Method for recovering lead

A lead recovery and lead paste technology, which is applied in the field of lead recovery from lead-containing waste, can solve the problems of difficult reduction of lead sulfate, air pollution, corrosion of refractory materials, etc., and achieve the effects of low pollution, low energy consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

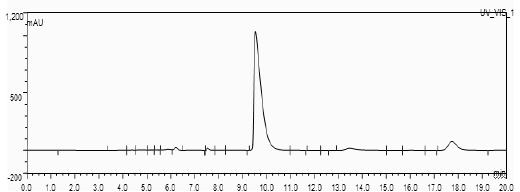

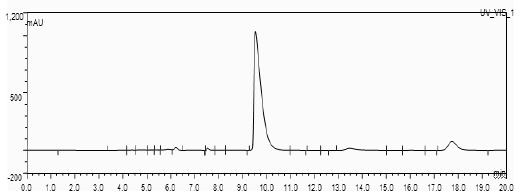

Image

Examples

Embodiment 1

[0063] Embodiment 1 prepares lead citrate with PbO

[0064] Lead oxide is processed with citric acid fermented liquid, is 1:1 to add citric acid fermented liquid by the mol ratio of lead oxide and citric acid, in the citric acid fermented liquid, citric acid content 101g / L, miscellaneous acid content 3.8%; °C until the reaction is complete. After the reaction was complete, precipitated for 15 minutes and then filtered. The collected solids were washed with distilled water, filtered, and dried at 80 °C. The filtrate was analyzed and the results are shown in Table 2.

[0065] The performance of Pb is similar to that of PbO. The above conditions and results for lead oxide apply to lead, yielding essentially the same results.

Embodiment 2

[0066] Example 2 with PbO 2 Preparation of lead citrate

[0067] Lead dioxide is processed with citric acid fermented liquid, adds citric acid fermented liquid by the mol ratio 1:4 of lead dioxide and citric acid, and in the citric acid fermented liquid, citric acid content is 101g / L, and miscellaneous acid content is 3.8%, Add 27.5% hydrogen peroxide solution according to the molar ratio of lead dioxide to hydrogen peroxide 1:2, and add appropriate amount of water according to the solid-liquid ratio of 1:50; treat at a temperature of 30°C until the reaction is complete. After the reaction was complete, precipitated for 15 minutes and then filtered. The collected solids were washed with distilled water, filtered, and dried at 80°C. The filtrate was analyzed and the results are shown in Table 2.

Embodiment 3

[0068] Example 3 Using PbSO 4 Preparation of lead citrate

[0069] Treat lead sulfate with citric acid fermentation broth, add citric acid fermentation broth according to the molar ratio of lead sulfate to citric acid 1:2, the content of citric acid in the citric acid fermentation broth is 101g / L, and the content of heteroacids is 3.8%. The molar ratio of lead to sodium citrate is 1:1, add sodium citrate solid, according to the solid-liquid ratio of 1:40, add an appropriate amount of water; treat at a temperature of 20°C until the reaction is complete. After the reaction was complete, precipitated for 15 minutes and then filtered. The collected solids were washed with distilled water, filtered, and dried at 80°C. The filtrate was analyzed and the results are shown in Table 2.

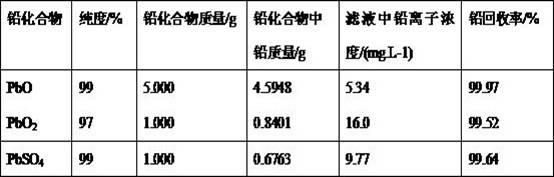

[0070] The recovery effects of Examples 1-3 are shown in Table 2.

[0071] Table 2 Lead concentration and recovery rate in the filtrate

[0072]

[0073] Visible, with citric acid instead of pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com