Clean productive process for extracting citric acid from citric acid fermentation liquid

A citric acid fermentation broth and citric acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., to achieve the effects of reducing operators, shortening the production process, and saving production sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

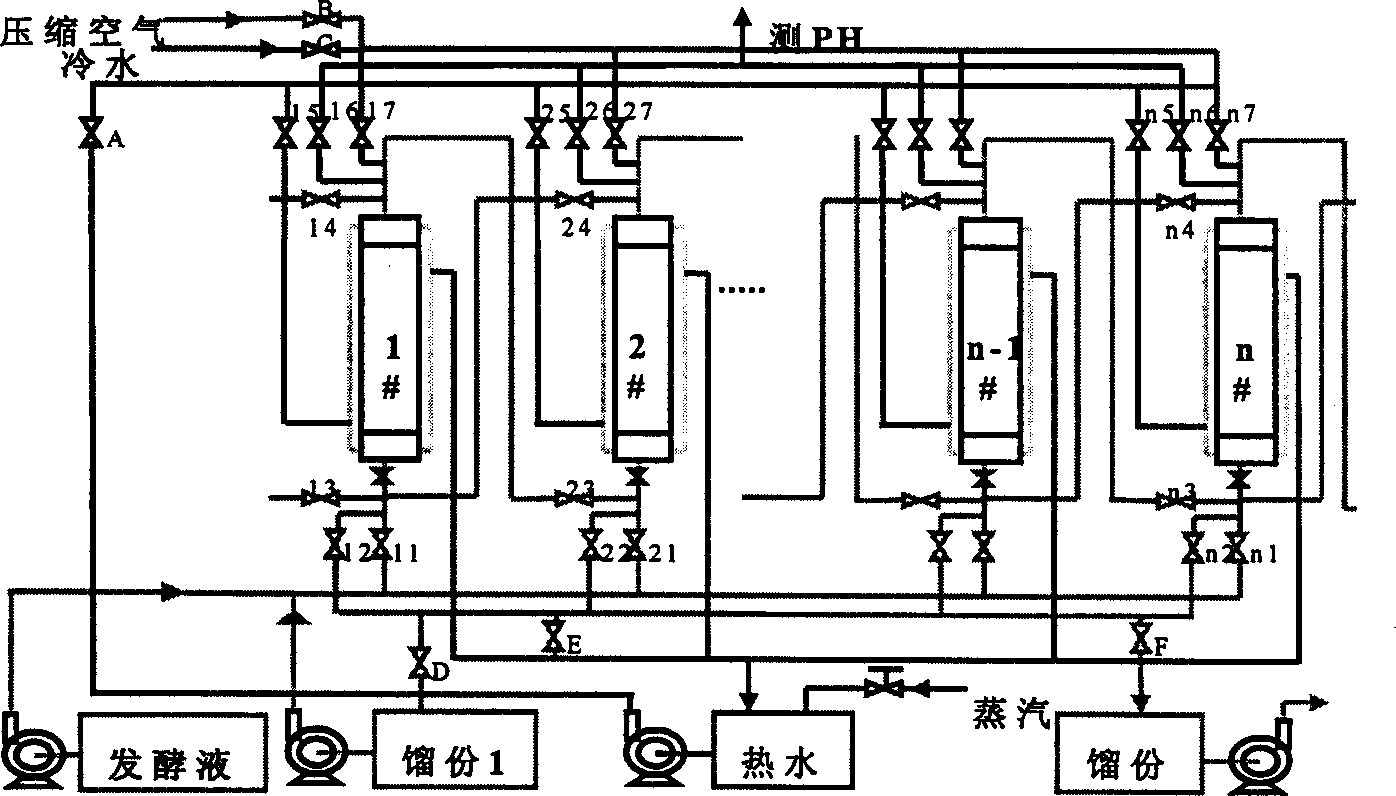

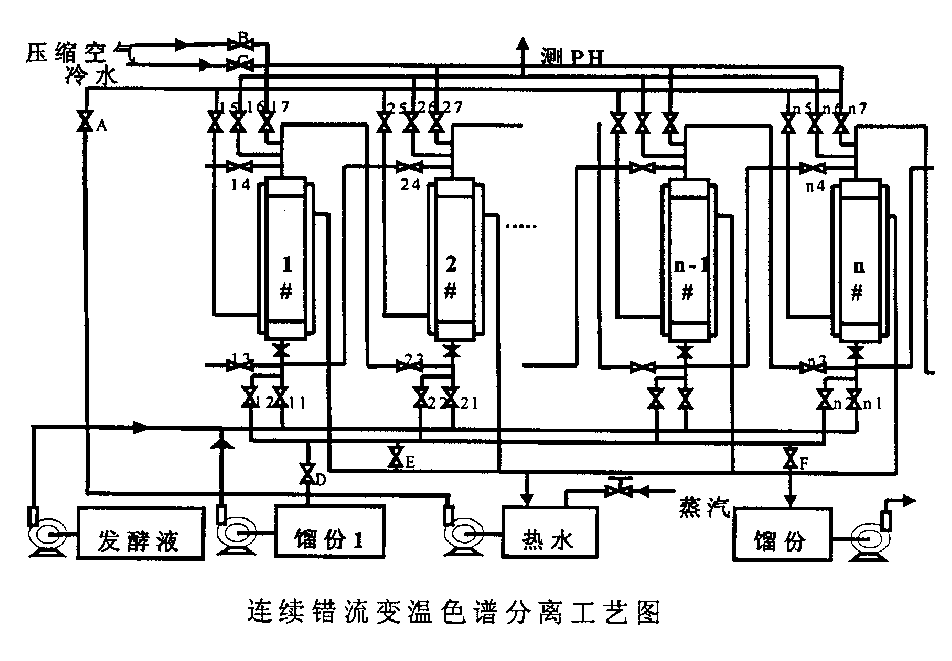

Method used

Image

Examples

example 1

[0040] Example 1 Oil Phase A

[0041] Styrene 40 g; Acrylic acid 50 g; Divinylbenzene 15 g (82%);

[0042] Isoheptane 45g; Benzoyl peroxide 1g Water Phase B

[0043] 180 grams of water; 40 grams of sodium chloride; 0.3 grams of sodium carboxymethylcellulose; 15 drops of 1% methylene blue

[0044] Slowly add the oil phase A into the water phase B under stirring, and adjust the stirring speed until the oil phase forms droplets of the desired size in the water phase. Then slowly raise the temperature to 75-80°C, and react under heat preservation. After 5 hours, the product was filtered and washed thoroughly, and dried in vacuum at 100° C. to obtain 98 g of the product, with a yield of 93.3%.

[0045] The product obtained was in the form of beige round particles with an anion exchange capacity of 3.8 meq / g dry resin.

example 2

