Sludge hot digesting apparatus for preparing biological solid

A biosolid, thermal digestion technology, applied in the field of environmental protection and comprehensive utilization of resources, achieves the effects of small size, fully automated equipment and system operations, and reduced stirring power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

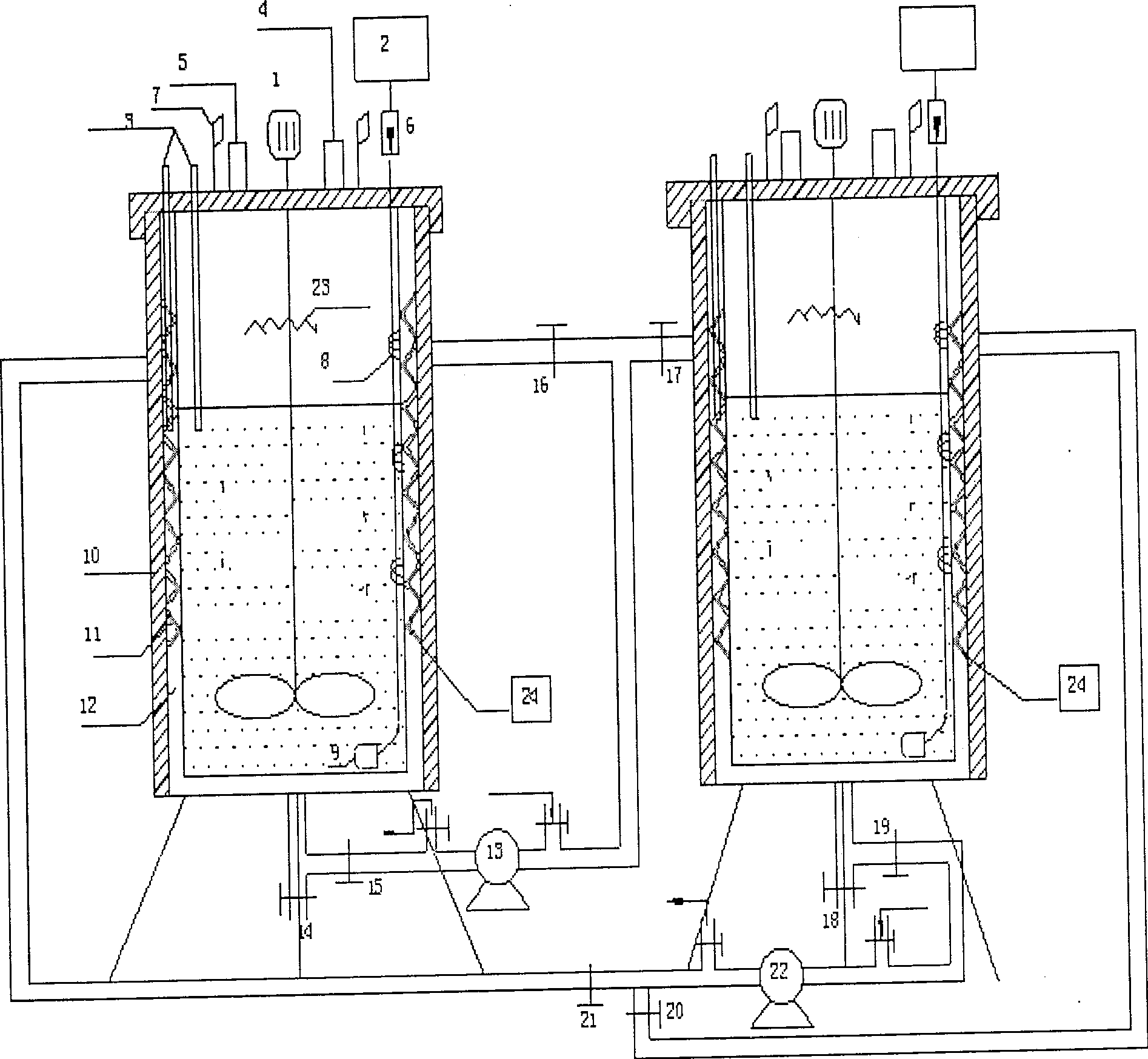

Method used

Image

Examples

Embodiment 1

[0041] Using a reaction tank for sludge high-temperature aerobic automatic defoaming reaction:

[0042] The sewage is taken from a sewage treatment plant, the moisture content of the sludge is 95.2%, the pH value is 7.21, and the VSS is 2.95×10 4 mg / L, COD is 18000mg / L, DO is 2.1mg / L, ORP is -246mV. A reaction tank is used to carry out the high-temperature aerobic automatic defoaming reaction of sludge. The intermittent sludge feeding method is adopted. The sludge feeding amount is 100kg / h. The tank water bath temperature was adjusted to 60°C, the stirring speed was 200r / min, and the aeration rate was 0.55 (V air / V sludge / min). After running for 8 days, samples were taken and analyzed at different positions (upper, middle and lower liquid levels of the sludge) in the reaction tank, and the average value was taken. The pH value of the sludge was 7.0, and the VSS was 1.75×10 4 mg / L, VSS degradation rate is 40.7%; COD is about 4500mg / L, COD removal rate is about 75%; DO concent...

