Waterproof fibrous zn-co water-based battery and preparation method thereof

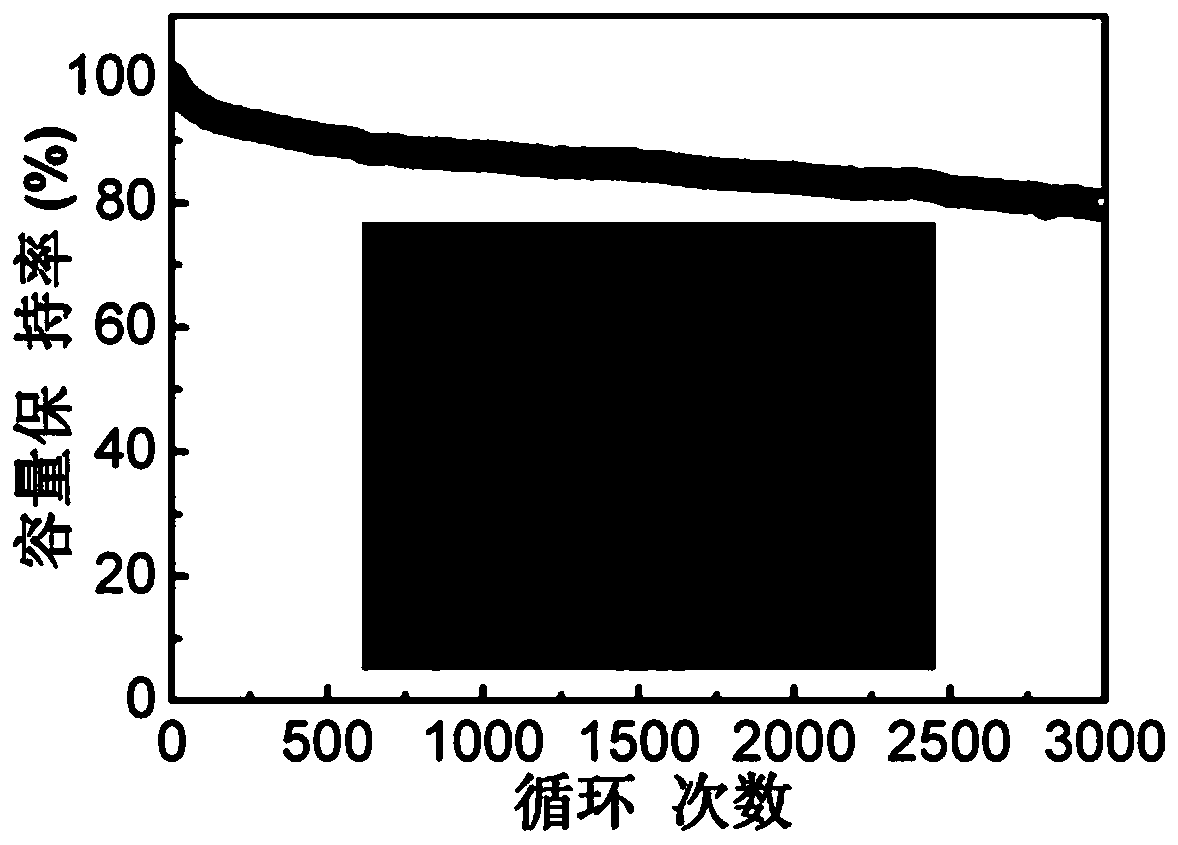

A fibrous, water-based technology, applied in the direction of microscopic fiber electrodes, small-sized batteries/battery packs, electrode manufacturing, etc., can solve the problems of poor cycle stability, low specific energy density, low specific capacitance, etc., and achieve good flexibility and tensile properties, avoiding safety accidents, and inhibiting the effects of excessive growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

