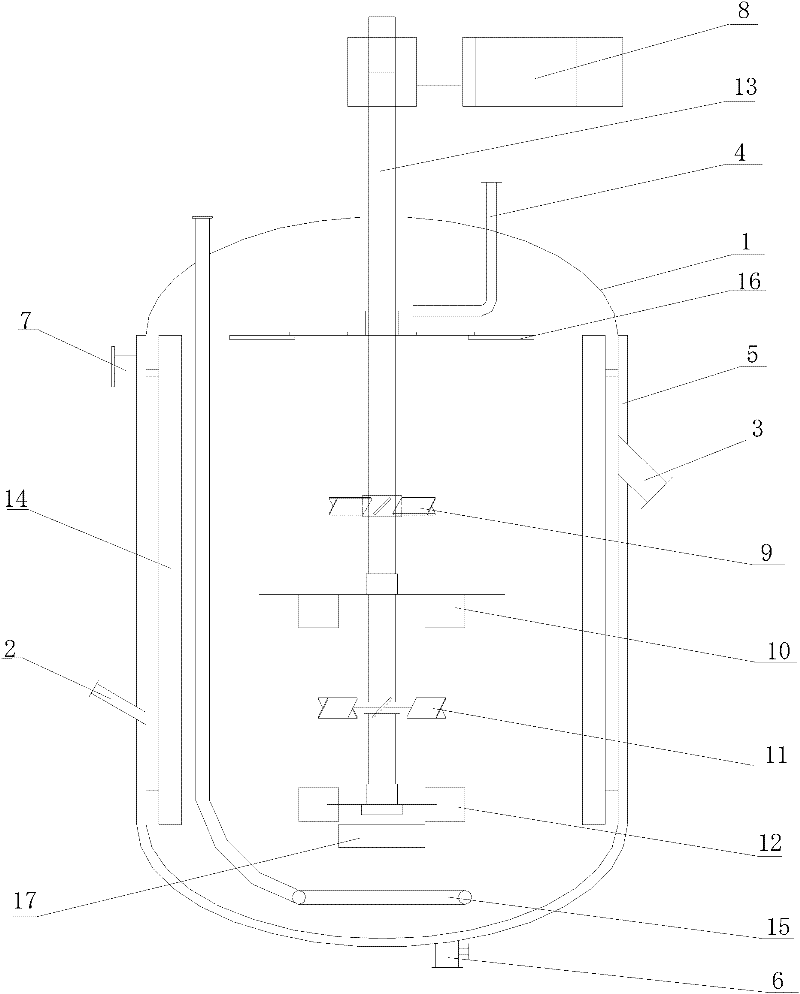

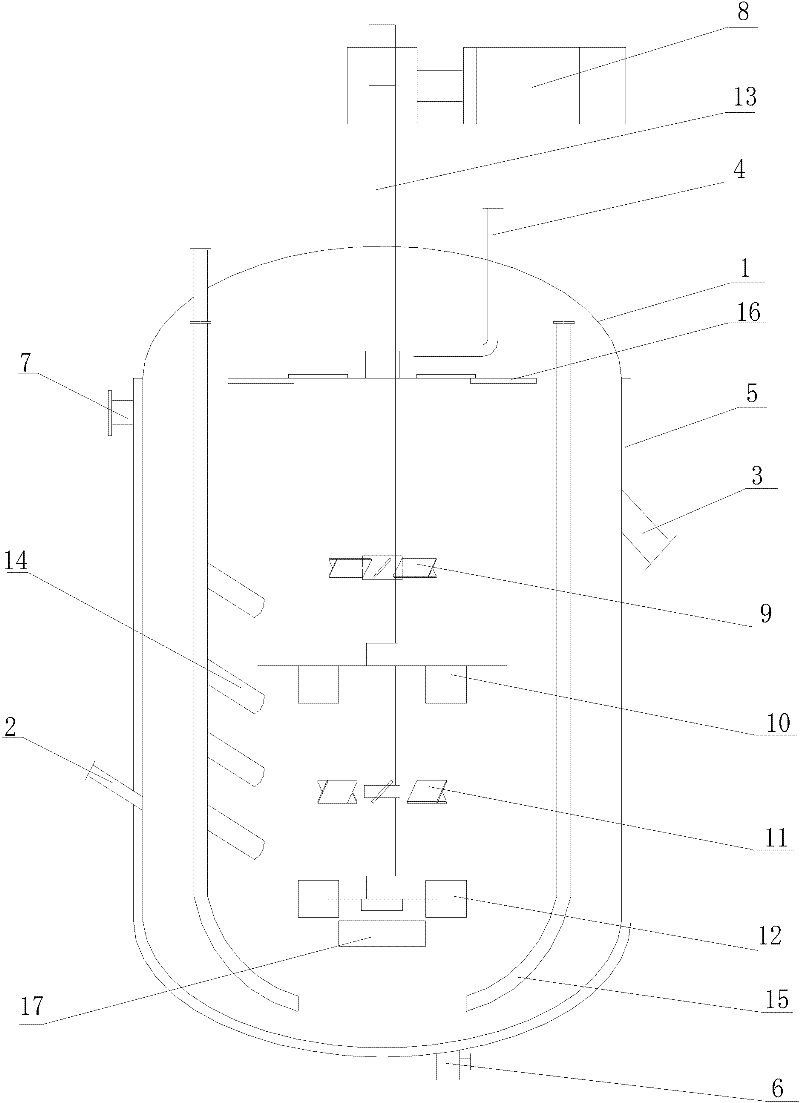

Stirred tank reactor

A stirred tank and reactor technology, which is applied in the field of stirred tank reactors for olefin slurry polymerization, can solve the problems of shortening the cleaning cycle of the heat exchanger, increasing the scaling of the heat exchanger, decreasing the heat exchange capacity, etc. The effect of reducing residence time, slurry entrainment, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

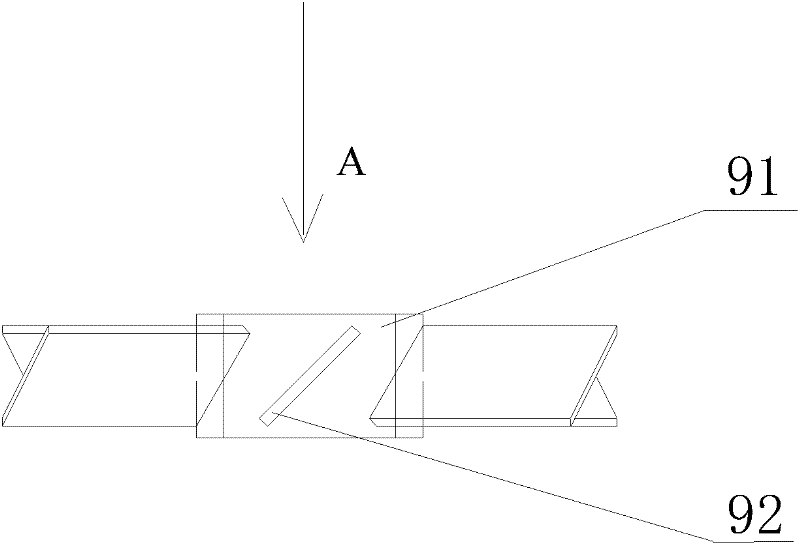

[0063]Embodiment 1 adopts a specific structure of the stirred tank reactor of the present invention, and there are 8 air inlet pipes, wherein, half of the air inlet pipes run through the top of the stirred tank body 1 and extend to the bottom of the stirred tank body 1, and the other half of the air inlet pipes are at the bottom of the stirred tank body 1. Inside the stirred tank body 1, it extends from the end close to the top to the bottom. The baffle 14 is a finger-shaped baffle, and 4 finger-shaped baffles are equidistantly installed on one intake pipe (1# finger-shaped baffle means the first finger-shaped baffle from the top of the stirring tank to the bottom of the stirring tank) 1# turbine means the first layer of turbines from the top of the stirred tank to the bottom of the stirred tank, and so on, the same below), 4 of the 8 inlet pipes are provided with finger-shaped baffles, a total of 16 finger-shaped baffles shaped baffle.

[0064] The first layer of turbine 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com