Patents

Literature

212 results about "Citric acid fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Citric acid is a commercially important product that has been obtained by submerged fermentation of glucose or sucrose by Aspergillus niger. This work was undertaken to determine the potential of food processing solid residues as a substrate for citric acid production by solid state fermentation using Aspergillus niger.

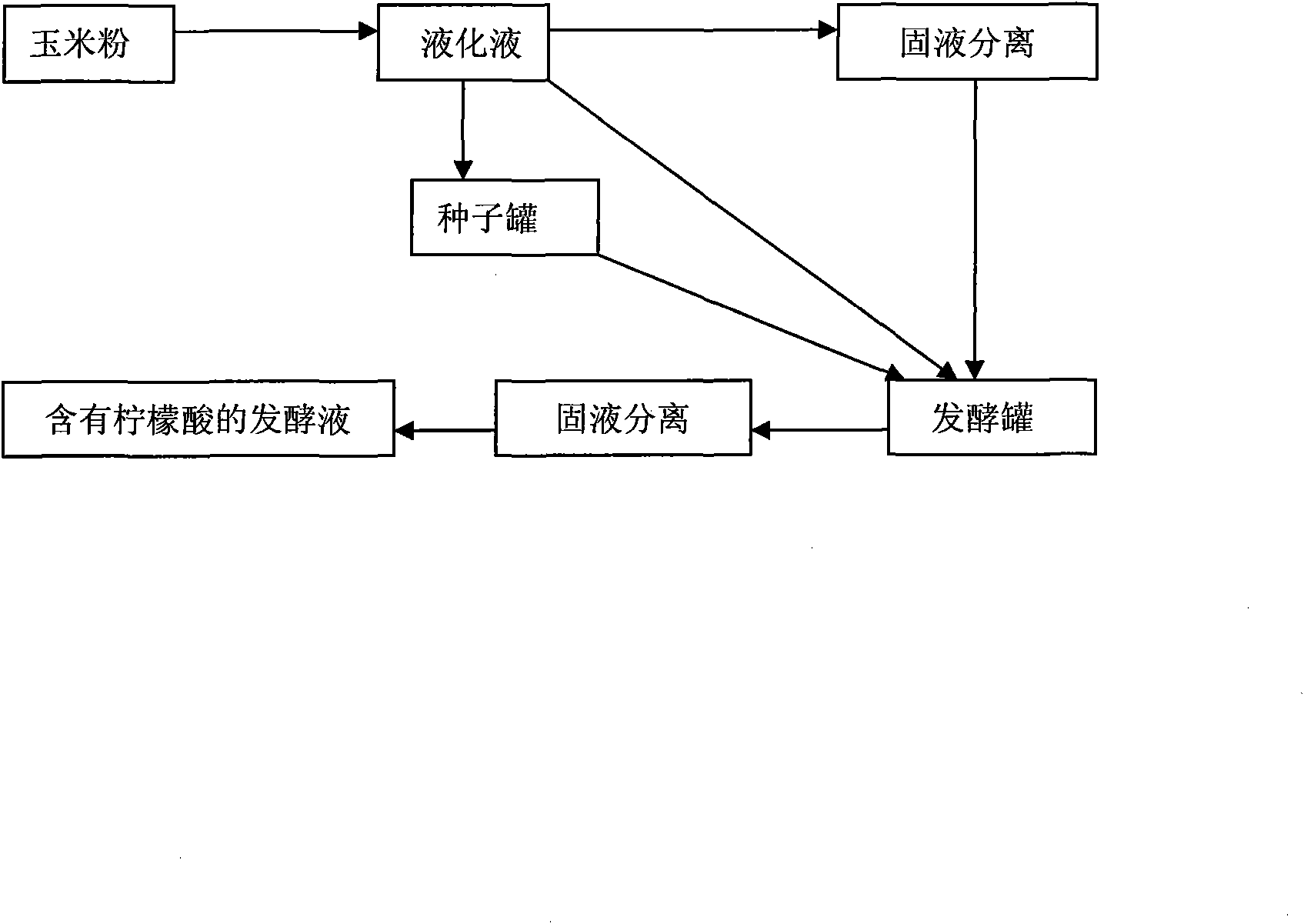

Preparation method of citric acid fermentation solution

ActiveCN101555497ASimple processReduce manufacturing costMicroorganism based processesFermentationNitrogen sourceCitric acid fermentation

The invention discloses a preparation method of a citric acid fermentation solution, which comprises the steps of: (1) mixing dry corn powder with water to form paste, adding amylase into the paste and then heating the paste, conducting spraying liquefaction by one time on the paste at the temperature ranging from 92 DEG C to 98 DEG C and then flash evaporation by one time, lowering the temperature to 88 DEG C to 90 DEG C and maintaining the liquefaction for 90min to 120min to obtain liquefied solution; (2) taking 5 percent to 15 percent of the liquefied solution obtained in the step (1), putting the liquefied solution into a seed tank, adding a nitrogen source, heating and sterilizing, maintaining for 20min to 30min, then lowering the temperature to 36 DEG C, and inoculating the obtained mixture into aspergillus niger strains for strain culture; (3) taking 5 percent to 15 percent of the liquefied solution obtained in the step (1), putting the liquefied solution into a fermenter; (4) taking the rest of the liquefied solution obtained in the step (1) for solid-liquid separation to obtain liquefaction clear liquid, putting the obtained liquefaction clear liquid into the fermenter, adding a nitrogen source, raising the temperature to 80 DEG C to 90 DEG C by heating, sterilizing, maintaining for 5min to 10min, lower the temperature to 38 DEG C, and leading the substances in the seed tank obtained in the step (2) into the fermenter; and (5) conducting solid-liquid separation to obtain the citric acid fermentation solution after ferment. The preparation method has the advantages of simple technique and low production cost.

Owner:COFCO BIOTECHNOLOGY CO LTD

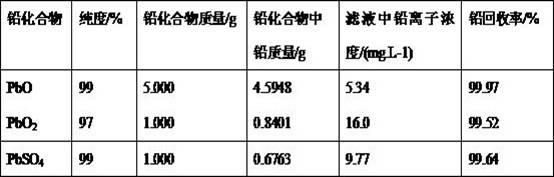

Method for recovering lead

InactiveCN102560122AImprove performanceLow costProcess efficiency improvementElectrical batteryLead oxide

The invention discloses a method for recovering lead, in particular a method for recovering lead from a waste lead battery. The method comprises the following steps of: mixing lead wastes containing PbSO4, PbO2, PbO and Pb and citric acid fermentation liquor and reacting to form lead citrate; and separating the lead citrate from an aqueous solution, and converting the lead citrate into the lead or lead oxide. By the method, the problems that SO2 is discharged and the lead is volatilized at high temperature in a pyrometallurgical process for lead paste are solved; and the lead wastes are directly treated by the citric acid fermentation liquor, so that cost and pollution are reduced, and particularly the lead can be recovered from the waste battery in a more effective and energy-saving mode.

Owner:NANJING UNIV OF TECH

Clean productive process for extracting citric acid from citric acid fermentation liquid

InactiveCN1358707ARealize cleaner productionHigh yieldCarboxylic compound separation/purificationOrganic acidOrganic solvent

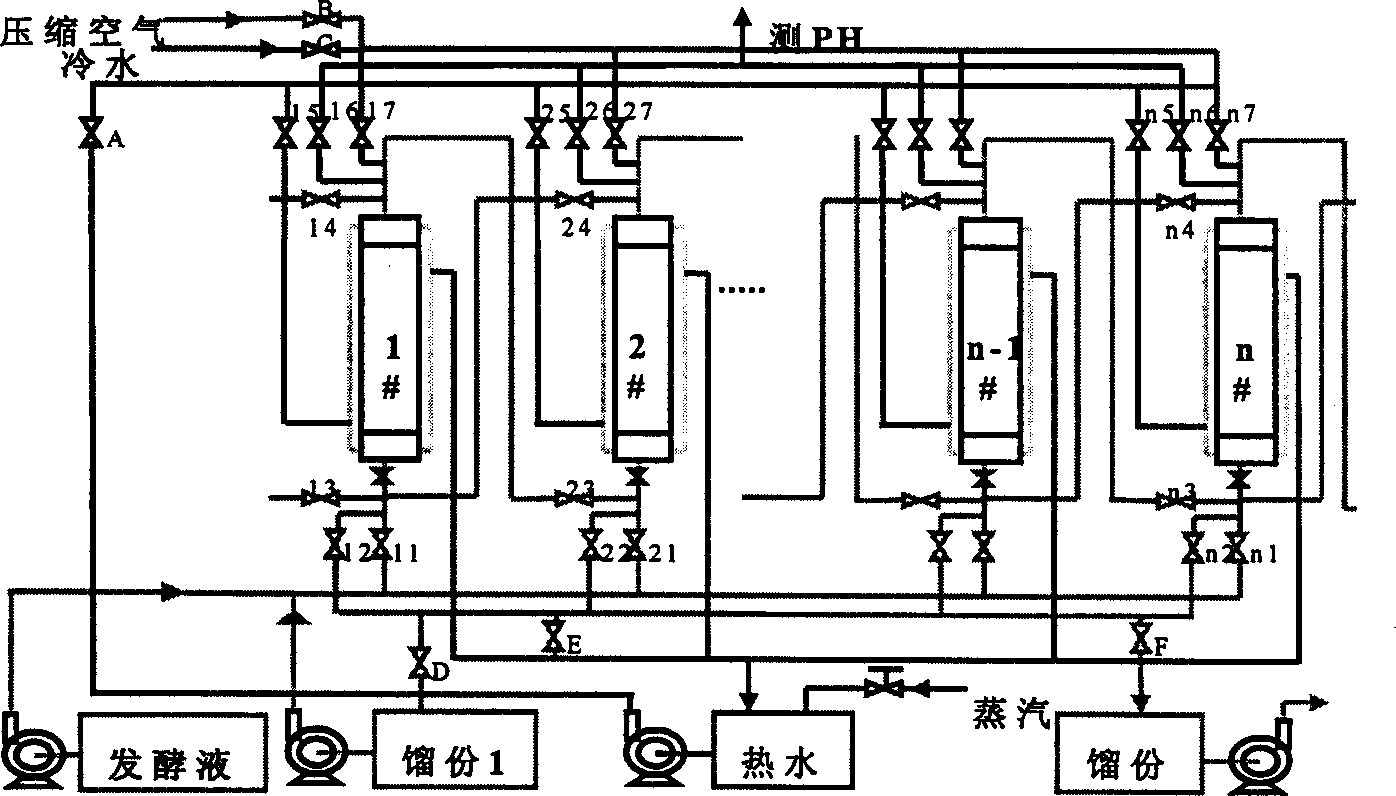

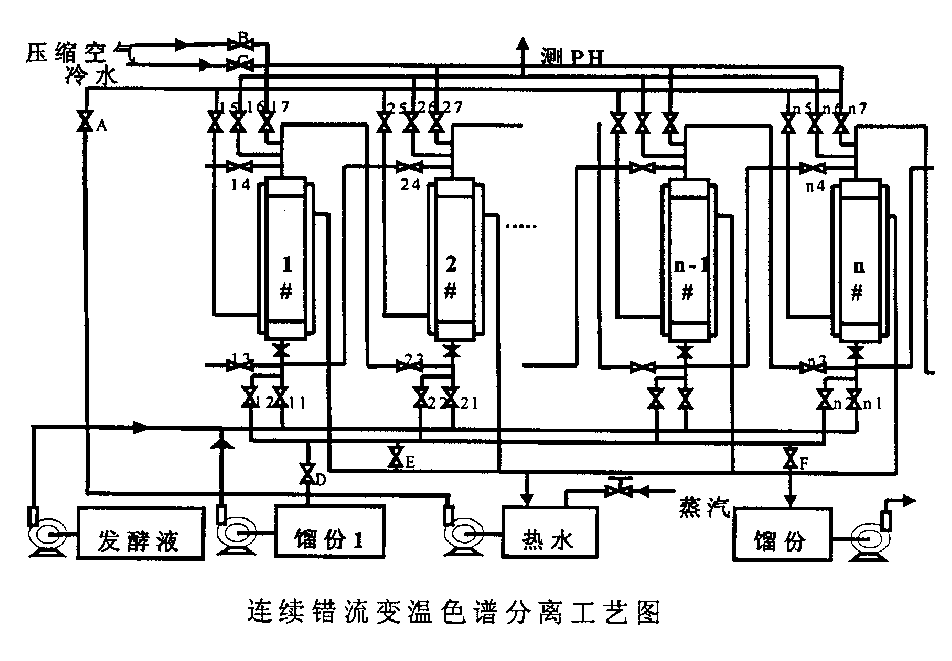

The present invention relates to a clean production process for extracting citric acid from citric acid fermented liuqor, includes the following steps: synthesizing weak-acid strong-base amphoteric resin specially used for adsorbing and separating citric acid, adopting fixed bed with said resin and using continuous cross-current temperature-changing chromatographic adsorption technique to make separation and purification from the fermented liquor so as to obtain clean and pure citric acid product. Under the condition of low temp. the fermented liquor is passed through the resin bed, the citric acid can be adsorbed, and then the hot water can be used, and passed through the saturated resin bed, so the citric acid can be desorbed. It uses heat difference as power for elution, so it does not used acid, does not use alkali and orgnaic solvent chemical product.

