Oxidation reactor for producing polybasic carboxylic acid

A technology of oxidation reactor and vertical container, which is applied in the field of reactors, can solve the problems such as the inability to apply polycarboxylic acid production, and achieve the effects of reducing the possibility of intensification of side reactions, uniform temperature, and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the embodiment, in order to compare the gas-liquid volume mass transfer coefficient in the reactor with / without draft tube and single / double-layer draft tube reactor, the volume mass transfer coefficient test was carried out on different component forms. The determination test uses a chemical method, using copper ions as a catalyst to oxidize sodium sulfite, and the oxygen dissolved in water can immediately oxidize sulfite ions to become sulfate ions. Since the sodium sulfite oxidation reaction catalyzed by copper ions is first-order to oxygen, choosing an appropriate catalyst concentration can make the concentration of oxygen in the main body of the water phase almost zero. At this time, the absorption rate of oxygen is calculated by derivation. The equilibrium concentration of oxygen at the liquid phase interface can be obtained.

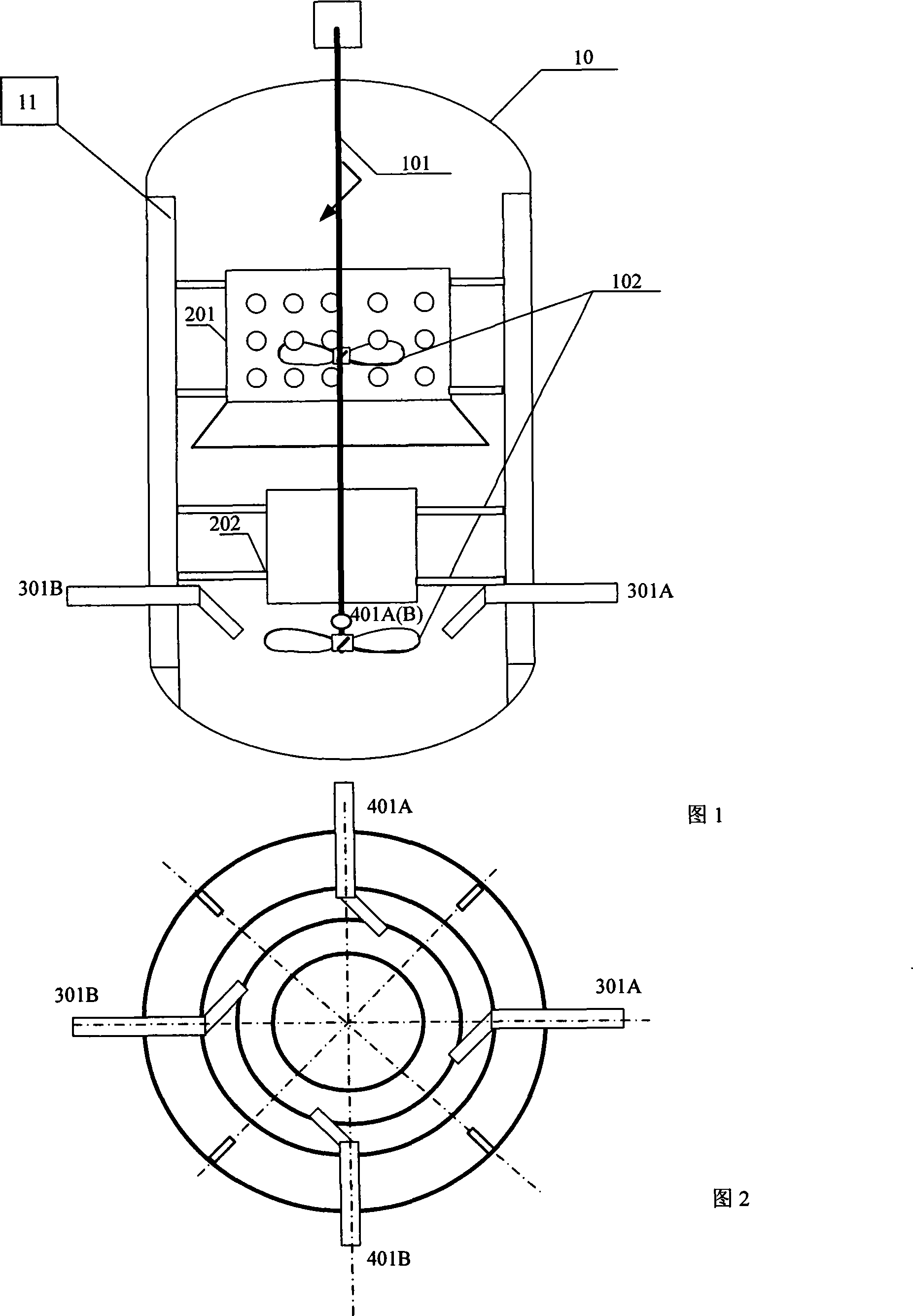

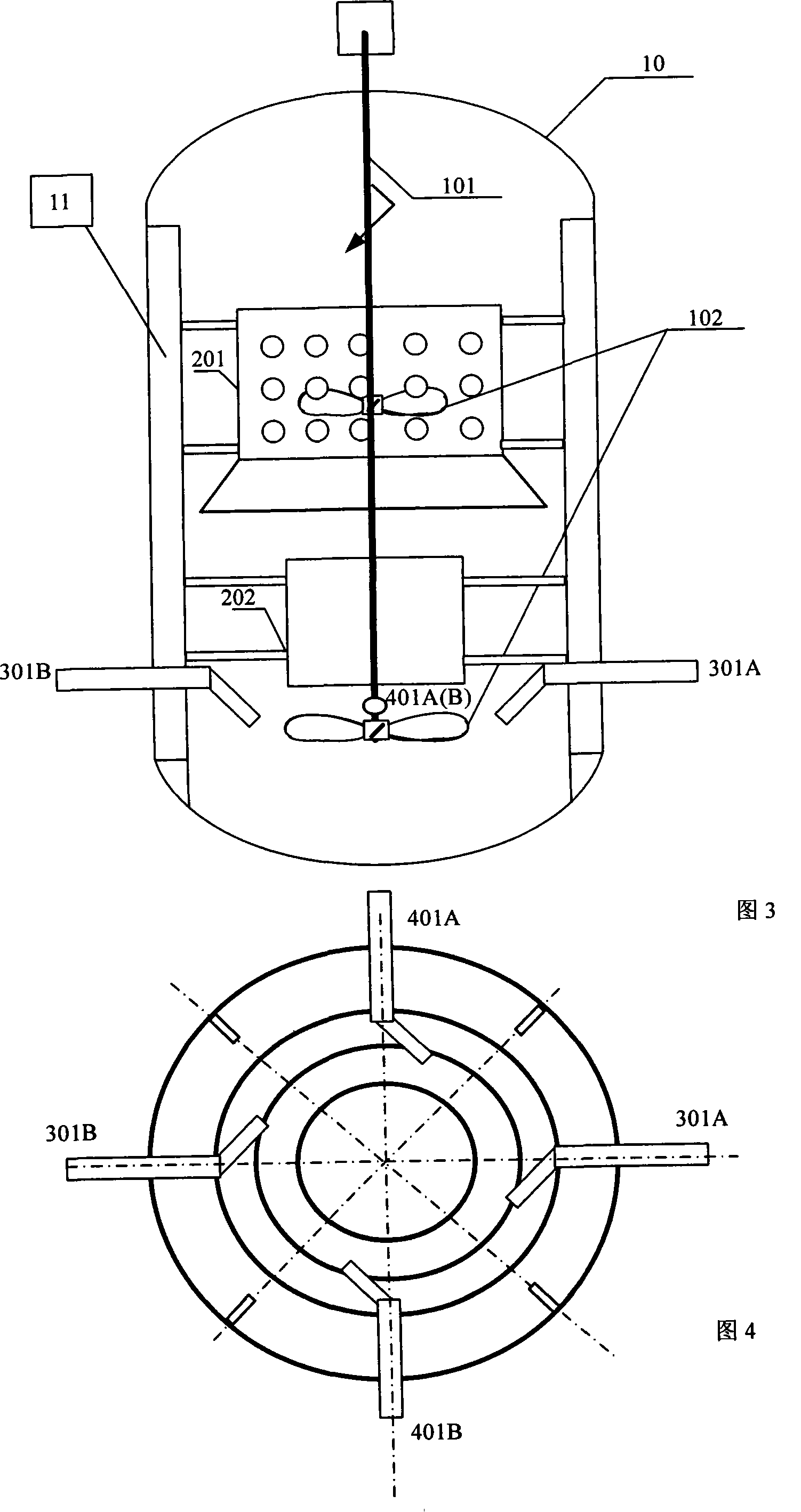

[0044] The oxidation reactor used in the test adopts the structure shown in Figure 1. The inner diameter of the reactor is 0.383m. Fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com