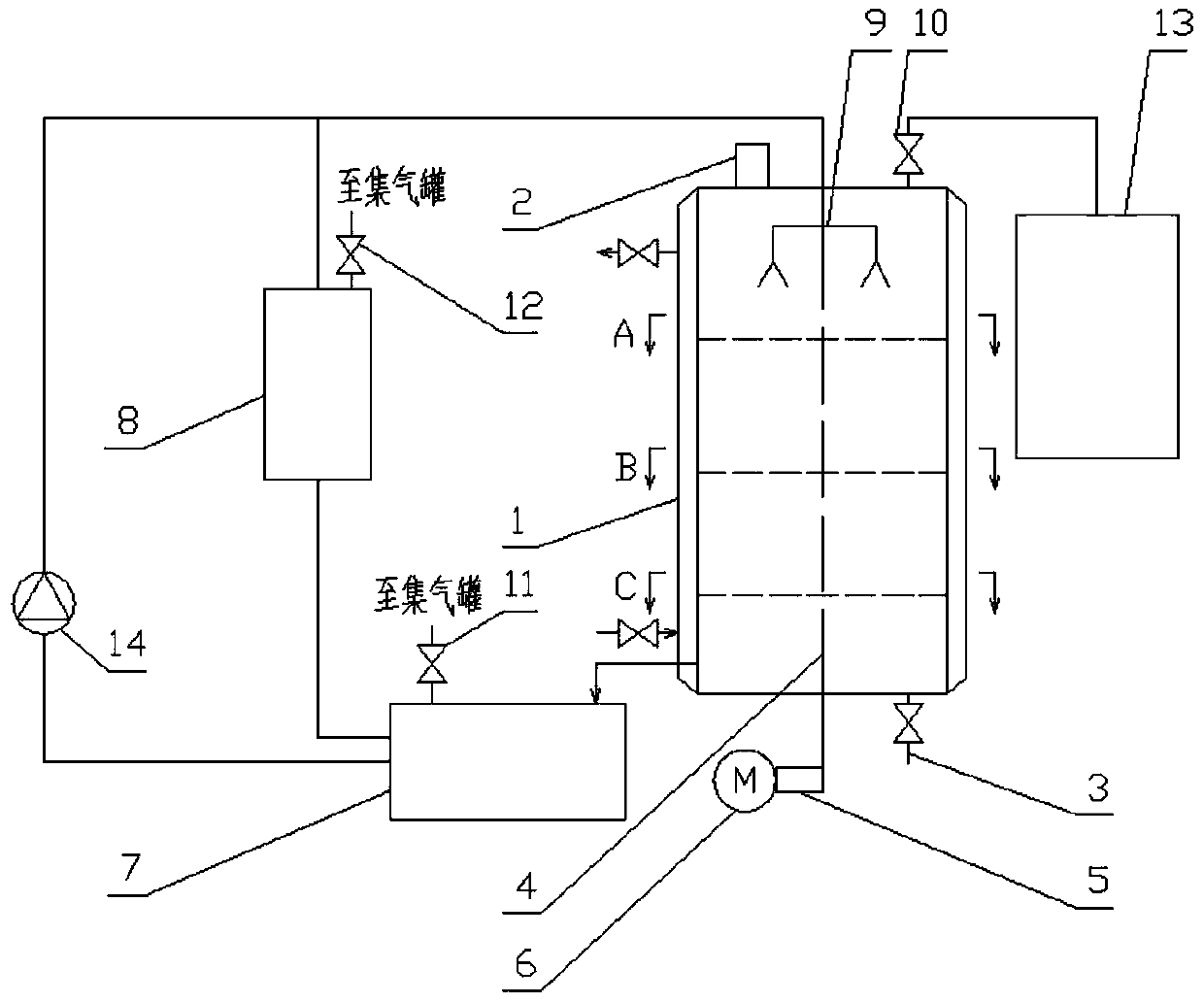

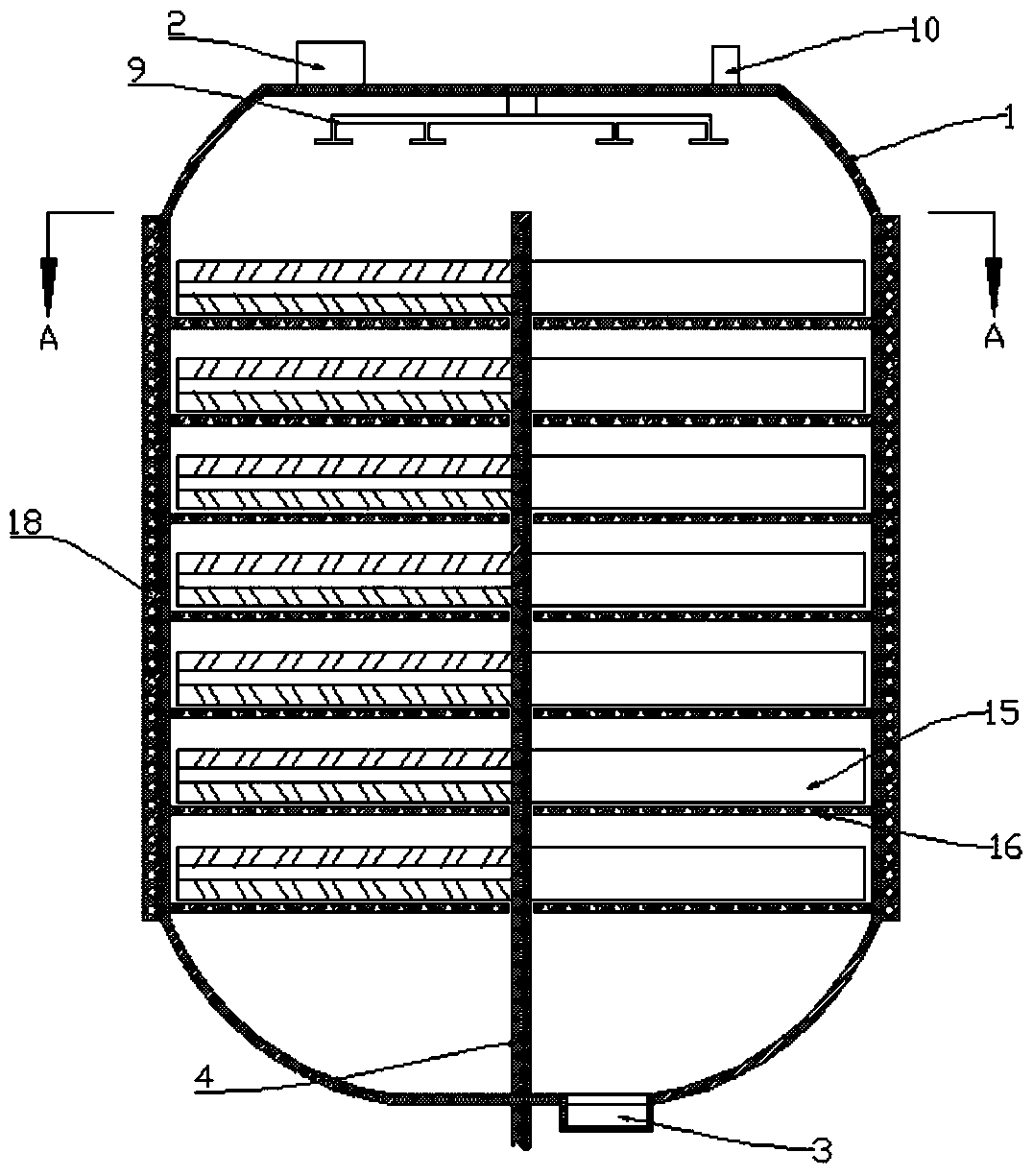

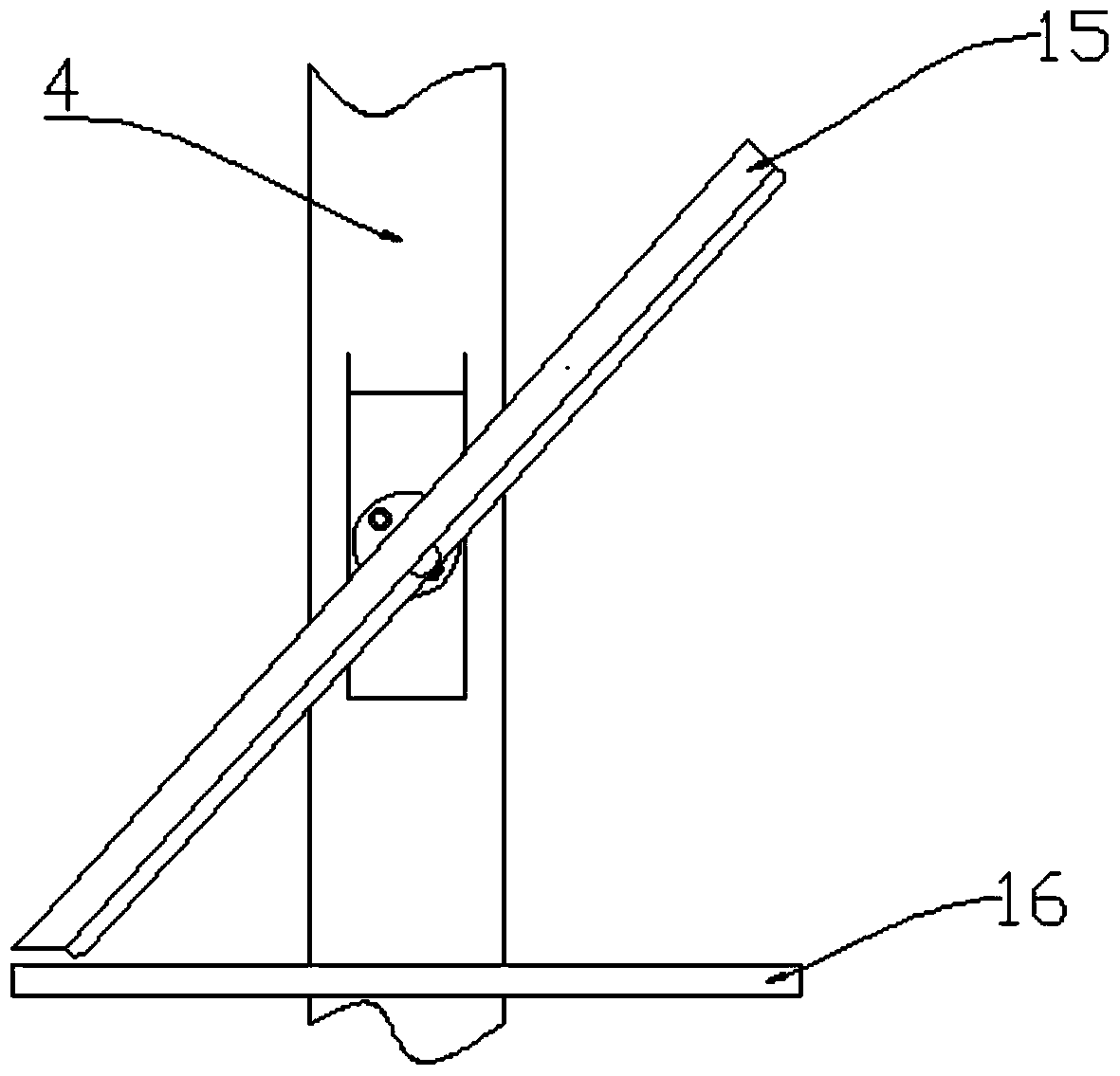

A device for producing biogas by continuous solid-state fermentation

ActiveCN105349409BLow crushing requirementsAdaptableBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous fermentationMethane

