A kind of jelly for three-dimensional shape frozen drink, three-dimensional shape frozen drink and preparation method thereof

A technology for frozen drinks and three-dimensional modeling, which is used in food preparation, application, frozen desserts, etc., and can solve the problems of inability to show product surface details, poor performance, and melting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

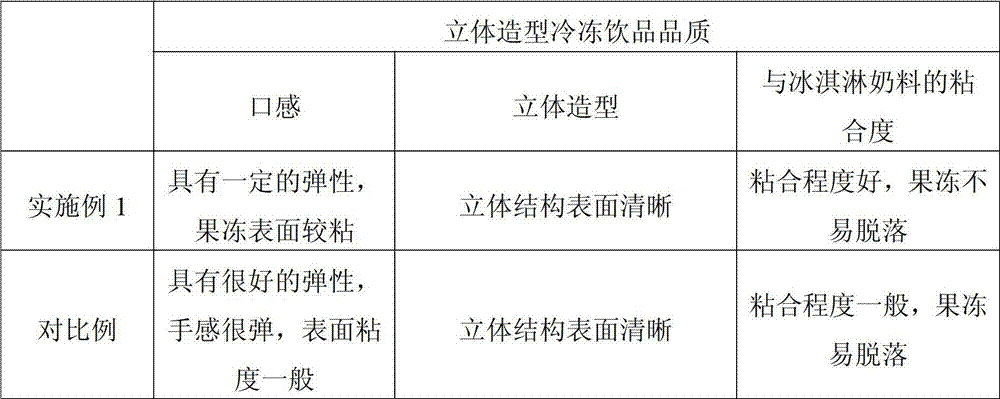

Examples

Embodiment 1

[0020] Embodiment 1 prepares three-dimensional modeling jelly (100 parts by weight) for frozen drinks

[0021] Jelly formula: 12 parts by weight of white granulated sugar, 26 parts by weight of maltose, 10 parts by weight of fructose syrup, 1 part by weight of gelatin, 1 part by weight of carrageenan, and the rest of water.

[0022] The jelly preparation method comprises the following steps:

[0023] 1) Stir gelatin and drinking water at room temperature according to the ratio of 1:5; because gelatin is very easy to absorb water, it is not easy to stir when it is agglomerated in hot water, so it is necessary to use room temperature water in the preparation process and stir according to the above ratio;

[0024] 2) Mix white sugar and carrageenan evenly, add water and stir;

[0025] 3) Add maltose and fructose syrup;

[0026] 4) Add the remaining water;

[0027] 5) The jelly liquid is boiled in the sandwich pot, and the method of low-temperature long-term sterilization (63-6...

Embodiment 2

[0030] Example 2 Preparation of three-dimensional modeling jelly for frozen drinks (100 parts by weight)

[0031] Jelly formula: 18 parts by weight of white granulated sugar, 20 parts by weight of maltose, 16 parts by weight of fructose syrup, 3 parts by weight of gelatin, 0.4 part by weight of carrageenan, and the balance of water.

[0032] The preparation method is the same as in Example 1.

Embodiment 3

[0033] Embodiment 3 prepares the chocolate coating for three-dimensional modeling frozen drink

[0034] The chocolate coating used in the present invention is the chocolate coating for conventional frozen drinks, and the main difference is that it needs to be mixed with coconut oil and palm oil before the subsequent chocolate coating.

[0035] The raw material composition of conventional chocolate coating (per 1000 parts by weight) for frozen drinks includes: white granulated sugar: 200-260 parts by weight; cocoa powder: 50-100 parts by weight; cocoa butter: 20-40 parts by weight; milk solids: 180- 240 parts by weight; fat: 400-500 parts by weight; PGPR90: 0.5-2 parts by weight; lecithin: 2-5 parts by weight.

[0036] Chocolate coating preparation method comprises the following steps:

[0037] Refining with a conventional chocolate refiner, weighing raw materials according to the formula, heating up, sterilizing, finely grinding, and discharging to obtain chocolate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com