Solid-type filter stick formed by granular assembling and preparation method thereof

A filter rod and particle technology, which is applied in e-liquid filter, application, tobacco and other directions, can solve the problems of shortage of special wood pulp raw materials, increase the production cost of cigarette enterprises, etc., and achieve the effect of improving smoking quality, stable structure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

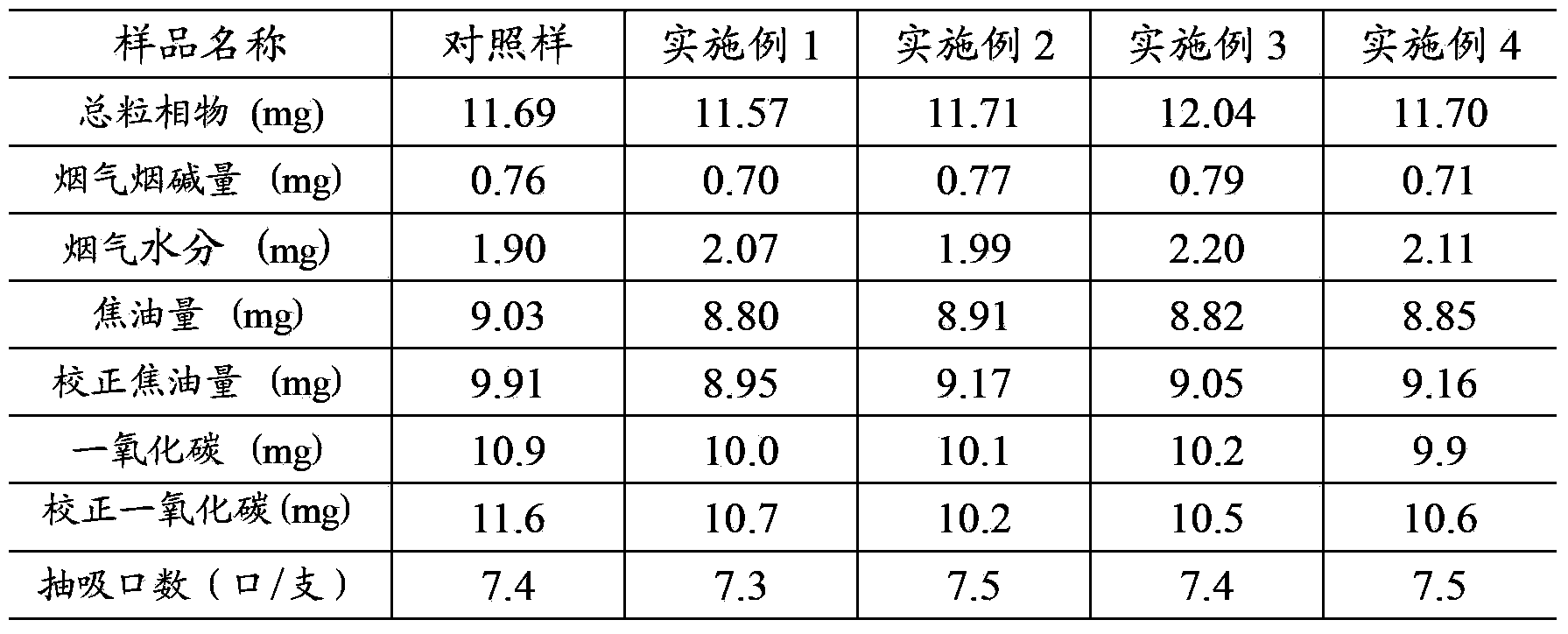

Embodiment 1

[0031] Use ethylene-vinyl acetate copolymer EVA hot-melt adhesive powder as a binder to produce solid filter rods of tobacco stem particles in a batch manner, including the following steps:

[0032] Tobacco stem particles of 40-60 mesh are selected, the binder is ethylene-vinyl acetate copolymer EVA hot melt adhesive powder, and the mass ratio of tobacco stem particles to EVA is 5:1. After the raw materials are mixed evenly, take 7cm3 of the material and fill it into a cylindrical stainless steel mold with a length of 160mm and a diameter of 7.5mm, and then compact both ends. The length of the material in the mold is compressed to 80mm, and then the mold is heated to 120 degrees Celsius. Hold for 2 minutes, and after the temperature of the mold is lowered to room temperature, demoulding treatment is carried out to obtain a solid filter rod of tobacco stem particles with a length of 80 mm and a diameter of 7.5 mm.

Embodiment 2

[0034] Using dextrin and polycaprolactone powder as a mixed binder, continuous production of tobacco stem particle solid filter rods includes the following steps:

[0035] Choose tobacco stem particles of 60-80 mesh, the binder is a mixed powder of dextrin and polycaprolactone (the mass ratio of dextrin to polycaprolactone is 1:3), the mass ratio of tobacco stem particles to the mixed binder It is 5:2. After the raw materials are mixed evenly, the continuous pneumatic filling device is used to continuously fill the materials from the (a) end of the cylindrical stainless steel mold with an inner diameter of 7.6mm. The tobacco stem granule solid filter rod comes out from the (b) end of the mould, and is quantitatively cut according to the length specification of the product to obtain a tobacco stem granule solid filter rod with a diameter of 7.6 mm and an adjustable length.

Embodiment 3

[0037] Using polyurethane photosensitive adhesive as a binder, the interstitial production of fragrant wood particle solid filter rods includes the following steps:

[0038]Choose fragrant wood particles of 40-60 mesh, the binder is polyurethane photosensitive adhesive, and the mass ratio of fragrant wood particles to polyurethane photosensitive adhesive is 4:1. After the raw materials are mixed evenly, take 8cm3 of the material and fill it into a cylindrical transparent mold with a length of 200mm and a diameter of 7.5mm, and then compact both ends. The length of the material in the mold is compressed to 100mm, and then irradiate the mold with ultraviolet light for 3 minutes , followed by demoulding treatment to obtain a solid filter rod of fragrant wood particles with a length of 100 mm and a diameter of 7.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com