Analysis method of citric acid fermentation aqueous solution

A technology of fermented clear liquid and analysis method, which is applied in the field of analysis of citric acid fermented clear liquid, can solve the problems of inability to accurately quantify the content of various sugars, and inability to detect specific types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

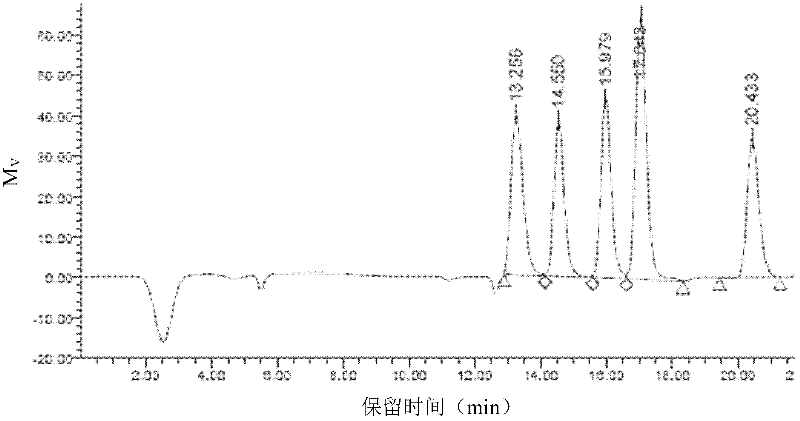

[0030] This example is used to illustrate the analysis method of the citric acid fermentation serum provided by the present invention.

[0031] (1) Preparation of citric acid fermented liquid: the citric acid fermented liquid obtained after stirring and culturing for 20 hours according to the above-mentioned method is 4.21% by weight of citric acid fermented liquid, get 50mL of this citric acid fermented liquid, centrifuged at 4000rpm for 5min to obtain the supernatant, namely the citric acid fermentation supernatant.

[0032] (2) Chromatographic analysis: the 10mL citric acid fermentation supernatant liquid that step (1) gained is diluted 10 times with mobile phase (the mobile phase is sulfuric acid aqueous solution (concentration is 0.005mol L -1 , pH is 2.15) mixed with acetonitrile in a volume ratio of 98.5: 1.5) to obtain a mixed solution. At 60°C, and driven by the eluent at a flow rate of 0.6mL / min, 20uL of the mixed solution was passed into the high-performance liquid...

Embodiment 2

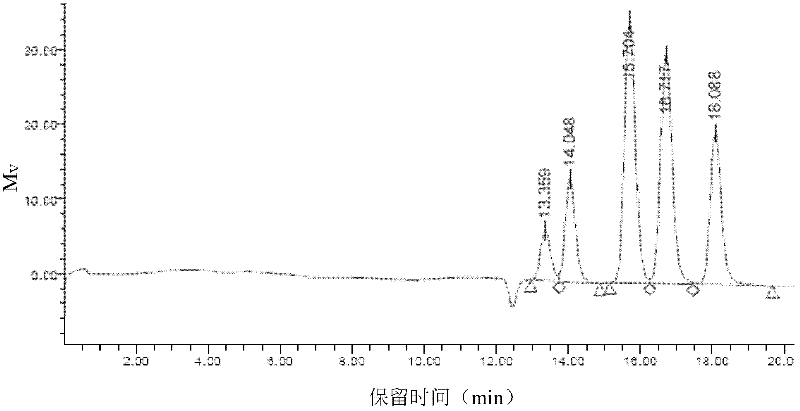

[0035] This example is used to illustrate the analysis method of the citric acid fermentation serum provided by the present invention.

[0036] (1) Preparation of citric acid fermented liquid: the citric acid fermented liquid obtained after stirring and cultivating for 30 hours according to the above-mentioned method is 5.26% by weight of citric acid fermented liquid, get 50mL of this citric acid fermented liquid, centrifuged at 4000rpm for 5min to obtain the supernatant, i.e. the citric acid fermentation supernatant

[0037] (2) Chromatographic analysis: the citric acid fermentation supernatant liquid of step (1) gained is diluted 5 times with mobile phase (the mobile phase is sulfuric acid aqueous solution (concentration is 0.005mol L -1 , pH is 2.15) mixed with acetonitrile in a volume ratio of 96.5:3.5) to obtain a mixed solution. At 60°C, and driven by the eluent at a flow rate of 0.6mL / min, 20uL of the mixed solution was passed into the high-performance liquid chromatog...

Embodiment 3

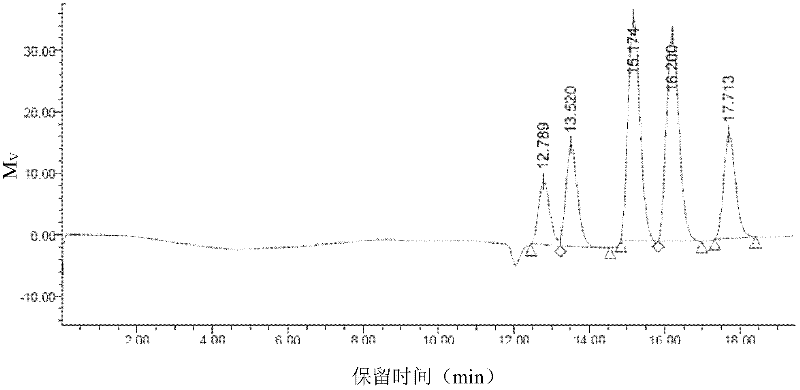

[0040] This example is used to illustrate the analysis method of the citric acid fermentation serum provided by the present invention.

[0041] (1) Preparation of citric acid fermented liquid: the citric acid fermented liquid obtained after stirring and cultivating for 40 hours according to the above-mentioned method is 10.21% by weight of citric acid fermented liquid, get 50mL of this citric acid fermented liquid, centrifuged at 4000rpm for 5min to obtain the supernatant, namely the citric acid fermentation supernatant.

[0042] (2) Chromatographic analysis: the citric acid fermentation supernatant liquid of step (1) gained is diluted 10 times with mobile phase (the mobile phase is sulfuric acid aqueous solution (concentration is 0.005mol L-1, pH is 2.15) and acetonitrile by volume ratio of 95:5) to obtain a mixed solution. At 40°C, and driven by the eluent at a flow rate of 0.5mL / min, 20uL of the mixed solution was passed into the high-performance liquid chromatograph, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com