The invention discloses a device for continuously producing biogas by means of solid-state fermentation, and belongs to the field of anaerobic treatment technologies for organic waste. The device comprises a fermentation tank and a biogas collecting tank. A feed inlet is formed in the upper portion of the fermentation tank, a discharge outlet is formed in the lower portion of the fermentation tank, and a stirring shaft is arranged in the middle of the fermentation tank along the axial direction of a tank body. A plurality of support plates are parallelly arranged on the stirring shaft, are perpendicular to the axial direction of the stirring shaft and are used for carrying fermentation materials, and an opening is formed in each support plate, so that the fermentation materials can be transferred on different layers of support plates. Scraper blades are arranged on the stirring shaft, are perpendicular to planes of the support plates and can rotate on the planes of the support plates along with the stirring shaft, and a first biogas outlet is formed in the top of the fermentation tank and is connected with the biogas collecting tank by a pipeline, so that the biogas can be collected. The device has the advantages that the fermentation materials can be continuously fermented by the device for a long time, stirring power can be effectively reduced, and accordingly the economical efficiency of the integral reaction device can be improved.

Owner:TSINGHUA UNIV

Composite electromagnetic stirring process of preparing semi-solid metal slurry continuously

The present invention relates to semi-solid material preparing technology, and is composite electromagnetic stirring process of preparing semi-solid metal slurry continuously. Smelted overheat metal liquid is first poured into one preheated pouring basket continuously and the metal liquid inside the pouring basket is stirred electromagnetically for homogeneous cooling to temperature near the liquid phase line. The metal liquid is then led out of the pouring basket through duct strongly stirred electromagnetically and cooled to obtain equiaxial fined homogeneous semi-solid metal slurry; and the metal liquid is finally led into one heat retainer. The slurry after heat retaining treatment may be further formed rheologically or thixotropically. The present invention has the advantages of advanced technological process, simple apparatus, easy control, high practicability, low slurry cost, great output and high product quality.

Owner:有研金属复材技术有限公司

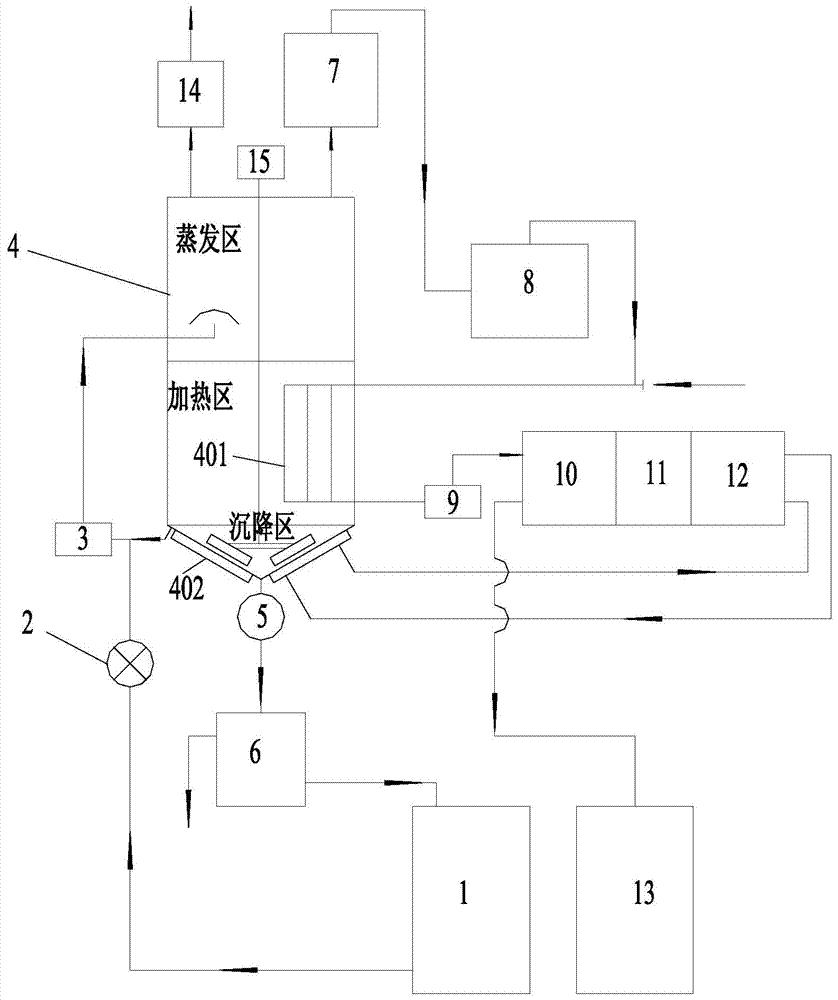

An industrial sewage treatment system

ActiveCN104761009BReduce volumeLess investmentHeat recovery systemsWater/sewage treatment by heatingIndustrial waste waterWater storage tank

