Subassembly between gas-liquid contacting and in use for knockout tower for mass transfer

A gas-liquid contact and assembly technology, which is applied in the field of mass transfer separation tower technology, can solve the problems of increasing mist entrainment, energy loss, and performance reduction of mass transfer separation tower, so as to increase the gas channel area and improve the liquid lift. The effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

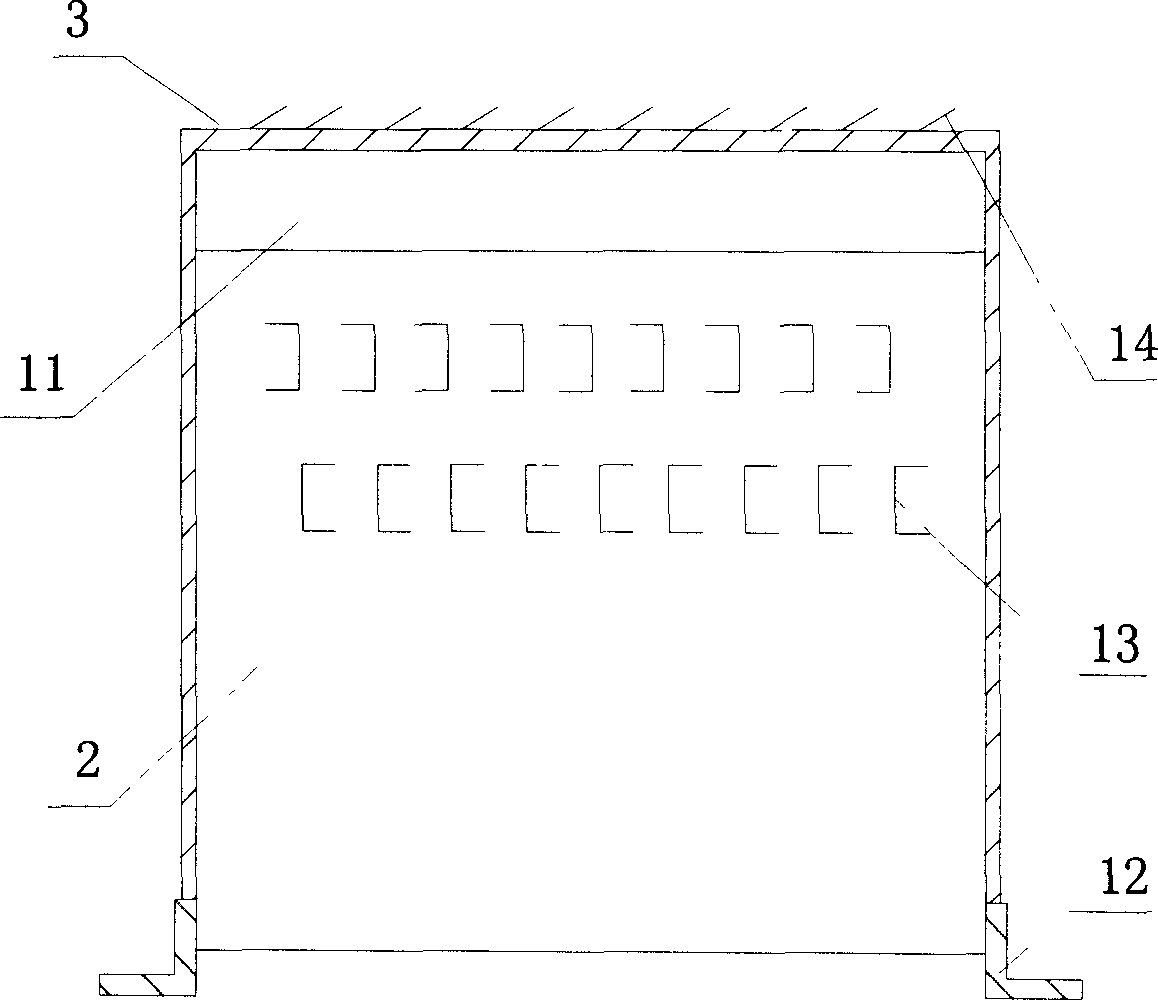

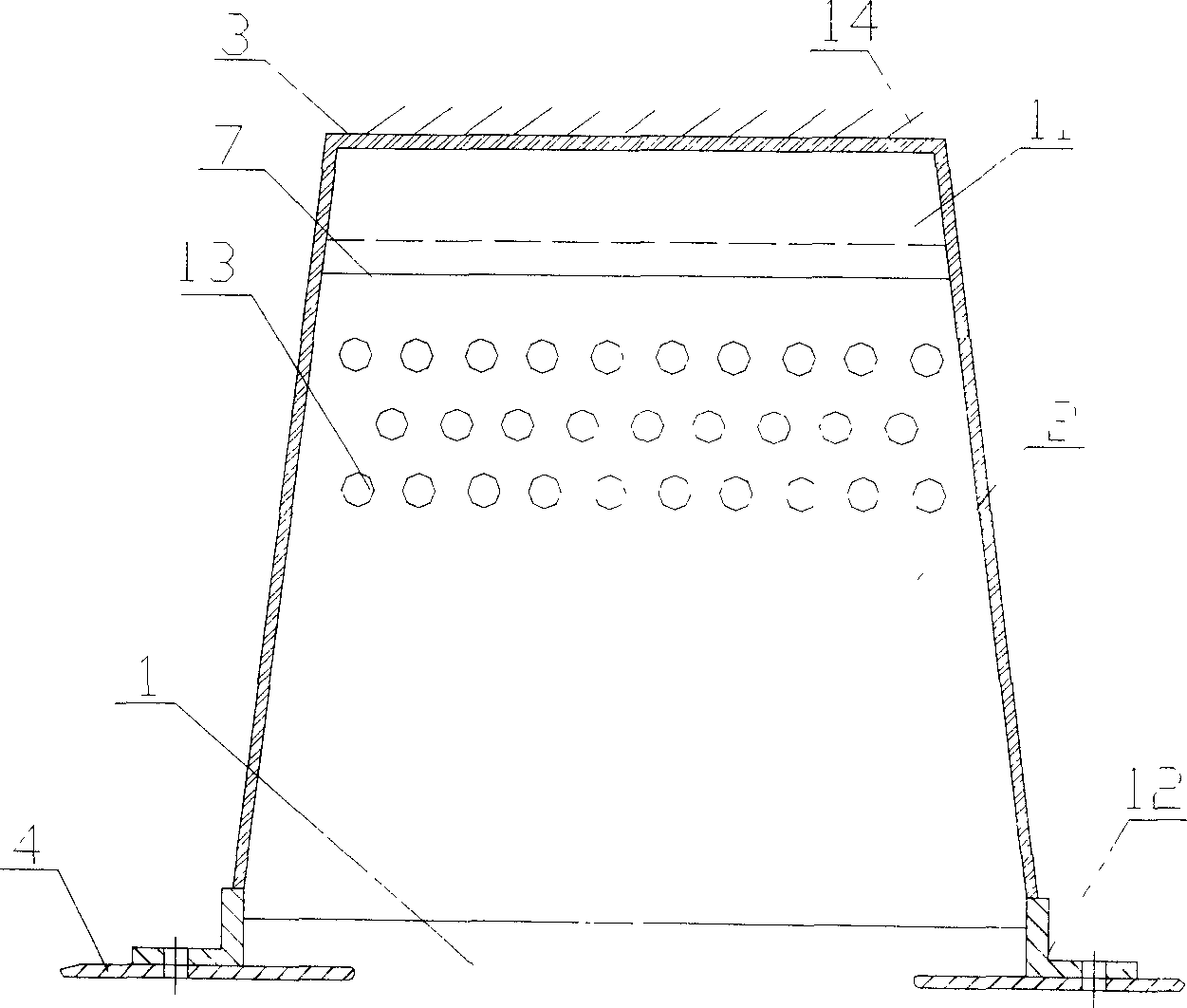

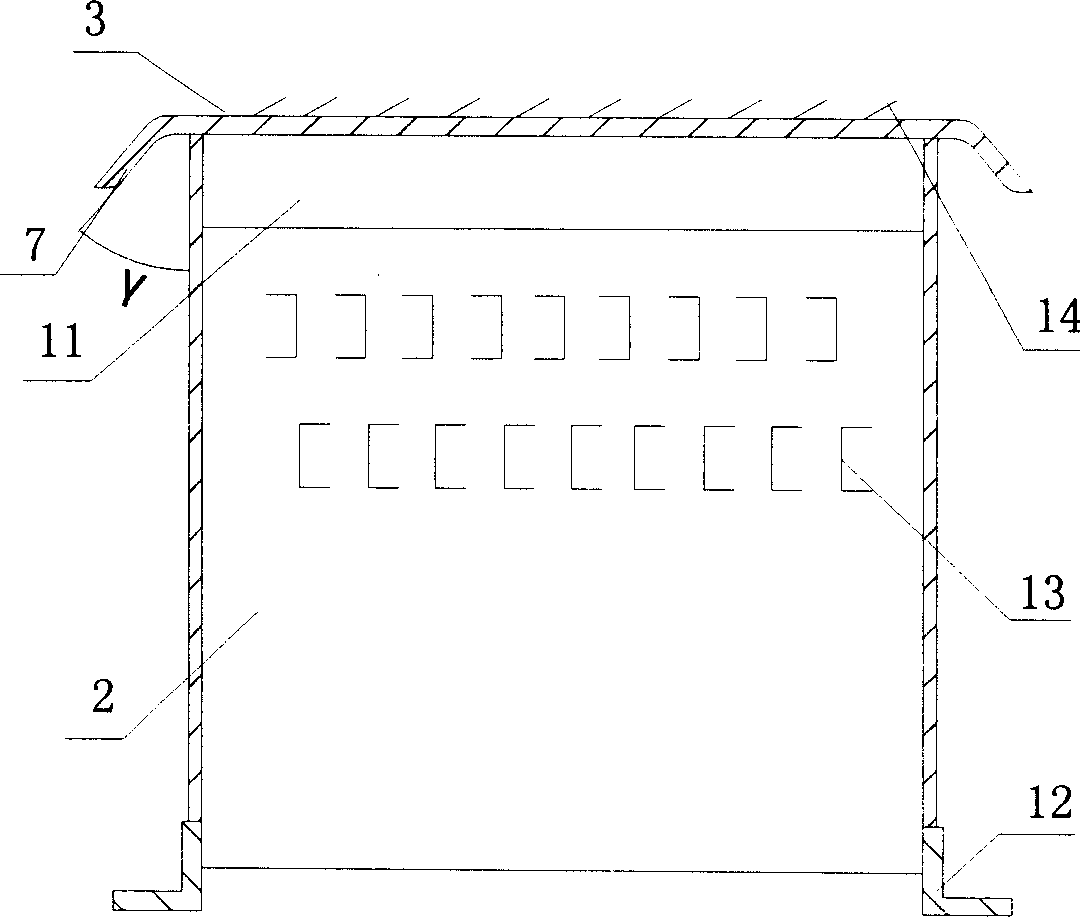

[0035] Vinyl chloride monomer low-boiling rectification tower (the original tower diameter is Φ600mm), adopts F1 type float valve tray, the number of trays is 38, the tray is single overflow type, the cross section of the downcomer is bow-shaped, and the overflow weir The length is 