Owner:俞铮 +1

Method for treating starchy raw material and method for preparing citric acid

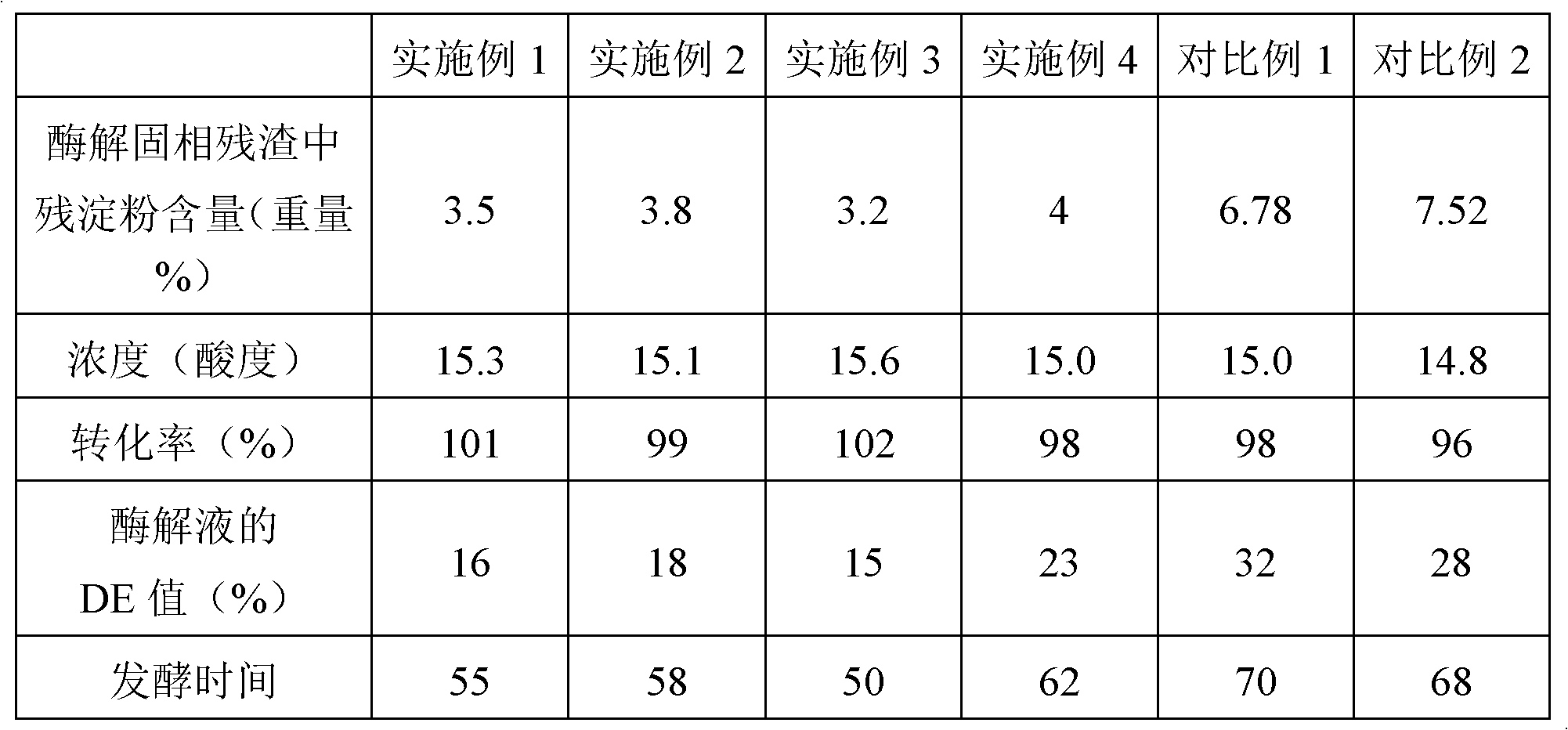

InactiveCN102321704ALow DE valueGood saccharification effectMicroorganism based processesFermentationEmulsionSlurry

The invention relates to a method for treating a starchy raw material and a method for preparing citric acid. The method for treating the starchy raw material comprises the following steps of: mixing powder of the starchy raw material and water to obtain farinaceous size, and mixing the farinaceous size and first part amylase to obtain a mixture; performing primary injection on the mixture by using first steam at the temperature of between 80 and 100 DEG C to obtain primary emulsion, and performing secondary injection on the primary emulsion by using second steam at the temperature of between120 and 150 DEG C to obtain secondary emulsion; performing flash evaporation and reducing the temperature; and mixing a product obtained through flash evaporation and temperature reduction and secondpart amylase, and performing enzymolysis. By the method, a dextrose equivalent (DE) value can be reduced, and the fermentation period of the citric acid can be shortened.

Owner:COFCO BIOTECHNOLOGY CO LTD

Purification method of citric acid fermentation broth

ActiveCN101648864AReduce manufacturing costReduce pollutionPreparation from carboxylic acid saltsCalcium hydroxidePurification methods

The invention relates to a purification method of citric acid fermentation broth, comprising the following steps: adding calcium carbonate or calcium hydroxide into clear liquid to carry out neutralization reaction to generate reaction liquid containing at least one of two precipitates, including calcium dihydrogen citrate and calcium monohydrogen citrate, wherein the bacteria in the clear liquidare removed out of the citric acid fermentation broth, and the pH value at the end point of the reaction reaches 2.0 to 4.0; carrying out solid-liquid separation and washing solid phases; carrying out acidolysis reaction on the solid phases obtained in the previous step, wherein the pH value at the end point of the reaction reaches 1.5 to 2.5; after the reaction, carrying out solid-liquid separation and washing solid phases to obtain calcium salts and citric acid acidolysis liquid with the concentration of 20 percent to 45 percent by weight t; in addition, adding calcium carbonate or calcium hydroxide into liquid phases obtained in the first step to carry out reaction to generate reaction liquid containing at least one of two precipitates, including calcium monohydrogen citrate and calcium citrate, wherein the pH value at the end point of the reaction reaches 5.0 to 7.0; carrying out solid-liquid separation and washing solid phases; and returning the washed solid phases to the step (1) and joining in the reaction again. The method has the advantages of low production cost, high yield and less wastes.

Owner:COFCO BIOTECHNOLOGY CO LTD

Method for extracting citric acid and/or sodium citrate from fermentation liquor by using extraction method

