Citric acid fermentation technology

A fermentation process, citric acid technology, applied in the direction of fermentation, microorganisms, biochemical equipment and methods, etc., to shorten the fermentation cycle, facilitate growth, and improve the effect of cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

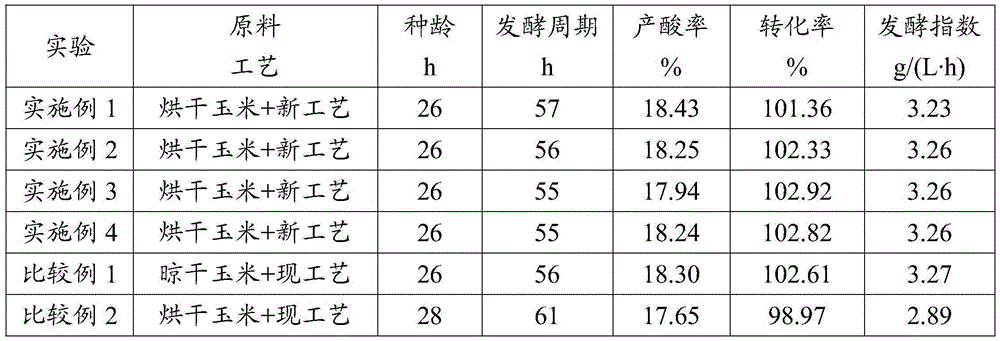

Examples

Embodiment 1

[0032] A citric acid fermentation process, its concrete steps are:

[0033] (1) Grind the high-temperature dried corn and mix it with 55°C warm water at a weight ratio of 1:2.6 to prepare the slurry. After stirring evenly, add high-temperature-resistant α-amylase at a ratio of 0.5kg amylase / t flour, and spray once (temperature 95°C), and then maintained for 1.5h, and then sprayed twice (temperature 105°C), adding amylase at a ratio of 0.3kg amylase / t flour, waiting for use after passing the iodine test, and the total sugar of the liquefied liquid is 22g / 100ml.

[0034] (2) Add the liquefied corn liquefied liquid I and ammonium sulfate into the seed tank, add water to constant volume, and prepare the seed tank culture medium that the total sugar is 10.2g / 100ml and the total nitrogen is 0.22g / 100ml, wherein the corn liquefied liquid I The ratio of nitrogen content to ammonium sulfate is 2.5:1, sterilized at 121°C for 30 minutes, kept under pressure and cooled down for later use;...

Embodiment 2

[0046] (1) Grind the high-temperature dried corn and mix it with 55°C warm water at a weight ratio of 1:2.8 to prepare the slurry. After stirring evenly, add high-temperature-resistant α-amylase at a ratio of 0.5kg amylase / t flour, and spray once (temperature 95°C), and then maintained for 1.5h, and then sprayed twice (at a temperature of 105°C), adding amylase at a ratio of 0.3kg amylase / t flour, waiting for use after passing the iodine test, and the total sugar of the liquefied liquid is 20.9g / 100ml .

[0047] (2) Add the liquefied corn liquefied liquid I and ammonium sulfate into the seed tank, add water to constant volume, and prepare a seed tank culture medium whose total sugar is 9.9g / 100ml and total nitrogen is 0.22g / 100ml, wherein the corn liquefied liquid I The ratio of nitrogen content to ammonium sulfate is 2.5:1, sterilized at 121°C for 30 minutes, kept under pressure and cooled down for later use; at the same time prepare trace element solution for seed tank: CuSO...

Embodiment 3

[0059] (1) Grind the high-temperature dried corn and mix it with 55°C warm water at a weight ratio of 1:3.0 to prepare the slurry. After stirring evenly, add high-temperature-resistant α-amylase at a ratio of 0.5kg amylase / t flour, and spray once (temperature 95°C), then maintain for 1.5h, and then spray twice (temperature 105°C), add amylase at the ratio of 0.3kg amylase / t flour, stand by after passing the iodine test, the total sugar of the liquefied liquid is 20.0g / 100ml .

[0060] (2) Add the liquefied corn liquefied liquid I and ammonium sulfate into the seed tank, add water to constant volume, and prepare the seed tank culture medium that the total sugar is 9.6g / 100ml and the total nitrogen is 0.22g / 100ml, wherein the corn liquefied liquid I The ratio of nitrogen content to ammonium sulfate is 2.5:1, sterilized at 121°C for 30 minutes, kept under pressure and cooled down for later use; at the same time prepare trace element solution for seed tank: CuSO 4 .7H 2 O50mg, Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com