Method for preparing citric acid by fermentation

A technology of citric acid and fermentation medium, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of low fermentation cost, low citric acid yield and fermentation conversion rate, high fermentation cost, etc., and achieve improvement The effect of fermentation level, reduction of stirring power and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0067] Preparation of fermentation medium for fermentation

[0068] 1) Grinding of raw materials: Soak the harvested corn in a hot water tank until the water content of the corn is 15% by weight, and then grind it through a grinder (Jiangsu Muyang Group Co., Ltd., 968-3 type) to obtain a starchy raw material grinding product (50% by weight of the crushed particles have a particle diameter less than 0.1 cm);

[0069] 2) Sizing: mix water at 50°C with the crushed product of the starchy raw material obtained in 1) to make a starch slurry. The weight ratio of the crushed product of the starchy raw material to water is 1:3, and the pH of the starchy slurry is Value is 5.5;

[0070] 3) Enzymolysis: mix the starch slurry obtained in step 2) with 1 / 2 enzyme (adding starch The total weight of the enzyme is mixed with 15U / g corn flour pulverized product), and the first injection liquefaction is carried out at 95°C and the pH is 5.5 for 5 minutes, and then the second injection liquefac...

preparation example 2

[0074] Preparation of fermented strain seed solution

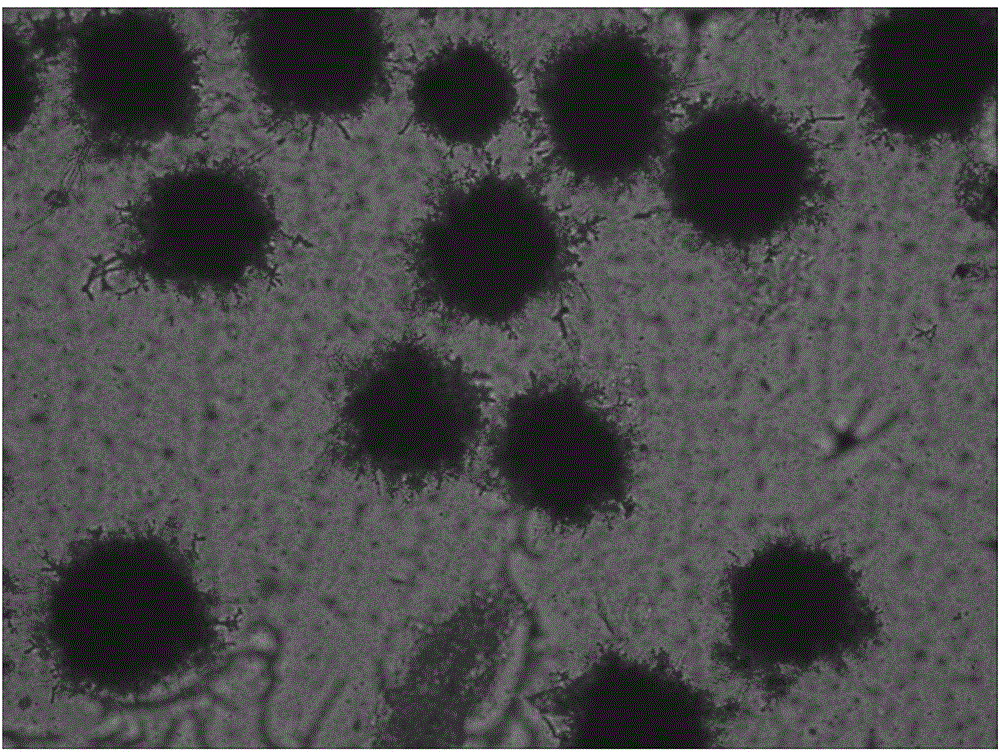

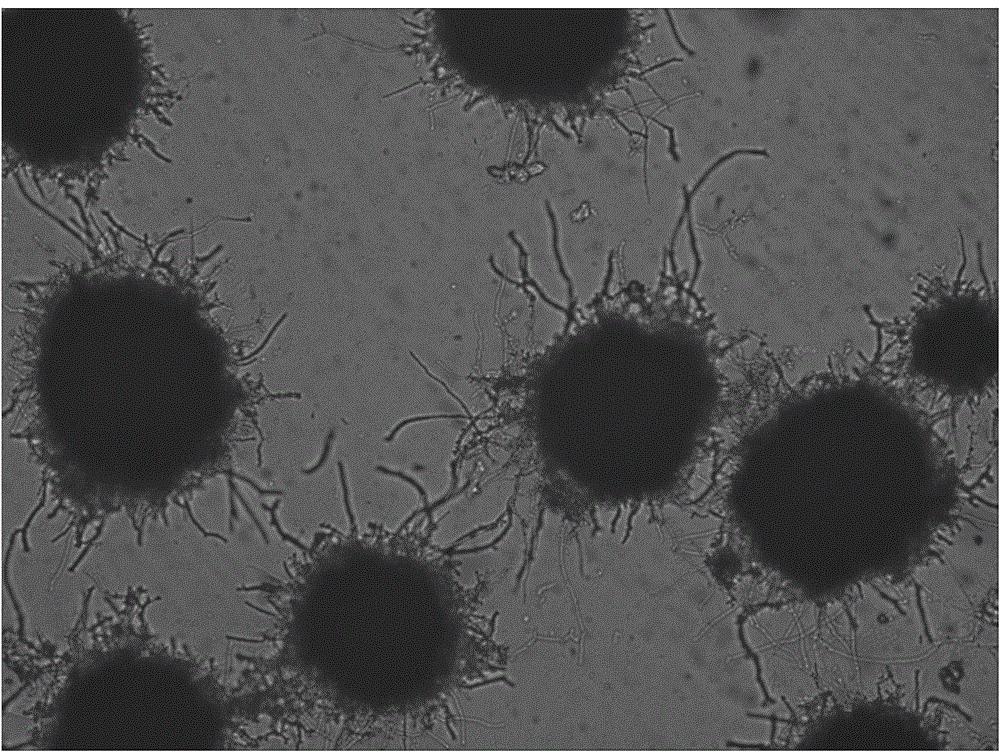

