Olefin polymerization reactor

A technology of olefin polymerization and reactor, which is applied in the field of reactors, can solve problems such as researches on variable-diameter kettles and expansion sections, etc., and achieve the effects of improving heat removal capacity, large production capacity, and low stirring power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

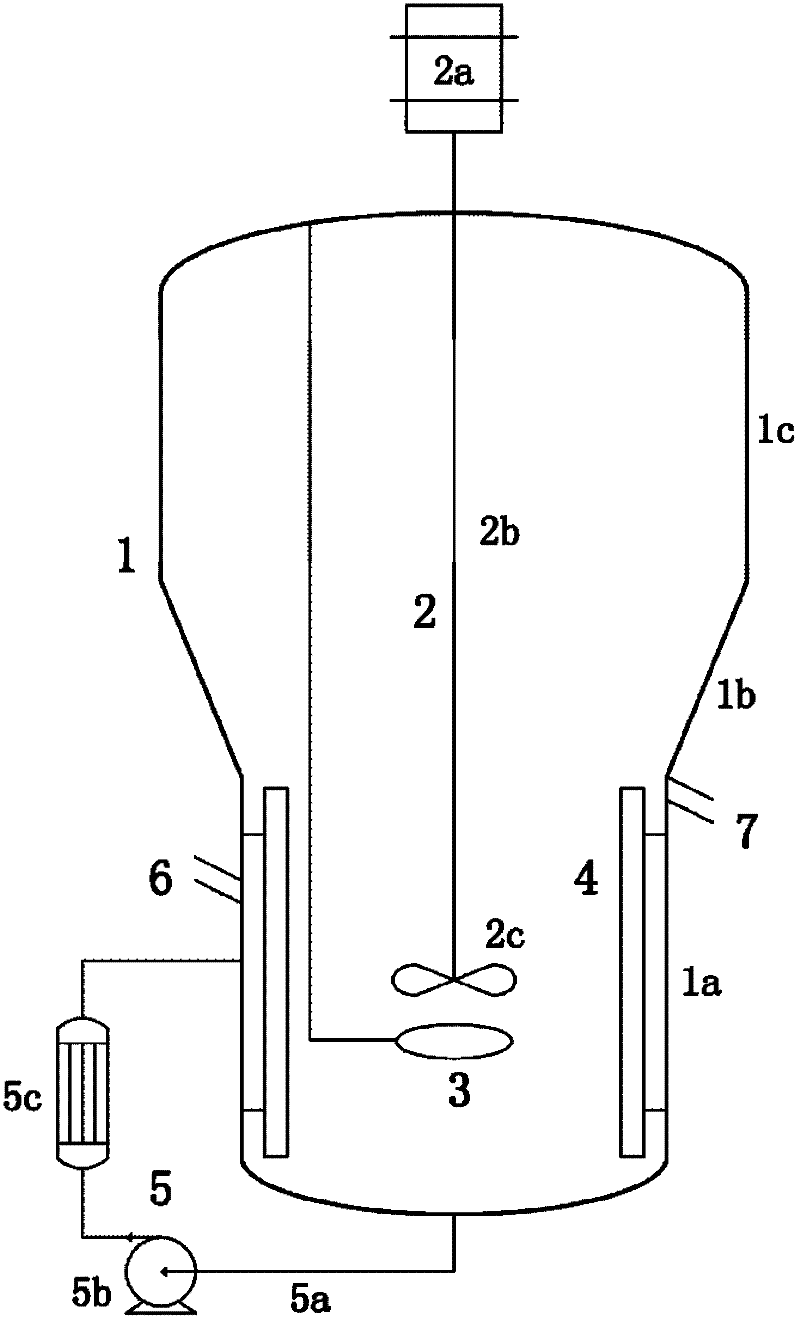

[0047] as attached figure 1 Shown, a kind of olefin polymerization reactor comprises:

[0048] Polymerizer still body 1 is made up of reaction section 1a, expansion section 1c and connection section 1b between reaction section 1a and expansion section 1c;

[0049] The stirring device 2 installed in the center of the polymerization kettle body 1 is used to realize the three-phase mixing of gas, liquid and solid in the kettle. The stirring device 2 is composed of a transmission device 2a, a stirring shaft 2b and a stirring turbine 2c connected in sequence;

[0050] A gas distribution device 3 located in the reactor body 1 of the polymerizer for dispersing the raw material gas passing into the reactor;

[0051] A baffle 4 for enhancing the mixing effect in the kettle near the inner wall surface of the reaction section 1a of the polymerization kettle;

[0052] The slurry external circulation system 5 located outside the reaction section 1a of the polymerization tank is used for ...

