Equipment and method for disposing kitchen waste based on high-temperature aerobic fermentation technology

A technology for kitchen waste and aerobic fermentation, which is applied in the fields of organic fertilizer equipment, preparation and application of organic fertilizers, etc., can solve the problem that it is difficult to meet the requirements of daily production and clearing of kitchen waste, affects the appearance of the city, the appearance of the city and traffic, and endangers the people. The health of the masses and other issues, to achieve the effect of being conducive to fermentation and digestion, facilitating manual pouring, and reducing the requirements for stirring effects

Inactive Publication Date: 2017-03-15

SHANDONG CRRC HUATENG ENVIRONMENT CO LTD

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Bad smells are likely to be produced near the garbage collection site, causing people's sensory resentment; due to the high water content of kitchen waste, there are a series of problems in the transportation process

Irregular transport vehicles are prone to leakage and dumping of kitchen waste, seriously affecting city appearance, city appearance and traffic; the most important thing is that most of the garbage from urban catering enterprises is collected by farmers and used directly as breeding feed. Disposal enters the human food chain, endangering the health of the people; at the same time, waste oil is collected and re-refined to become cheap edible oil, which is circulated in the market again, endangering the health of the people

[0004] At present, the treatment technologies of food waste mainly include landfill, incineration, feed treatment, anaerobic fermentation and aerobic composting, etc. Among them, anaerobic fermentation and aerobic composting have more potential, but the treatment period of these two methods is relatively long , it is difficult to meet the requirements of the daily production and clearing of kitchen waste. At the same time, the exposed waste disposal is easy to emit a large unpleasant smell, and there is a problem of polluting the environment. In summary, there is no economical system equipment to deal with Better and faster treatment of food waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is:

