Liquid crystal orientation agent as well as preparation method and application thereof

A liquid crystal aligning agent and solvent technology, used in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of poor solubility of macromolecules, affect the uniformity of film thickness, and poor fluidity, and improve spray coating. Uniformity, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

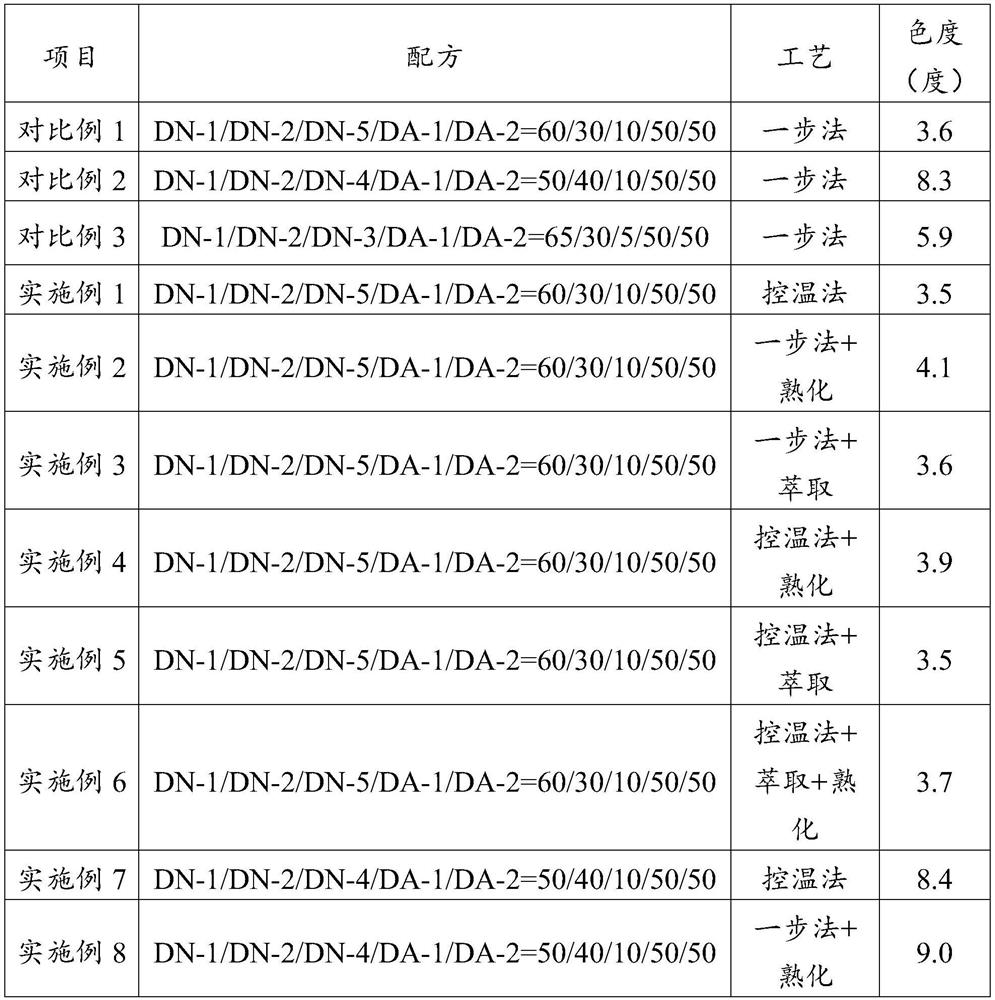

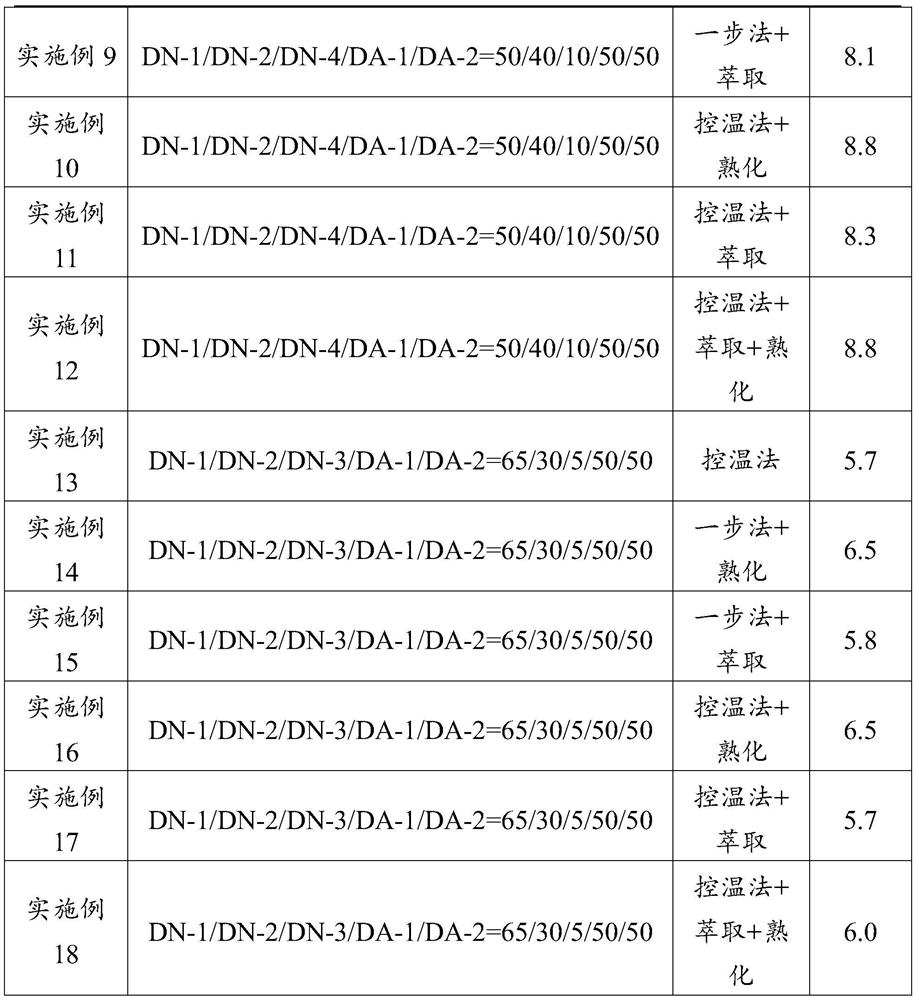

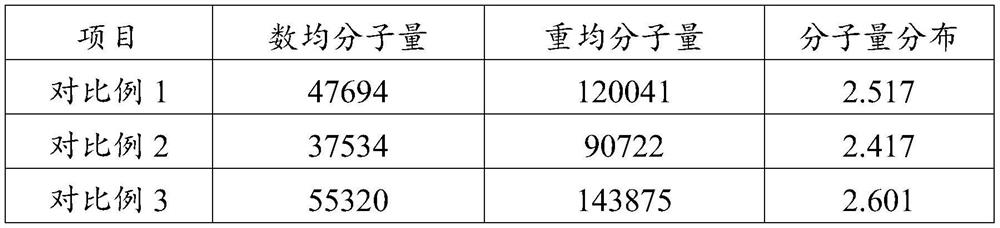

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of liquid crystal aligning agent, comprises the following steps:

[0038] (1) In a protective atmosphere, the diamine monomer, the acid anhydride and the solvent are mixed and subjected to a variable temperature reaction to obtain a polyamic acid solution;

[0039] (2) extracting, removing impurities and drying the polyamic acid solution in sequence to obtain a polyimide solid;

[0040] (3) In a protective atmosphere, the polyimide solid is dissolved and matured at high temperature in sequence to obtain the liquid crystal aligning agent.

[0041] In the present invention, the protective atmosphere in step (1) is preferably nitrogen, argon or helium.

[0042] In the present invention, the diamine monomer in the step (1) preferably includes p-phenylenediamine, 2,2-bis(trifluoromethyl)-4,4-diaminobiphenyl, 1,5-di- (3-aminophenyl)-1,5-dipentanone, 5-(3-octyl-cyclohexyloxy)-1,3-phenylenediamine and 4-(6-decyl-decalin- On...

Embodiment 1

[0073] (1) Prepare VA type polyamic acid liquid crystal aligning agent by temperature control method