[0047] Quaternization of the resin obtained in Example 1: add 10 grams of the product to a mixed solution of 8 milliliters of dichloroethane and 10 milliliters of methyl chloride ether, soak at 30°C for 3 hours; cool down to about 25°C, add 8 grams of chlorine Zinc, heat up to 45°C and keep it warm; after 8 hours, cool down to room temperature, filter out the mother liquor, wash with water until pH = 2-3, and then air-dry for several hours; add 15 ml of acetone, then control the temperature below 40°C, and add 20 Milliliter trimethylamine aqueous solution was adjusted to pH = 11, and kept at 30°C for 6 hours; after the reaction was completed, it was filtered and washed with water until neutral to obtain 122 g of the product.

[0048] The product obtained was in the form of dark brown round particles with an anion exchange capacity of 4.9 meq / g dry resin.

example 3

[0049] Example 3 Oil Phase A

[0050] Styrene 40 g; Vinyl acetate 50 g; Divinylbenzene 15 g (82%);

[0051] Benzoyl Peroxide 1 g Water Phase B

[0052] 150 grams of water; 30 grams of sodium chloride; 0.25 grams of sodium carboxymethylcellulose; 10 drops of 1% methylene blue

[0053] The synthesis conditions are as in Example 1, and the product yield is 95.3%.

[0054] The product obtained was in the form of off-white round particles with an anion exchange capacity of 4.3 meq / g dry resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com