Method for extracting citric acid and/or sodium citrate from fermentation liquor by using extraction method

A technology of citric acid and extraction method, which is applied in the field of preparing citric acid or sodium citrate, can solve the problems of unsuitability for industrial production, and achieve the effects of benefiting subsequent production, large extraction distribution coefficient, and short equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

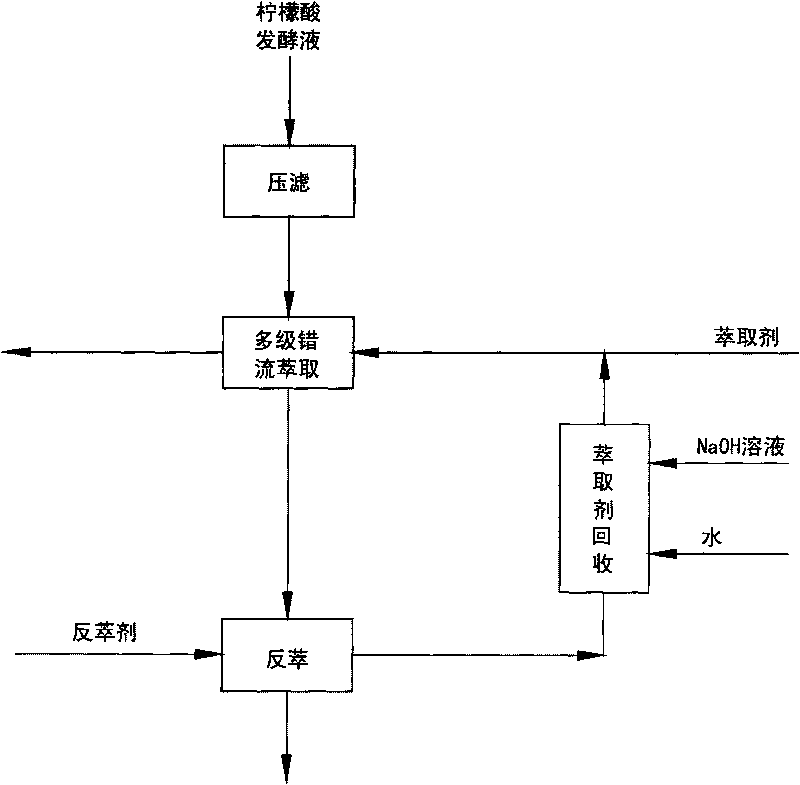

[0036] Such as figure 1 shown. The fresh citric acid fermentation broth is pre-coated with diatomaceous earth by a plate-and-frame filter press to filter the citric acid fermentation broth, and then the filter cake is washed with water to obtain a press-filter, wherein the acidity of citric acid is 10.63%.

[0037] Take 300mL of the above-mentioned press-filtered liquid, mix it with 300mL of the extractant prepared in a volume ratio of 3:7 (TOA:n-octanol) on a shaker for 5 minutes, the temperature is 26.5°C, the primary partition coefficient is 3.24, and the concentration of the raffinate aqueous phase is After three-stage cross-flow extraction, the concentration of citric acid in the raffinate phase is 0.14%, and the extraction yield of citric acid can reach 98.7%.

[0038] The raffinate phase mainly contains residual sugar and other organic acids (such as aconitic acid, oxalic acid, etc.) left in the fermentation process. After the extraction is completed, it can be dischar...

Embodiment 2

[0042] according to figure 1 shown. For embodiment 1 gained citric acid pressure filtrate, add water and dilute to citric acidity and be 8.05%.

[0043] Take 500mL of the diluted citric acid press filtrate, mix and extract with 500mL of the extractant configured in a volume ratio of 1:3 (TOA:n-octanol) in a shaker for 10 minutes, the extraction temperature is 25.4°C, and the aqueous phase is measured after phase separation The content of citric acid in the medium is 1.07%, and the primary distribution coefficient is 6.47. After two cross-flow extractions in the same operation, the content of citric acid in the aqueous raffinate phase is 0.13%. The extraction yield of citric acid was 98.30%.

