Fermentation equipment with diversion device

The technology of fermentation equipment and diversion device is applied in the field of fermentation tanks, which can solve the problems of chaotic flow of fermentation liquid, uneven stirring, low dissolved oxygen, etc., and achieves the effects of speeding up the circulation speed, reducing the stirring diameter, and increasing the flow process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

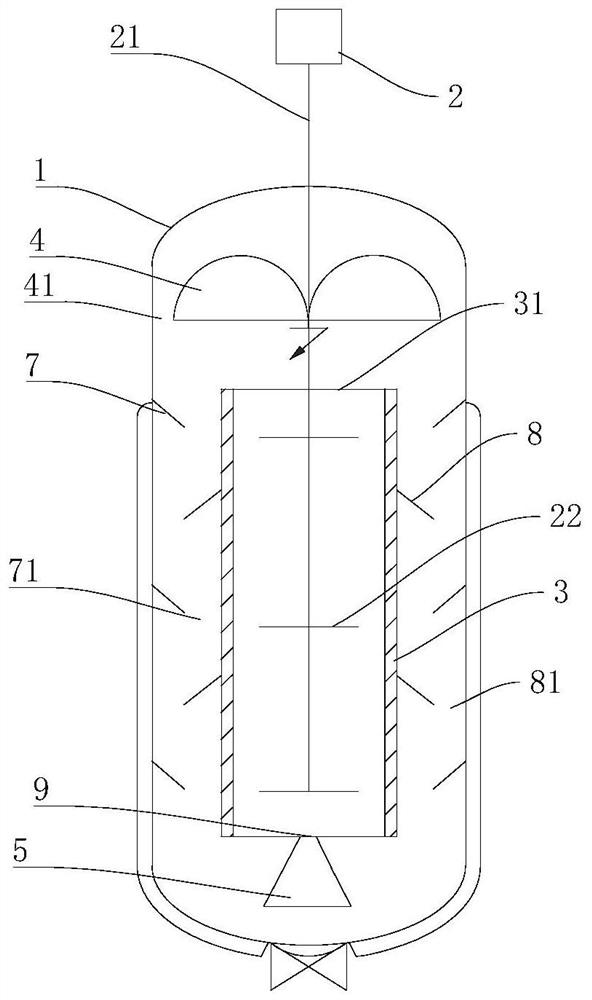

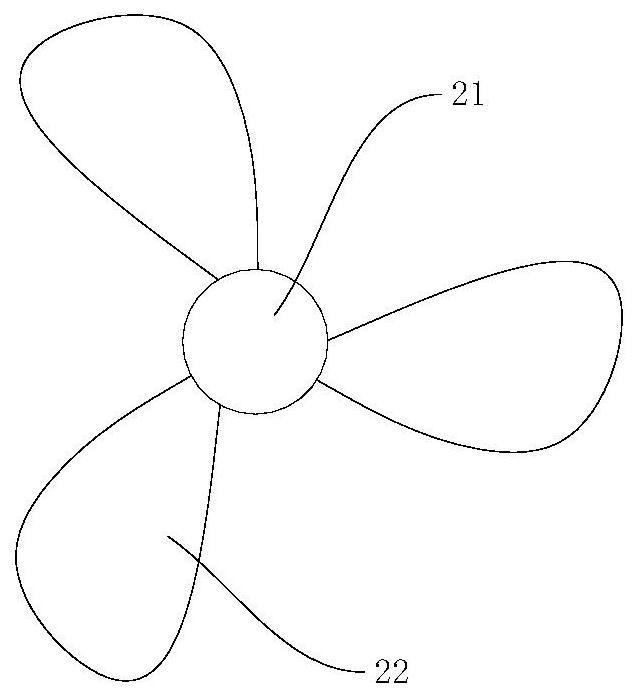

[0019] Embodiment: a kind of fermenting equipment with guide device, as Figure 1-2 As shown, the tank body 1 is included, the motor 2 is arranged above the tank body 1, the output end of the motor 2 is connected to the stirring shaft 21, and the stirring shaft 21 extends downward to the inside of the tank body 1, and multiple sets of stirring shafts are arranged on the stirring shaft 21. Paddle, the stirring paddle of present embodiment is provided with three groups, combines figure 2 It can be seen that each group of stirring paddles includes a plurality of twisted paddles 22 that push up the liquid, that is, when the twisted paddles 22 rotate, they can drive the nearby fermentation liquid to move upward.

[0020] There is a guide tube 3 in the middle of the tank body 1, which divides the tank body 1 into two parts. The diameter of the guide tube 3 is 50-75% of the diameter of the tank body 1. The guide tube 3 is connected to the inner wall of the tank body 1 through a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com