Method for filtering and clarifying citric acid fermentation broth

A technology of citric acid fermentation liquid and filtrate, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of poor turbidity of fermentation liquid, high protein colloid content, etc., and achieve good yield, product quality, and process flow Concise and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

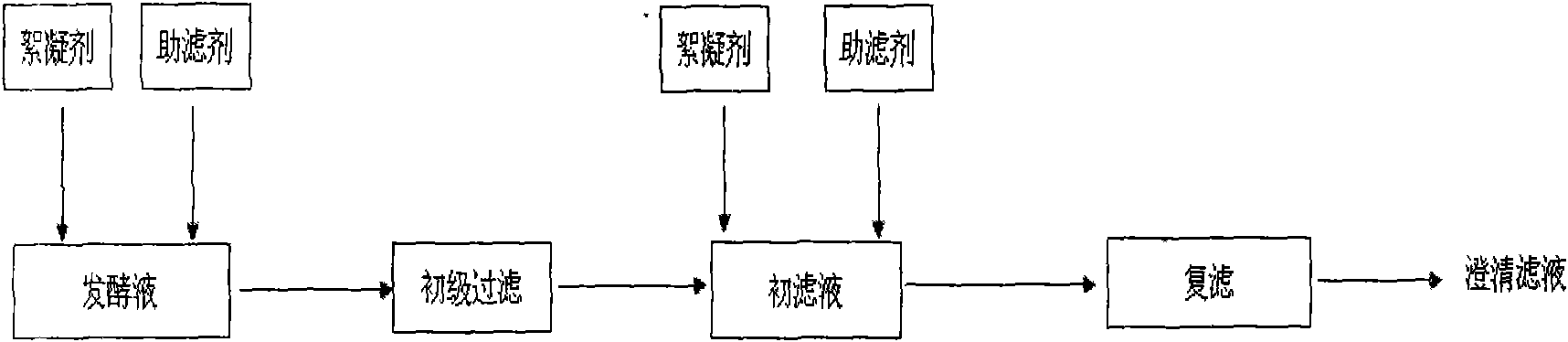

Method used

Image

Examples

Embodiment 1

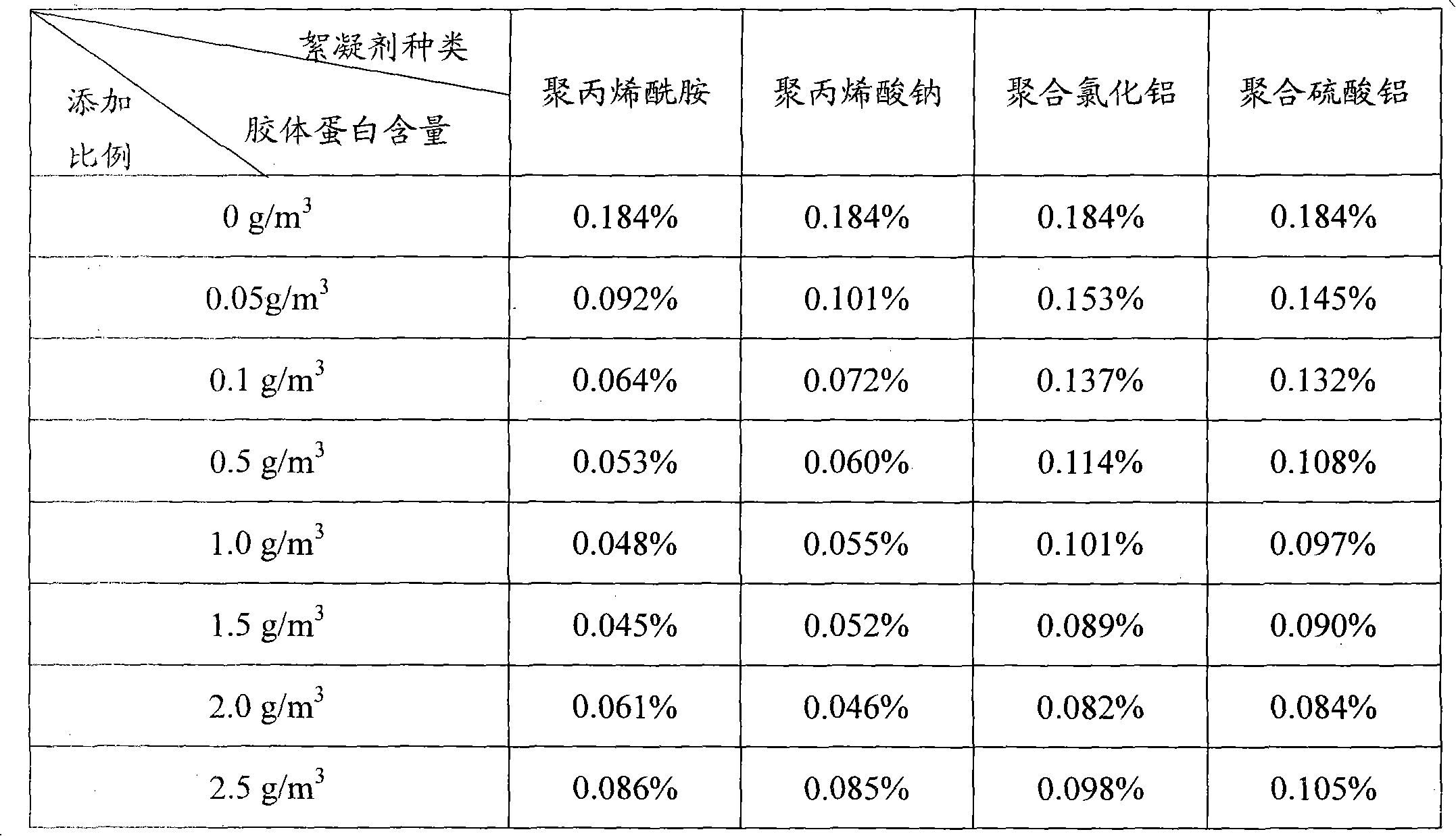

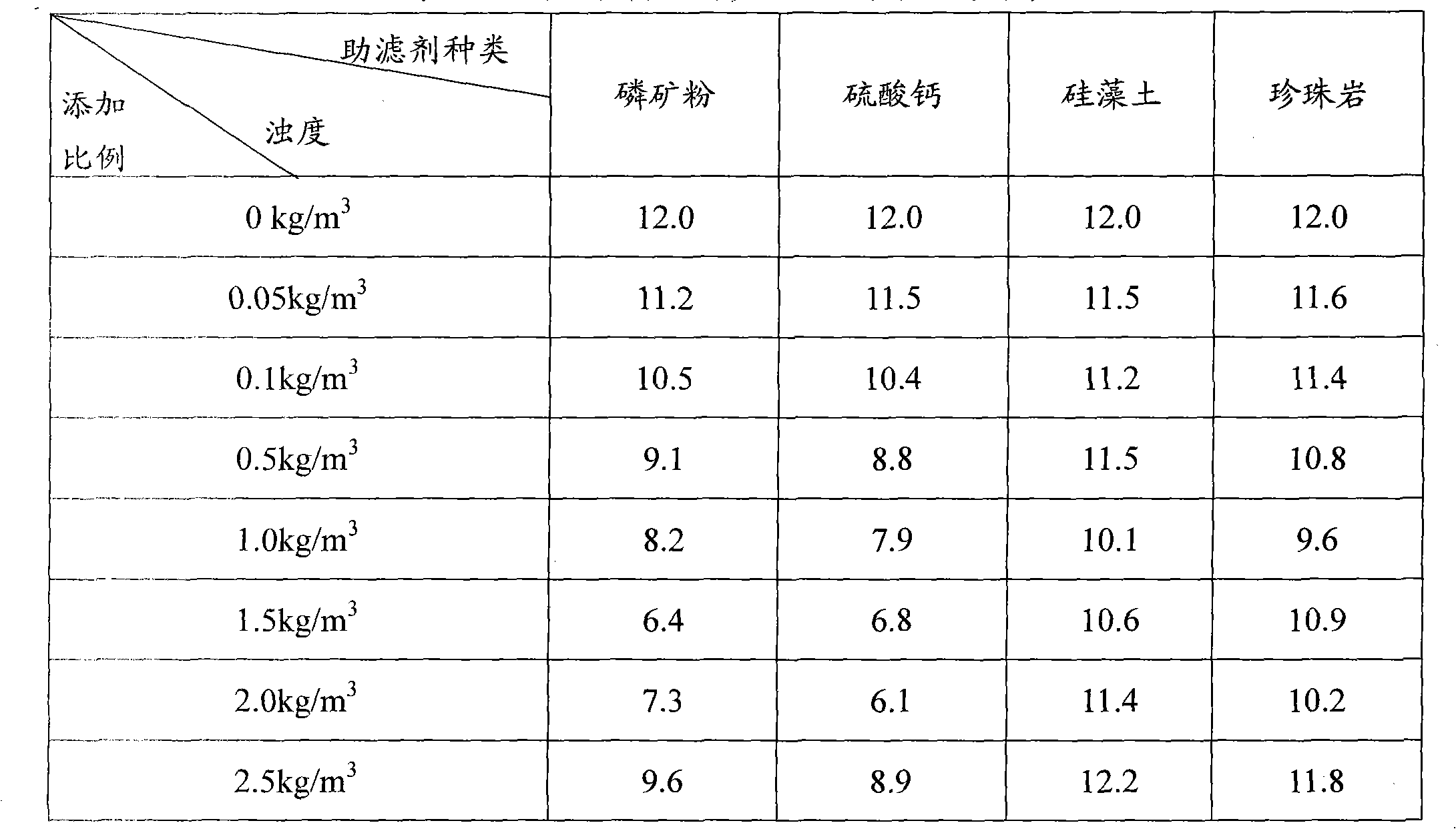

[0034] A method for filtering and clarifying citric acid fermented liquid, comprising the following steps:

[0035] 1. Add the flocculant polyacrylamide to the citric acid fermentation broth and stir evenly, the addition ratio is 0.1g / m 3 ;

[0036] 2. Add filter aid phosphate rock powder to the citric acid fermentation broth and stir evenly, the addition ratio is 1.0kg / m 3 ;

[0037] 3. The above-mentioned mixed solution is subjected to first-level solid-liquid separation with a plate and frame filter press;

[0038] 4. Add flocculant polyaluminum chloride to the filtered filtrate again and stir evenly, the addition ratio is 0.3g / m 3 ;