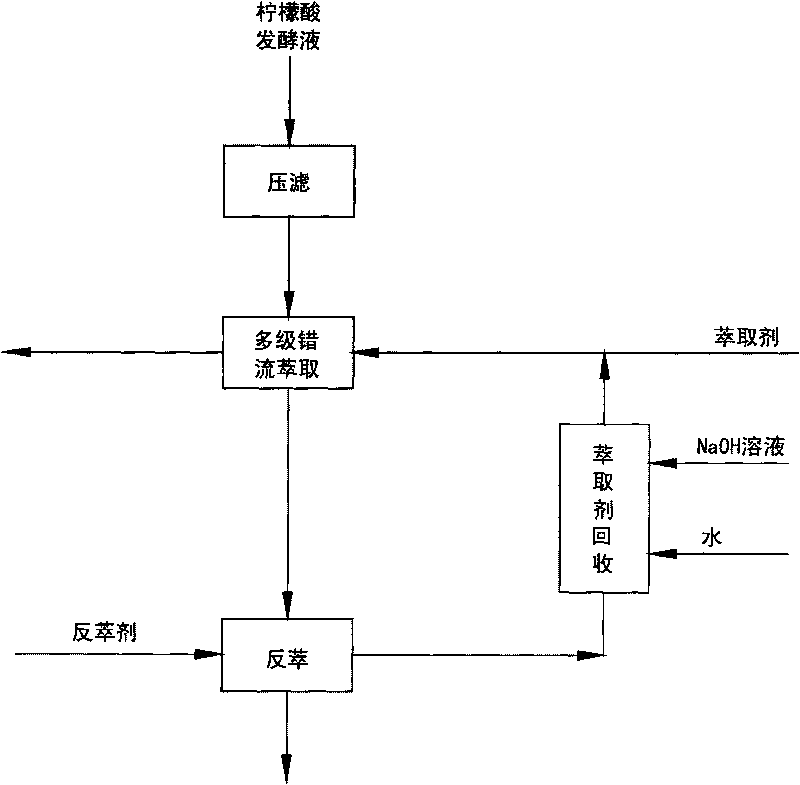

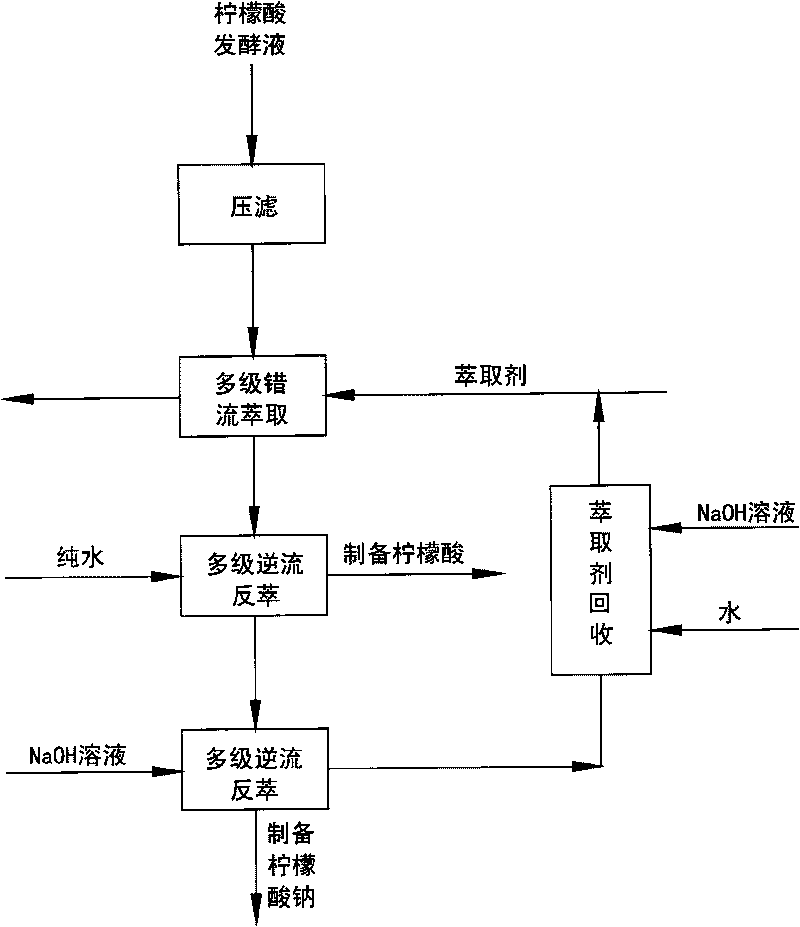

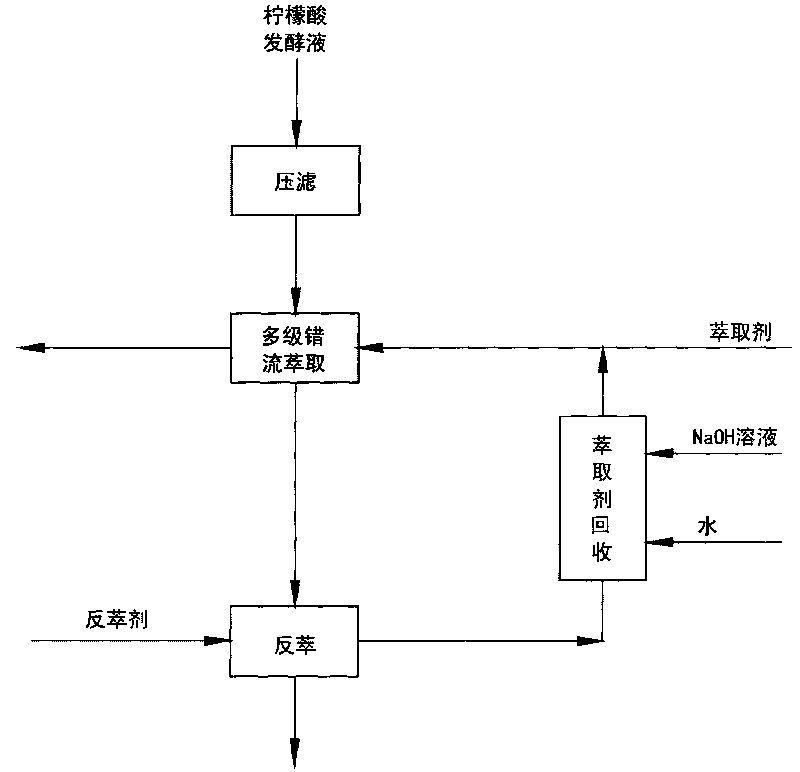

ActiveCN101704739AEasy to produceReduce the degree of emulsificationCarboxylic compound separation/purificationFilter pressSodium citrate

The invention provides a method for extracting citric acid and / or sodium citrate from fermentation liquor by an extraction method. In the method, a mixed solution of tertiary amine and high alcohol is used as a complex extracting agent for carrying out multilevel cross-flow extraction on citric acid fermentation liquor, and pure water and / or a NaOH aqueous solution is selected to carry out back extraction on an extraction phase. A more ideal extraction distribution coefficient can be reached by using the mixed extracting agent of the tertiary amine and the high alcohol to extract a filter-press clear citric acid solution, and the extraction yield by utilizing the multilevel cross-flow extraction can reach more than 98 percent. The extraction phase is back extracted by utilizing the pure water or the NaOH solution so as to prepare citric acid and sodium citrate aqueous solutions being suitable for concentration and crystallization.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Production and fermentation process for citric acid

The invention provides a production and fermentation process for citric acid. The process is characterized in that feeding liquid is refilled into a fermentation tank during the fermentation process of citric acid. According to the invention, through fed batch of the feeding liquid with high concentration of sugar during fed batch fermentation, the concentration of the acid through fermentative production is improved, and inhibition of high initial sugar concentration on fermentation of the citric acid is avoided. With the production and fermentation process provided by the invention, the concentration of the acid through fermentative production is improved, fermentative production intensity is enhanced, the conversion ratio of sugar to the acid during fermentation and the utilization rate of equipment are increased, and thus, economic benefits of an enterprise are increased and competitiveness of the enterprise is improved.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Recrystallization production method for citric acid

ActiveCN101607891AEmission reductionNo emissionsCarboxylic compound separation/purificationCondensation processBacteria removal

The invention provides a recrystallization production method for citric acid, which comprises the following steps that: citric acid fermented liquor is subjected to bacteria removal and impurity removal to form clear citric acid liquor; the clear citric acid liquor is subjected to primary condensation and crystallization to form crude citric acid crystals; the crude citric acid crystals are dissolved, decolorized, desalted, secondarily concentrated and crystallized to obtain citric acid crystals; and the secondary concentrated and crystallized mother liquor returns to the primary condensation process. The method has the advantages that the method has stable product quality, high product yield, and little accessory consumption, concentrates byproducts into sugar feed, reduces the discharge amount of CO2, and has no wastewater discharge, and the like.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