The invention discloses an industrial waste water processing system. The industrial waste water processing system comprises a waste water storage tank, a waste water pipeline, a control valve, a chemical pump, a MVR evaporation system, and a recycled water storage tank; the MVR evaporation system comprises an evaporator and a compressor; heat pump technology is adopted to transform heat energy of condensed water to soft water in a hot water tank as an auxiliary heat source of the evaporator; an evaporation zone is connected with a vacuum pump; a discharge port of the evaporator is connected with a negative pressure discharging mechanism so as to guarantee system continuous feeding and continuous discharging. The industrial waste water processing system is capable of reducing the size of the evaporator and the size of a heat exchanger; the evaporator is connected with a chemical pump forced circulation via external connection, so that stirring power is reduced greatly; and at the same time, sinking and crystallization of concentrated waste water are realized, and continuous waste material discharging is realized; latent heat of condensed water is fully used; maximum energy utilization is realized; waste water harmless treatment is realized, and at the same time treatment cost is reduced as far as possible; and the processing process is automatic, continuous, and controllable.

Owner:南通宝正环保科技有限公司

Integrated reaction system for siloxane cracking

ActiveCN104815605BReduce generationImprove the flow fieldChemical/physical/physico-chemical nozzle-type rreactorsFeed devicesEngineeringTower

The invention discloses a siloxane pyrolysis integrated reaction system which comprises a cylindrical kettle body. A central spindle connected with an external motor is vertically arranged inside the kettle body. The system is characterized in that three layers of stirrers are vertically arranged on the central spindle; a circulatory diversion heat-exchange cylinder with upper and lower openings sleeves the periphery of the stirrers; the upper end of the circulatory diversion heat-exchange cylinder is provided with a feed diversion distributor; 4-6 side-wall diversion full-baffles are uniformly distributed on the inner wall of the kettle body; the upper end of the kettle body is connected with a rectifying tower; the three layers of stirrers are an upper turbine-type agitator, a middle turbine-type agitator and a lower turbine-type agitator; the circulatory diversion heat-exchange cylinder is a frustum-shaped structure with big top and small bottom; and the body of the circulatory diversion heat-exchange cylinder is an annular enclosed structure enclosed by two layers of heat exchange plates, outer surfaces of which are embossed. The system provided by the invention has the following advantages: three-step reactions of the pyrolysis process are effectively controlled; heat exchange effect is improved; flow field of a pyrolysis kettle is optimized; and the purpose of raising yield of the annular body, stabilizing production, prolonging reaction period and improving quality of the annular body is achieved.

Owner:SEDIN NINGBO ENG

Combined quenching tank provided with inner tank with bottom inserted propeller

ActiveCN102352428BReduce stirring powerImprove flow uniformityQuenching devicesMetallic materialsPropeller

The invention discloses a combined quenching tank provided with an inner tank with a bottom inserted propeller, and belongs to the technical field of metal material heat treatment. The combined quenching tank comprises an outer tank, a support, at least one inner tank and corresponding bottom plate, and at least one stirring mechanism, wherein the outer tank and the inner tank form a structure which can be separated or combined relatively, the inner tank, the bottom plate and the support are arranged in the outer tank from top to bottom, the stirring mechanism is arranged in a corresponding water inlet on the bottom plate, the liquid at the bottom of the outer tank is delivered into the inner tank under the drive of the stirring mechanism, and the liquid moves in the inner tank from bottom to top, overflows from an upper opening of the inner tank to a gap between the outer tank and the inner tank and flows down and back to the bottom of the outer tank. By adopting the combined quenching tank provided with the inner tank with the bottom inserted propeller, higher stirring capability, uniform and oriented flow field and good cooling capability can be obtained. Meanwhile, the combined quenching tank structure can be combined flexibly according to the size of the workpiece and can also facilitate the installation, repair and cleaning of the equipment.

Owner:SHANGHAI JIAOTONG UNIV

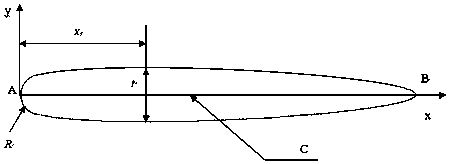

Olefin polymerization reactor

The invention discloses an olefin polymerization reactor. The reactor comprises a polymerization kettle body, a stirring device, a feeding port and an overflowing port, wherein the polymerization kettle body is composed of a reaction segment, an enlargement segment, and a connection segment located between the reaction segment and the enlargement segment; the stirring device is arranged at the center inside the polymerization kettle body, is used for stirring raw materials in the kettle, and is composed of a transmission device, a stirring shaft and a stirring turbine which are sequentially connected; the feeding port is arranged on the side wall of the reaction segment of the polymerization kettle body and is used for adding solvent, catalyst and the like; and the overflowing port is used for discharging the slurry and controlling the liquid level in the kettle. By using the reactor, the entrainment can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