456mm, and the board spacing is 300mm. Its production capacity is 30,000 tons of PVC / year, and the product contains C 2 h 2 Amount ≤ 10 ~ 20ppm. The low-boiling tower was transformed with a vertical sieve tray tower (only the trays were replaced, and other factors such as tower diameter, number of trays, and plate spacing remained unchanged), and the production capacity was increased to 55,000 tons of PVC / year. Contains C 2 h 2 The amount drops to 0 (it cannot be detected by the instrument, the same below), and the plate resistance drops to about 60% of the original. Another low-boiling tower of the same type that has been transformed with a vertical sieve plate using the gas-liquid contact ass...

Embodiment 2

[0037] A PVC monomer high boiling rectification tower with a diameter of Φ1400. F1 type float valve trays are adopted, the number of trays is 40, of which 24 are in the rectification section, 16 are in the stripping section, and the spacing between the trays is 300mm and 350mm respectively. Pipe, the original design production capacity is 75,000 TPVC / year monomer. It is required that the finished monomer contains high boilers (dichloroethylene, etc.) ≤ 80-100ppm. Operational runs have shown that the above requirements cannot be met. The vertical sieve plate column technology is used to redesign, the diameter of the new column is φ1000, and the number of trays is the same as that of the float valve column. After being put into production, it shows that the production capacity can reach 90,000 TPVC / year monomers. And the content of high boilers in the finished monomer is reduced to 5-8ppm. It shows that the processing capacity is greatly increased (if converted with the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com