Stirred tank with baffle plates capable of reducing accumulating materials at tank bottom

A technology of mixing tank and tank bottom, which is applied in mixer accessories, dissolving, mixer and other directions, and can solve problems such as disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

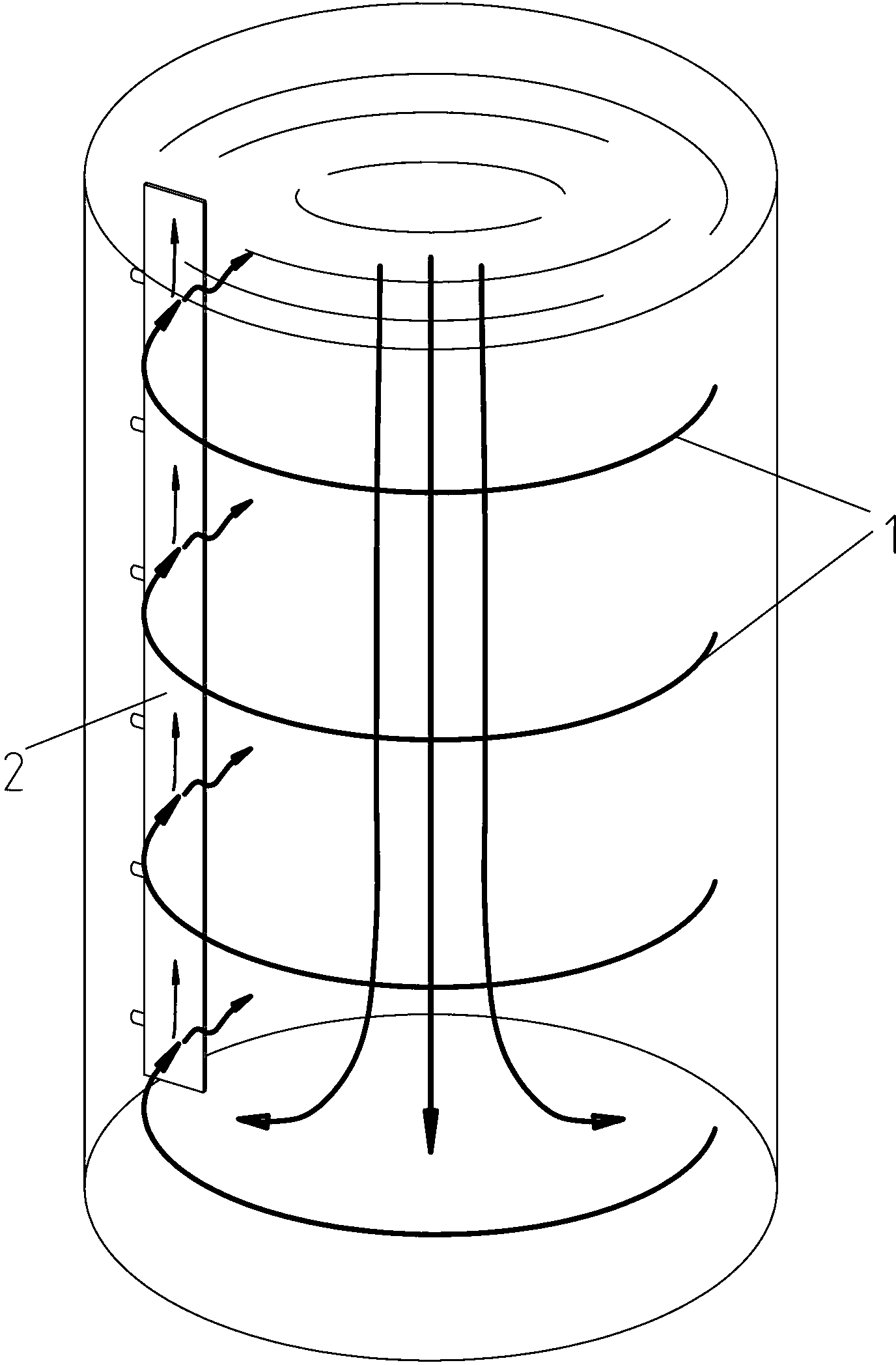

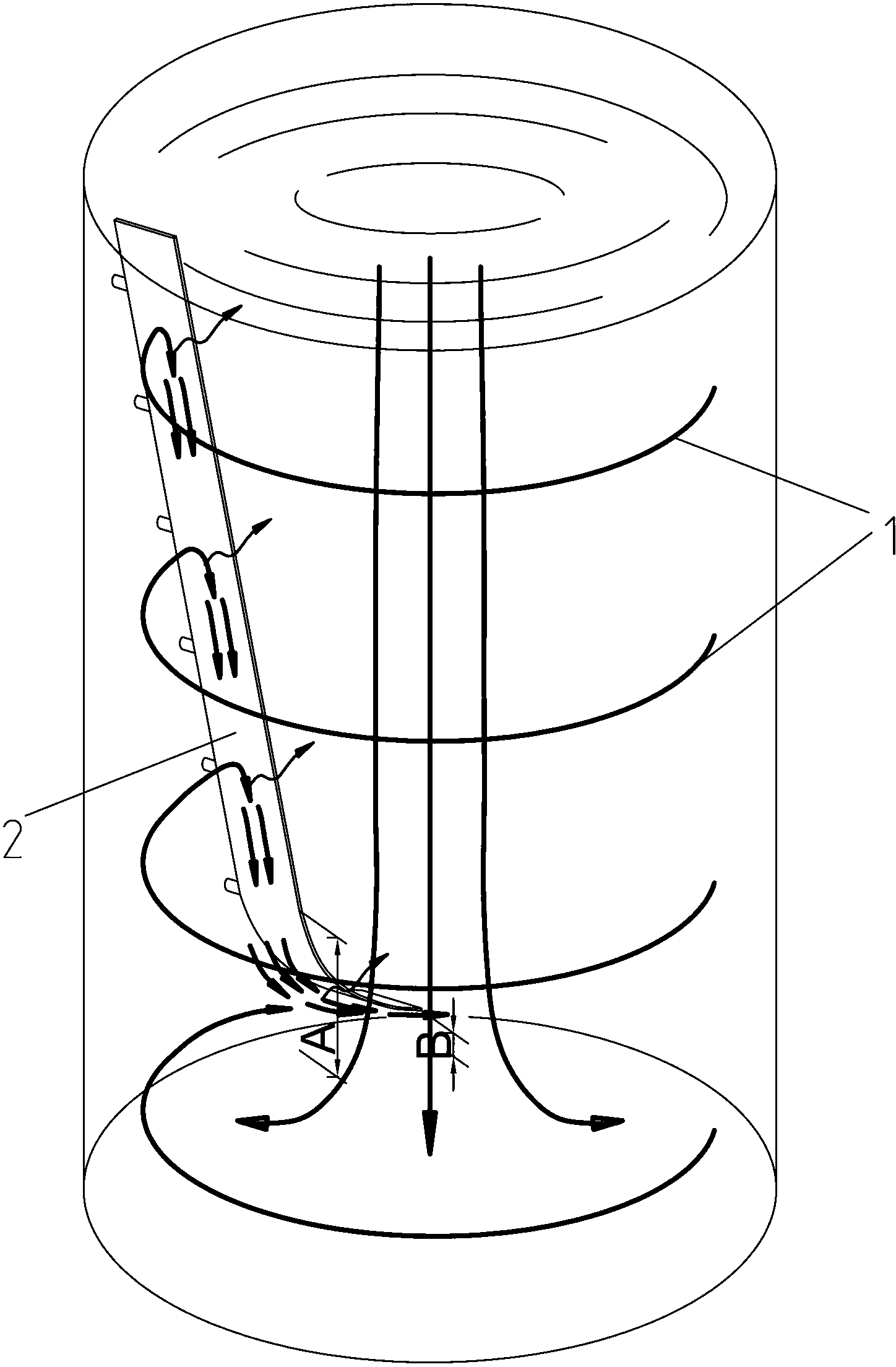

[0015] Such as figure 2 As shown, the present invention has a stirring tank with a baffle plate for reducing the accumulation at the bottom of the tank, including a tank body 1 and a baffle plate 2, and the straight plate shape of the middle and upper part of the baffle plate 2 is at an angle between 0-90 degrees with the axis of the tank body 1. In this embodiment, the included angle is 20 degrees. The lower part of the baffle plate 2 is arc-shaped and extends toward the bottom of the tank. The extending direction of the arc is consistent with the rotation direction of the feed liquid. The circumference is evenly distributed, the starting point of the arc at the lower part of the baffle 2 is A, and the end point is B; the distance between point A and the bottom of the groove is 1500-8000mm; the distance between point B and the bottom of the groove is 100-600mm, and the radius of the arc is 1000-8000mm. The tangent direction of the baffle is horizontal.

Embodiment 2

[0017] The middle and upper straight plate shape of the baffle plate 2 in the embodiment 1 forms an included angle of 3 degrees with the axis of the tank body 1 . Others are with embodiment 1.

Embodiment 3

[0019] The middle and upper straight plate shape of the baffle plate 2 in the embodiment 1 forms an angle of 85 degrees with the axis of the tank body 1 . Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com