Crystallizer with rectifying hood

A technology of fairing and crystallizer, applied in the direction of solution crystallization, can solve the problems of complicated calculation, high cost of crystallizer, complex force, etc., and achieve the effects of being conducive to growth, reducing stirring power and uniform flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

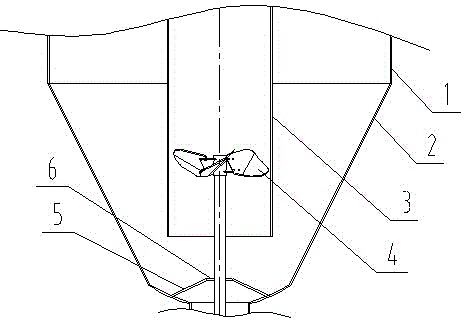

[0028] like figure 1 As shown, this embodiment includes a cylinder body 1 and a cone bottom 2, and a conical fairing I5 is built in the lower part of the cone bottom 2; device 4. The cone angle of the conical fairing I5 is 120°, the diameter of the bottom of the conical fairing I5 is 1 times the diameter of the guide tube 3, and the cone generatrix of the conical fairing I5 is a straight side. The top end of the conical fairing I5 is provided with an opening 6 . The cone angle of the cone bottom 2 is 60°, and the bottom is in the shape of a spherical crown. The cylinder 1 is the body of an existing conventional crystallizer. The cylinder body 1, cone bottom 2, conical fairing I5, guide tube 3 and stirring device 4 described in this embodiment are all installed concentrically.

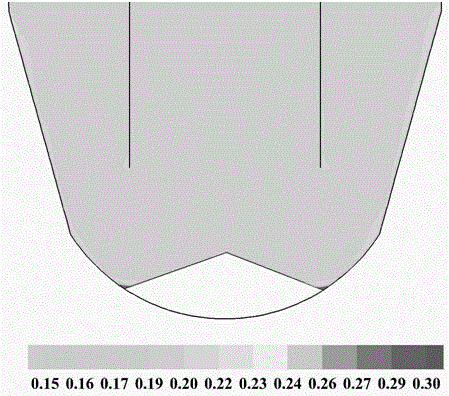

[0029] By ANSYS FLUENT to simulate the crystallizer with fairing in this embodiment, there is almost no dead angle of stirring in the mother liquor crystallization process, such as figure 2 As sh...

Embodiment 2

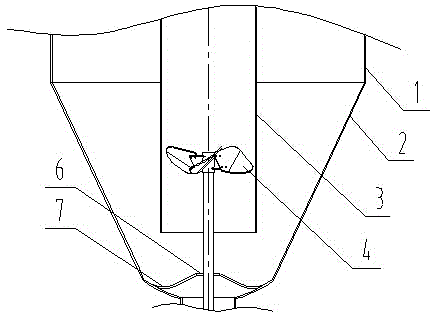

[0031] like image 3 As shown, this embodiment includes a cylinder body 1 and a cone bottom 2, and a conical fairing II7 is built in the lower part of the cone bottom 2; device 4. The cone angle of the conical fairing II7 is 120°, the diameter of the bottom of the conical fairing II7 is 1 times the diameter of the guide tube 3, and the cone generatrix of the conical fairing II7 is a curved side, and the curved side The radius of curvature is 0.4 times the radius of the cylinder. The top end of the conical fairing II7 is provided with an opening 6 . The cone angle of the cone bottom 2 is 60°, and the bottom is in the shape of a spherical crown. The cylinder 1 is the body of an existing conventional crystallizer. The barrel body 1, the cone bottom 2, the conical fairing II7, the guide tube 3 and the stirring device 4 described in this embodiment are all installed concentrically.

[0032] By ANSYS FLUENT to simulate the crystallizer with a fairing in this embodiment, there i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com