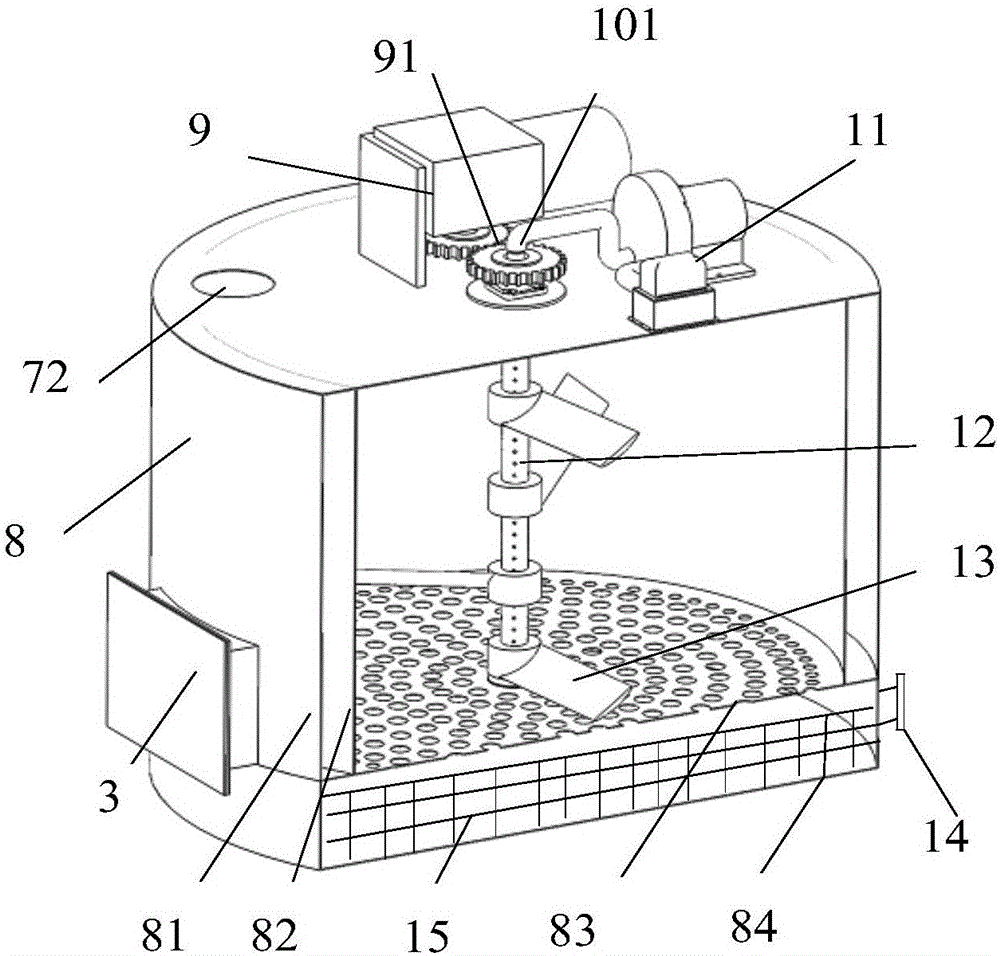

[0066] The hollow shaft is arranged around a stirring rotating shaft, and there are multiple hollow shafts. The hollow shaft is used to let in air, and the stirring rotating shaft is used to rotate, and the material is stirred by the stirring paddles.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