Embodiment 2

[0065] The cold mold device was established in the laboratory, and the gas-liquid-solid three-phase slurry entrainment cold mold experiment was carried out in four stirred tanks with different diameters of the enlarged sections.

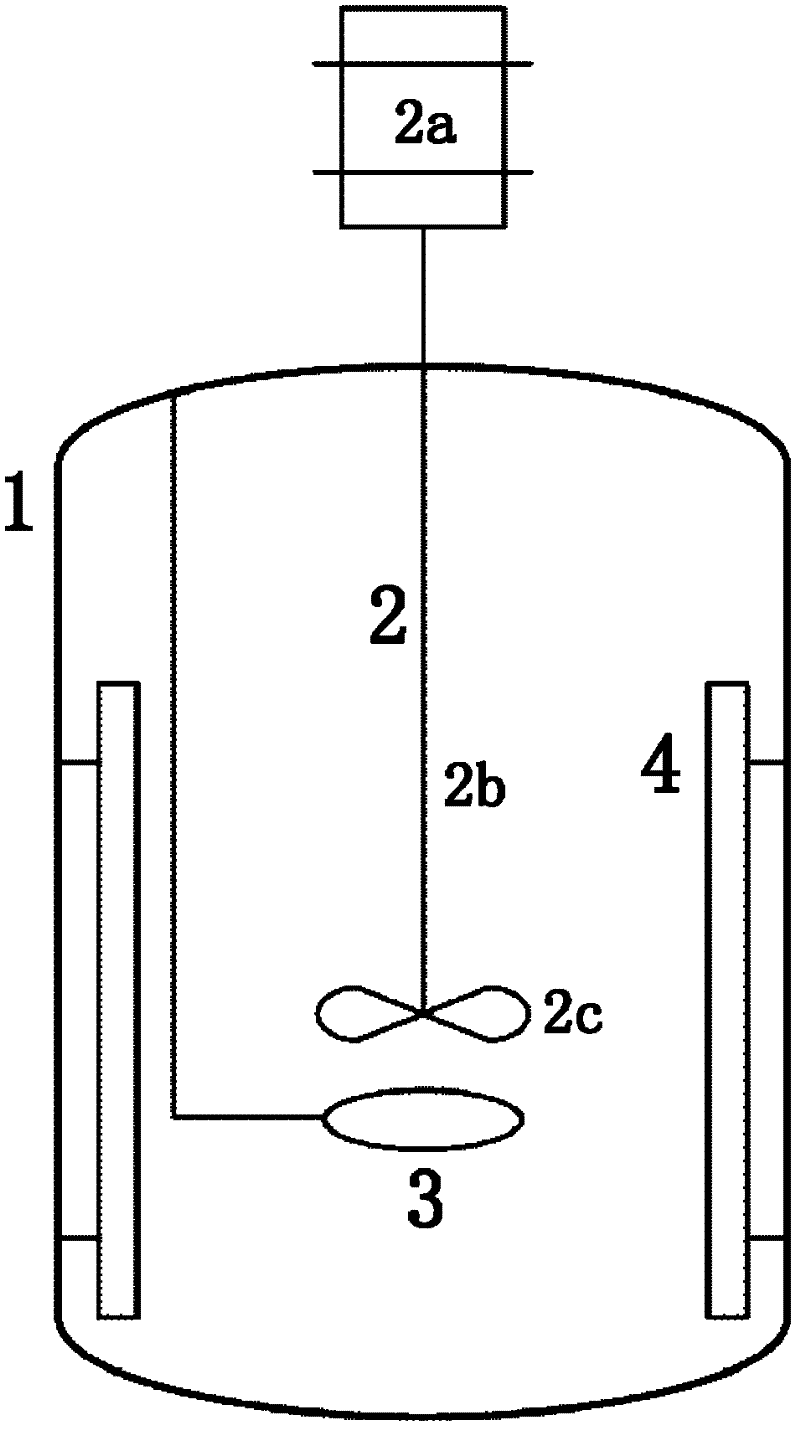

[0066] 1# stirred tank is an ordinary stirred tank without expansion section and connecting section, its structure is as attached figure 2 As shown, it includes: a vertical cylindrical polymerization kettle body 1, a stirring device 2 installed in the center of the polymerization kettle body 1 for realizing the three-phase mixing of gas, liquid and solid in the kettle, and the stirring device 2 is composed of sequentially connected transmission devices 2a, a stirring shaft 2b and a stirring turbine 2c; a gas distribution device 3 located in the polymerization kettle body 1 for dispersing the raw material gas fed into the kettle; The baffle plate 4 of mixing effect; the baffle plate 4 is a straight baffle plate. The inner diameter of the vertical cy...