[0075] Dilute part of the corn liquefaction solution in step 3) of Preparation Example 1 with water until the total sugar content is 11% by weight, put the culture solution into the seed tank, heat it to 121°C for disinfection, keep it for 20 minutes and then quickly cool it down to 36°C, then Enter Aspergillus niger bacterial classification (Aspergillus niger T01, Tianjin Institute of Industrial Microbiology, be this Aspergillus niger bacterial classification in the embodiment of the present invention, inoculum size is: every milliliter of nutrient solution is a benchmark, inoculates 1 * 10 5 spores), the temperature is 37°C, the ventilation rate is 0.4V / V·min, the air pressure is 0.05-0.06Mpa, the stirring speed is 750rpm, and the strains are carried out under the condition of maintaining the tank pressure during this stage. Cultivate; observe the growth of Aspergillus niger through sampling microscope inspection, acidit...

Embodiment 1

[0077] This example is used to illustrate the method for preparing citric acid by fermentation provided by the present invention.

[0078] The Aspergillus niger seed liquid cultivated in Preparation Example 2 is added to the fermentation medium of Preparation Example 1 to start fermentation, wherein, in terms of per milliliter of fermentation medium, the inoculum size of Aspergillus niger is 3.0 × 10 4 spores, the fermentation conditions include a temperature of 37°C, a culture pressure of 0.04Mpa, an aeration rate of 0.8 volume: (volume·min), and a stirring speed of 850rpm. During the fermentation process, samples were continuously taken to determine the bacterial content in the culture medium.

[0079] When the content of Aspergillus niger in the fermentation medium reached 1.4% by weight, the continuous addition of Tween-60 solution with a concentration of 0.6g / L fermentation broth began in the fermentation medium. Wherein, in terms of per liter of fermentation medium, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com