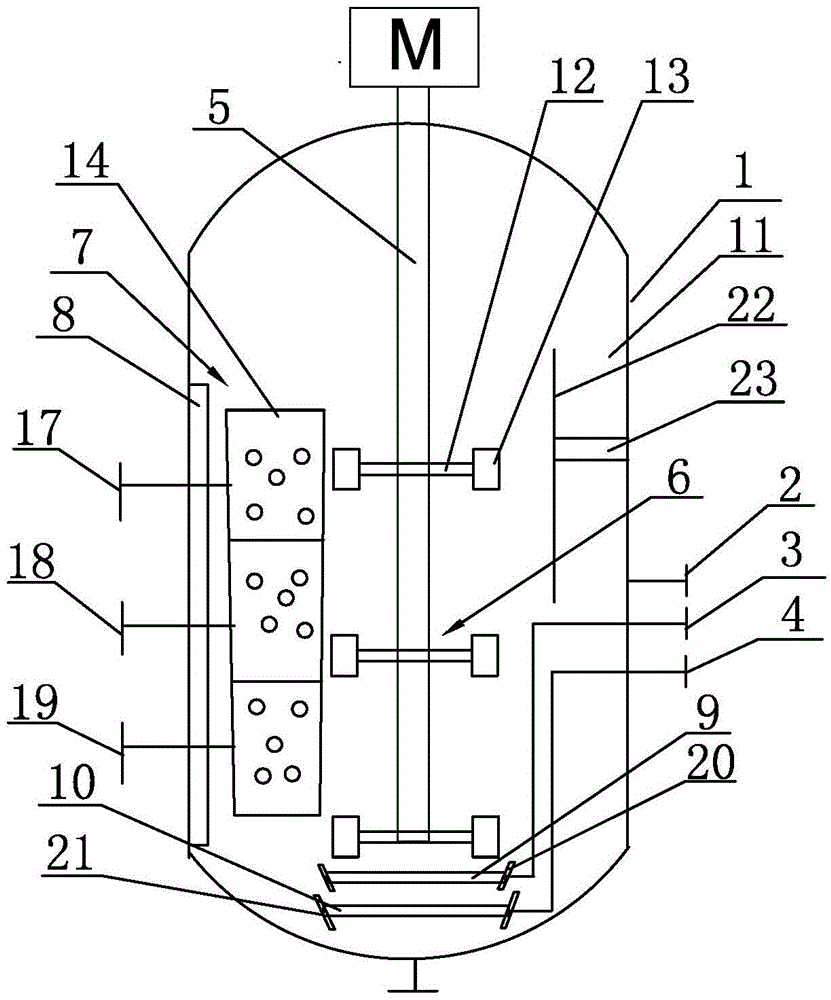

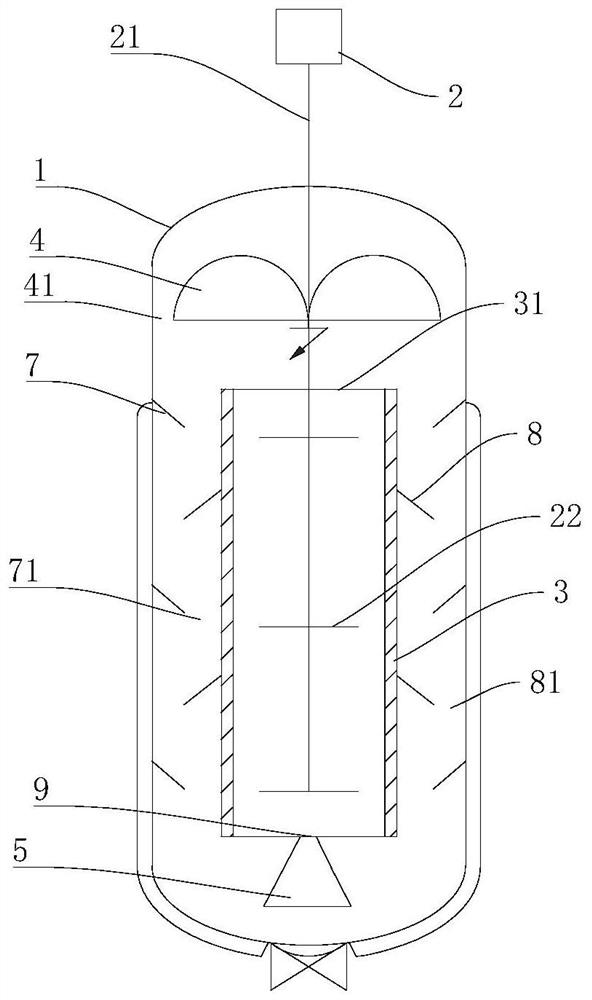

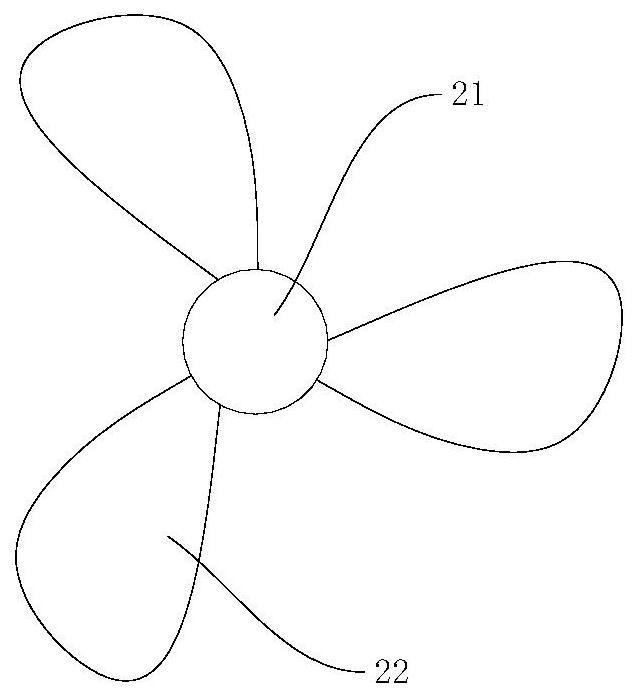

Fermentation equipment with diversion device

ActiveCN108949514BSpeed up the flowIncrease dissolved oxygenBioreactor/fermenter combinationsBiological substance pretreatmentsStructural engineeringMechanical engineering

