A kind of ultra-low de value maltodextrin and its preparation method and application

A maltodextrin, ultra-low technology, applied in the fields of application, food ingredients, fermentation, etc., can solve the problems of few researches on maltodextrin, and achieve the effects of rapid blood sugar rise, fast metabolism, and fast energy replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of ultra-low DE value maltodextrin, the preparation steps are as follows:

[0036] (1) adding water to 1kg waxy cornstarch to adjust the slurry to a dry matter mass concentration of 15%, and adjusting the pH to 5.8 to obtain starch slurry;

[0037] (2) Add high-temperature-resistant α-amylase to the starch slurry prepared in step (1), the amount of high-temperature-resistant α-amylase added is 50 μL, then heat up to 90°C, and keep warm for 5 minutes under stirring at 100 rpm, after testing , the light transmittance is 42.25%, and the DE value is 1.21), then pressurize to a pressure of 0.05Mpa, heat up to 127°C, and keep warm for 15min to obtain a liquefied liquid;

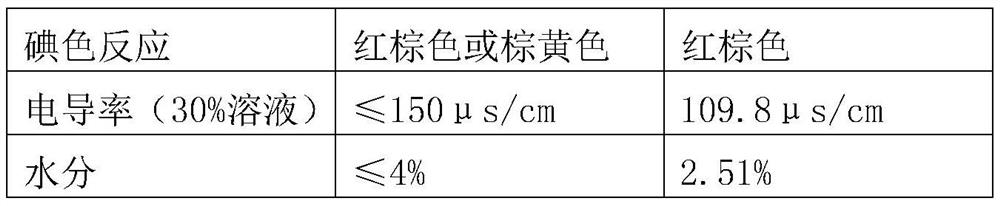

[0038] After testing, the DE value is 1.39 and the conductivity is 109.8μs / cm;

[0039] (3) Add 10 g of activated carbon to the liquefied liquid prepared in step (2) for adsorption for 15 minutes, then filter, concentrate, dry and pulverize to a fineness of 160 mesh to obtain ultra-low ...

Embodiment 2

[0047] A preparation method of ultra-low DE value maltodextrin, the preparation steps are as follows:

[0048] (1) adding water to 1kg of waxy cornstarch to adjust the slurry to a dry matter mass concentration of 20%, and adjusting the pH to 6.1 to obtain starch slurry;

[0049] (2) Add 40 μL of high-temperature-resistant α-amylase to the starch slurry prepared in step (1), then heat up to 90° C., and keep warm for 10 minutes under 100 rpm stirring condition (after testing, the light transmittance is 44.65%, and the DE value is 0.86), then pressurize to a pressure of 0.05Mpa, heat up to 130°C, and keep warm for 20min to obtain a liquefied liquid;

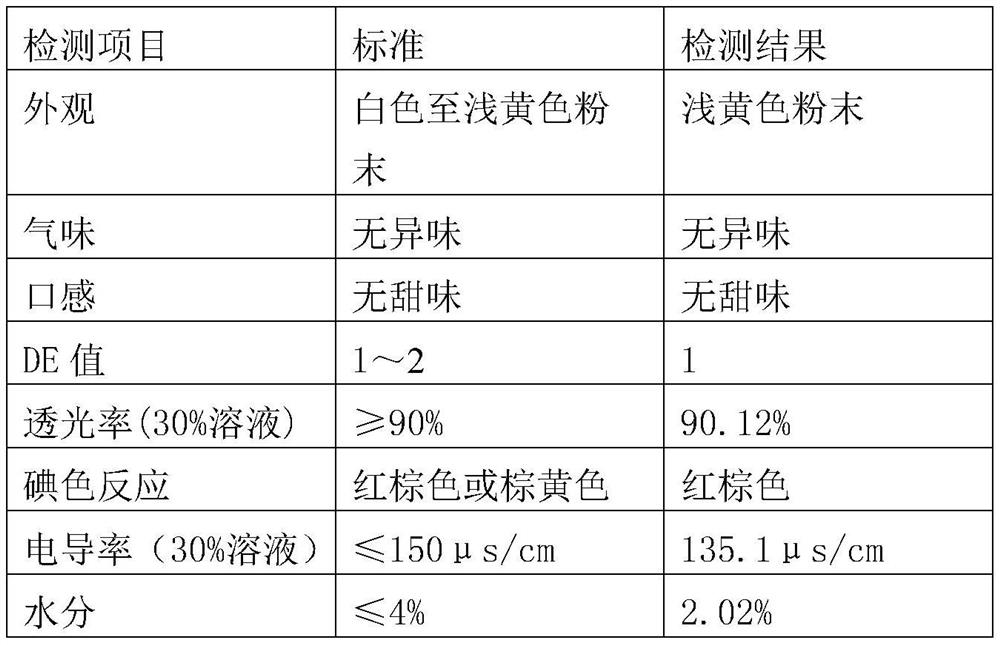

[0050] After testing, the DE value is 1, and the conductivity is 135.1μs / cm;

[0051] (3) Add 10 g of activated carbon to the liquefied liquid prepared in step (2) for adsorption for 15 minutes, then filter, concentrate, dry and pulverize to a fineness of 160 mesh to obtain ultra-low DE value maltodextrin; The product solubility is ...

Embodiment 3

[0058] A preparation method of ultra-low DE value maltodextrin, the preparation steps are as follows:

[0059] (1) adding water to 1kg of waxy cornstarch to adjust the slurry to a dry matter mass concentration of 10%, and adjusting the pH to 5.5 to obtain starch slurry;

[0060] (2) Add 30 μL of high-temperature-resistant α-amylase to the starch slurry prepared in step (1), then heat up to 85° C., and keep warm for 10 minutes under 150 rpm stirring condition (after testing, the light transmittance is 45.31%, and the DE value is 1.39), then pressurize to a pressure of 0.06Mpa, heat up to 125°C, and keep warm for 25min to obtain a liquefied liquid;

[0061] After testing, the DE value is 1~2, and the conductivity is ≤150us / cm;

[0062] (3) Add 5 g of activated carbon to the liquefied liquid prepared in step (2) for adsorption for 15 minutes, then filter, concentrate, dry and pulverize to a fineness of 160 mesh to obtain ultra-low DE value maltodextrin; The product solubility i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com