Embodiment 2

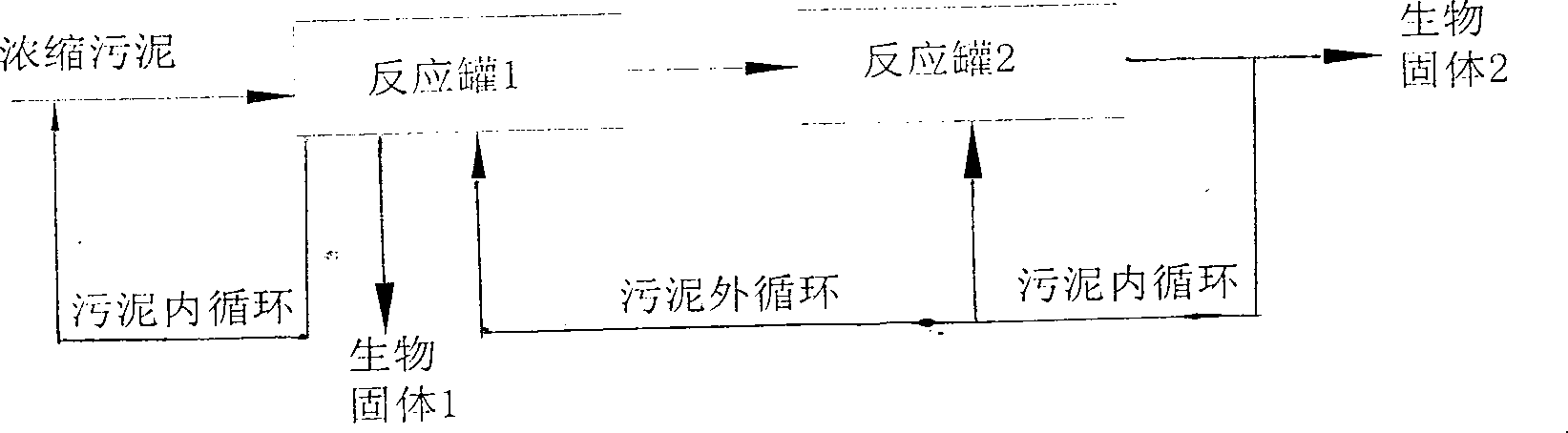

[0044] Using two reaction tanks in series to carry out the sludge self-heating and automatic defoaming high-temperature aerobic digestion process:

[0045] The sludge is taken from a sewage treatment plant, the moisture content of the sludge is 97%, the initial pH value is 7.2, and the concentration of volatile suspended solids (VSS) is 3.86×10 4 mg / L, the chemical oxygen demand (COD) is 15000mg / L, the dissolved oxygen concentration (DO) is 2.5mg / L, and the oxidation-reduction potential (ORP) is -215mV. Since the sludge concentration does not meet the sludge inlet standard for autothermal high-temperature aerobic digestion, the sludge is firstly concentrated. After concentration, the moisture content of the sludge is about 91.8%, which meets the sludge inlet standard. Intermittent mud feeding is adopted, 5t of mud is fed at one time, and the two reaction tanks are operated in series. Part of the sludge (0.1%-2% of the amount of mud feeding) from the reaction tank 2 is returned...

Embodiment 3

[0047] Reaction tank 1 performs high-temperature anaerobic automatic defoaming and digestion treatment of sludge, and reaction tank 2 performs high-temperature aerobic automatic defoaming and digestion treatment. The two reaction tanks operate in series:

[0048] Sewage is taken from a sewage treatment plant, the moisture content of the sludge is 96%, the pH value is 7.25, and the VSS is 3.95×10 4 mg / L, COD is 17000mg / L, DO is 2.3mg / L, ORP is -238mV. The reaction tank 1 carries out the high-temperature anaerobic automatic defoaming digestion reaction of the sludge; the reaction tank 2 carries out the high-temperature aerobic automatic defoaming digestion reaction of the sludge. The continuous mud feeding method is adopted, the mud feeding amount is 200kg / h, and the two reaction tanks are operated in series. Part of the sludge (0.1%-2% of the mud feeding amount) from the reaction tank 2 is returned to the reaction tank 1, and the reaction tank 1. The temperature of the water b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com