Embodiment 3

[0088] The cold mold device was established in the laboratory, and the gas-liquid-solid three-phase slurry entrainment cold mold experiment was carried out in two stirred tanks with different expansion sections.

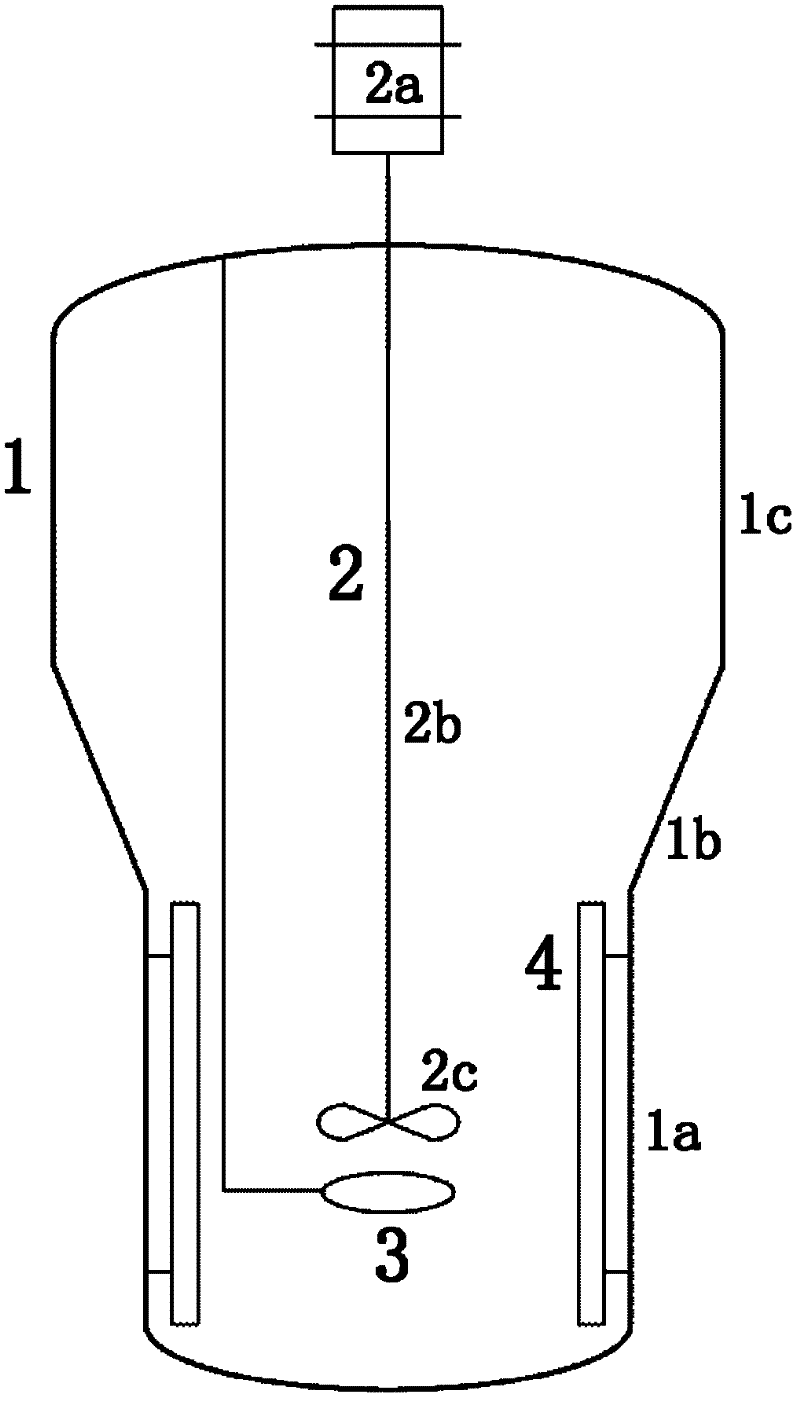

[0089] 3# stirred tank is the 3# stirred tank in embodiment 1, and what use is vertical cylindrical expansion section 1c and inverted conical connection section 1b, and enlarged section 1c internal diameter is 1.73 times of reaction section 1a internal diameter; 5# The stirring tank is attached Figure 4 As shown, except that the spherical top expansion section 1c (a kind of curved cylinder) is used, the diameter of the spherical part is the same as the inner diameter of the 3# stirred tank expansion section 1c, and the expansion section 1c is tangent to the connecting section 1b, other structures are the same as 3# stirring tank is the same. The inner diameter and height of the reaction section 1a and the inclination angle of the connecting section 1b of the two ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com