Method for treating starchy raw material and method for preparing citric acid

A technology of starchy raw materials and processing methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as difficult gelatinization, difficult liquefaction of starchy raw materials, and unfavorable effects of glucoamylase , to achieve the effect of facilitating saccharification, shortening the fermentation cycle, and reducing the content of residual starch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

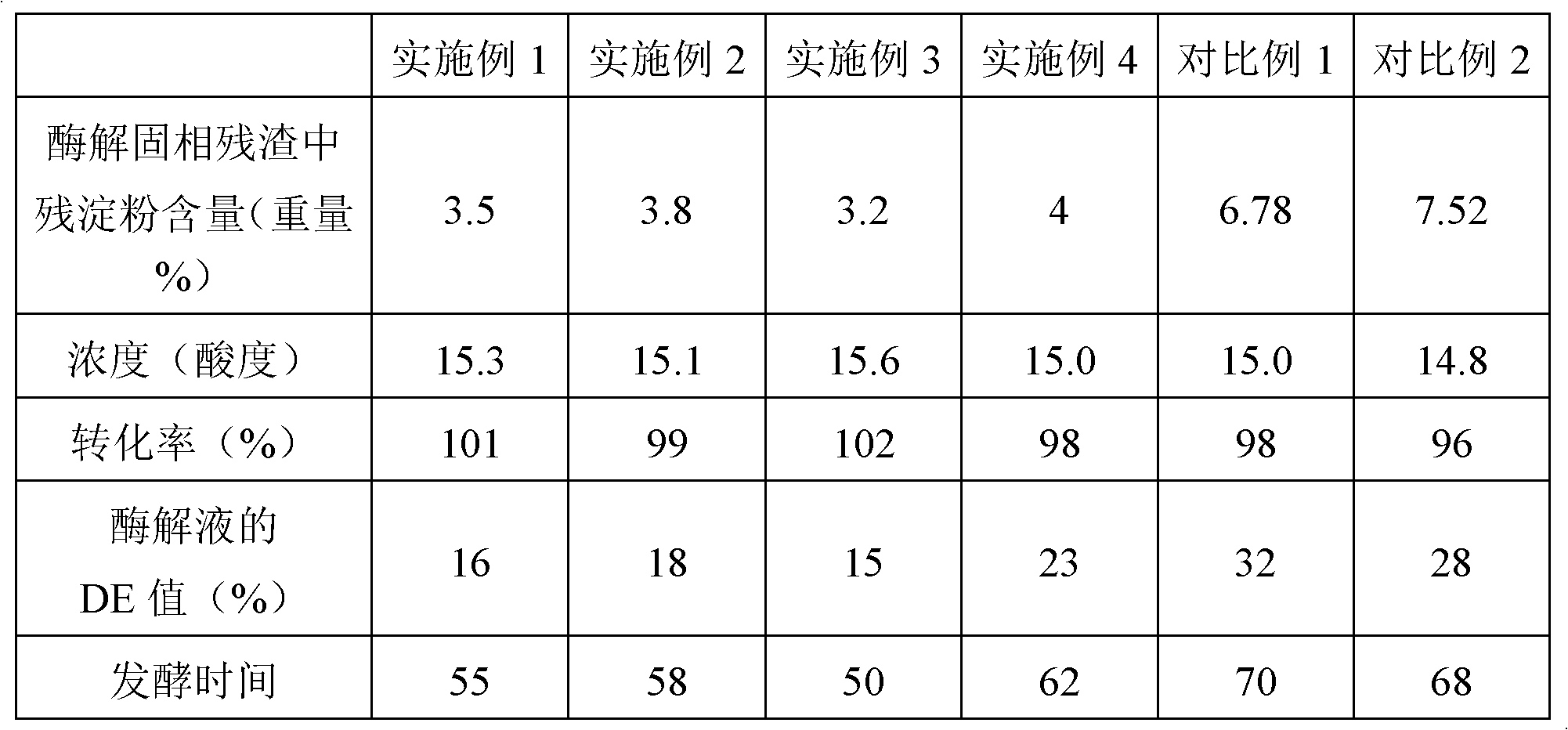

Examples

preparation example Construction

[0037]The present invention also provides a method for preparing citric acid. The method includes treating the starchy raw material according to the above method to obtain an enzymatic hydrolysis product, and fermenting the enzymatic hydrolysis product in the presence of Aspergillus niger. Preferably, the enzymatic hydrolysis product is used as a fermentation broth, sterilized at 80-90°C for 15-30 minutes, and after cooling down to 36-38°C, Aspergillus niger is inoculated into the fermentation broth for fermentation.

[0038] Since the preparation method of citric acid provided by the present invention mainly involves the improvement of the processing method of starchy raw materials before fermentation, there is no special limitation on the fermentation process, which can be the same as the prior art. For example, the type and amount of Aspergillus niger and the conditions of fermentation can be carried out with reference to the prior art, and the present invention will not rep...

Embodiment 1

[0044] 100 parts by weight of corn are pulverized to obtain a pulverized product with an average particle diameter of 400 microns, and the pulverized product is mixed with 400 parts by weight of water at 45° C. to obtain a starch slurry, and the pH value of the starch slurry is adjusted to 5.5.

[0045] At 45°C, the starch slurry was mixed with the α-amylase of 6.4 enzyme activity units / g corn flour for 60 minutes to obtain a mixture, which was sprayed into contact with steam at 156°C in an injector (steam and mixture The weight ratio is 0.05:1), the contact time is 5 seconds, so that the temperature of the mixture after contacting with the steam is 95°C, and the laminar flow is maintained for 120 minutes to obtain a primary liquefied liquid.

[0046] The above-mentioned primary liquefied liquid is again sprayed and contacted with steam at 156°C in the injector (the weight ratio of steam to mixture is 0.05:1), and the contact time is 3 seconds, so that the temperature of the m...

Embodiment 2

[0051] 100 parts by weight of corn are pulverized to obtain a pulverized product with an average particle diameter of 400 microns, and the pulverized product is mixed with 180 parts by weight of water at 60° C. to obtain a starch slurry, and the pH value of the starch slurry is adjusted to 6.2.

[0052] At 60°C, the starch slurry was mixed with the α-amylase of 12 enzyme activity units / g corn flour for 60 minutes to obtain a mixture, which was sprayed into contact with steam at 160°C in an injector (steam and mixture The weight ratio is 0.1:1), the contact time is 1 second, so that the temperature of the mixture after contacting with steam is 98° C., and the laminar flow is maintained for 180 minutes to obtain a primary liquefied liquid.

[0053] The above-mentioned primary liquefied liquid is again sprayed and contacted with steam at 160°C in the injector (the weight ratio of steam to mixture is 0.1:1), and the contact time is 3 seconds, so that the temperature of the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com