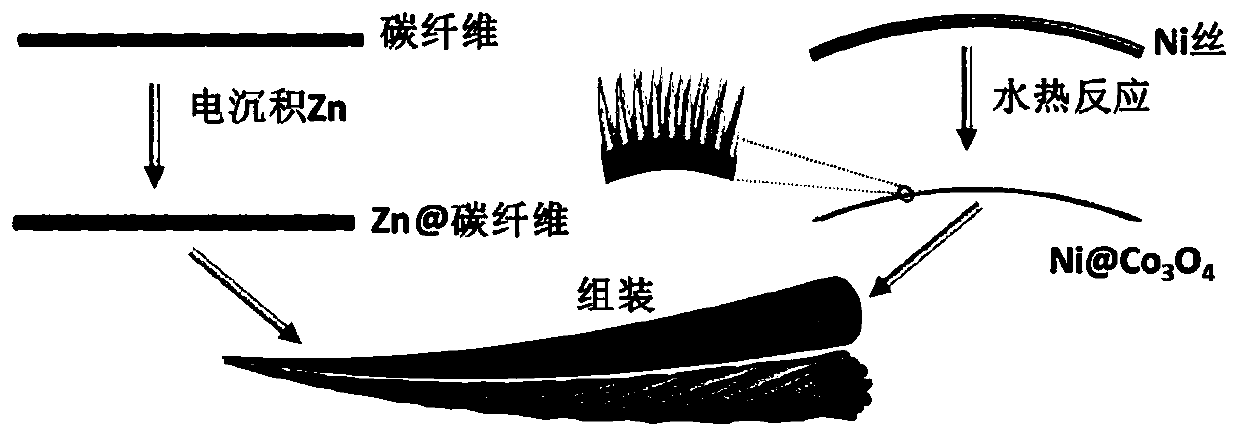

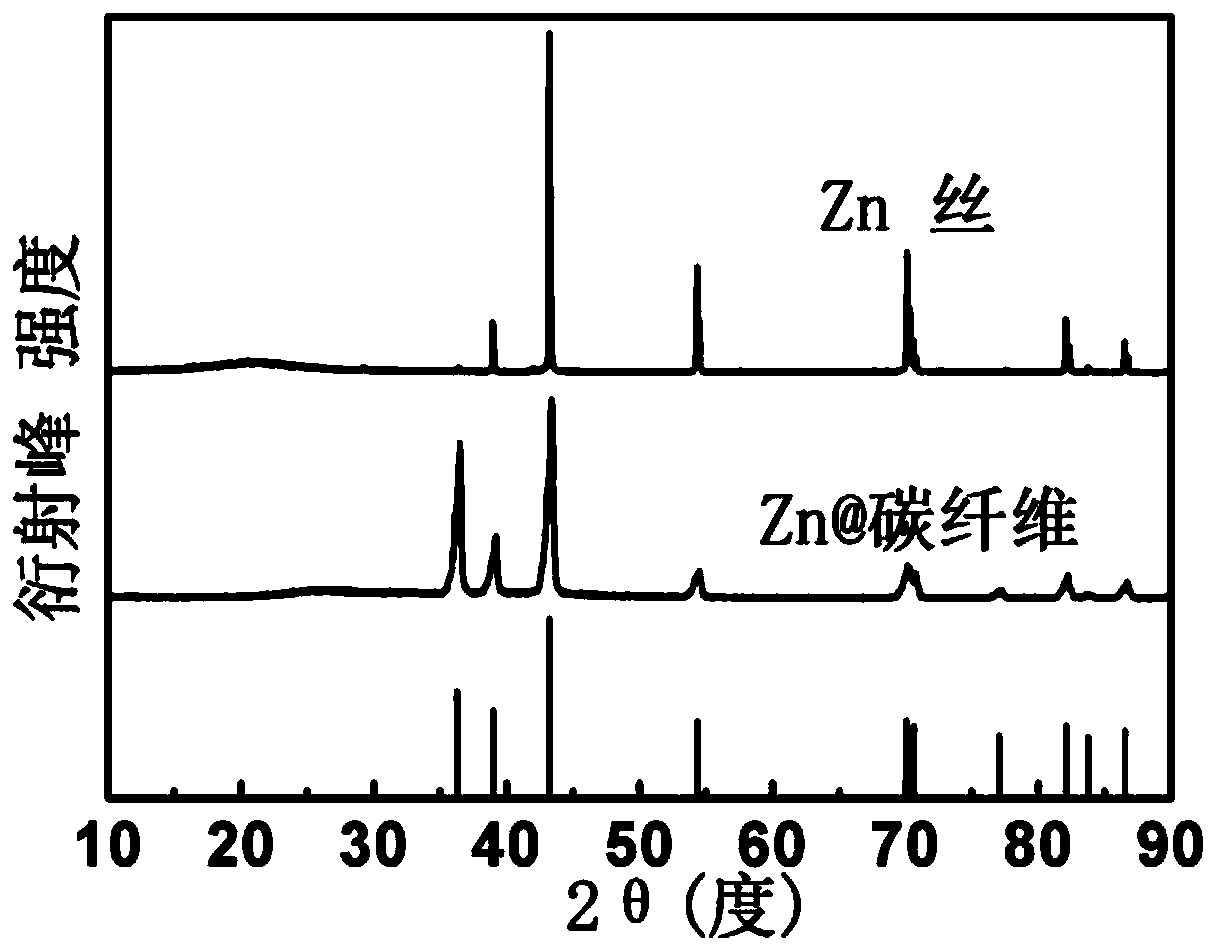

[0034] Take 3cm of 1K carbon fiber and soak it for 0.5h in the order of concentrated hydrochloric acid, concentrated nitric acid, acetone, and absolute ethanol, then wash and dry with deionized water. Weigh 7.4 g of trisodium citrate and 2.87 g of zinc sulfate, stir and dissolve in 50 mL of deionized water solution, add dilute sulfuric acid to adjust the pH to 5-6. Three electrodes are used for constant pressure deposition. Saturated calomel and platinum tablets are used as reference electrode and counter electrode respectively. After depositing at -1.5V for 0.5h, remove the zinc@carbon fiber electrode, clean with deionized water, and dry to obtain Zn @CF Fiber Anode Material.

[0035] Take 100μm Ni wire 3cm, first ultrasonically clean it with absolute ethanol, dry it, and calcinate it in an air atmosphere at 200°C for 5 minutes to obtain Ni wire with a NiO layer on the surface. Take 0.06g cobalt nitrate hexahydrate and 0.02g ammonium fluoride respectively, stir and dissolve in ...

Embodiment 2

[0038] Take 3cm of 1K carbon fiber and soak it for 0.5h in the order of concentrated hydrochloric acid, concentrated nitric acid, acetone, and absolute ethanol, then wash and dry with deionized water. Weigh 3.7 g of trisodium citrate and 1.44 g of zinc sulfate, stir and dissolve in 50 mL of deionized water solution, add dilute sulfuric acid to adjust the pH to 5-6. Three electrodes are used for constant current deposition. Saturated calomel and platinum sheet are used as reference electrode and counter electrode respectively. After depositing at -100mA for 0.5h, remove the zinc@carbon fiber electrode, clean with deionized water, and dry to obtain Zn@ CF fiber anode material.

[0039] Take 100μm Ni wire 3cm, first ultrasonically clean it with absolute ethanol, dry it, and calcinate it in an air atmosphere at 200°C for 5 minutes to obtain Ni wire with a NiO layer on the surface. Take 0.06g cobalt nitrate hexahydrate and 0.02g ammonium fluoride respectively, stir and dissolve in 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com