[0074] In a nitrogen atmosphere, add 0.06 mol of DN-1, 0.03 mol of DN-2, 0.01 mol of DN-5 and 104.02 g of NMP, and control the speed at room temperature to be 240 rpm and stir for 30 min until the diamine monomers are completely dissolved, and then Add 0.05 mol of DA-1 and 0.05 mol of DA-2, control the temperature at 30°C, stir at 300rpm for 30min, then raise the temperature to 60°C, control at 300rpm and stir for 3.5h, and obtain a polyamic acid solution after the reaction; After diluting the polyamic acid solution with 319.49 g of NMP and 423.51 g of BC, it was filtered through a PP filter membrane with a pore size of 0.45 μm to obtain a transparent viscous polyamic acid solution.

Embodiment 2

[0076] (1) Prepare VA type polyamic acid liquid crystal aligning agent by traditional one-step method

[0077] In a nitrogen atmosphere, add 0.06 mol of DN-1, 0.03 mol of DN-2, 0.01 mol of DN-5 and 104.02 g of NMP, and control the speed at room temperature to be 240 rpm and stir for 30 min until the diamine monomers are completely dissolved, and then Add 0.05 mol of DA-1 and 0.05 mol of DA-2, control the temperature at 60 ° C, and stir at 300 rpm for 4 hours. After the reaction, a polyamic acid solution is obtained; the polyamic acid solution is mixed with 319.49 g of NMP and 423.51 g of After BC dilution, a transparent viscous polyamic acid solution was obtained.

[0078] (2) Polyamic acid aging treatment

[0079] In a nitrogen atmosphere, the diluted polyamic acid solution was aged at 80°C for 4 hours, and after the aging was completed, it was filtered with a PP material filter membrane with a pore size of 0.45 μm to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com