[0044] Use 4% sodium hydroxide aqueous solution to back-extract at 75°C, the back-extraction ratio is 1:1, and the distribution coefficient is 6.31. After three-stage countercurrent extraction, the yield of citric acid can reach 94.4%, and the pH of the aqueous phase is 7.65.

[0045] ...

Embodiment 3

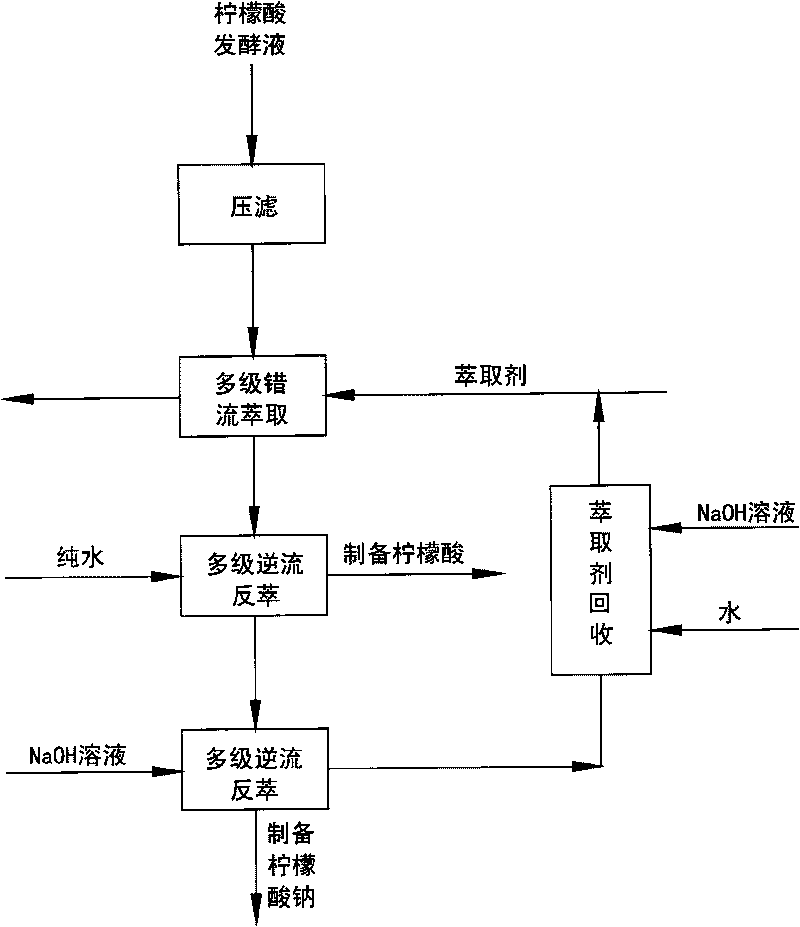

[0047] according to figure 2shown. Get fresh citric acid fermentation press filtrate, its citric acidity is 10.25%. Take 1L of the above-mentioned press filtrate, and use the extractant configured at a volume ratio of 3:7 (TOA:n-octanol), and stir the citric acid press filtrate and the extractant in a mixing tank at a ratio of 1:1 at a temperature of 26.5°C After mixing for 10 minutes, the mixture was allowed to stand for stratification. The content of citric acid in the raffinate phase was 2.12%, and the distribution coefficient was 3.85. Three cross-flow extractions were carried out using the same process, and the content of citric acid in the raffinate phase was 0.12%. The extraction yield reached 98.9%.

[0048] The extraction phase is treated in two steps: 1) First, use pure water to conduct continuous countercurrent extraction at 85°C using a rotary disk extraction tower to obtain citric acid; 2) Then use 4% NaOH aqueous solution to extract the organic phase after ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com