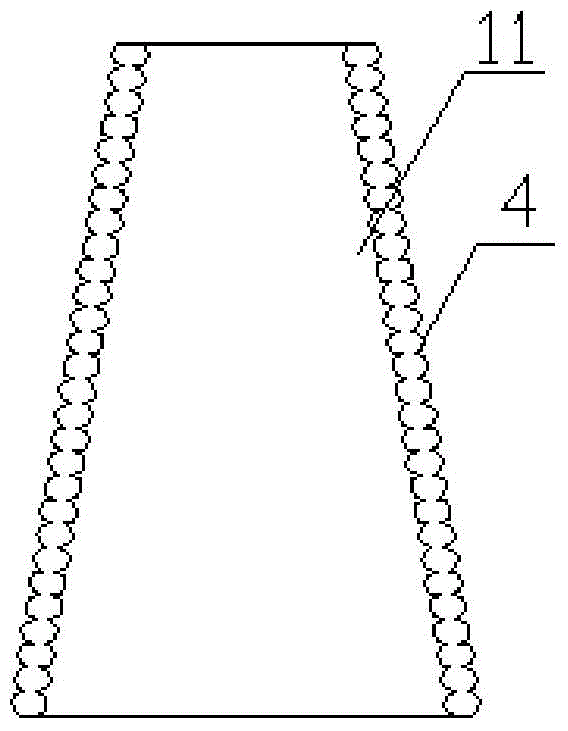

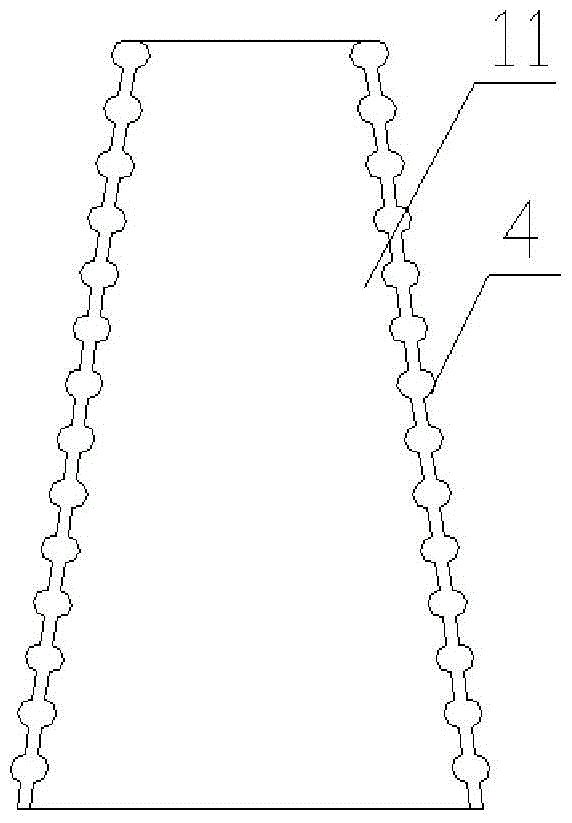

The invention discloses fermentation equipment with a flow guiding device, and relates to the technical field of a fermentation tank. The fermentation equipment with the flow guiding device comprisesa tank, wherein multiple groups of stirring paddles are arranged on a stirring shaft of the tank; each group of stirring paddles comprises a plurality of twisted paddles which push liquid upwards; a flow guiding barrel is arranged at the middle of the tank; a gap is formed between the flow guiding barrel and the inner wall of the tank; openings are formed in the upper end and lower end of the flowguiding barrel; the stirring paddles are located inside the flow guiding barrel; a flow guiding shell with a downward opening is formed inside the tank, is located at the upper end of the flow guiding barrel, and is semicircular; the center of the flow guiding shell sinks toward the flow guiding barrel; a flow guiding body is arranged inside the tank, is located at the lower end of the flow guiding barrel and is a cone; the vertex of the cone faces toward the flow guiding barrel; and the axis of the cone and the axis of the flow guiding barrel are located on the same straight line. Accordingto the technical scheme, the circulation speed of fermentation liquid in the tank can be accelerated, so that the fermentation liquid in the tank is fully mixed with oxygen, the dissolving of the oxygen is increased, and the stirring diameter is reduced, thereby reducing stirring power and consumption and saving energy.