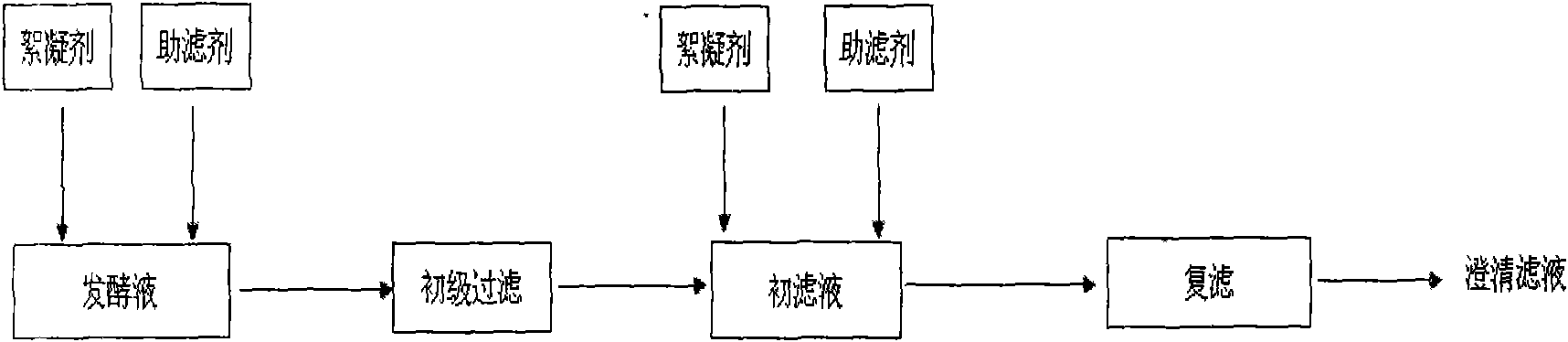

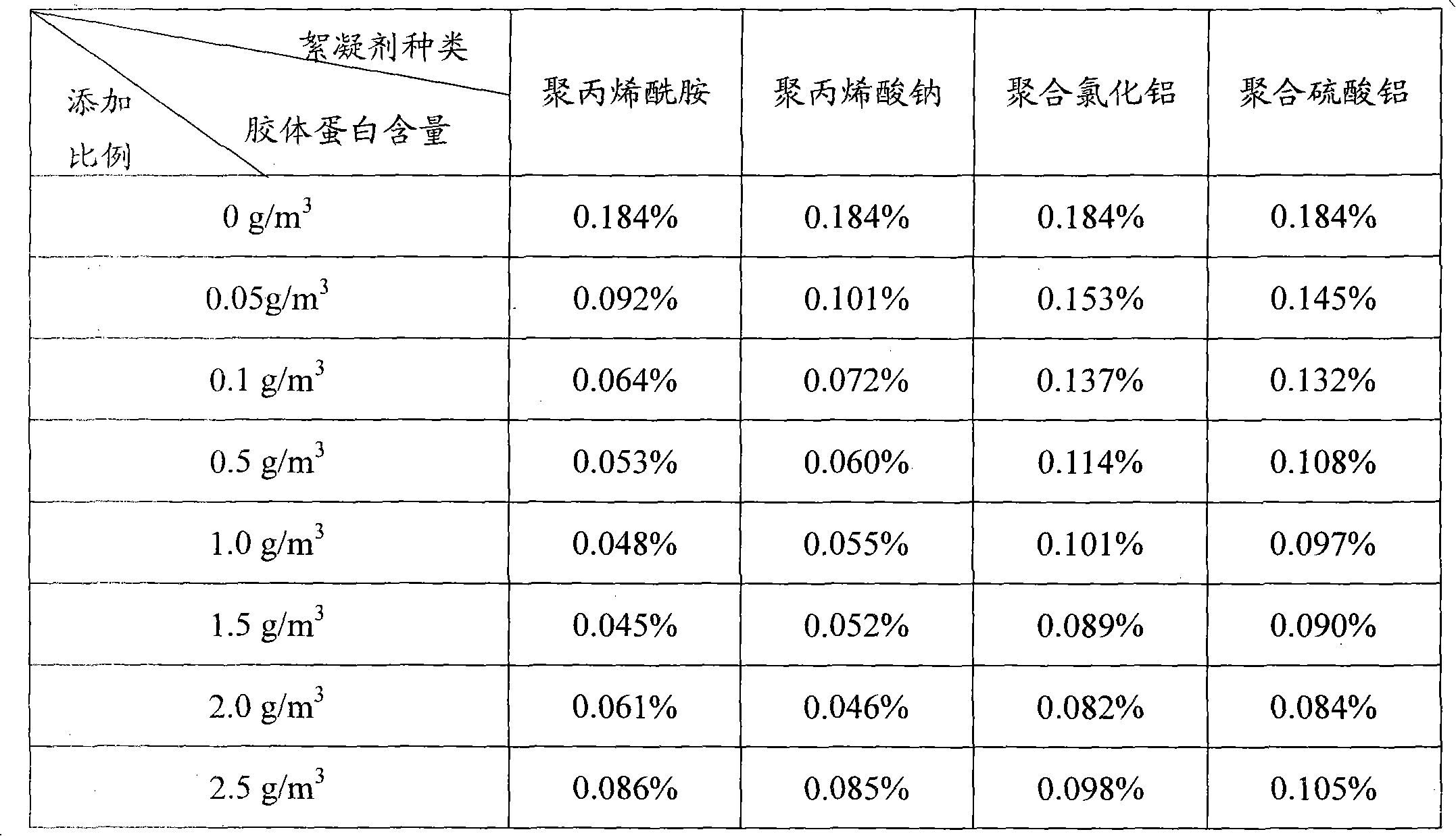

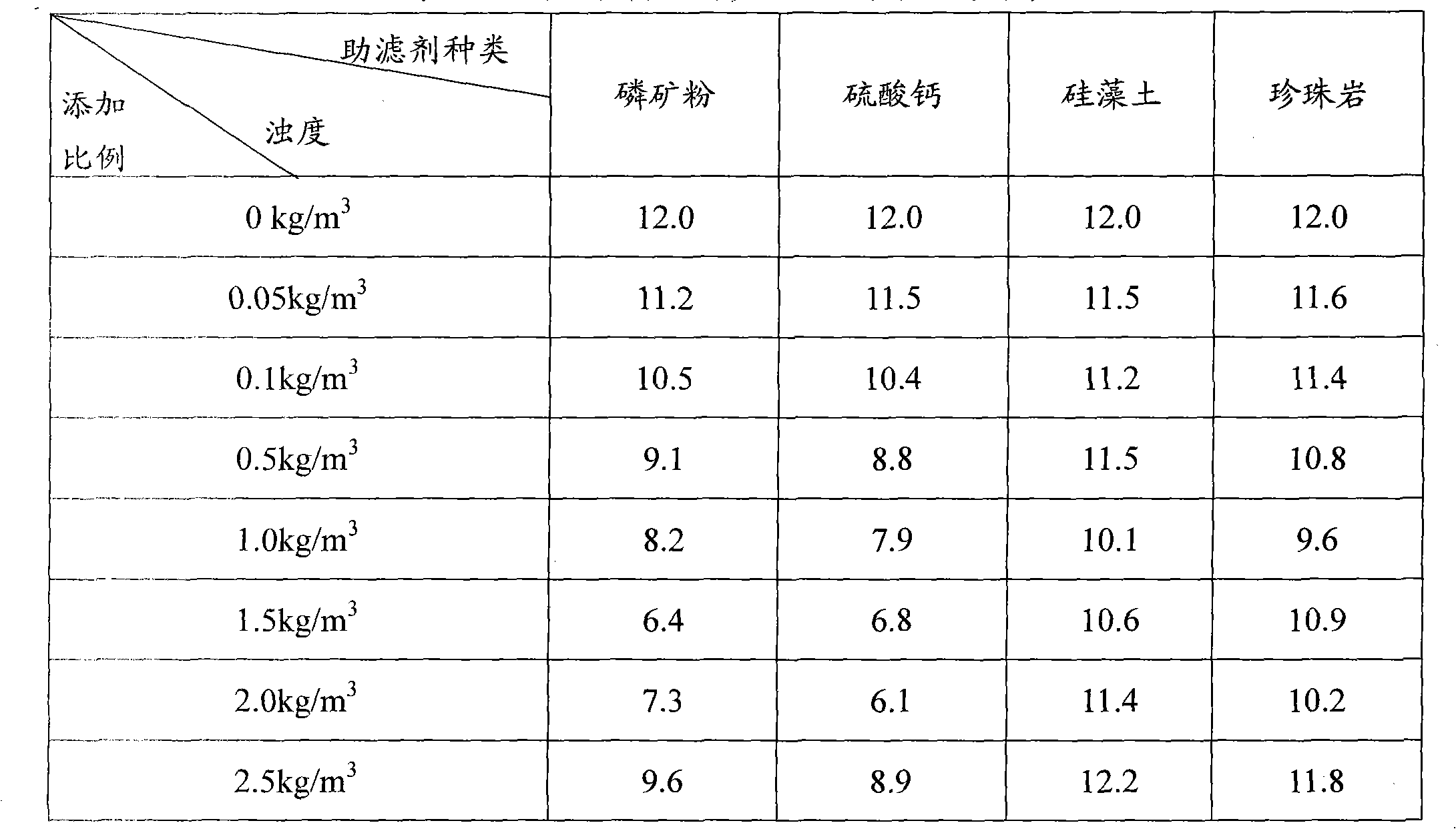

Method for filtering and clarifying citric acid fermentation broth

ActiveCN102249894ALow impurity contentHigh clarityCarboxylic compound separation/purificationTurbidityLactic acid fermentation

The invention relates to a method for filtering and clarifying a citric acid fermentation broth. The method is characterized by the steps that: before the citric acid fermentation broth is processed, various flocculating agents and filter aids are added to feed liquid; filtering is then carried out, such that the clarified fermentation broth with a turbidity lower than 5 is obtained. With the method provided by the invention, quality of the fermentation broth is substantially improved. Not only the turbidity of the fermentation broth is substantially reduced, but the contents of internal colloids, proteins and other impurities in the fermentation broth are also reduced. Therefore, a burden on post extraction is greatly reduced.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Method for protease fed-batch during citric acid fermentation process

ActiveCN103642855ASpeed up the absorption and utilization of nitrogen sourcesPromote growthMicroorganism based processesFermentationOxygenBacterial strain

The invention provides a critic acid production fermentation technology, which is characterized in that: during a critic acid fermentation process, protease is added into a fermentation tank through a fed-batch method so as to hydrolyze the protein in a culture medium into nitrogen sources, which can be rapidly utilized by bacterial strains, such as small molecular peptides, amino acid, and the like. The method can increases the content of amino acid, which can be directly utilized by bacterial strains, in a fermentation fluid; also can fully dissolves out the starch particles, which combine with the protein, reduces the viscosity of the fermentation fluid, improves the oxygen transmission efficiency in the fermentation fluid, promotes the bacterial strains to produce acid, solves the problem that in the current critic acid production process the protein utilization effect is bad in the early fermentation period, shortens the fermentation period, reduces the residual total sugar and grain consumption for fermentation, and increases the economic profits for entrepreneurs.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

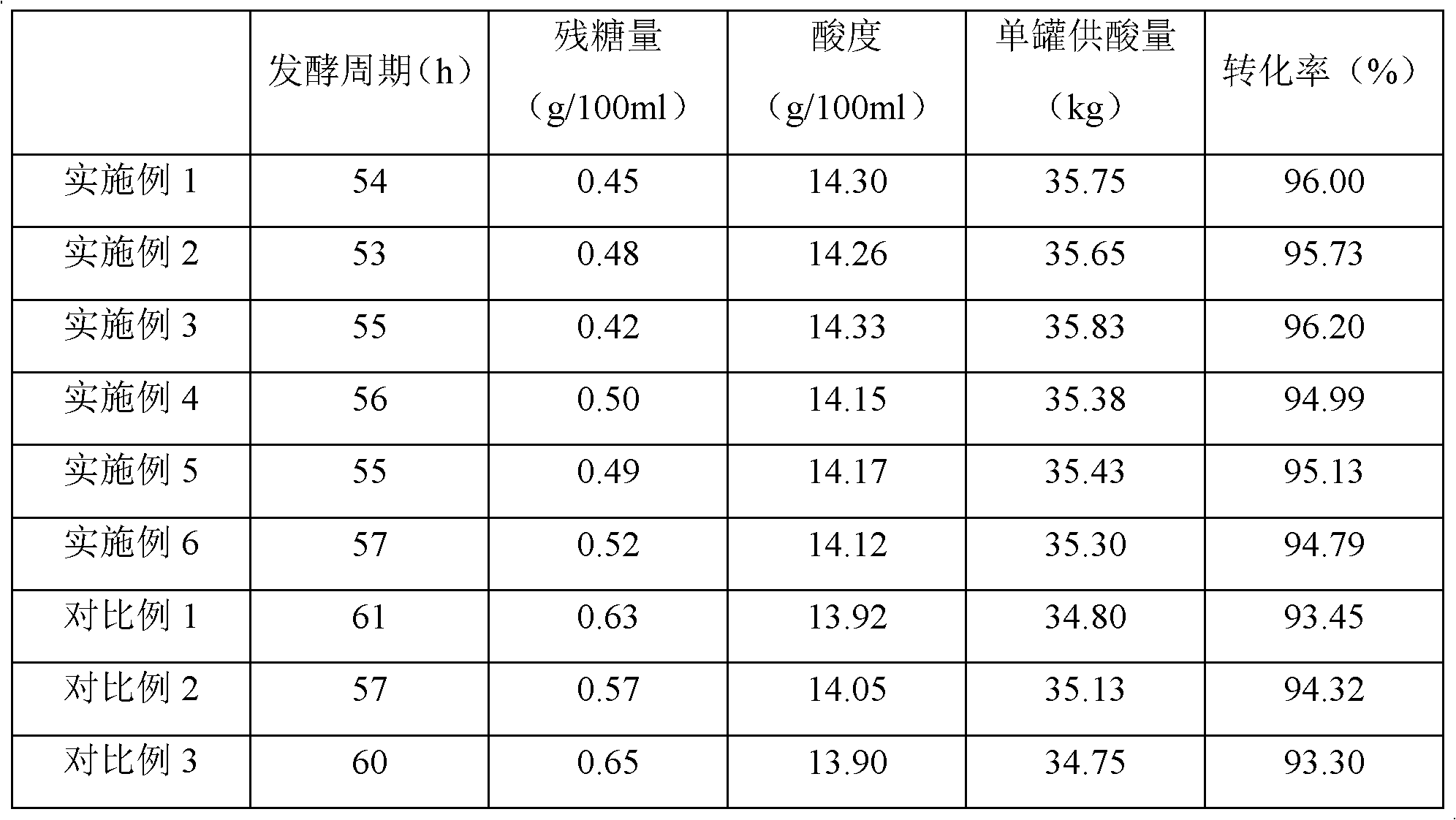

Method for preparing citric acid by fermentation

ActiveCN102533877ATroubleshoot compositingSolve the requestMicroorganism based processesFermentationSugarCitric acid fermentation

The invention discloses a method for preparing citric acid by fermentation, which comprises the following steps: under the conditions of generating citric acid, inoculating citric acid fermentation strain into fermentation media, and carrying out fermentation, thereby obtaining the fermentation liquid. The invention is characterized in that the method also comprises the step of adding saccharifying enzyme into the fermentation media 0-8 hours after inoculating the citric acid fermentation strain. The method disclosed by the invention enhances the saccharifying capacity in the fermentation process, solves the contradiction between the pH value requirements from citric acid synthesis and saccharification in the fermentation process, and avoids the adverse effect of high DE (dextrose equivalent) value on Aspergillus niger, so that the sugar solution in the fermentation media is saccharified more thoroughly, thereby lowering the residual sugar amount in the fermentation liquid, enhancing the end citric acid content and single-tank acid supply amount, increasing the conversion rate of sugar acid and shortening the fermentation period.

Owner:COFCO BIOTECHNOLOGY CO LTD

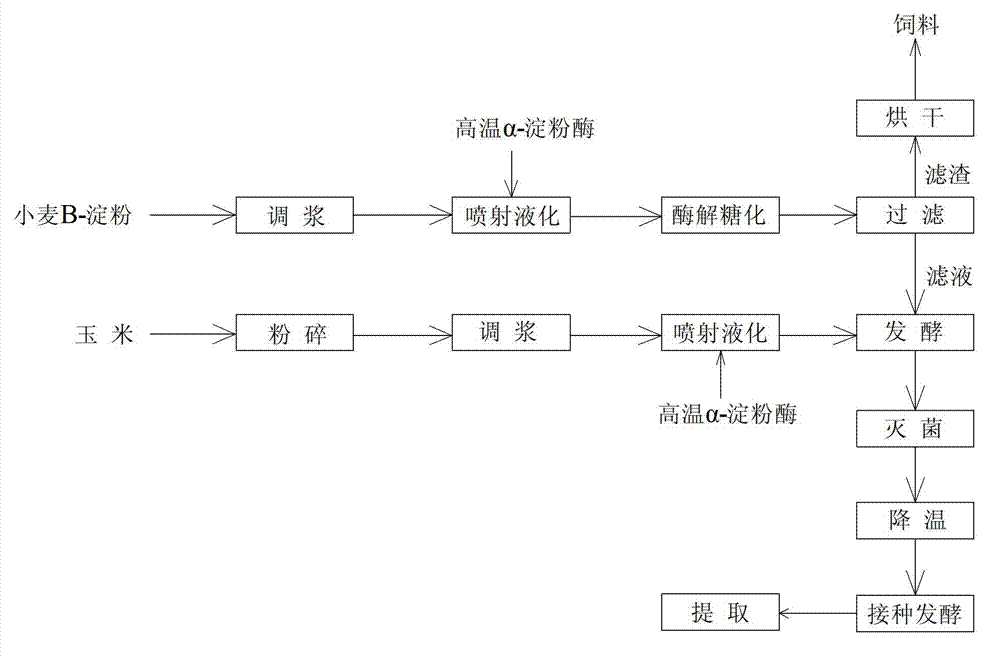

Method for production of citric acid through fermentation of wheat B-starch

InactiveCN102899364AReduce consumptionLow costMicroorganism based processesFermentationFiltrationDissolution

The invention relates to a method for production of citric acid through fermentation of wheat B-starch. The method is characterized in that the method improves a conventional citric acid fermentation process with corn as a raw material by using the by-product B-starch produced during processing of wheat to partially replace corn for fermentation production of citric acid and comprises the procedures of slurry mixing, liquefaction, enzymatic hydrolysis, saccharification, filtration and fermentation, and through full liquefaction, enzymatic hydrolysis and saccharification of the wheat B-starch and filtration, the method allows the viscosity of feed liquid to be greatly reduced while allowing the conversion rate of the starch to substantially reach a theoretical value and overcomes the problems of poor mass transfer and bad dissolution of oxygen in deep aerobic fermentation process of the wheat B-starch. On such an occasion that grain raw materials are in shortage, the process utilizes the cheap wheat B-starch, so production cost of citric acid is substantially reduced, and the source of raw materials for citric acid is broadened.

