Connecting device between tank and pump

A technology of connectors and connecting parts, which is applied in the direction of valve details, valve devices, valve housing structures, etc., can solve the problems of large space occupation and complicated installation, and achieve the effect of small space occupation, increased effective space and small installation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

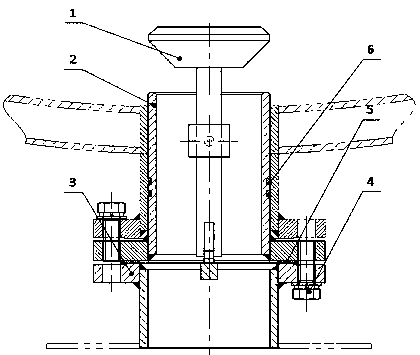

[0024] In order to overcome the problems of complex installation and large space occupation of existing pumps, the present invention provides such figure 1 , figure 2 The connector between the tank and the pump shown is small in vertical installation size, which not only increases the effective space of the tank but also facilitates the maintenance of the pump.

[0025] A connector between a tank and a pump, including a valve core 1 and a valve seat 2, the lower end of the valve seat 2 is covered with a pump feed port connector 3, the valve core 1 is composed of a valve shoe 1.1, a valve stem 1.2, and a valve head 1.3 Composition, the lower end of valve stem 1.2 is connected with valve shoe 1.1, the upper end of valve stem 1.2 is connected with valve head 1.3; On the support plate 3.2 provided at the upper end of the pump inlet connector 3.

[0026] It includes at least a valve core 1, a valve seat 2, and a pump feed port connector 3; the valve core 1 and valve seat 2 are i...

Embodiment 2

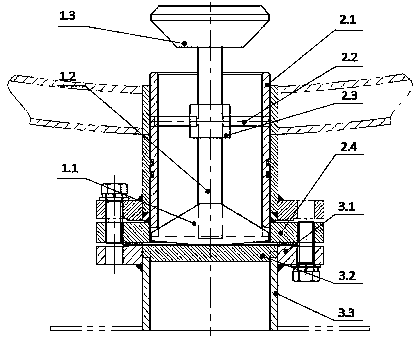

[0029] Based on the basis of Embodiment 1, in this embodiment, the valve core 1 is composed of a valve shoe 1.1, a valve stem 1.2, and a valve head 1.3. The bottom of 1.1 is a reverse arch, and the valve head 1.3 is a truncated cone.

[0030] The valve head 1.3 in the valve core 1 is a truncated cone and can play a sealing role when the upper end surface of the valve seat cylinder 2.1 in the valve seat 2 is fitted; the lower end surface of the valve seat cylinder 2.1 in the valve seat 2 has a gap , the valve shoe 1.1 in the spool 1 snaps into the gap after the pump inlet connector 3 is installed in place.

[0031] The valve stem 1.2 in the valve core 1 is in sliding fit with the sliding sleeve 2.3 in the valve seat 2.

[0032] The valve seat 2 is composed of a valve seat cylinder 2.1, a sliding sleeve fixing rod 2.2, a sliding sleeve 2.3, and a valve seat flange 2.4. The valve seat cylinder 2.1 and the sliding sleeve 2.3 are connected through the sliding sleeve fixing rod 2.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com