Owner:ZHENJIANG FENGZE BIOTECH EQUIP MFG

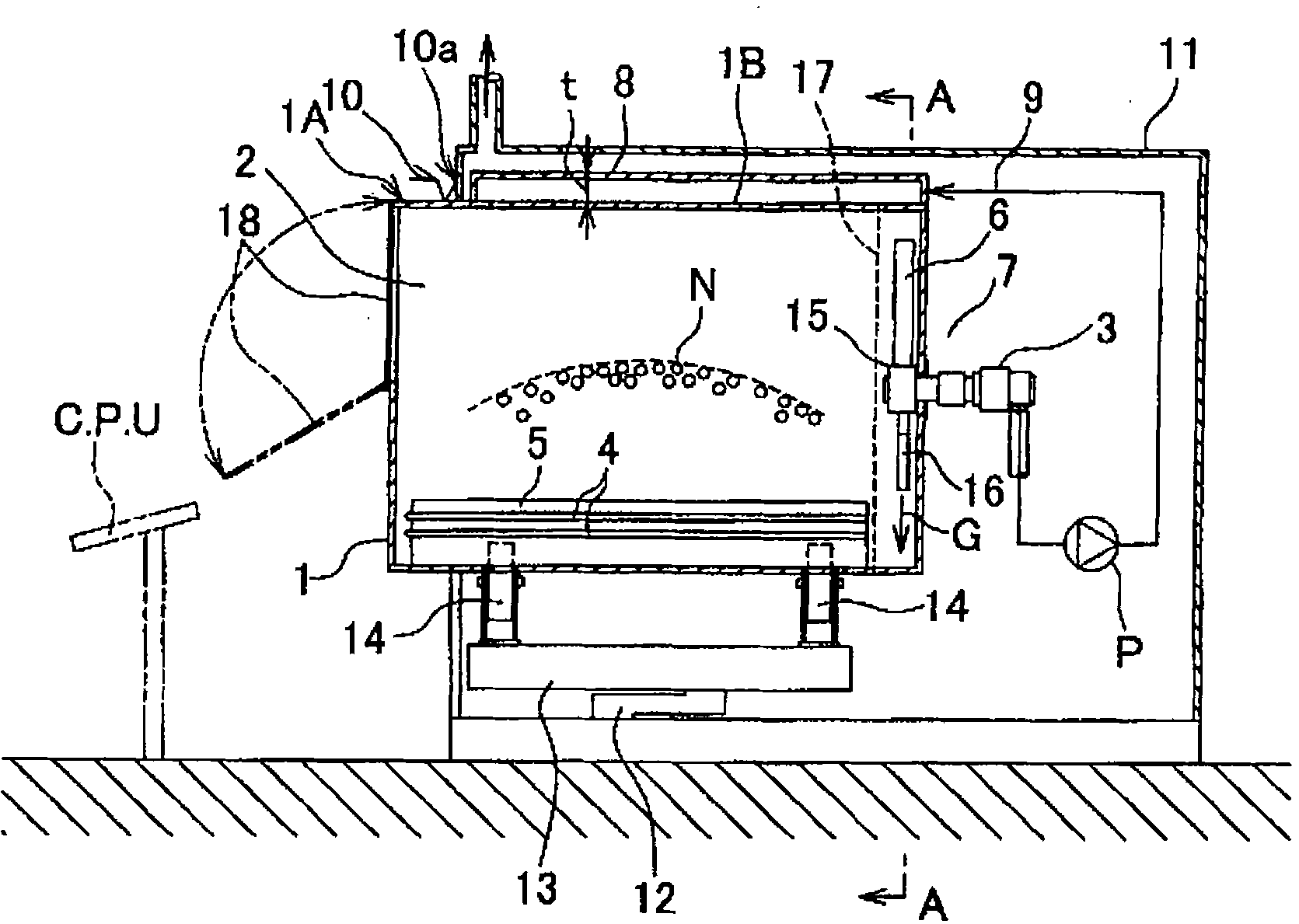

Vacuum drying device of domestic garbage

ActiveCN101419016BFacilitate heat transferEliminate non-operational conditionsDrying using combination processesDrying solid materials with heatLitterAir pump

The invention relates to a vacuum drying apparatus of domestic garbage that is an apparatus for vacuum drying of domestic garbage by rotary barrel, and is also an apparatus for improving reducing of stirring power and thermoconductivity by a heater installed on a stirring vane. The apparatus has: an input and output opening (2) of domestic garbage installed at one side, the rotary barrel (1) rotatably supporting the center at the other side by a rotary joint (3) connected with a vacuum air pump (P); the stirring vane (5) installed at the internal wall of the rotary barrel and provided with the heater (4); and a vacuum absorption mechanism (7) having an absorption port (6) usually stressed by an upper coercive power pointing the upper part of the rotary barrel.