Owner:RIZHAO LUXIN JINHE BIOCHEM

Method for producing citric acid by fermentation of mixed raw materials

ActiveCN101948881AImprove liquidityImprove fermentation indexMicroorganism based processesFermentationFiltrationCitric acid fermentation

The invention discloses a method for producing citric acid by fermentation of mixed raw materials. The method comprises the following main steps of: performing crushing, size mixing, spraying liquefaction and filtration on corn and cassava respectively, then mixing two parts of filtrate according to a proportion and fermenting the mixture, and finally extracting the citric acid. The method effectively avoids cost rise caused by the fluctuation of single raw material, meanwhile enriches the nutrient components of fermented liquor, is favorable for improving the acid producing capability of citric acid fermentation strains, enables an enterprise to have great choice on the raw materials, and reduces the production cost. Moreover, compared with a method for producing the citric acid by the single raw material, the method has the advantages that: the fermentation liquor has good liquidity, the fermentation period is obviously shortened, and the fermentation index is higher.

Owner:JIANGSU GUOXIN UNION ENERGY CO LTD

Method for extracting refined citric acid from citric acid fermentation liquid

ActiveCN101781190AReduce energy consumptionIncrease labor intensityCarboxylic compound separation/purificationParticulatesEnvironment effect

The invention discloses a method for extracting refined citric acid from citric acid fermentation liquid. The citric acid products are obtained from the citric acid fermentation liquid through the steps of membrane disinfection, decoloration using powder carbon, electrodialytic treatment, decoloration using particulate carbon, ion exchange, concentration and crystallization. The method is used for preparing the citric acid products through the technology of membrane disinfection, decoloration, electrodialysis, ion exchange, concentration and crystallization, and the citric acid products have the advantages of high whiteness, low carbon, difficult caking, short technological process, stable production quality, energy conservation and emission reduction and slight environmental pollution, and the extraction ratio is about 90 percent.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Chromatographic separation method for citric acid

InactiveCN101607889AIncrease the level of automationHigh yieldCarboxylic compound separation/purificationChromatographic separationCitric acid fermentation

The invention provides a chromatographic separation method for citric acid, which comprises the following steps: removing bacteria and impurities from citric acid fermented liquor to obtain clear citric acid liquor; decolorizing and desalting the clear liquor; then feeding the clear liquor to an ion exclusion chromatographic system; treating the clear liquor by water or dilute acid as an eluting agent to obtain citric acid solution; and removing impurities, concentrating and crystallizing the citric acid solution to obtain citric acid crystals. The method has the advantages of stable product quality, high product yield, little accessory consumption, no calcium sulphate discharge, and the like.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Aspergillus niger seed liquid preparation method and citric acid fermentation preparation method

ActiveCN104277978AQuality improvementReduce incubation timeFungiMicroorganism based processesSocial benefitsSpore

The invention provides an anspergillus niger seed liquid preparation method which is as follows: anspergillus niger is inoculated into a seed culture liquid for culturing, wherein the before the anspergillus niger is inoculated into the seed culture liquid for culturing, anspergillus niger spore is precultured, thepreculture condition comprises pH value of 6.2-7.2. In addition, the invention also discloses a citric acid fermentation preparation method. By use of the anspergillus niger seed liquid preparation method, he culture time of the aspergillus niger in a seed tank can be shortened, the utilization rate of equipment is improved, energy consumption is reduced, the quality of the seed liquid is improved, the fermentation level is greatly improved, and the method has considerable economic and social benefits.

Owner:COFCO BIOTECHNOLOGY CO LTD

Alkaline soil amendment and application

InactiveCN109777441AEffective distributionImprove solubilityAgriculture tools and machinesOrganic fertilisersPullulanAmino acid

The invention belongs to the field of soil amendments, and particularly relates to an alkaline soil amendment. The alkaline soil amendment is prepared from polyglutamic acid, activated humic acid, amino acid waste liquid, ammonium polyphosphate, citric acid fermentation waste residues, Pullulan polysaccharide, polyaspartic acid, sodium carboxymethyl starch, tetrahydropyrimidine and trehalose. Accordingly, the purpose of improving alkaline soil is achieved by adding a water retaining agent to control salt, adding acidic organic matter to activate humic acid, adding the amino acid waste liquid to control the pH value, adding a chelating agent to prevent solidification and adding an osmotic pressure stabilizer to prevent root dehydration. The amendment has the advantages that raw materials are natural, non-toxic and biodegradable, the cost is low, the yield is high, and the effectiveness of soil nutrients can be fully achieved; the activated humic acid improving the reactivity of organicmatter and the amino acid waste liquid mainly consisting aginomoto waste liquid are synergized; the water retaining agent, the chelating agent and the osmotic pressure stabilizer act together, and theadvantages of the amendment are strengthened.

Owner:QILU UNIV OF TECH

Processing method of starch raw material and method for preparing citric acid

InactiveCN104164458AHigh protein contentIncrease vitalityMicroorganism based processesFermentationAmylaseProteinase activity

The invention discloses a processing method of a starch raw material, wherein the method includes the starch raw material, mycelia and water are mixed and subjected to slurry conditioning to obtain a starch slurry, and the starch slurry, an amylase and a protease are mixed and subjected to enzymolysis, wherein the mycelia are obtained after solid liquid separation of a citric acid fermentation liquid; relative to 100 parts by weight of the starch raw material, the mycelia amount is 5-40 parts by weight, and the water amount is 50-500 parts by weight. The invention also provides a method for preparing citric acid through using the enzymatic hydrolysate obtained by the processing method. The processing method of the starch raw material can reduce grain consumption, and the protein content of the obtained enzymatic hydrolysate is high. Moreover, the obtained enzymatic hydrolysate is adopted to be subjected to citric acid fermentation, and the conversion rate of citric acid fermentation can be increased.

Owner:COFCO BIOTECHNOLOGY CO LTD

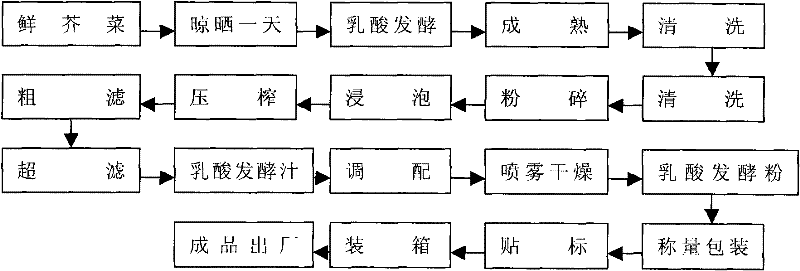

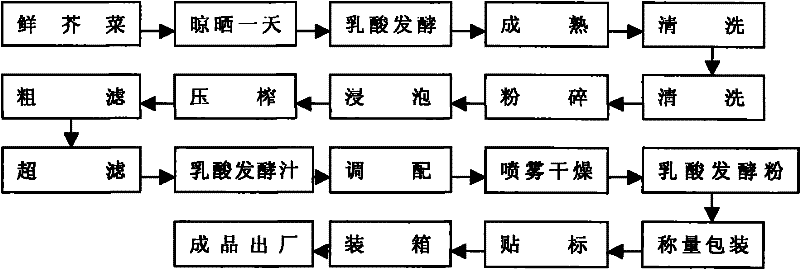

Processing method of lactic acid fermented mustard powder flavoring

InactiveCN102326755AGreat tasteSimple processing technologyFood preparationMicroorganismPreservative free

The invention relates to a processing method of lactic acid fermentated mustard powder flavoring, which is characterized in that: fresh mustard is selected to be processed in lactic acid fermentation after being aired for 0.5 to 1 day; the mustard which is well processed in the lactic acid fermentation is filtered after being pulverized, soaked and juice extracted, so clear lactic acid fermented mustard juice can be obtained; the lactic acid fermented mustard juice is prepared and then is dried in an atomizing way to obtain lactic acid fermented mustard powder; the processing method is simpleand is easy to operate, the prepared flavoring has good taste, is rich in amino acid and minerals and is free from containing antiseptic, and the salt content is low and is only 8 percent to 12 percent; compared with the traditional liquid mustard juice, because the lactic acid fermentated mustard powder flavoring is a powder product, the quality is stable, the shelf life is long, and the flavoring is difficult to change the color and flavor due to the influence of light rays and air microorganisms; and moreover, the lactic acid fermented mustard powder flavoring is convenient to pack and transport, and the cost is low.

Owner:ZHEJIANG WANLI UNIV

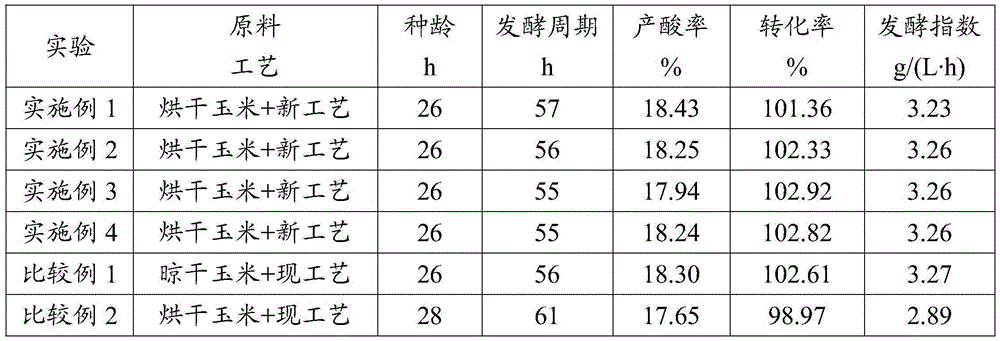

Citric acid fermentation technology

ActiveCN105385711AGood training effectImprove the cultivation effectMicroorganism based processesFermentationEconomic benefitsNitrogen source

The invention relates to the field of citric acid fermentation, in particular to a citric acid fermentation technology. The citric acid fermentation technology is characterized in that in a citric acid seed tank and a fermentation tank culture process, a mixed nitrogen source and microelements are added to compensate for the loss of nutritional ingredients of high-temperature dried corn in the high-temperature drying process to reach the ideal culture effect; the optimal culture effect is achieved by regulating the variety and ratio of the nitrogen source and adding the microelements according to the different characteristics of strains in the growing and acid production stages. After the technology is adopted, the seed age of seed culture can be shortened, fermentation stability can be improved, fermentation production intensity can be improved, the fermentation period can be shortened, the fermented sugar acid conversion rate and the equipment utilization rate can be increased, the source of citric acid fermentation raw materials is expanded, the competitiveness of the citric acid industry is improved, and then the economic benefits of an enterprise are improved.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

L-lactic acid fermentation method by using polyvinyl alcohol to solidify rhizopus oryzae

InactiveCN101519675AIncrease productionAvoid pollutionMicroorganism based processesOn/in organic carrierWater bathsPolyvinyl alcohol

The invention discloses an L-lactic acid fermentation method by using polyvinyl alcohol to solidify rhizopus oryzae. The method comprises the following steps: heating polyvinyl alcohol and sodium alginate in a boiling water bath to be jointly dissolved; mixing with a rhizopus oryzae spore suspension; using an injector to drip the mixed solution to a saturated boric acid solution containing calcium chloride while using a magnetic stirrer to continuously stir so that particles are spherical and good immobilized particles can be hardened at a low temperature; and then, treating by a monobasic sodium phosphate solution and washing with distilled water after solidified cells are propagated and grow so as to be used for the batch fermentation and the repetitive batch fermentation of the L-lactic acid. The improved L-lactic acid fermentation method by using the polyvinyl alcohol to solidify the rhizopus oryzae overcomes the defects of spherical carriers and poor permeability of the prior polyvinyl alcohol and has the advantages of great mechanism strength, large acid production amount, high acid production speed and good repetitive use effect.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Citric acid fermented stock solution and preparation method for citric acid and starch sugar

InactiveCN102517345AOvercome the defect that the conversion rate is still not highImprove conversion rateMicroorganism based processesFermentationNitrogen sourceSugar

The invention provides a citric acid fermented stock solution. The citric acid fermented stock solution contains a nitrogen source, sugar scum and a liquefied clear solution, wherein the sugar scum is a filter residue obtained by filtering a saccharifying solution; the saccharifying solution is a product obtained by contacting a liquefied solution of a starchy raw material with a saccharifying enzyme under a saccharifying condition; the liquefied clear solution is a filtrate obtained by filtering the liquefied solution of the starchy raw material; and the starchy raw material used for preparing the saccharifying solution and the starchy raw material used for preparing the liquefied solution are the same or different. The invention also provides a preparation method for a citric acid. The invention also provides a co-production method for the citric acid and starch sugar. Through the technical scheme, the preparation method for the citric acid is capable of reaching conversion rate of over 90 percent.