[0039] 5. Add filter aid diatomite to the filtered filtrate again and stir evenly, the addition ratio is 0.5kg / m 3 ;

[0040] 6. The above mixed solution was subjected to secondary solid-liquid separation with a plate and frame filter press, and the turbidity of the obtained fermentation filtrate was 3.27.

Embodiment 2

[0042] A method for filtering and clarifying citric acid fermented liquid, comprising the following steps:

[0043] 1. Add the flocculant sodium polyacrylate to the citric acid fermentation broth and stir evenly, the addition ratio is 2.0g / m 3 ;

[0044] 2. Add filter aid calcium sulfate to the citric acid fermentation broth and stir evenly, the addition ratio is 0.5kg / m 3 ;

[0045] 3. The above-mentioned mixed solution is subjected to first-level solid-liquid separation with a plate and frame filter press;

[0046] 4. Add flocculant polyaluminum sulfate to the filtered filtrate again and stir evenly, the addition ratio is 0.1g / m 3 ;

[0047] 5. Add filter aid perlite to the filtered filtrate again and stir evenly, the addition ratio is 1.0kg / m 3 ;

[0048] 6. The above mixed solution was subjected to secondary solid-liquid separation with a plate and frame filter press, and the turbidity of the obtained fermentation filtrate was 3.52.

Embodiment 3

[0050] A method for filtering and clarifying citric acid fermented liquid, comprising the following steps:

[0051] 1. Add the flocculant polyacrylamide to the citric acid fermentation broth and stir evenly, the addition ratio is 1.0g / m 3 ;

[0052] 2. Add filter aid phosphate rock powder to the citric acid fermentation broth and stir evenly, the addition ratio is 0.1kg / m 3 ;

[0053] 3. The above-mentioned mixed solution is subjected to first-level solid-liquid separation with a plate and frame filter press;

[0054] 4. Add flocculant polyaluminum chloride to the filtered filtrate again and stir evenly. The addition ratio is 0.7g / m 3 ;

[0055] 5. Add filter aid diatomite to the filtered filtrate again and stir evenly, the addition ratio is 2.0kg / m 3 ;

[0056] 6. The above mixed solution is subjected to secondary solid-liquid separation with a plate and frame filter press, and the obtained fermentation filtrate has a turbidity of 4.45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com