Composite electromagnetic stirring process of preparing semi-solid metal slurry continuously

A semi-solid metal, electromagnetic stirring technology, applied in the field of semi-solid metal processing, can solve the problems of slow progress of semi-solid slurry or blank, discontinuous slurry flow, low efficiency, etc. High stirring power to avoid the effect of huge equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

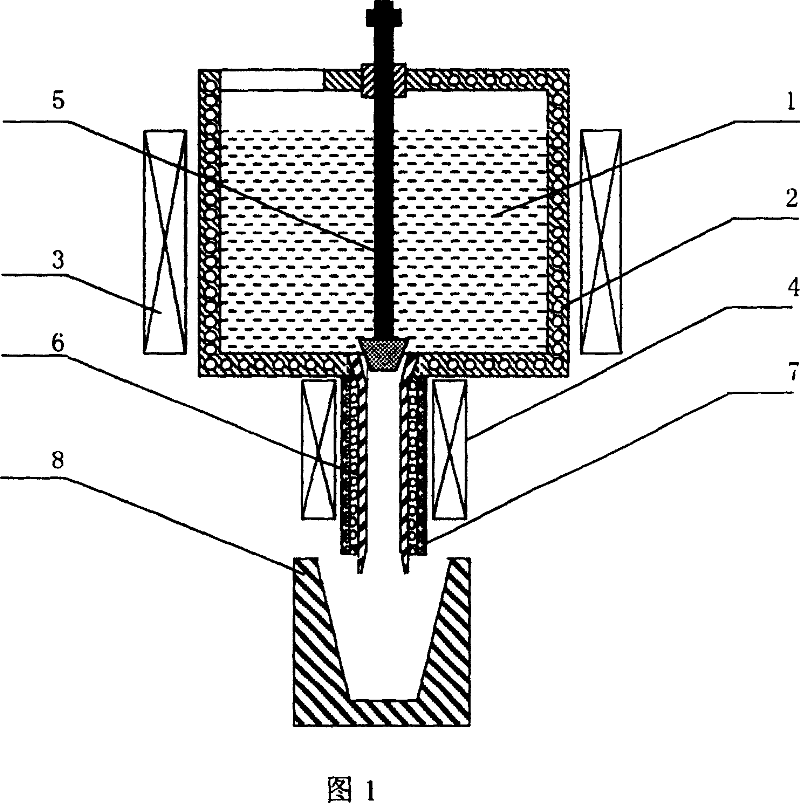

[0023]As shown in Figure 1, the tundish 2 is a receiving container, the upper top wall is provided with the inlet of the metal liquid, and the lower bottom wall is provided with the outlet of the metal liquid, and the outlet is connected to the guide tube 6, and the guide tube 6 wall A temperature controller 7 is provided. In the receiving container 2, a stopper rod 5 runs through from its upper top to its lower bottom. The upper part of the stopper rod 5 penetrates the upper top wall of the receiving container 2 and is slidably connected with the upper top wall. The handle of the stopper rod 5 exposed outside the receiving container 2 can be used to operate the stopper rod 5 to move up and down. The lower end of the stopper rod 5 is provided with a piston. The handle can control the relative position of the piston and the outlet of the molten metal in the receiving container 2, so as to control the opening, closing and flow of the outlet of the molten metal. An upper agitator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com