Owner:COFCO BIOTECHNOLOGY CO LTD

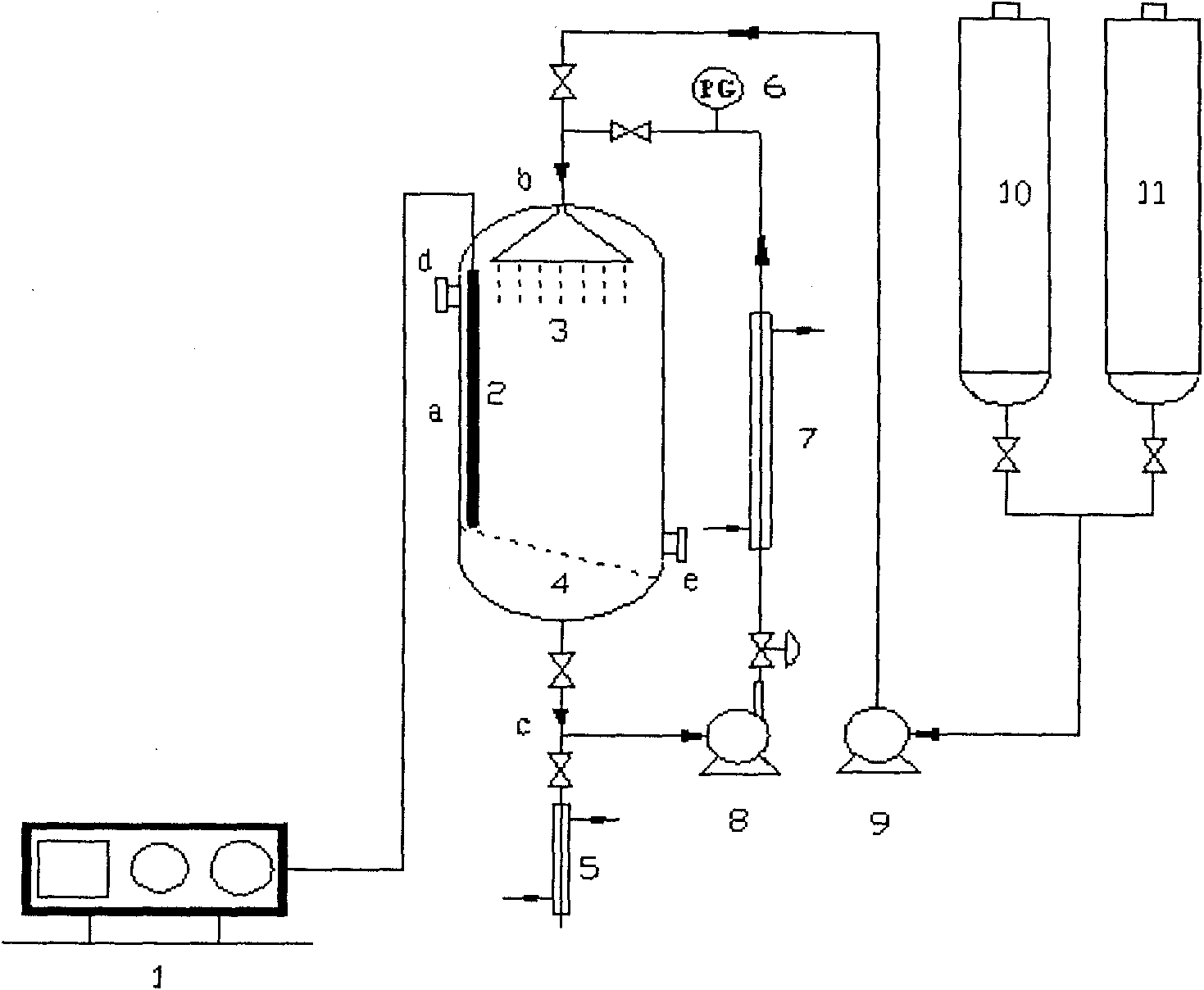

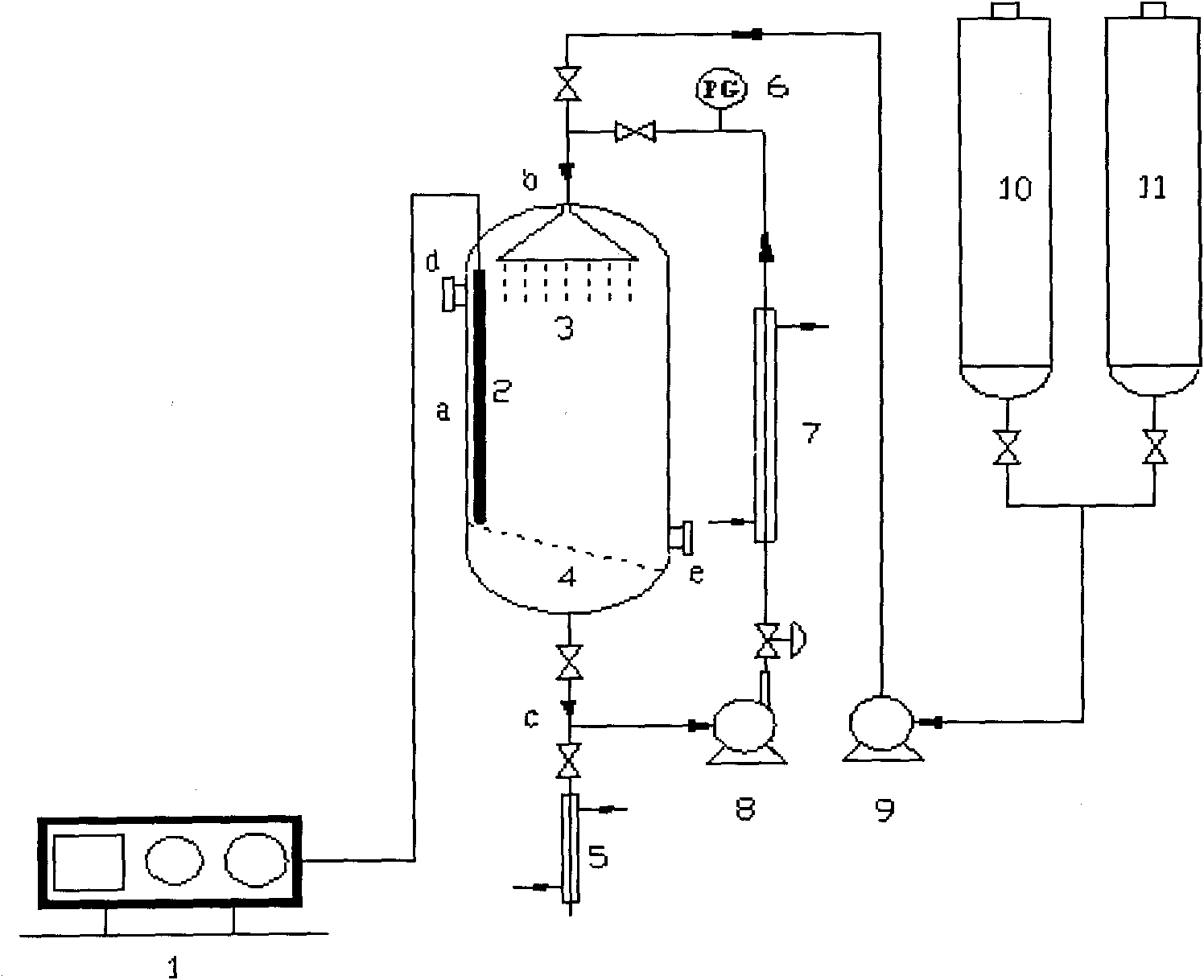

Device and method for hydrolyzing plant hemicellulose by fermented citric acid wastewater

InactiveCN101787086AReduce processing costsSolve the sourceFermentationHigh concentrationWater storage tank

The invention relates to a device capable of effectively utilizing fermented citric acid wastewater to hydrolyze plant hemicellulose. The device is mainly composed of a circulating spray flushing and filtering reactor, an acid storage tank, a water storage tank and a heat exchanger; the method is characterized by comprising the steps: at first, mixing the citric acid wastewater with raw material of the plant hemicellulose for hydrolysis reaction at 100 to 200 DEG C to obtain hydrolyzate mainly containing pentose, and then adding cellulase into hydrolyzed residues for batch enzyme hydrolysis to obtain high-concentration dextrose for the fermentation of ethanol. The method for preparing fermentable sugar for ethanol by pretreating the raw material of the plant hemicellulose by using the fermented citric acid wastewater can not only sufficiently utilize the fermented citric acid wastewater to save water resource, but can also lower the cost for treating wastewater from fermented citric factory and the production cost of the fermentable sugar for cellulose ethanol.

Owner:NANJING UNIV OF TECH

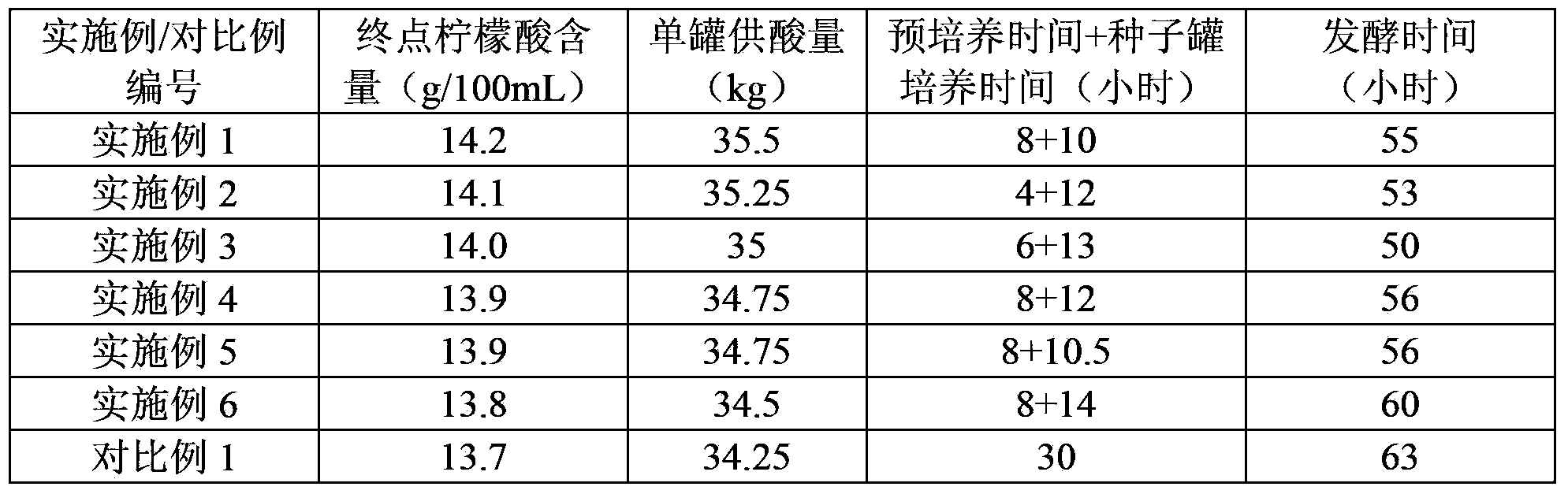

Method for culturing citric acid fermenting seeds and method for preparing citric acid by fermenting

ActiveCN102864082AShorten the time periodShorten the fermentation cycleFungiMicroorganism based processesBiotechnologyCitric acid fermentation

The invention discloses a method for culturing citric acid fermenting seeds. The method includes inoculating citric acid fermenting strains into a seed culture medium of a seed tank for seed culturing to obtain seed liquid. The method for culturing citric acid fermenting seeds is characterized in that pressure of the seed tank, ventilatory capacity and stirring rotation speed are all higher than previous pressure, ventilatory capacity and stirring rotation speed after seed culturing for 10-15 hours. The invention further discloses a method for preparing citric acid by fermenting. The method for preparing citric acid by fermenting includes subjecting the citric acid fermenting strains to seed culturing under the condition of seed culturing, inoculating the seed solution obtained after seed culturing into the fermenting culturing medium to ferment under the condition of generating citric acid so as to obtain fermenting liquid. The method for preparing citric acid by fermenting is characterized in that the citric acid is subjected to seed culturing according to the above method. By the methods, seed age can be shortened, seed quality is improved, fermenting period is shortened, conversion rate and final citric acid content are increased, consumption of power such as water and electricity is reduced and cost is saved.

