Method for preparing citric acid by fermentation

A technology of citric acid and fermentation strains, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of unfavorable synthesis and action of glucoamylase, unfavorable growth of Aspergillus niger strains, high DE value of fermentation medium, etc. , to achieve the effect of improving the conversion rate of sugar and acid, avoiding adverse effects, and reducing the amount of residual sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

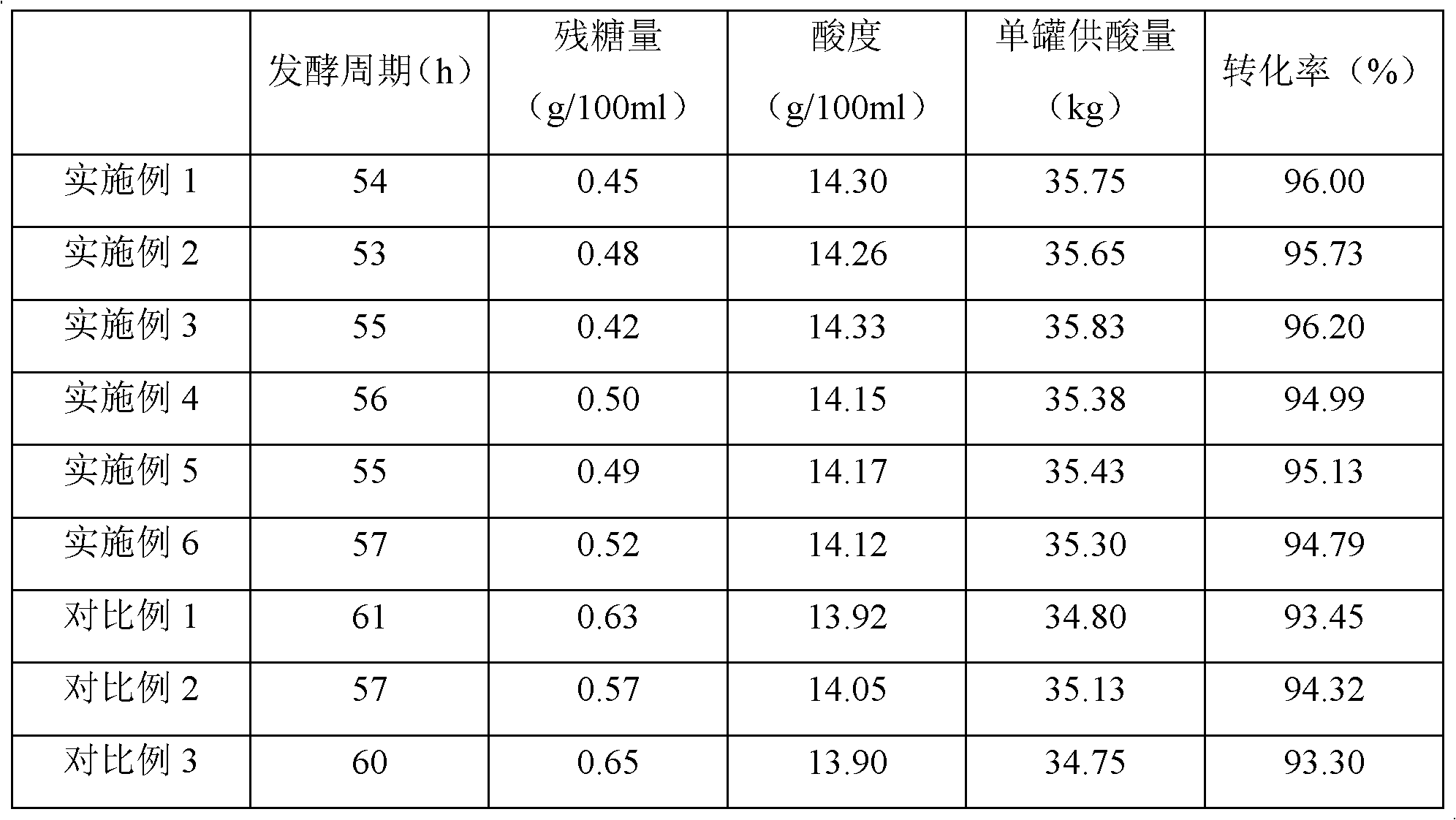

Examples

Embodiment 1

[0058] This example is used to illustrate the method for preparing citric acid by fermentation provided by the present invention.

[0059] (1) 56 kilograms of harvested corn were moistened and stewed in a hot water tank until the water content of the corn was 15% by weight, and then pulverized to obtain a pulverized product with an average particle diameter of 400 microns.

[0060] (2) The pulverized product is slurried at a concentration of 25% by weight. For every gram of the pulverized product, 20 enzyme activity units of amylase (Novozymes, α-amylase, an embodiment of the invention) are added. and the comparative example are all the amylase), enter the ejector, and enzymolyze for 100 minutes under the conditions of 85° C. and pH 5.5, to obtain the enzymolysis product.

[0061] (3) The enzymolysis product is filtered by a hydraulic plate and frame filter press to separate the enzymolysis liquefaction liquid and the enzymolysis filter residue, wherein the water content of th...

Embodiment 2

[0066] This example is used to illustrate the method for preparing citric acid by fermentation provided by the present invention.

[0067] (1) 56 kg of harvested corn was moistened and stewed in a hot water tank until the water content of the corn was 20% by weight, and then pulverized to obtain a pulverized product with an average particle diameter of 800 microns.

[0068] (2) The pulverized product is slurried at a concentration of 25% by weight. For every gram of the pulverized product, 50 enzyme activity units of amylase are added, and the product enters the ejector, and the product is 5.7 at 95°C and the pH is 5.7. Enzymolysis was carried out for 110 minutes to obtain an enzymolysis product.

[0069] (3) The enzymolysis product is filtered by a hydraulic plate and frame filter press to separate the enzymolysis liquefaction liquid and the enzymolysis filter residue, wherein the water content of the enzymolysis residue is 40% by weight.

[0070] (4) Prepare a fermentation ...

Embodiment 3

[0074] This example is used to illustrate the method for preparing citric acid by fermentation provided by the present invention.

[0075] (1) 56 kilograms of harvested corn were moistened and stewed in a hot water tank until the water content of the corn was 10% by weight, and then pulverized to obtain a pulverized product with an average particle diameter of 500 microns.

[0076] (2) The pulverized product is slurried at a concentration of 25% by weight. For every gram of the pulverized product, 15 enzyme activity units of amylase are added, and the product enters the ejector, and the mixture is placed under the conditions of 80° C. and pH 5.4. Enzymolysis was carried out for 120 minutes to obtain an enzymolysis product.

[0077](3) Press-filter the enzymolysis product with a hydraulic plate and frame filter press to separate the enzymolysis liquefaction liquid and enzymolysis filter residue, wherein the water content of the enzymolysis residue is 70% by weight.

[0078] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com