Drum mixer

A mixer and drum-type technology, which is applied in the direction of mixer accessories, cement mixing devices, mixers, etc., can solve the problems of inability to ensure uniform mixing of mixing materials, high structural costs, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

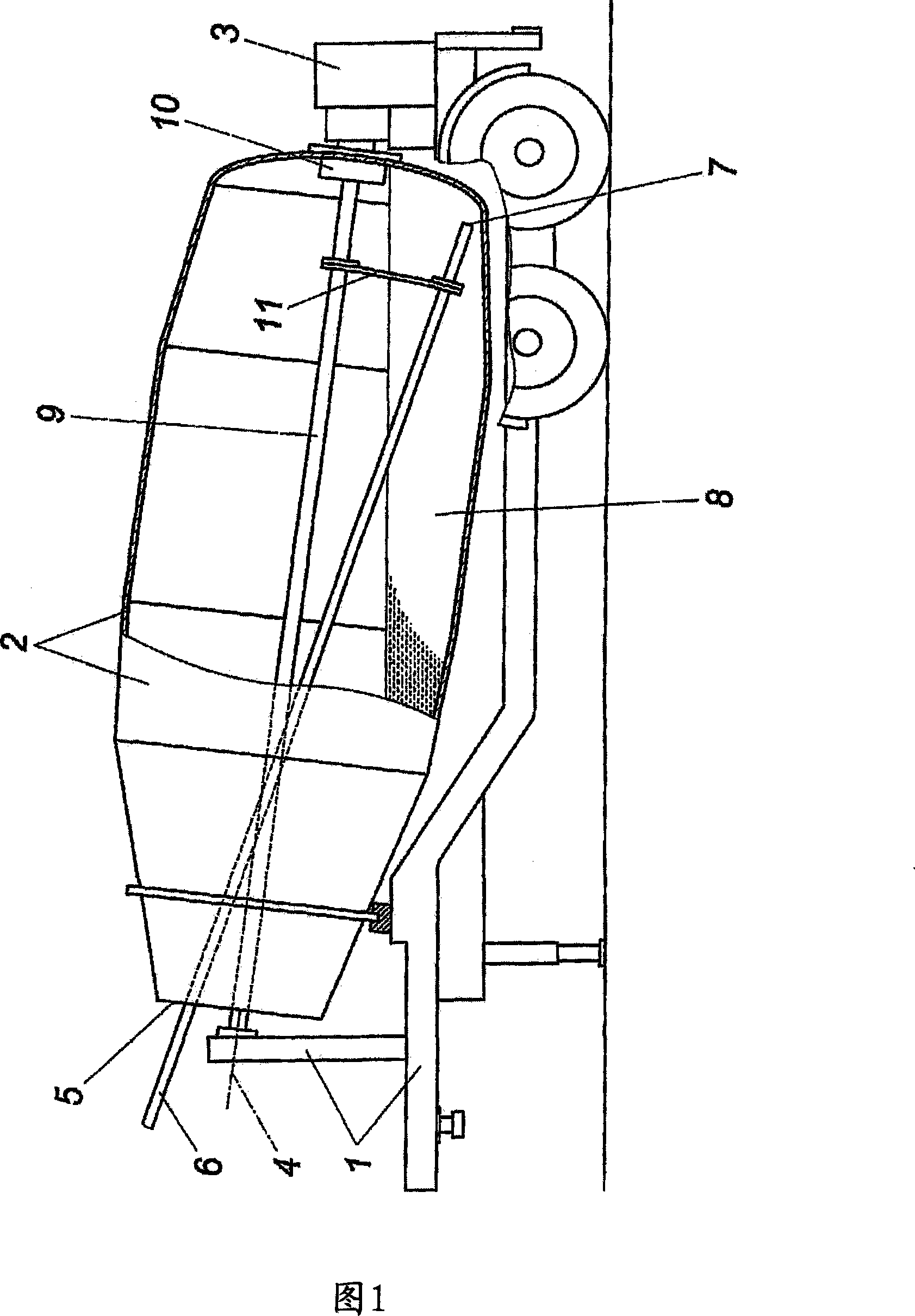

[0010] According to the exemplary embodiment shown, the drum mixer has a drum 2 mounted rotatably on a support 1 , wherein the support 1 is designed as a movable carriage. The drum 2 is connected to a transmission 3 which moves the drum 2 about an axis of rotation 4 running obliquely to the horizontal. In the drum 2, from the end side feeding port 5 of the drum 2, a material taking pipe 6 with its feeding port 7 extends into the mixing material 8, so that the mixing material 8 of the drum 2 can be taken out. Distributed within the drum 2 is a support 9 connected to the support 1 , which is rigidly connected to the extraction tube 6 inside the drum 2 . Thus, unlike the prior art, the extraction tube 6 is held securely in the mixing material 8 of the drum 2 without the use of a high flexural strength extraction tube 6 . In addition to reducing the structural outlay of the retrieving pipe 6, this also ensures that the retrieving pipe 6 reliably removes the uniformly stirred mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com