Owner:COFCO BIOTECHNOLOGY CO LTD

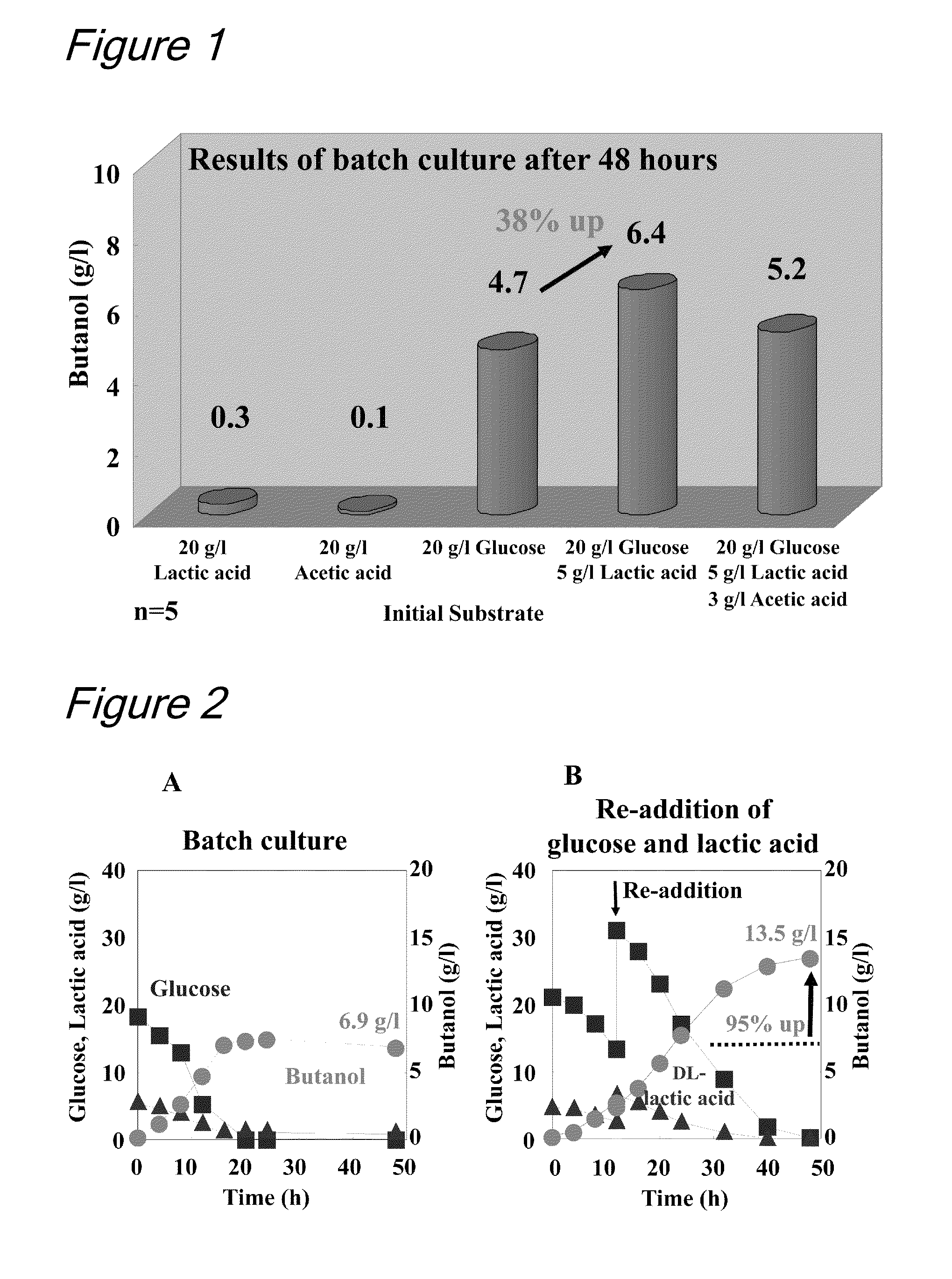

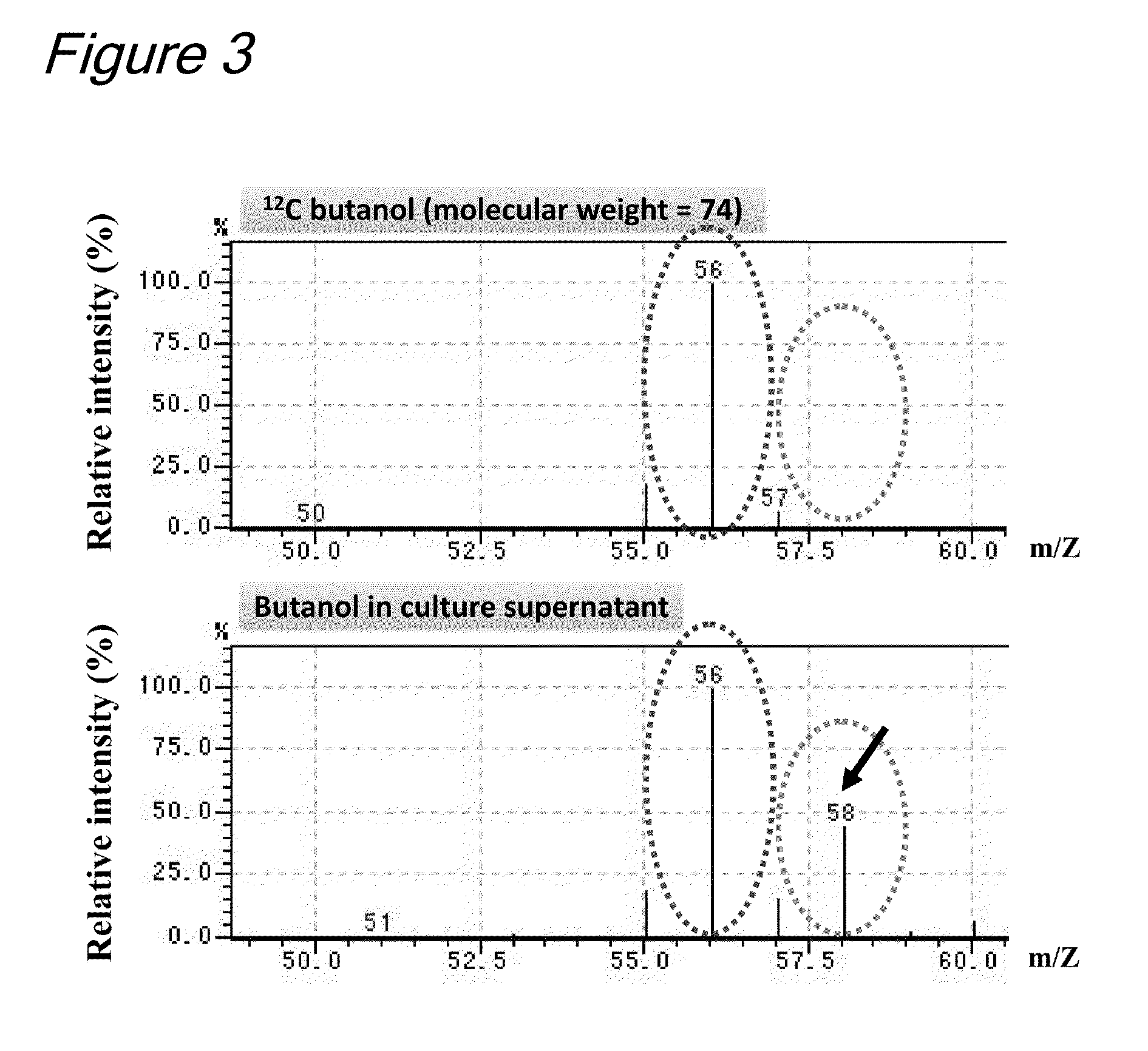

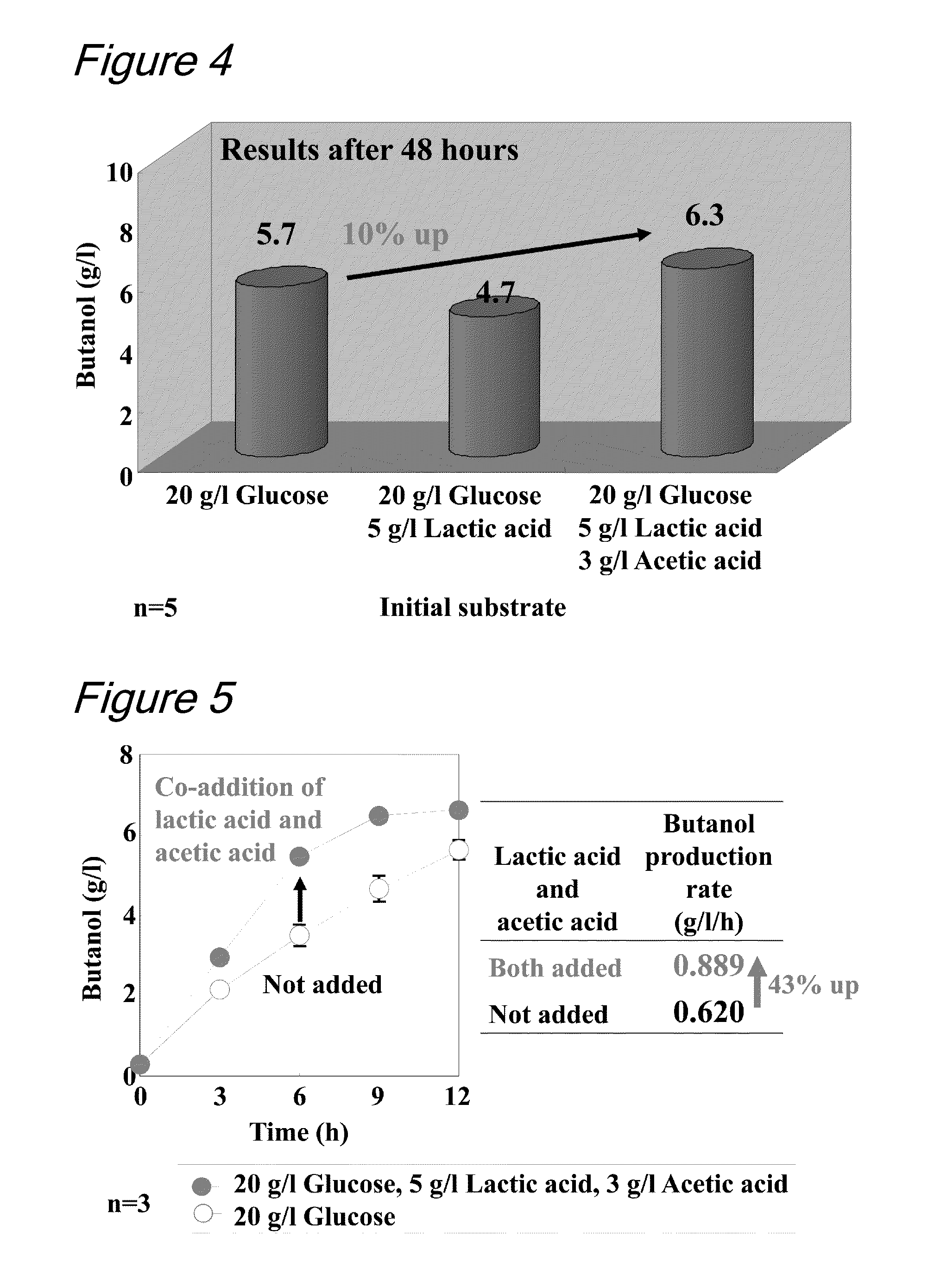

Method of producing butanol

InactiveUS8420359B2Improve maximum concentrationIncrease ratingsBacteriaBiofuelsGenetics manipulationGenus

The present invention provides a method of producing butanol, comprising: causing a microorganism which belongs to the genus Clostridium and is capable of producing butanol to produce butanol in a medium comprising saccharides assimilable by a microorganism which belongs to the genus Clostridium, lactic acid and / or acetic acid as substrates. By the method of the present invention, the concentration of butanol produced in a culture medium (solution) can be increased and, furthermore, the rate of butanol production can also be increased. In the present invention, a mixture of D-lactic acid and L-lactic acid obtained by lactic acid fermentation or a fermentation product of hetero-lactic acid fermentation containing acetic acid as a by-product can be utilized. By combining lactic acid fermentation and the method of the present invention, a practical system of butanol production from inedible biomass which requires neither expensive enzyme nor advanced technology such as genetic manipulation can be constructed.