Owner:TAIKO KIKAI IND CO LTD JP

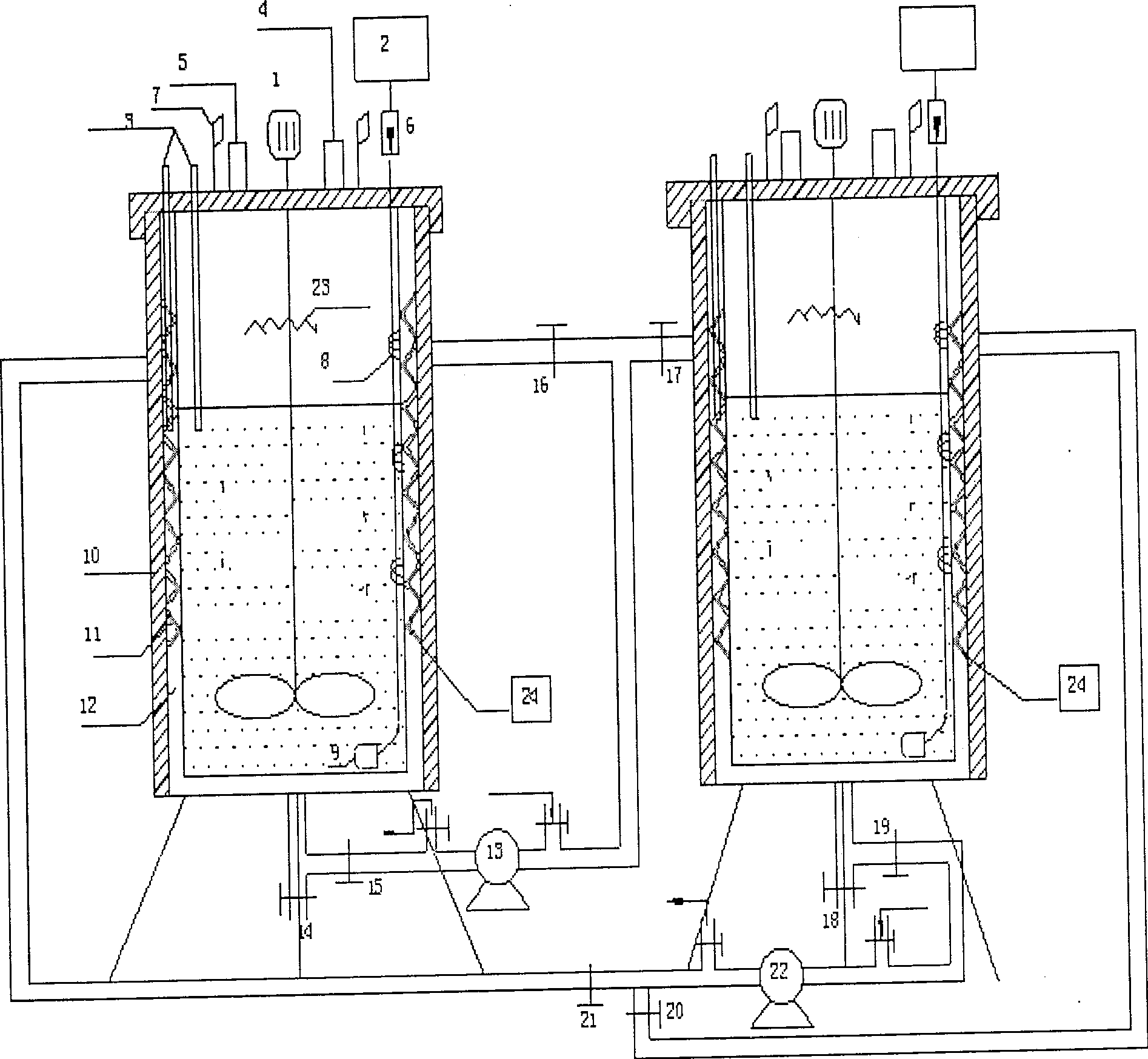

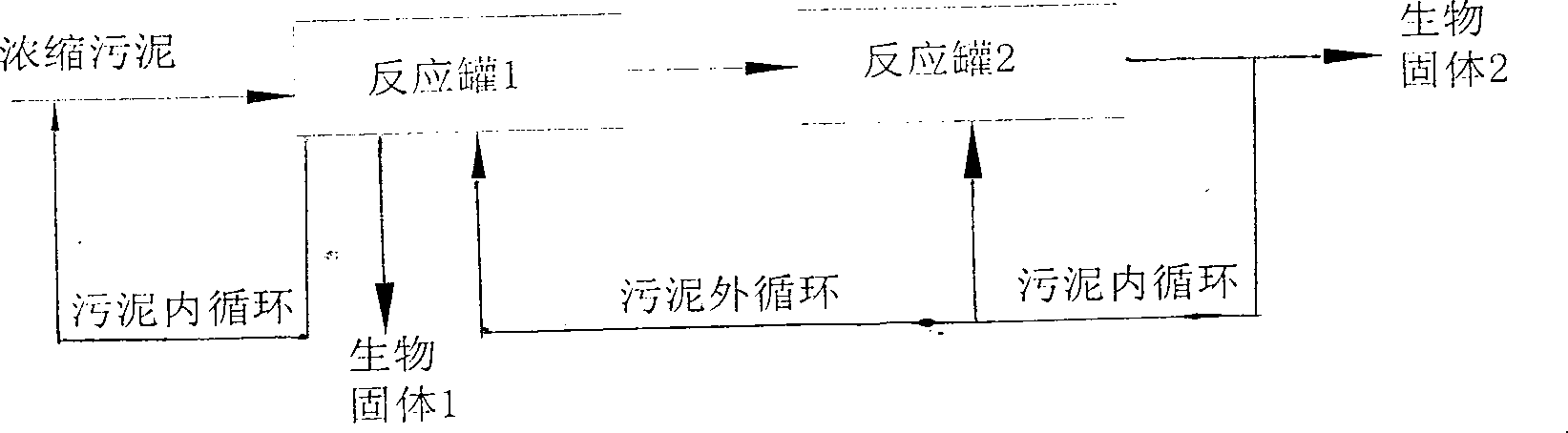

Sludge hot digesting apparatus for preparing biological solid

InactiveCN100500601CIncrease effective spaceHigh speedSludge processingBiological sludge treatmentWater bathsReaction rate

The sludge hot digesting apparatus for preparing biological solid includes one sealed reaction tank possessing one water bath jacket with electrically heating pipe and one sludge discharge port in the bottom; one reaction tank top cover with sludge inlet and gas collecting port; one stirring paddle; and one aerating head. There is defoaming filament fixed onto the electric wire connected between the stirring paddle and the stirring motor. There may be also one other reaction tank connected serially to the first one. Inside the apparatus, may be realized aerobic sludge digestion, anaerobic / aerobic sludge digestion, self-heating aerobic sludge digestion and two section high temperature aerobic / medium temperature anaerobic sludge digestion. The present invention has high reaction rate and efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Method of preparing syndiotectic polystyrene

A process for preparing the syndiotactic polystyrene from stylene features that the metallocene compound, triisobutyl aluminium and alkyl aluminium are used as catalyst, the inertial solvent is used as medium and reaction temp is 10-100 deg.C.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com