Method for separating iron, chromium, nickel, copper and zinc from high-iron high-chromium electroplating sludge leachate

A technology of electroplating sludge and separation method, which is applied in the field of separation of iron, zinc, chromium, nickel, and copper in the leaching solution of high-iron and high-chromium electroplating sludge, so as to achieve the effects of reducing impurity ions, reducing saponification process, and improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The sludge selected in this example comes from a wastewater treatment plant in a surface treatment park in Wuxi, with a moisture content of about 65%, a dry basis containing 5.74% chromium, 7.7% iron, 0.54% copper, 0.54% nickel, and 3.87% zinc. Put 1 kg of wet sludge in a 5 L polypropylene stirred reactor, control the liquid-solid ratio to 5:1, adjust the pH value to 1.8 with sulfuric acid, stir at 500 rpm, and stir for 2.0 hours to complete the leaching. The chromium content in the leachate is 11.3 g / L , iron 10.56 g / L, copper 1.06 g / L, nickel 1.12 g / L, zinc 7.65 g / L.

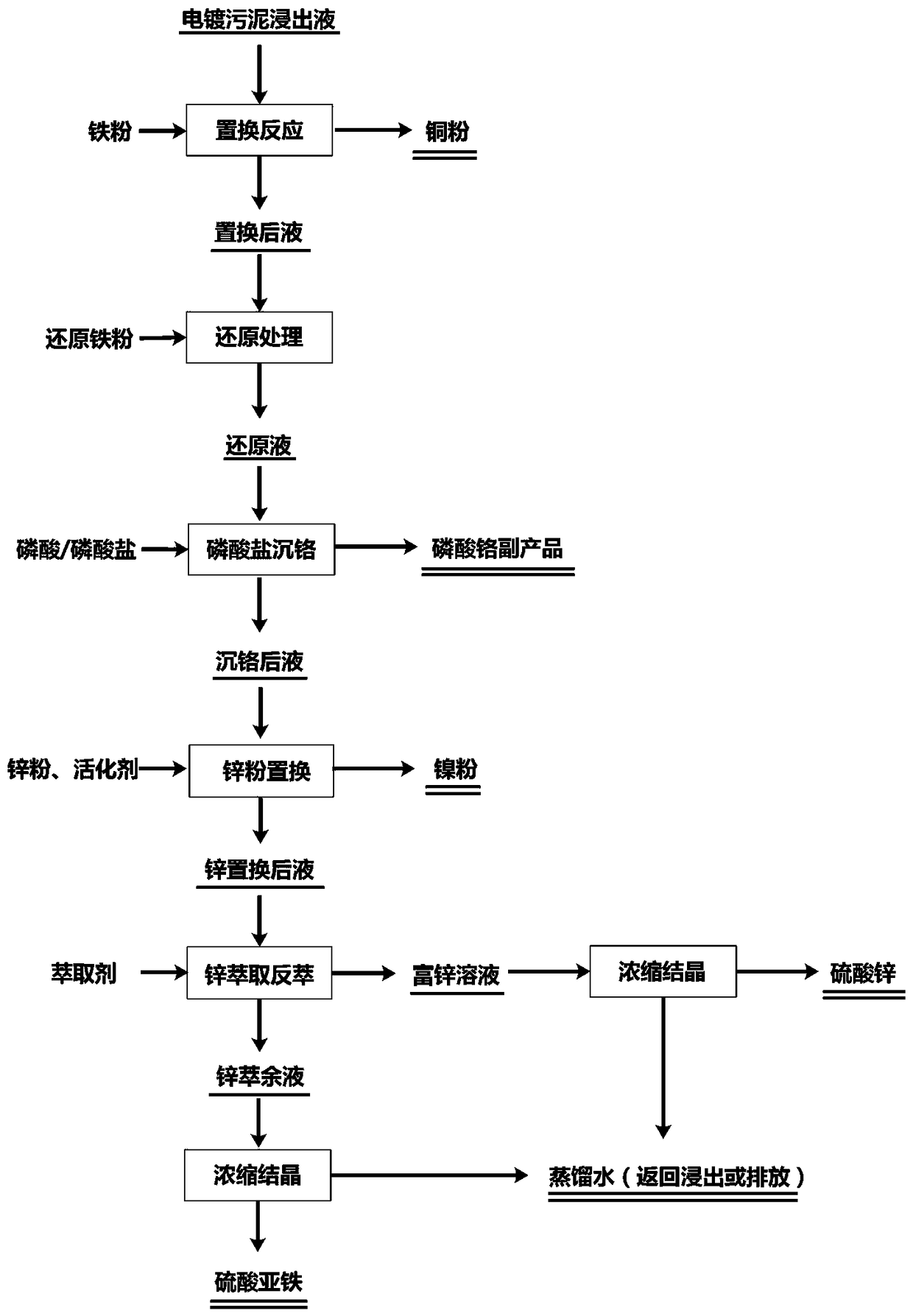

[0044] According to the separation method of iron, chromium, nickel, copper and zinc in the high iron and high chromium electroplating sludge leach solution of the present invention, the copper, chromium, nickel, zinc and iron in the above sludge leach solution are sequentially separated, comprising the following steps, as figure 1 Shown: (1) Take 1 L of leaching solution and place it in the correspondi...

Embodiment 2

[0046] The sludge selected in this example comes from a wastewater treatment plant in a surface treatment park in Zhejiang, with a moisture content of about 58%, a dry basis containing 6.7% chromium, 18% iron, 2.1% copper, 1.6% nickel, and 5.7% zinc. Put 1 kg of wet-based sludge into a 5 L polypropylene stirred reactor, add acidophilic mixed bacteria solution (containing Acidithiobacillus ferrooxidans ATCC 23270 and Acidiphilium acidophilum ATCC 27807, each accounted for 50%) pulping, sulfuric acid to adjust the pH value to 1.5, stirring speed 500rpm, stirring for 8.0 hours to complete the leaching, chromium 13.27 g / L, iron 34.20 g / L, copper 4.12 g / L, nickel 3.17g / L, zinc 11.29 g / L, after washing the leaching slag, a harmless leaching slag was obtained, with a moisture content of about 60%. After drying, the main components were gypsum and ferric hydroxide, which accounted for 82% and 17% by mass respectively.

[0047] According to the separation method of iron, chromium, ...

Embodiment 3

[0049] In this example, an electroplating sludge high iron sulfate leaching solution in Shenzhen (containing chromium 15.28g / L, iron 23.7 g / L, copper 3.51g / L, nickel 11.5 g / L, zinc 10.3 g / L) was selected, and the leaching residue was washed to obtain The harmless leached slag has a moisture content of about 62%. After drying, the main component is gypsum, which accounts for about 88.9%. The total content of other heavy metals is less than 1%.

[0050] According to the separation method of iron, chromium, nickel, copper and zinc in the high iron and high chromium electroplating sludge leach solution of the present invention, the copper, chromium, nickel, zinc and iron in the above sludge leach solution are sequentially separated, comprising the following steps: (1) ) Pour 100 L of leaching solution into a stirring tank with a stirring linear speed of 5 m / s, add 650 g of industrial iron powder below -100 mesh to the rapidly stirring leaching solution, which is twice the amount re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com