Owner:SUMITOMO CORPORATION +1

Method for using dried potato flour to prepare potassium citrate

InactiveCN101693907AReduce pollutionReduce manufacturing costMicroorganism based processesCarboxylic acid salt preparationPotassium hydroxidePotassium

The invention discloses a method for using dried potato flour to prepare potassium citrate, comprising the following steps of grinding dried sweet potatoes or tapioca chips into 60 to 80 class, making into a pasty mixture according to a proportion of 1: 4 to 5 of flour and water, pumping the mixture into a fermentation tank, adding amylase and ammonium sulphate into the fermentation tank, liquefying the starch by rising temperature, lowering the temperature to 39 degrees after sterilization and disinfection, adding aspergillus niger that is a fermenting culture of citric acid to implement fermentation for 55 to 60 hours, heating the mixture to 70 to 80 degrees, getting fermentation liquor containing citric acid through separation, adding the aspergillus niger into the fermentation tank to implement fermentation after liquidation, sterilization and disinfection through rising temperature, and using the fermented fermentation liquor containing citric acid to prepare calcium citrate by a method of 'calcium salts' and further to prepare potassium citrate through adding potassium carbonate. Compared with the method for preparing potassium citrate through the reaction of finished citric acid and potassium hydrate, the invention directly extracts potassium citrate from the fermentation liquor, has the advantages of low production cost, high economic profit, short flow of production, less production waste and less environmental pollution, and can reduce the production cost by 20 to 30 percent.

Owner:HUNAN DONGTING CITRIC ACID CHEMICALS CO LTD

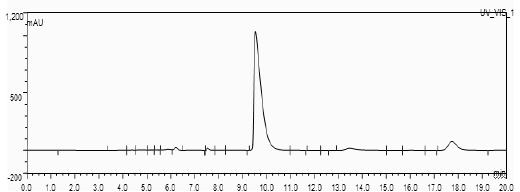

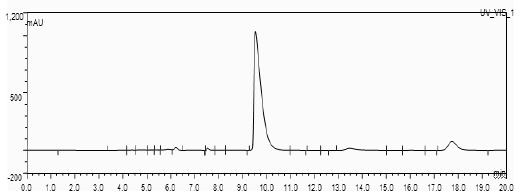

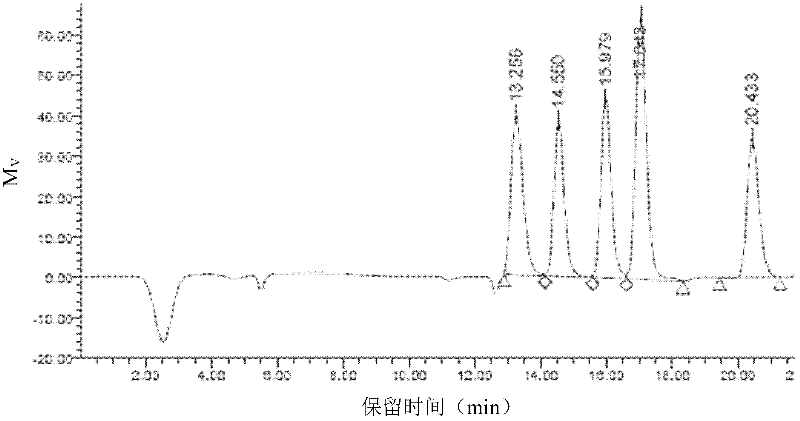

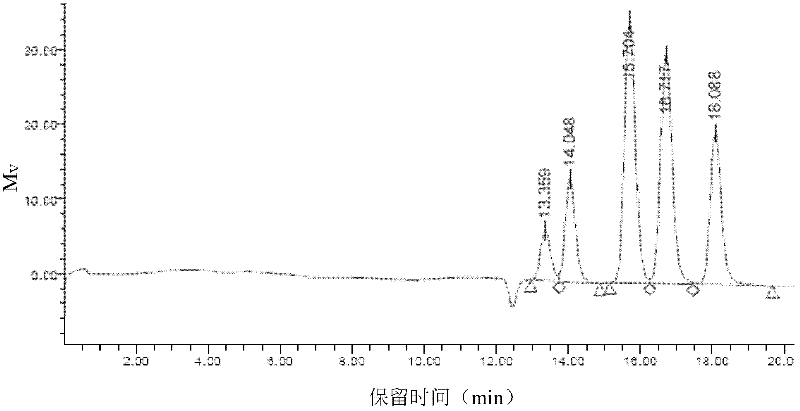

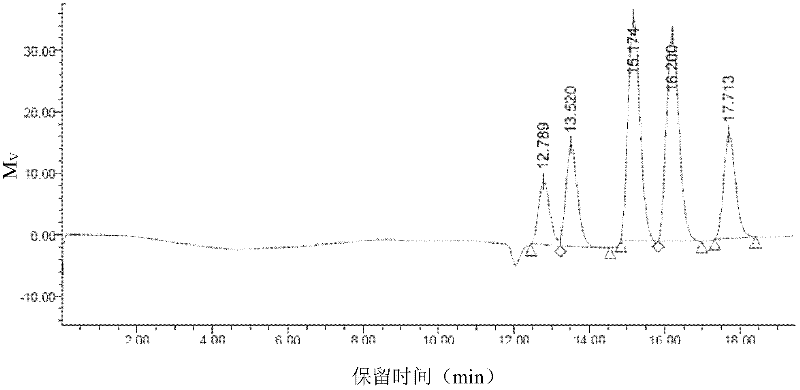

Analysis method of citric acid fermentation aqueous solution

The invention discloses an analysis method of a citric acid fermentation aqueous solution, comprising the following steps of: using a chromatographic column which contains a reversed phase chromatographic separating column and an ion-exclusion chromatographic column connected in series; introducing a mixed solution of the citric acid fermentation aqueous solution and a mobile phase from an upper end of the reversed phase chromatographic separating column under the condition of chromatographic separation, respectively contacting with the reversed phase chromatographic separating column and the ion-exclusion chromatographic column, continuously washing out the reversed phase chromatographic separating column and the ion-exclusion chromatographic column by the use of an eluent, leading out the eluant A from a lower end of the ion-exclusion chromatographic column, carrying out chromatography to obtain retention time and peak area, comparing with a standard spectrogram obtained under the same condition to obtain sugar components of the citric acid fermentation aqueous solution, contents of each component in the sugar and the content of citric acid in the fermentation aqueous solution, wherein the eluant has the same composition with the mobile phase. By the adoption of the method provided by the invention to detect the citric acid aqueous solution, citric acid and the sugar can be separated from each other, and concrete components of the sugar, the content of each component in the sugar and the content of citric acid can also be detected. The analysis method provided by the invention is simple.

Owner:COFCO BIOTECHNOLOGY CO LTD

Method for extracting chitin by utilizing citric-acid fermentation waste residue

The invention relates to a method for extracting chitin by utilizing citric-acid fermentation waste residues, which is characterized by comprising the following steps of: citric-acid waste-residue preprocessing, high-pressure wall breaking, coarse filtration, acid processing, alkali processing to obtain the chitin and deacetylation to obtain chitosan. The invention has the advantages that under the action of high-pressure wall breaking, a mycelium can become quite fine and can pass through a mesh screen of 20-40 meshes, and the solid impurities in the waste residues can be filtered. After a cell wall is broken, the chitin at the inner-layer part of the cell wall becomes easy to extract, thus not only the product purity is improved, but also the product yield is improved. The large-scale industrialized production is realized.

Owner:天津泰康生物制药有限公司

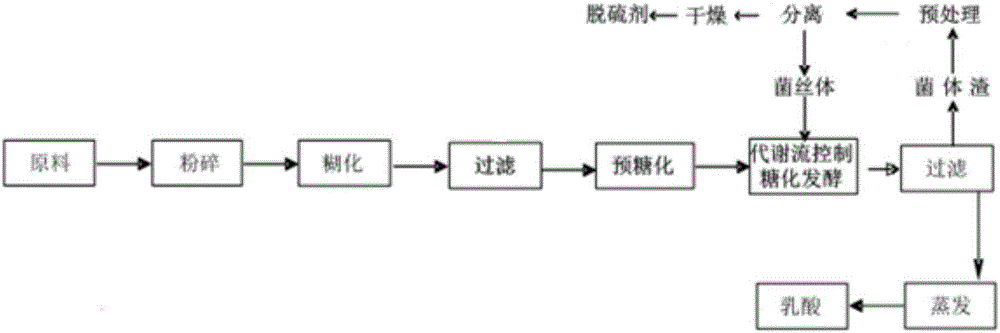

Method for lactic acid fermentation thallus residue pretreatment and method for circulation fermentation production of lactic acid

The invention belongs to the technical field of lactic acid fermentation, and particularly relates to a method for lactic acid fermentation thallus residue pretreatment and application of the method for circulation fermentation production of lactic acid. The method for pretreatment comprises the steps that thallus residues obtained through filtering and separation of a lactic acid fermentation solution are pretreated through a composite medium; the pretreated thallus residues are filtered and separated to obtain soluble nutrient substances and insoluble impurities; the composite medium is prepared from ammonium sulfate, ethylenediamine tetraacetic acid disodium salt, sodium dodecyl sulfate and sodium citrate. According to the method for lactic acid fermentation thallus residue pretreatment, soluble nutrient substances, including thallus and unconsumed nutrients, obtained after treatment of the composite medium can continue to participate in fermentation, the separated thallus is adopted as a nutrition nitrogen source to be returned to a fermentation working procedure, the consumption of nutrient substances in the fermentation culture medium can be reduced, the problem of fermentation waste residue outlet is solved, consumption of raw and auxiliary materials is lowered, the composite medium can be recycled, and resource recycling is achieved.

Owner:河南金丹乳酸科技股份有限公司

Method for high-protein feedstuff by fermenting citric acid cornstarch residue and mycelium residue

The invention relates to a method for preparing high-protein feedstuff by fermenting citric acid cornstarch residue and mycelium residue as base material through mixed bacteria. The cornstarch residue and the mycelium residue produced by citric acid fermentation are used as solid medium, the compound enzyme and the mixed bacteria are added to carry out solid state fermentation, and the products after fermentation are dried and crushed to produce high protein feed products. The method utilizes the biological fermentation technology to efficiently utilize the cornstarch residue and the mycelium residue in the citric acid production, thereby improving the utilization value of the citric acid fermentation residue and making it become a new protein feedstuff with high added value. The fermented high-protein feedstaff is rich in protein, organic acid, amino acids, vitamins, minerals, trace elements, biological enzymes and peptides, small peptides and so on enhancing immunity of animals, which have high nutritive value. With nutrition, attractant and prebiotics and other functions, animal digestion and absorption of animals are facilitated, animal digestive function is improved, and animal immunity is enhanced.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com