Integrated reaction system for siloxane cracking

A reaction system, siloxane technology, applied in chemical/physical/physicochemical nozzle reactors, chemical instruments and methods, feeding devices, etc., can solve the problems that are not mentioned and improved, the effect is not significantly improved, and it is difficult Breaking and other problems to achieve the effect of reducing momentum consumption, reducing stirring power, and improving mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

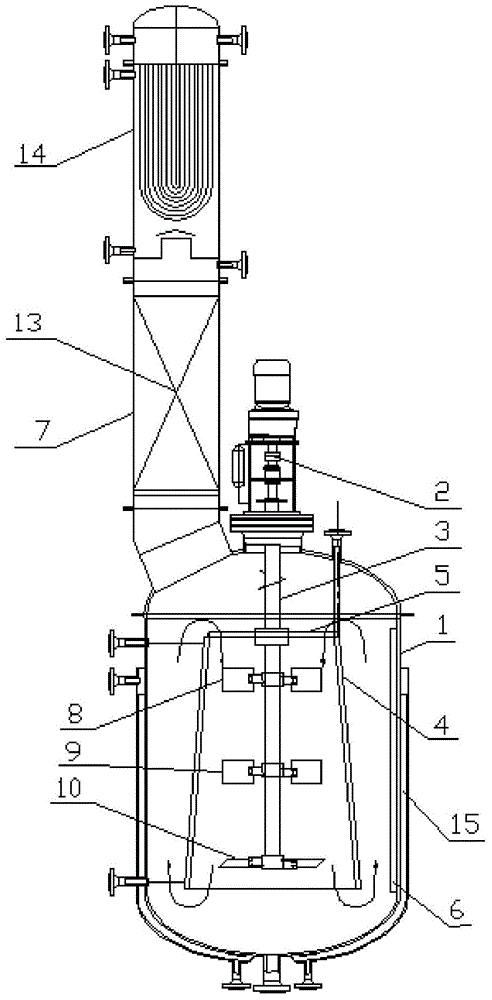

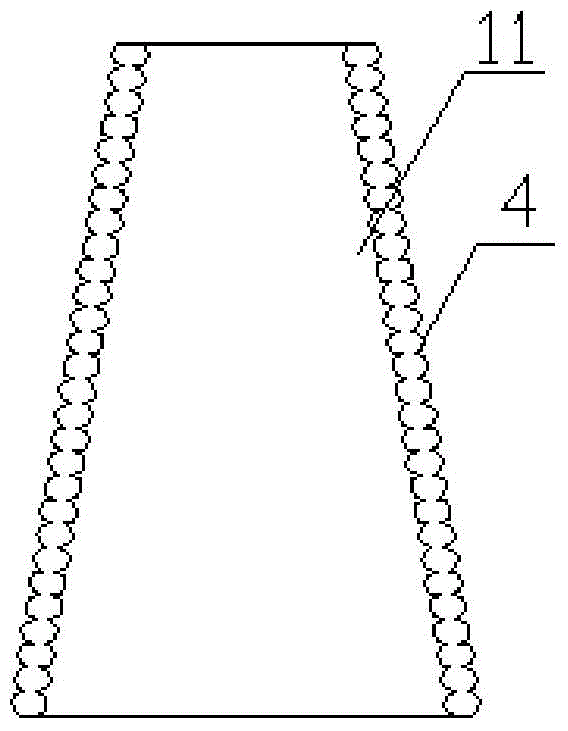

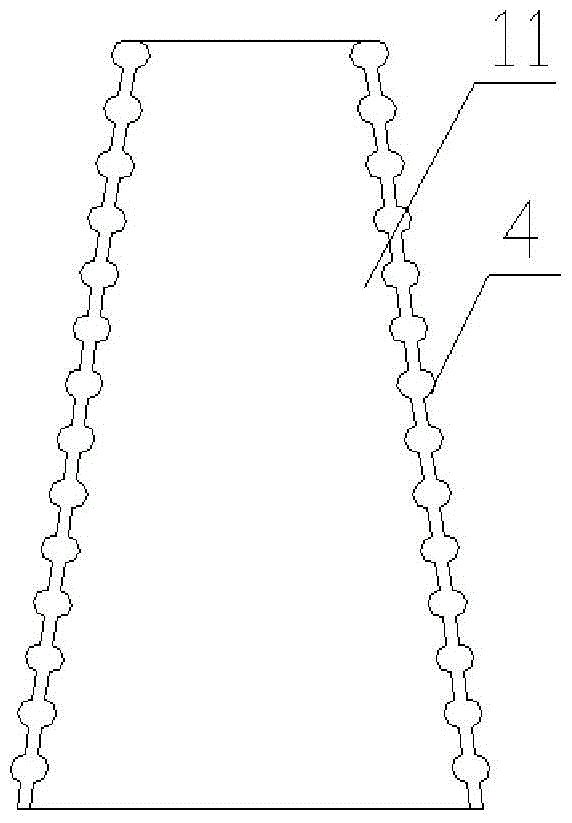

[0027] Siloxane cracking integrated reaction system, such as figure 1 As shown, a cylindrical kettle body 1 is included, and the kettle body 1 is vertically arranged. A central rotating shaft 3 connected to an external motor 2 is longitudinally arranged in the kettle body 1. A three-layer agitator is longitudinally arranged on the central rotating shaft 3, and the outer peripheral sleeve of the agitator is There is a circulation diversion heat exchange cylinder 4 with upper and lower openings, the upper end of the circulation diversion heat exchange cylinder 4 is provided with a feed diversion distributor 5, and the inner wall of the kettle body 1 is evenly distributed with 4-6 side wall diversion complete The baffle plate 6 and the upper end of the still body 1 are connected with a rectification tower 7 .

[0028] In this specific example, as figure 1 As shown, the three-layer agitator is an upper turbine agitator 8, a middle turbine agitator 9 and a lower propulsion agitato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com