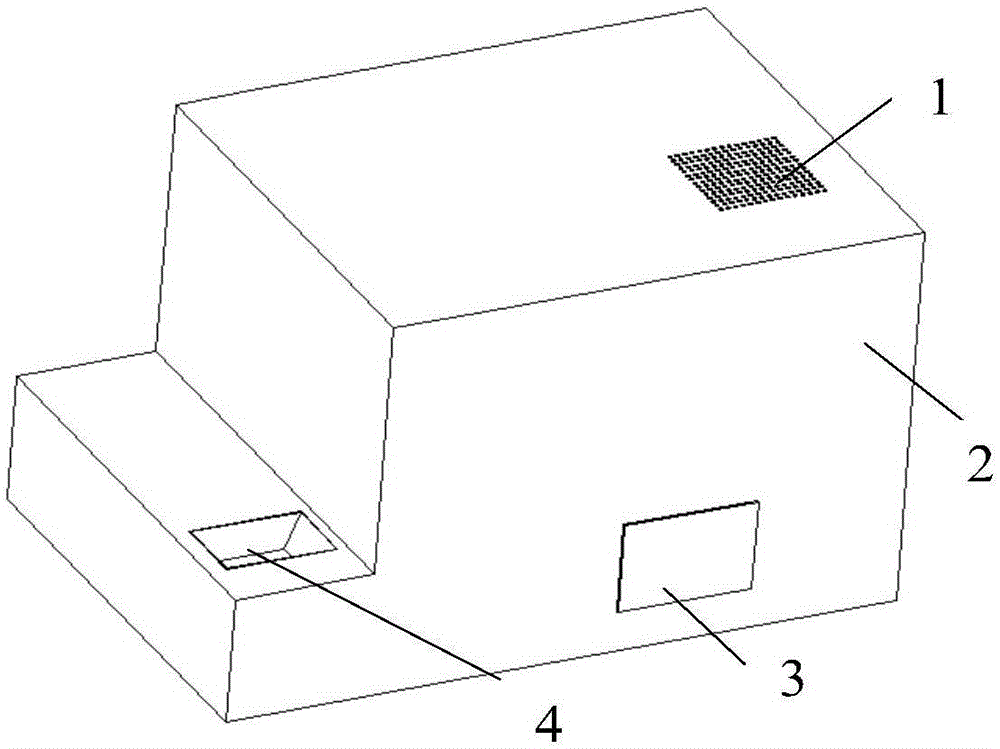

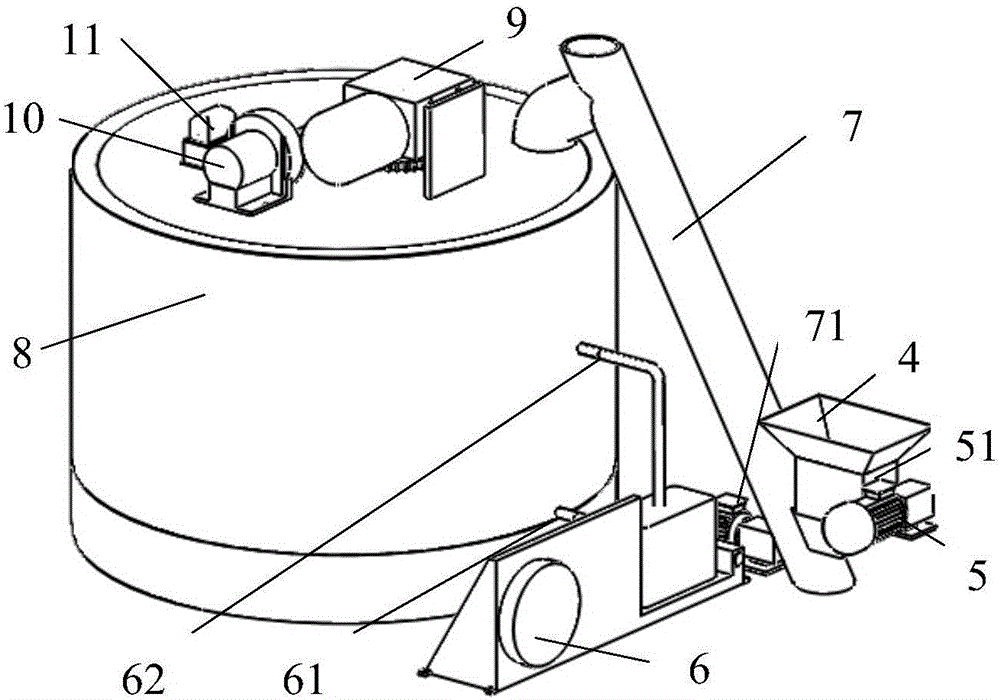

The invention discloses equipment and a method for disposing kitchen waste based on a high-temperature aerobic fermentation technology. The equipment comprises a shell, a waste conveyor and a waste fermentation tank, wherein a pouring opening through which the waste is poured is formed in the shell, the shell is step-shaped, and the pouring opening is formed in the shell at the position of the lowest step, so that the waste is convenient to pour; the waste conveyor is arranged slantly, and the inlet end of the waste conveyor is arranged at the bottom of the pouring opening; and the outlet end of the waste conveyor communicates with the waste fermentation tank, a heating source is arranged on the periphery of the waste fermentation tank so as to heat the waste in the waste fermentation tank, the waste fermentation tank is internally provided with at least one hollow shaft, a plurality of through holes are formed in the circumferential direction of the hollow shaft, and a filter layer is arranged at the bottom of the waste fermentation tank so as to discharge liquid generated through waste fermentation. Meanwhile, the requirement for the stirring effect of stirring paddles is reduced, and the stirring power is low. The filter structure is simple and reliable. The filter layer is arranged at the bottom of the fermentation tank, and liquid in the material is filtered by adopting fine sand, so that the equipment is simple in structure and good in filter effect.

Description

technical field [0001] The invention relates to kitchen waste treatment, in particular to a kitchen waste treatment equipment and method based on high-temperature aerobic fermentation technology. Background technique [0002] Kitchen waste mainly comes from food processing leftovers (kitchen waste) and food residues (swill) produced in the catering service industry, households, and canteens of enterprises and institutions. Food and kitchen waste treatment refers to a systematic method for on-site treatment and resource utilization of food and kitchen waste. With the rapid development of our country's economy and the gradual acceleration of urbanization, the output of kitchen waste is showing an upward trend year by year. In large and super-large cities in China, such as Beijing, Shanghai, Shenzhen, etc., the daily output of kitchen waste has reached thousands of tons, and the annual output of kitchen waste in the country has reached 10 million tons. If it is simply landfill...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C05F9/02C05F9/04

CPCC05F17/00C05F17/90Y02P20/129Y02A40/20

Inventor 李建军李斌刘晓龙郑金霞白超民李凯

Owner SHANDONG CRRC HUATENG ENVIRONMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com